FOR IMMEDIATE RELEASE

Street Trucks Military Charity Build Heads to Auction on Memorial Day.

Durham, North Carolina, May 1, 2024 – Street Trucks Magazine proudly announces the upcoming auction of Sergeant Square, a 1985 custom Chevy Squarebody truck, in support of Mission 22. This unique charity project is set to raise funds for Mission 22 through an exclusive online auction on Bring a Trailer, beginning on Memorial Day, May 27.

Sergeant Square represents the pinnacle of design and desirability in the custom truck community. Crafted by one of the nation’s top truck designers, this meticulously restored and modified Chevy Squarebody is not just a vehicle—it’s a symbol of our commitment to supporting our veterans.

“We’re honored to present Sergeant Square as a testament to our dedication to giving back,” says Chris Hamilton, Editor-in-Chief of Street Trucks Magazine. “This auction on Bring a Trailer offers enthusiasts the chance to own a piece of automotive history while contributing to a worthy cause.”

The auction provides an opportunity for individuals to make a difference in the lives of veterans while acquiring a unique collector’s item. Don’t miss your chance to bid on Sergeant Square and support the mission of Mission 22.

For more information and updates, visit sergeantsquare.com

For media inquiries, please contact:

Engaged Media LLC.

Email: Info@engaged.media

Off-roading in Florida combines an appreciation for our natural environment and a challenge for our vehicles that we take pride in. Now more than ever, off-road trail riders are recognizing the need for more trail riders to be aware of ways we can all do better on the trails in Florida. Trail leaders need to know the Tread Lightly Principles and share and demonstrate them with their riders.

One way, in Florida, that the Tread Lightly principles are being highlighted is through The Florida Trail Team Challenge Event. The event is being held this year from October 25-27, 2024 in Tavares, FL at Ol’ Florida Off-Road Park.

The event benefits Tread Lightly through requiring every competitor (20-2 person teams) and strongly encouraging all its volunteers (60+) to take the Tread Lightly online training course, as well as the donation of any profits from the event being donated directly to Tread Lightly.

The Florida Trail Team Challenge began in 2018 with its first event being held in 2019. The event itself is an off-road endurance challenge. No more than 20 – 2 person teams compete to accumulate the most points by completing challenges throughout the weekend. The challenges include Precision Off-road Driving, Vehicle Recovery, Marksmanship, Navigation, Medical Aid and Mechanical Repair. The mindset of all competitors should be that they are a team that is off-roading through Florida with a self-sustaining vehicle, and enduring whatever surprises could happen along the way.

During the event, a Tread Lightly Master Trainer is on site to participate in hosting challenges as well as to see the Tread Lightly principles in action as the competitors are also tasked with collecting any trash they find on the trails during the event for additional points. There is also a challenge designed to benefit the off-road park to show their appreciation for hosting the event and last year that included making a new trail called “The Military Trail” within the park to remember our different Military Branches in the US, which was particularly poignant.

There are bragging rights for the winners, trophies for the top teams and many prizes donated by generous sponsors of the event. Competitors camp on-site in 10’ X 10’ spaces in their area and the Volunteers mostly camp onsite as well or in local hotels during the event. Volunteers also give of their time and efforts in officiating at the challenges, providing medical aid if needed and a full media team to take photos and videos before, during and after the event!

In years past, the competitors and volunteers tell us that they learned a lot about off-roading during the event, perhaps a new way to solve a problem during a challenge or that there are many ways to problem solve during a challenge.

At the end of the event, everyone is mostly dirty, sweaty, happy and filled with a sense of accomplishment at the challenges they have faced head-on!

Bilstein B8 8112 (ZoneControl CR DSA+) is a direct fit, 3-way adjustable, 60mm, position sensitive coilover shock designed for light trucks and SUV’s. ZoneControl CR DSA+ is a revolutionary technology delivering position sensitive damping plus user Dual Speed Adjustability. The system incorporates a triple piston design, offering 3 stages of compression valving and 2 stages of rebound valving. Click adjuster knobs allow easy and precise Dual Speed Adjustment of both low and high speed compression plus an adjustable JCO (internal hydraulic bump stop). The coilover module utilizes a threaded spring seat for ride height adjustability ranging from 0-2.6” (depending on application). It is supplied with a remote reservoir for increased cooling along with an accompanied, bolt-on anodized reservoir chassis mount. Bilstein B8 8112 (ZoneControl CR DSA+) position sensitive Dual Speed Adjustable coilovers offer unparalleled ride comfort during every day driving combined with maximum control over large suspension inputs with the ability to quickly adjust the shock to tackle any terrain.

MSRP $1,425.90

Dealer locator: Dealer Locator – BILSTEIN

We are honoring the women in our automotive industry this month, so we wanted to do something a little different to show our appreciation through these pages. Sure, it’s no secret that the custom automotive industry can seem like a “man’s world,” and it’s true that ego and testosterone abound. This can be intimidating for some, but there are plenty of women out there who have conquered and grown this industry in ways unimaginable. With their help and them pursuing careers in this space, this industry is certainly better off.

Thousands of women out there in our industry are showing us just how it’s done—as many of them say (even on the personalized license plates of their custom vehicles read), “Chicks can, too!” Of course, we couldn’t feature them all here, but we did our best to track down some who have been influential to the custom classic truck scene in particular and honor and highlight them here in this issue. If you have a daughter like Bailey McKeska (cover truck owner/builder), be the dad (or mom) like Mike Mckeska by encouraging their passions to pursue a career in the automotive space.

Let’s get to it and take a look behind the scenes at some of the key players at automotive companies all across the US.

Operations – GSI Machine & Fabrication

Krysta Aranda was introduced to cars at a very young age. She grew up with an amazing father who shared this passion with her early on. In high school, she joined auto-shop class despite being a cheerleader and ballet dancer. She didn’t let that stop her. She wanted to learn everything she could and really enjoyed being around all things automotive and horsepower related.

Over the years, she has only had jobs in the automotive industry and has pursued growing that passion. At one point she was a service advisor and also worked as a parts manager at a speed shop. Currently, Krysta works for GSI Machine and Fabrication where she has continued her desire to learn everything she can in this industry. She has soaked up shop life like a sponge and learned all about the processes in manufacturing, machining, welding, and chassis design. It also helps that she really does have a huge passion for all things custom trucks, and even has a truck project of her own. Krysta is currently building a 1965 C10 with her husband. He has taught her much about these trucks, including LS swaps, air ride, the complete restoration process, and unfortunately, even wiring.

Krysta shared with us that she truly hopes her story and those of others will inspire more women to get out there and get involved!

“Ask anyone you know who has experience to teach you,” she shared. “Don’t be afraid to get dirty and make mistakes. You will learn how capable you are and you will enjoy every minute of it.”

We fully agree—get out there and show them what you’re made of!

Owner/Operations – McGaughys Suspension

Michelle Garcia-McGaughy is an absolute superwoman! Super mom, super human, and super business owner/operator extraordinaire—she really does it all with unmatched grace and humbleness. Michelle also grew up around cars her whole life and would eventually grow up to become partners in one of the largest aftermarket suspension companies in the US! Michelle and her husband Steve run and operate McGaughys Suspension as a small family-owned business, although “small” is not a word that would accurately describe anything about their now quite large operation.

No matter how big McGaughys Suspension has grown over the past few decades, the McGaughy family is truly the definition of the American dream, while still keeping family value intact. Sports, family, business, building custom cars together on the weekends—they do it all together! And like many women, Michelle is truly the glue that holds it all together for both the family and the company. The custom automotive aftermarket thrives in the States because of families and companies like the McGaughys. Michelle is truly one of the best examples of encouraging women in the industry to foster leadership roles, volunteer, give back, pursue their dreams, and continue to push further, setting a great example for others to follow. We’re awfully proud to call her a friend!

Account Supervisor – Kahn Media

Diana Brennan is an established communications professional with broad and in-depth experience in both the automotive and motorsports industries. As an account supervisor with Kahn Media, she currently oversees the PR strategy and media outreach for clients including SEMA, the Petersen Automotive Museum, Rod Shows, Rolex, and the Mullin Automotive Museum.

For almost 20 years, Diana worked in media and community relations at Sonoma Raceway— Northern California’s premier motorsports facility. After beginning her career as an intern in college, Diana ultimately worked her way up to vice president of marketing, communications and community relations at the raceway. In that role, she managed a diverse team consisting of media and community relations, marketing, social/digital media, and an events department to orchestrate high-level, year-round motorsports events, including NASCAR, NHRA drag racing, and IndyCar happenings.

Diana’s background in the motorsports industry and a lifelong passion for cars helped drive her to Kahn Media in October 2022. Diana graduated from the University of the Pacific and currently resides in San Francisco’s East Bay with her husband and son.

President – TREAD Agency

Beth Brennan is a marketing leader and project manager with 10-plus years’ experience in the outdoor industry and is also currently the president of TREAD Agency. Prior to TREAD, she was vice president of marketing for guidefitter and chief marketing officer for Go Fast Campers. Beth started in the industry as director of marketing at Tepui Tents from a startup through its acquisition by the Thule Group. Beth lives in Bozeman, Montana, and sits on the board of SEMA Businesswomen’s Select Committee, Overland Expo Foundation, Public Land & Water Access Association, American Fly Fishing Trade Association and volunteers for Backcountry Hunters & Anglers.

Beth has a passion for supporting women in their careers and helps with SEMA, Gear Up Girl, and Women & Leadership Forum to help advance women in automotive and other male-dominated outdoors industries. Beth’s lifelong love of adventure is what led her to the intersection of automotive and outdoor recreation.

Founder/Owner – Baja Forged

Theresa Contreras is a born-and-bred generational automotive lifer. Now a staple in this industry, Theresa hails from Southern California and is the founder of Baja Designs, but she has been a steady part of the automotive aftermarket for more than two decades already. Growing up at the shop with her dad, sister, and her now husband, the family business has always been automotive. Theresa was the head painter and helped run LGE/CTS in San Dimas, California, for 20-plus years before recently venturing out to begin her own line of custom truck parts that include bumpers, fenders, custom Bronco parts, and more.

Theresa has served on several SEMA/SBN councils, taken part in many Ford specialty builds, magazine covers, and has earned many various awards and accolades. Alongside Jessi Combs, Theresa helped launch The Real Deal to help encourage more women to pursue their passions within the automotive and motorcycle space through charity rides, events, and awareness campaigns. You’ll find Theresa surrounded by anything with wheels and a fun custom flare!

Senior Account Executive – Kahn Media

Anna Glennon is a world champion and eight-time national champion jet ski racer and digital media and communications specialist working as a senior account executive at Kahn Media. Before she could talk, Anna was making engine noises. She shadowed her father, a master mechanic and fluent gearhead, throughout her childhood and learned the ins and outs of engines and fell in love with going fast. Together, they restored a variety of cars, trucks, jet skis, and boats.

Anna’s experience in powersports media began as a side hustle to promote her budding jet ski racing career. It evolved into early jobs as a powersports journalist and photographer. Expanding outside of the watercraft industry, Anna kickstarted a career in motocross as a team media and sponsorship manager at Monster Energy Supercross and Lucas Oil Pro Motocross before she graduated from college. Anna uses her decade of marketing experience in personal watercraft racing, professional motorcycle racing, off-roading, and more to help Kahn Media’s off-road aftermarket and powersports clients navigate the changing marketing landscape. Specializing in influencer and digital media communications, Anna has worked to expand Kahn Media’s existing portfolio of influencer opportunities and connected clients with content creators with more online followers than many of the world’s leading media outlets.

In her spare time, Anna spends too much time keeping her 1987 Jeep Wrangler YJ running and trying to find new ways to make her 1500cc, 4-cylinder four stroke jet ski go even faster.

Sales & Marketing Coordinator – GSI Machine and Fabrication

Ashley Fritter is the sales and marketing coordinator for GSI Machine and Fabrication in Chandler, Arizona. Ashley grew up in Wilburton, a small town nestled in the heart of Southeastern Oklahoma. She shared, “growing up in a small town, there isn’t much that goes on aside from cruising or hanging out at someone’s shop—and my journey into the automotive industry was sparked by exactly that. I spent countless hours hanging out at the shop watching my friends bring their projects to life. Little did I know it was the inspiration that would lead me to develop a love for an industry and community that has now become a central part of my personal and professional life.”

Ashley currently works both remotely and on site at the manufacturing facility in Chandler. Beyond managing online sales and new merchandise development, she is also the creative force behind GSI social media content and all of the company’s email campaigns. Her role at the company has expanded her opportunity to travel and see new places, as well as meet new people while attending the numerous truck shows and events that GSI attends across the US.

In addition to her growing role with GSI, Ashley is also a mortgage consultant with Stride Mortgage, where she’s able to provide financing options for clients nationwide. Ashley’s passion for the automotive industry as well as personal growth has allowed her continuous opportunities to evolve and grow in this thriving industry.

Director of Marketing – Engaged Media

Nicole Hamilton is not only an extremely passionate person when it comes to custom automotive culture, but she’s also an integral part of behind-the-scenes operations with the largest and most widely distributed automotive publications in the country. A logistical mastermind is a simple way to describe the way Nicole’s mind works. If Motortopia were a circus (which, sometimes it feels like it is), Nicole would be the best juggler in the show replacing bowling pins with national brands. She is embedded throughout each and every automotive genre, and there’s not a style of custom ride that she dislikes. She has owned them, wrenched on them, and now takes part in publishing the most amazing rides in the country. If you’ve ever had a chance to meet Nicole at SEMA, you know how passionate she is, and how high her quality standards are when it comes to our brands. She always has a smile on her face and a mind focused on branding and marketing.

Moving into 2024, Nicole has taken on a new challenge by accepting the lead editor role of our newest title, Tesla Trends. It’s exciting to watch her grow professionally and fascinating to see her function day to day. If you have a chance, stop by our booth at SEMA 2024 and meet this master of success. Passion, process and much more than just a pretty smile – we are very proud and lucky to have Nicole on our side!

Controller & Human Resources – Switch Suspension

Ashley McAtee of Mesa, Arizona, entered the custom car and truck world when she turned 16. Growing up in Oregon, she had a 1994 Acura Integra two-door—a car that was very popular in the scene back then. She saved up her money to buy 18-inch wheels, a Wings West body kit, and a killer stereo, then topped it all off with a custom license plate: TZNYA.

Fast forward to today, and Ashley is the controller at Switch Suspension, where she’s been since its founding back in 2012. All of the money that goes in and out of the company goes through her first, making her a massively important part of the team. What once was a small shop that did installs and sold a few parts is now a multi-million dollar operation with Ashley taking care of the financials, employee oversight, payroll, and other HR related duties. And if that wasn’t enough, Ashley is also at every one of the many events that Switch attends, sponsors, or runs. She makes sure everything is set up properly, merch is on hand, and even conducts transactions on site, giving each customer a personalized experience along the way.

While Ashley doesn’t have that Integra anymore, she does have a ‘bagged 1970 Chevy Nova that’s pretty cool, and a few ideas for what’s next. Ashley loves her job and her place in the automotive industry and can’t wait to see what the future looks like for her and Switch Suspension. We sure know it’s a bright one!

CEO – Hellwig Products

Melanie White is known throughout the automotive aftermarket as a proven leader for both her own business accomplishments and her dedication to the industry. Hailing from a founding SEMA-member company that has exhibited since the very first SEMA show in 1967 at Dodger Stadium in Los Angeles, she represents the fourth generation to join the family business established by her great-grandfather in 1946. Melanie started in Hellwig’s sales department cold calling 18 years ago and worked her way up to vice president before ultimately becoming the company’s first female CEO.

In 2022, Hellwig received certification from the Women’s Business Enterprise National Council that the company is owned, operated, and controlled by a woman. Even while tackling those considerable company responsibilities, Melanie has always been an equally enthusiastic SEMA volunteer. In fact, her involvement with the association has included membership in six SEMA councils and networks. In addition to earning several service awards from her council groups, she was among SEMA News’ first roster of “35 Under 35” young and rising talents in 2012. She was named SEMA Person of the Year in 2018 and was awarded SEMA Businesswoman of the Year award in 2017. Melanie also served as chair of the Truck and Off-Road Alliance (TORA) and has been an outspoken industry advocate, participating in Washington, DC, rallies and joining other SEMA members on international business development trips. She currently is the chair elect on the SEMA board of directors, wife to her high school sweetheart, and mom to her 13-year-old son.

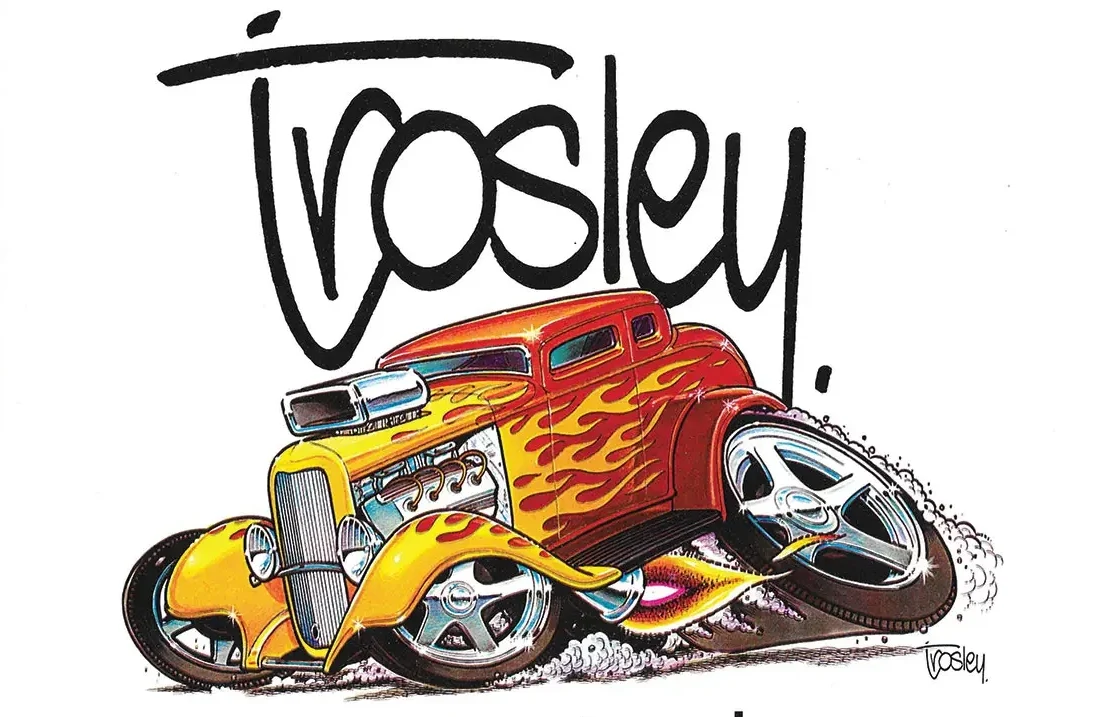

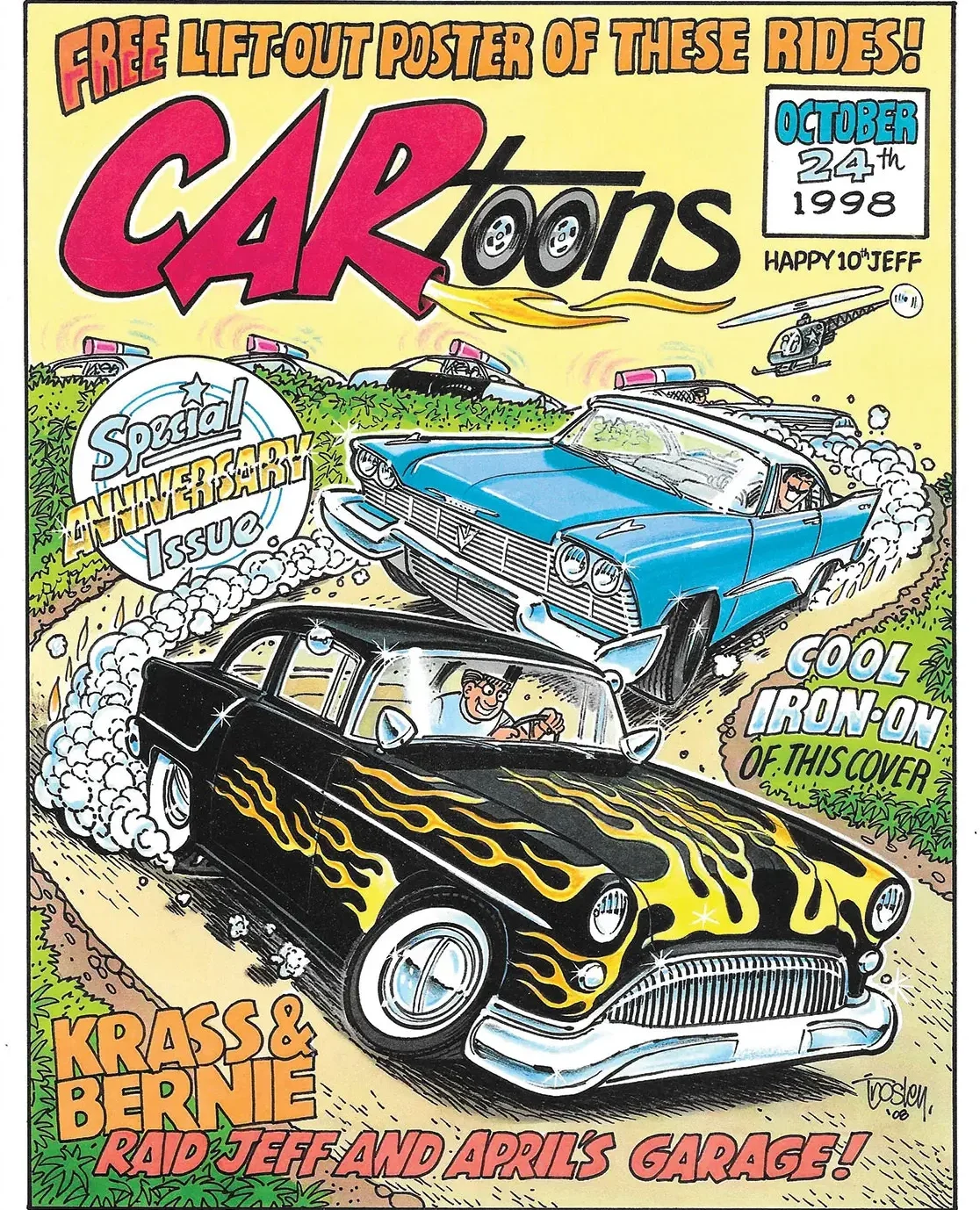

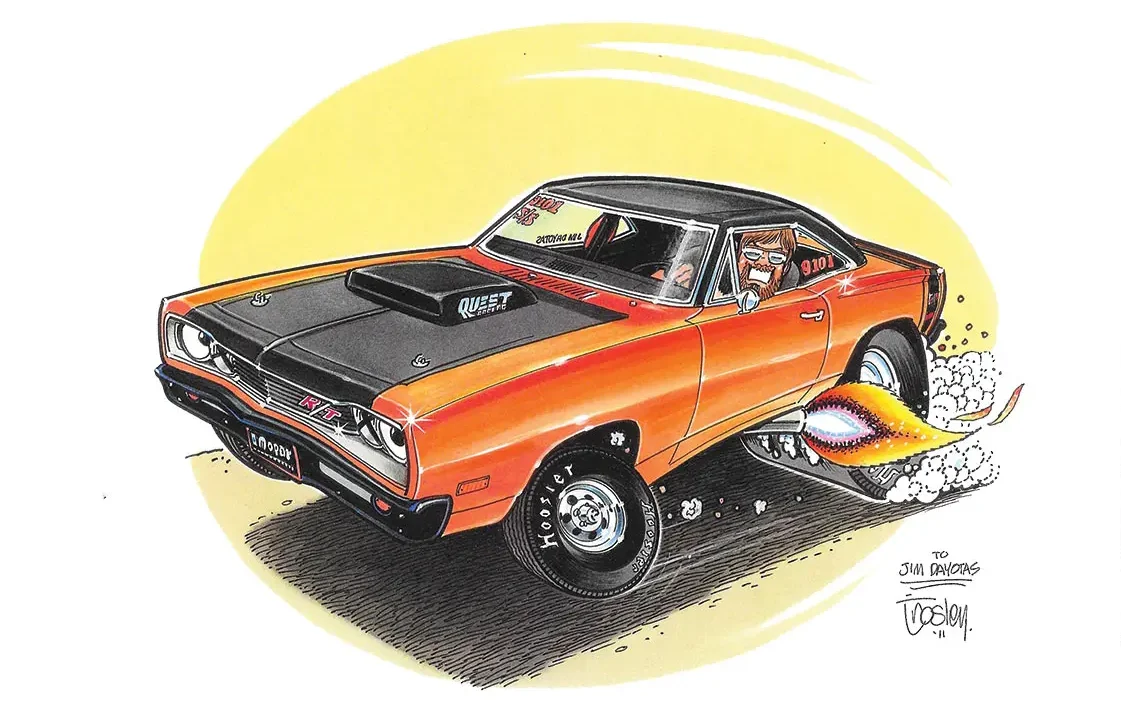

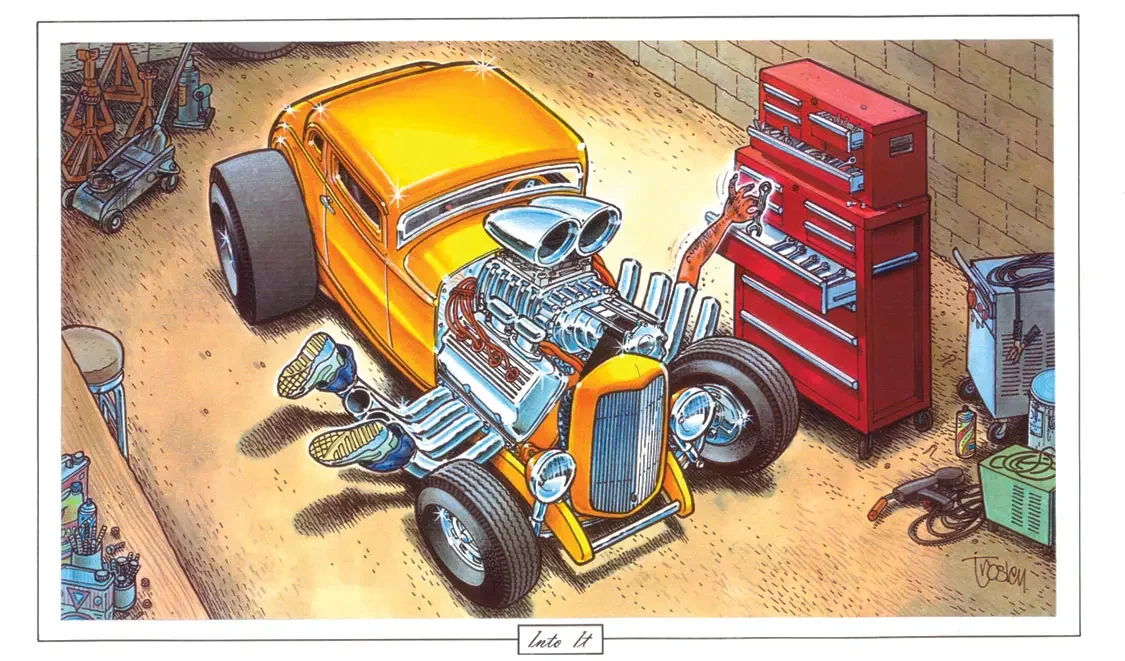

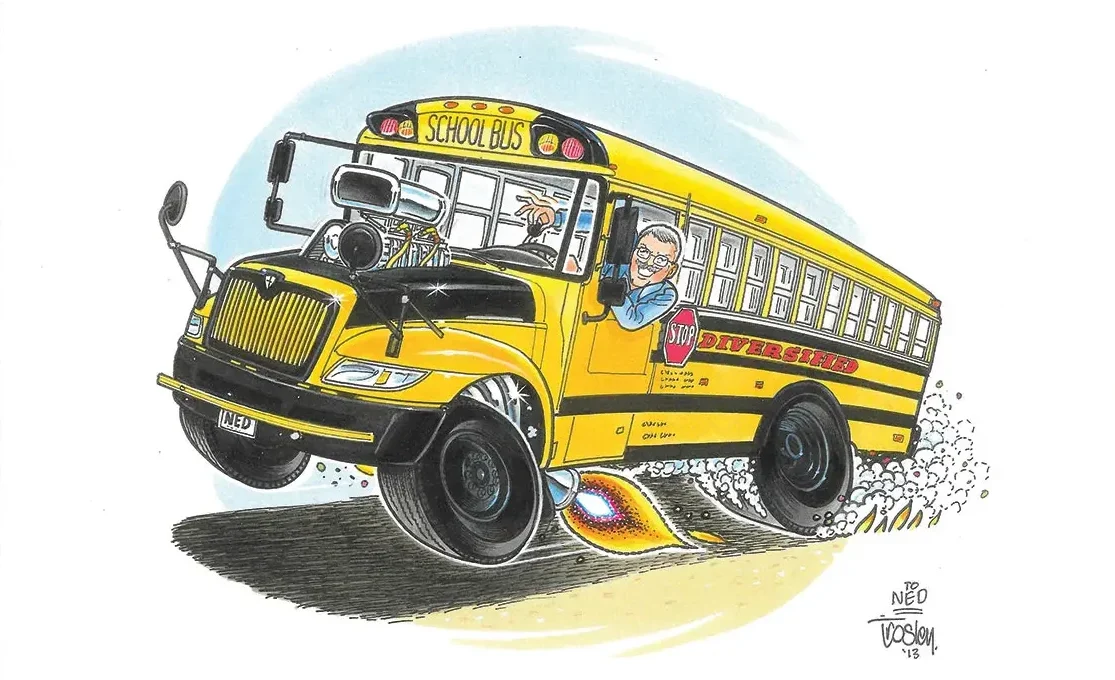

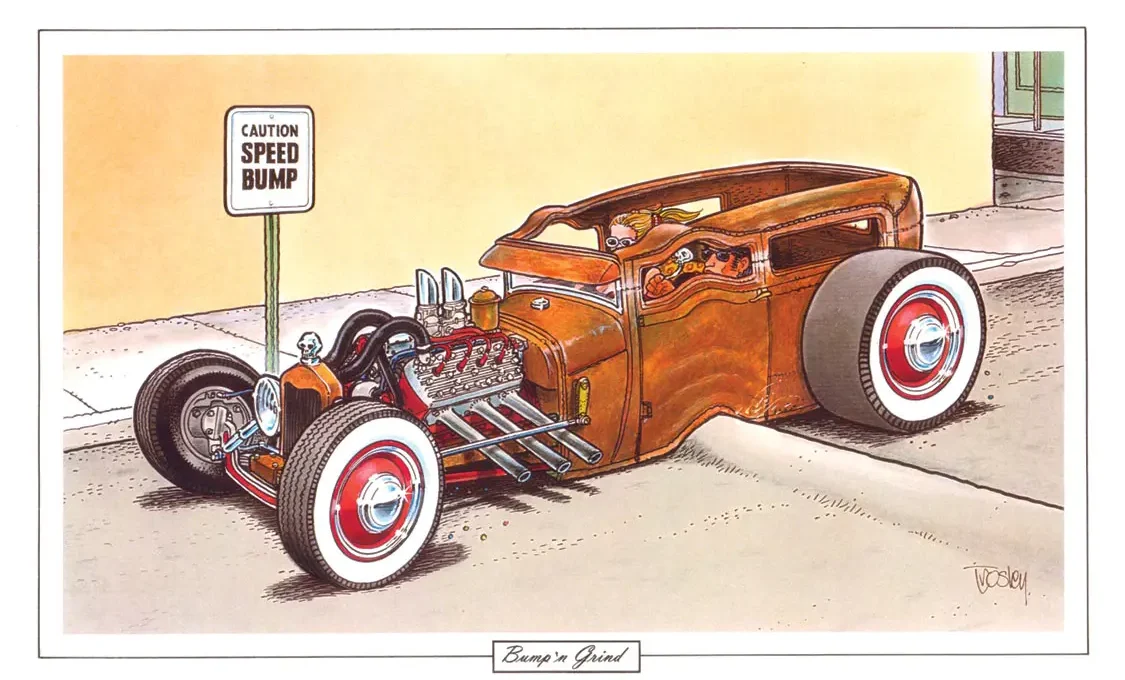

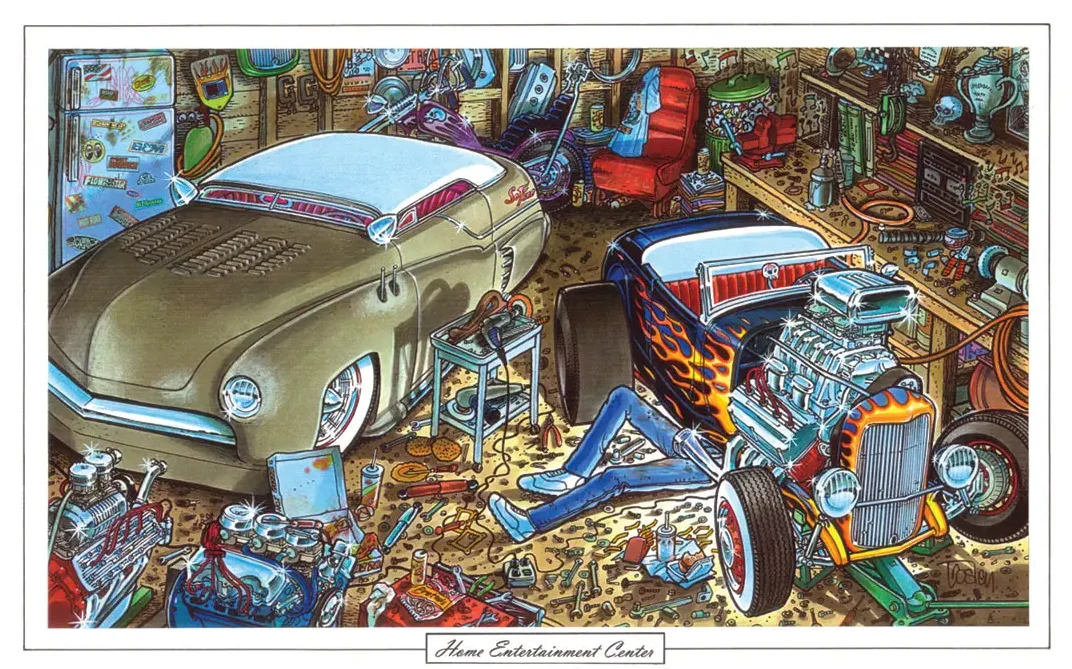

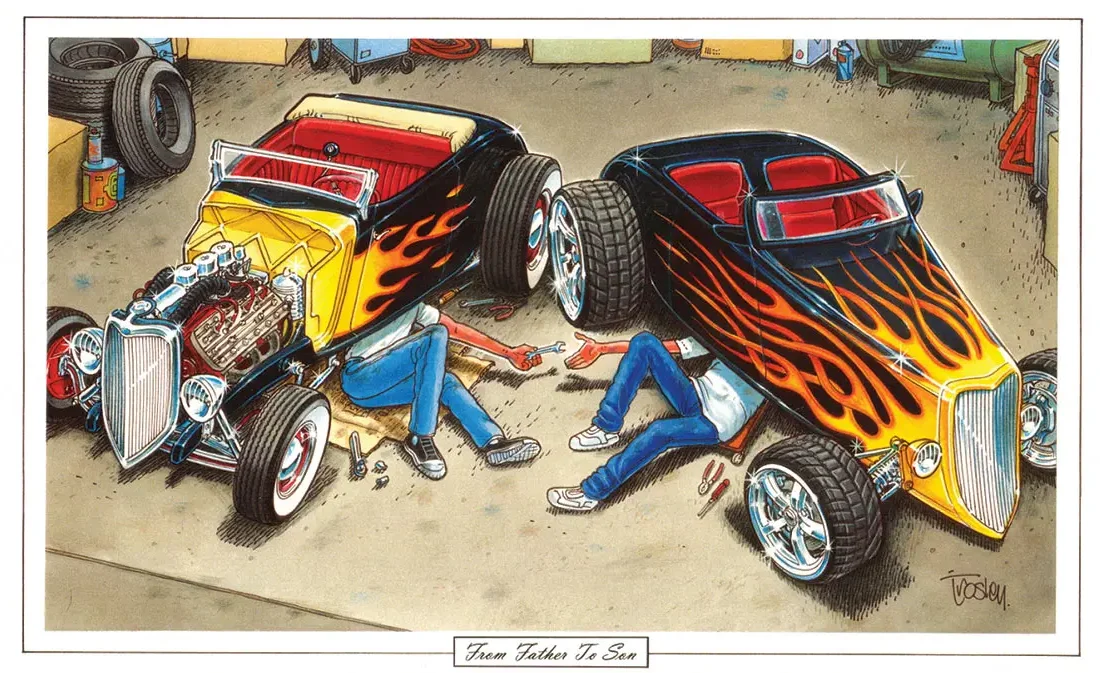

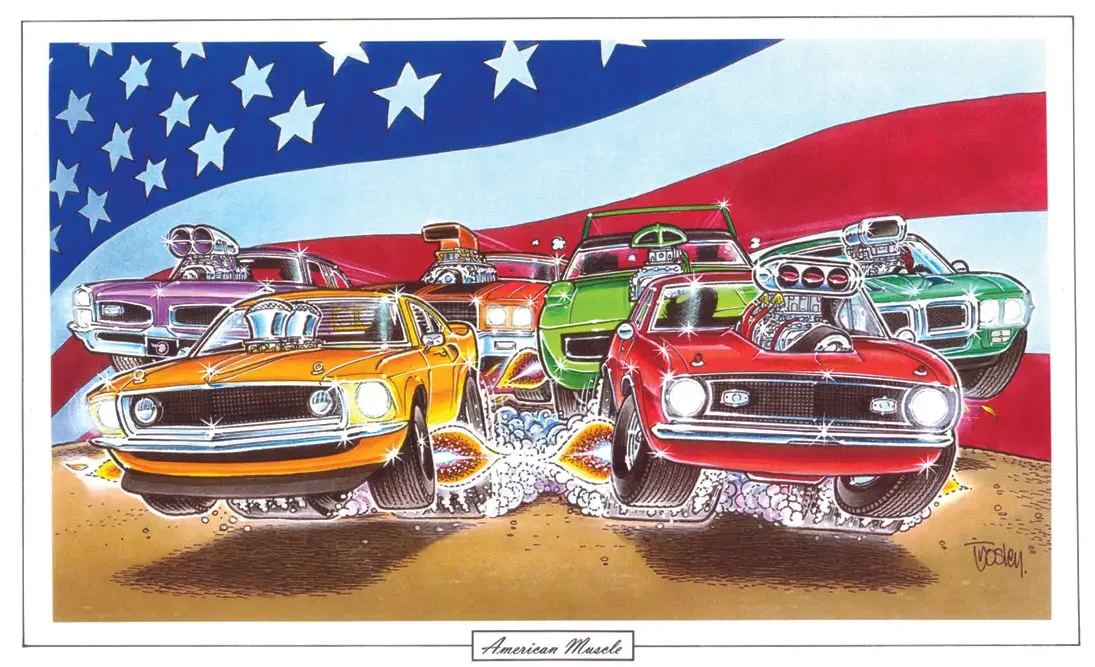

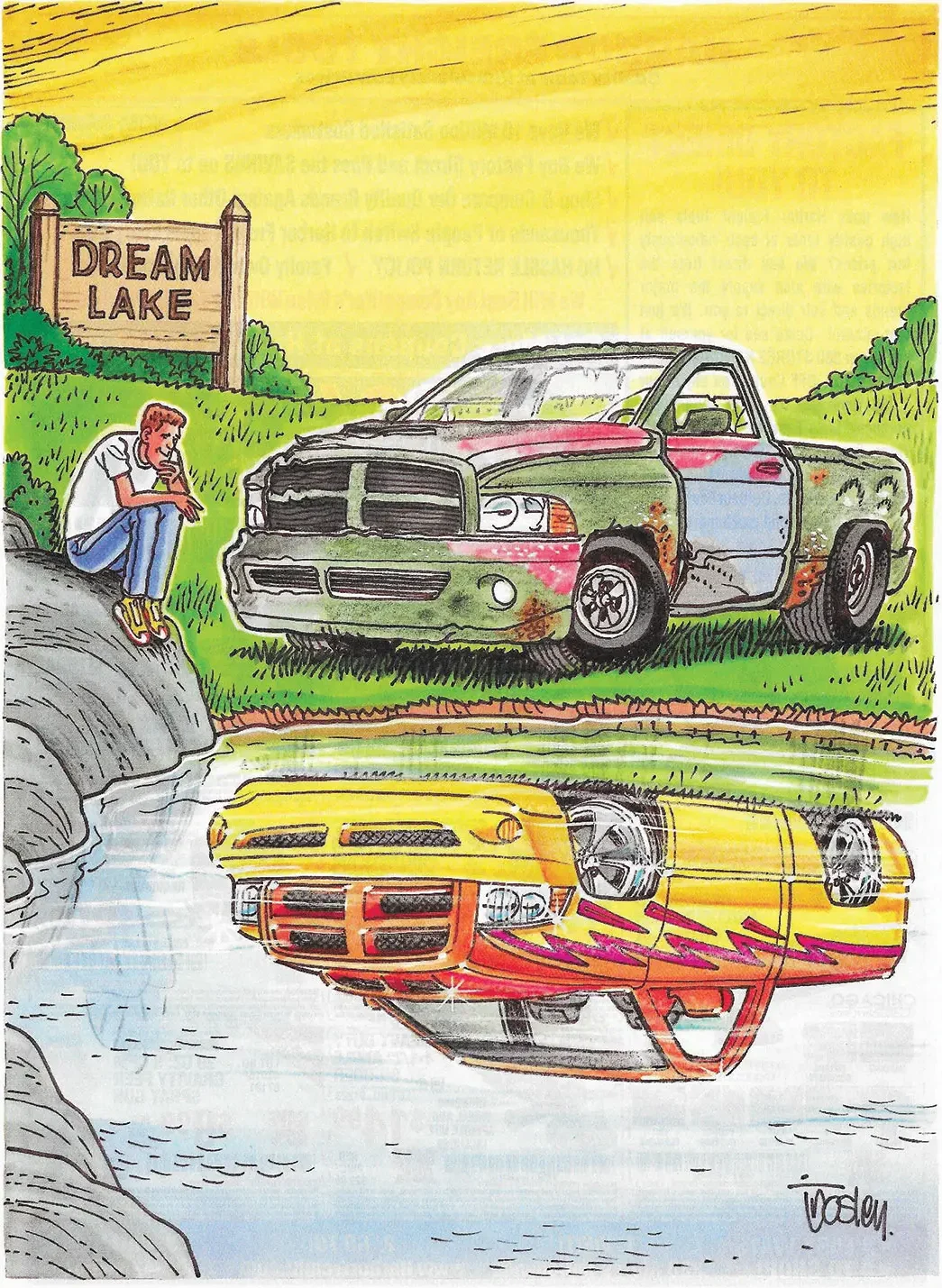

It’s an honor to interview the artist that has one of the most recognizable illustration styles. George Trosley has been a personal influence and inspiration since I was a kid. George has undoubtedly done the same for countless others.

By his mother’s account, George started drawing at the age of five. Mostly on the walls at this time. Later, his fourth-grade teacher, who was an amateur artist, took notice and recommended private art lessons from a local painter. George and his brother, Harold, would spend time drawing their “dream machines”. They also built model cars. George would come up with wild customizing ideas and used plastic wood to mold parts from one kit to another. Harold had the model body-working talent to turn them into prize-winning creations. They would be inspired by car magazines, devouring them for new ideas. The two began winning almost every hobby-shop model contest around. They were eventually banned from a few.

Soon they were old enough for real cars to fool around with. George’s first car was a ‘47 Plymouth sedan. Followed by a ‘55 Ford Tudor with a 312ci T-Bird engine and trans, and a severe rake. George even painted “Village Vandal” on the trunk lid, much to his mother’s displeasure.

George was accepted to the Hussian School of Commercial Art in Philadelphia. He commuted in his ‘39 Ford Deluxe Tudor sedan, spending the next four years learning about commercial art by day, and working on his prewar Ford by night. After art school, George set out on his own to give full-time freelance cartooning a try.

Trosley: “After art school, I landed jobs in various art studios in Philadelphia but found much of the work unrewarding and repetitious. in 1973, I jumped out on my own to give full-time freelance cartooning a try.

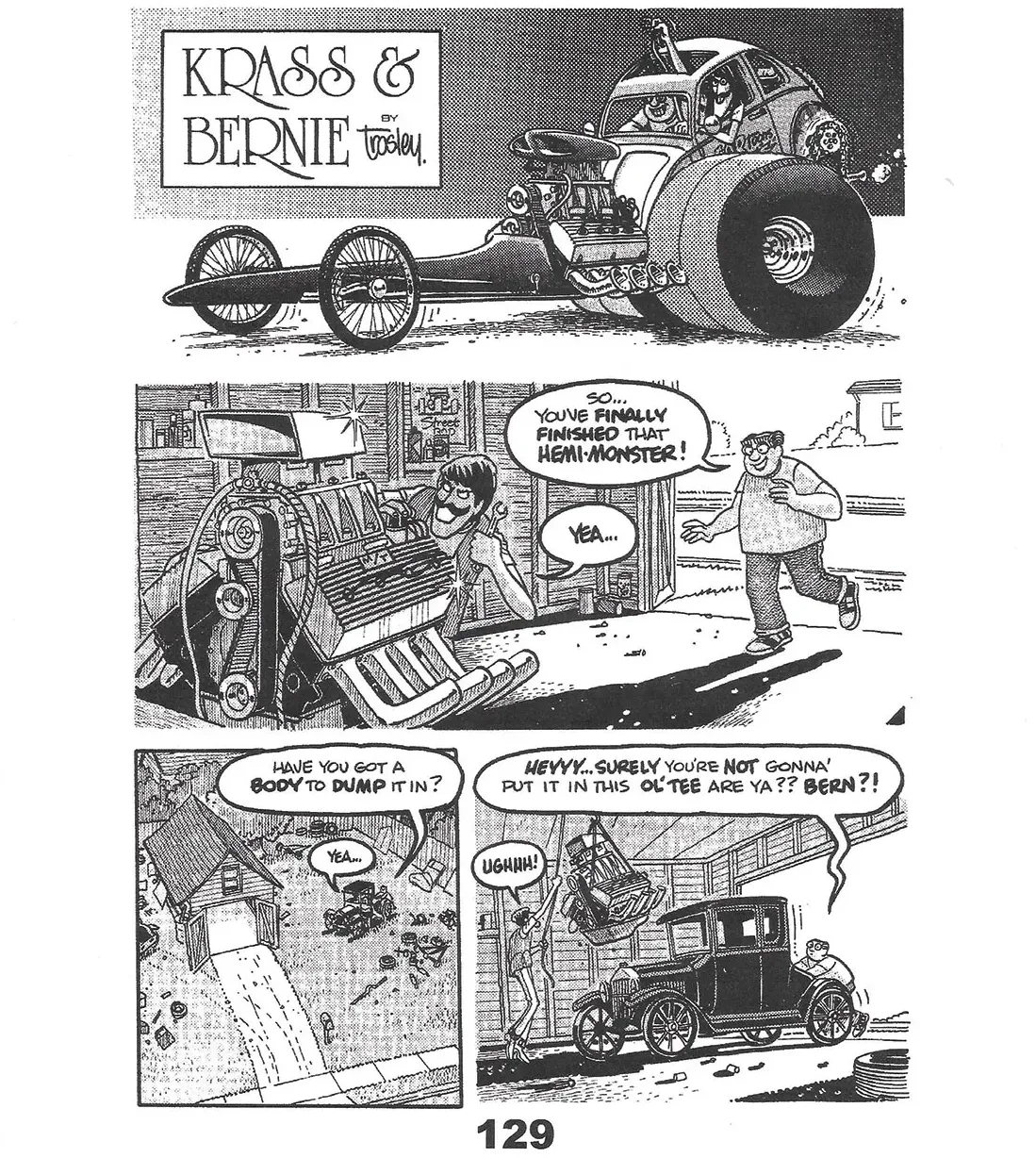

“I’d always been a major fan of Pete Millar and Petersen CARtoons, so I dropped it into gear. Eventually, editor Dennis Ellefson gave me the opportunity to do some of my reoccurring characters. I created Krass and Bernie, largely patterned after my brother and me. They ripped apart and rebuilt tons of wild rods for the next 20 years…and I loved it! During this period I also produced hundreds of cartoons and humorous illustrations for various other car magazines including Rod&Custom. My other work has been published in a variety of magazines such as the Saturday Evening Post, Saturday Review, National Enquirer, New Woman, and Hustler.”

Tell us a little about a typical work day in the life of artist, George Trosley

“Unfortunately, I sold the ‘39 when I began freelance cartooning. My long-time girlfriend, Susan, and I married in 1973, and after buying a house that needed a bit of work, bought a ‘40 Ford Deluxe Tudor sedan to work on too.”

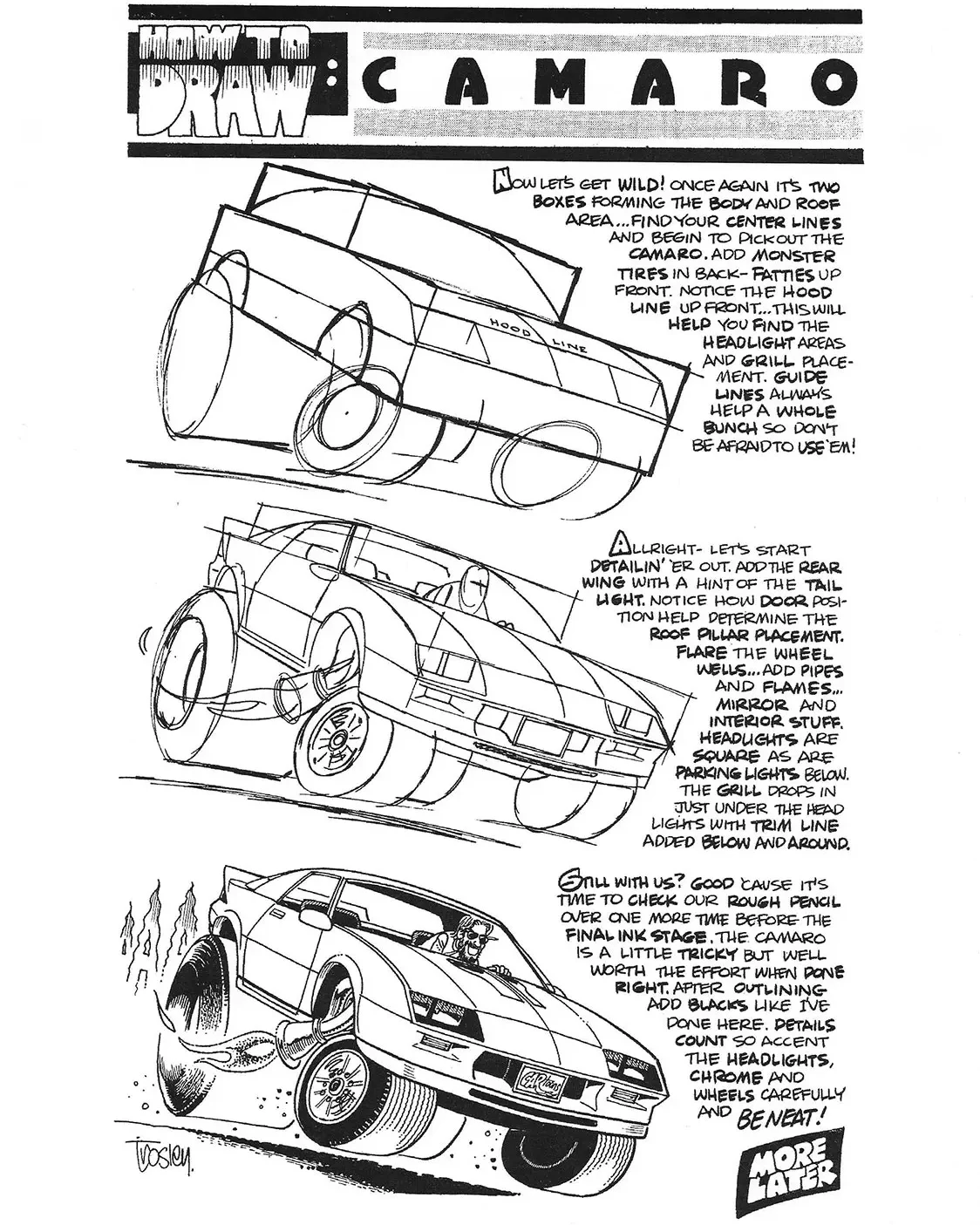

Trosley had early success as a freelance artist beginning with Krass & Bernie, a comic strip that ran continuously in CARtoons from 1975 until 1991. Trosley also produced many other features for CARtoons, including a regular “How To Draw” instructional series. In addition to the many automotive cartoons, illustrations and commercial work published, Trosley has produced adult-themed, satirical gag cartoons and comic strips for Hustler magazine and its sister publications Hustler Humor and Chic.

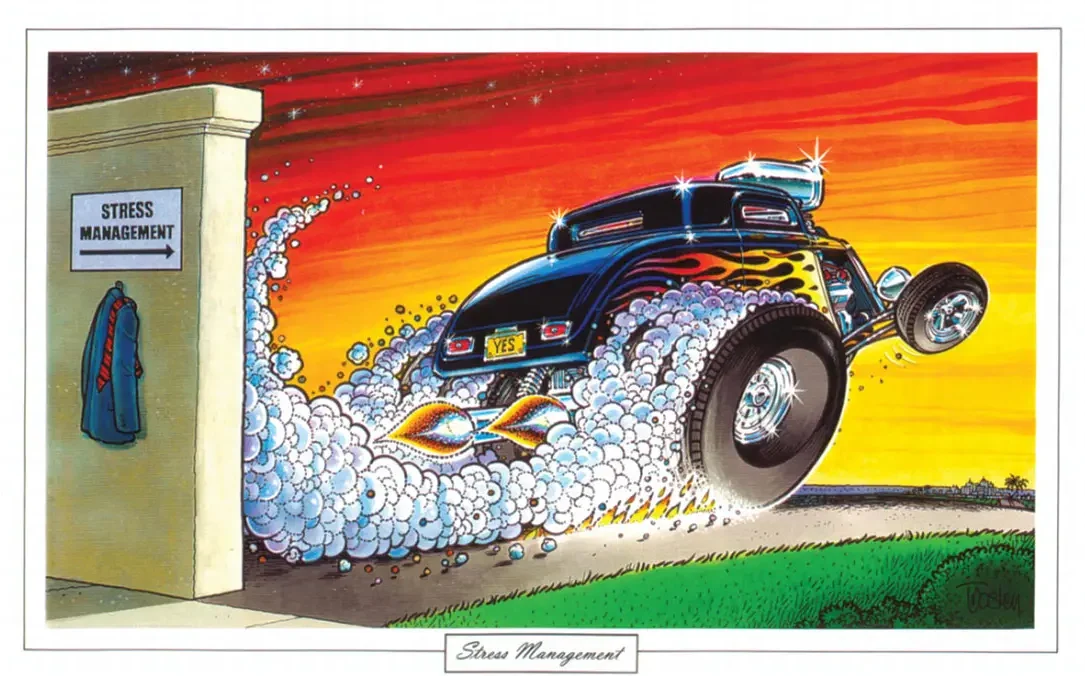

Trosley continues to create a rendered connection to the world around us. His drawings make us laugh and sometimes wince.

D! Tell us a little about a typical work day in the life of artist, George Trosley.

T: I get up early, grab a glass of milk and hit the drawing board. I have the TV on all day to keep up with current events and to pick up on new catch phrases and trends. I write all my own stuff so I spend some time going through magazines and newspapers mustering up ideas that I then show to my wife. She always adds something to make them much better cartoons with me, of course, taking full credit for them. I’m usually at it until about eight in the evening.

D! You grew up and spent a lot of time in Pennsylvania. I am astonished at how many car shows are in that state. You seem like a pretty serious car guy. Do you attend car shows?

T: Oh yeah… I usually make the Street Rod Nationals in New York and The Wheels of Time Show in Macungie… and a lot of local shows. I hit the New Jersey Shore for the Boardwalk Shows and the Race of Gentlemen on the beach in Wildwood which has really grown and fills the island with all kinds of wild creations.

D! Tell us about your experiences racing cars as a young man.

T: I’ve only drag raced once. I’d gotten a rebuilt flathead short block through the local Ford dealership for my ‘39 Ford and had almost put on the thousand break-in miles when my brother and I decided we should put the last of those miles driving it to the Cecil County Dragaway in Maryland and race it. Being still stone stock at this point they put us in the N/Stock Class. Garlits was there that weekend and things built until he blew down the strip at close to 200 MPH. As everyone began to head to the snack bar they ran N/Stock. I actually won the class with a blistering 68.07 MPH with a 19.76 second ET. My brother said I looked like Gartlits’ push truck following him down the strip. We drove home with a trophy and the decision to build it as a Street Rod. Although we never raced again… a few years later the ‘39 took third place at The Annual Philadelphia Convention Center Indoor Car Show.

D! I would guess you have a stable of radical rods. What do you drive these days?

T: My taste in cars is kind of tame actually. I presently drive another ‘39 Ford Tudor, maroon with a 350 Chevy engine auto trans, Ford nine inch rear and Mustang II front suspension, chrome reversed rims with Merc dogdish hubcaps and blackwalls and a slight rake do it for me.

I’ve always loved drawing cars but…

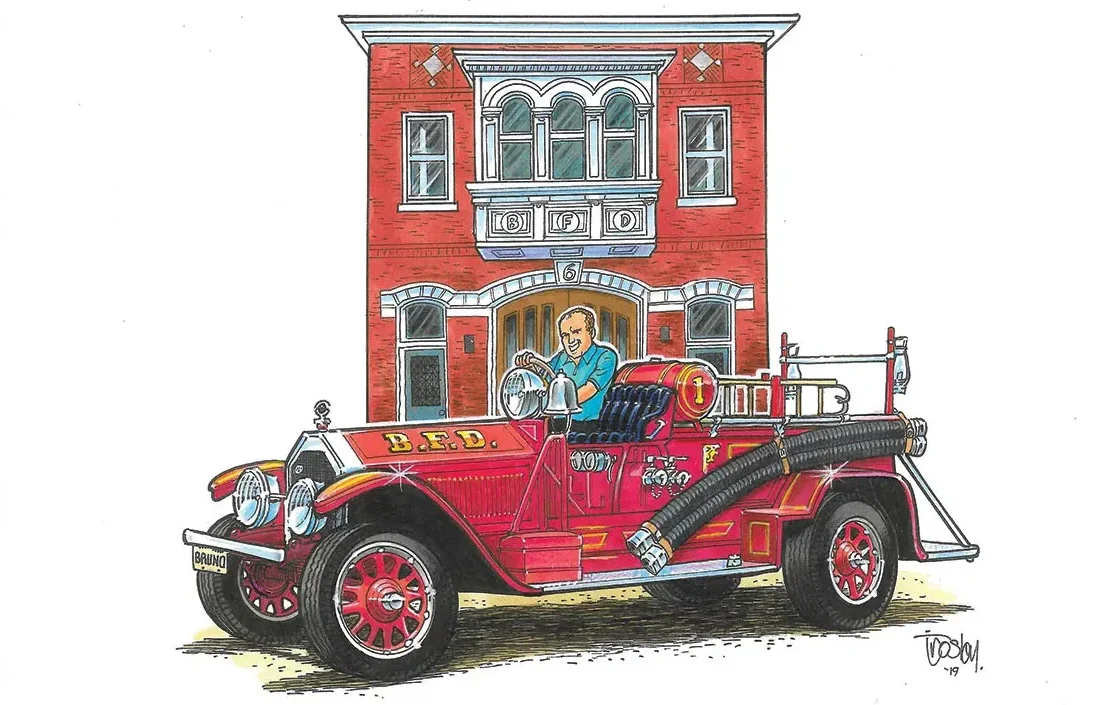

D! Where do you find inspiration for the many forms of humor you illustrate?

T: Most of my cartoons feature cars but the humor is usually about the people who own, build and love them. – A man is running out of a burning building carrying a load of precious car parts saying to the approaching firemen, “Quick….

My wife and kids are still inside!”

D! Graphic art and illustration is in an interesting period in history. Computer design software has augmented the tools that some artists use to communicate with their viewers. Your art has always had a distinctive hand-rendered look. Take us through a typical Trosley project. And if you don’t mind sharing one or two of your techniques.

T: I usually start with a very rough sketch to establish a point of view… head on? Maybe a bird’s eye view? Whatever will tell the story best is what I’m looking for. Then I put together a careful tracing paper drawing using a straight edge for tile floors, doors, furniture, everything. When that’s worked out I use a lightboard to trace the sketch onto good 108 lb. bond paper using various size black felt tip pens. I do this freehand but conscientiously following my ruled sketch so it looks like I can draw really well.

I began using markers for colors and grays when I worked in a Philadelphia Commercial Art Studio and still do today. I also use colored pencils to give the marker a shaded air brushed effect when needed …. with white paint for highlights and sparkles.

D! With all the cars, trucks, vans and motorcycles you have illustrated over your career, what vehicle do you find the most difficult to accurately render?

T: Any vehicle I’ve never drawn is tough…. The first thing I do is get some good clear photos of the car. My studio is full of magazines and files but now I usually Google the car and get a variety of images. Boxing out the car with important guide lines help me keep the perspective right and everything lined up. Other than that it’s mostly observing the basic shapes of the details and getting them right.

D! What’s your personal favorite subject to draw?

T: I’ve always loved drawing cars but after that I like drawing cartoon characters and exaggerating their movements… running… jumping… expressions… again it’s the human condition that’s fun.

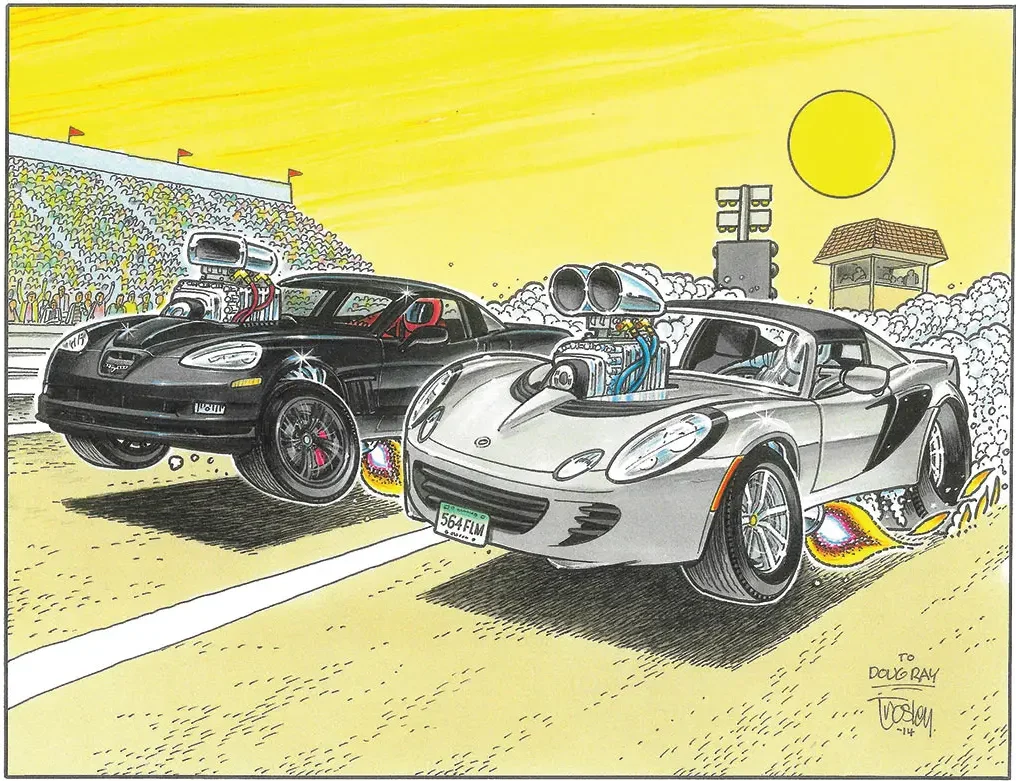

D! You also offer personal commissions of fan’s own cars. Tell us more about this unique opportunity.

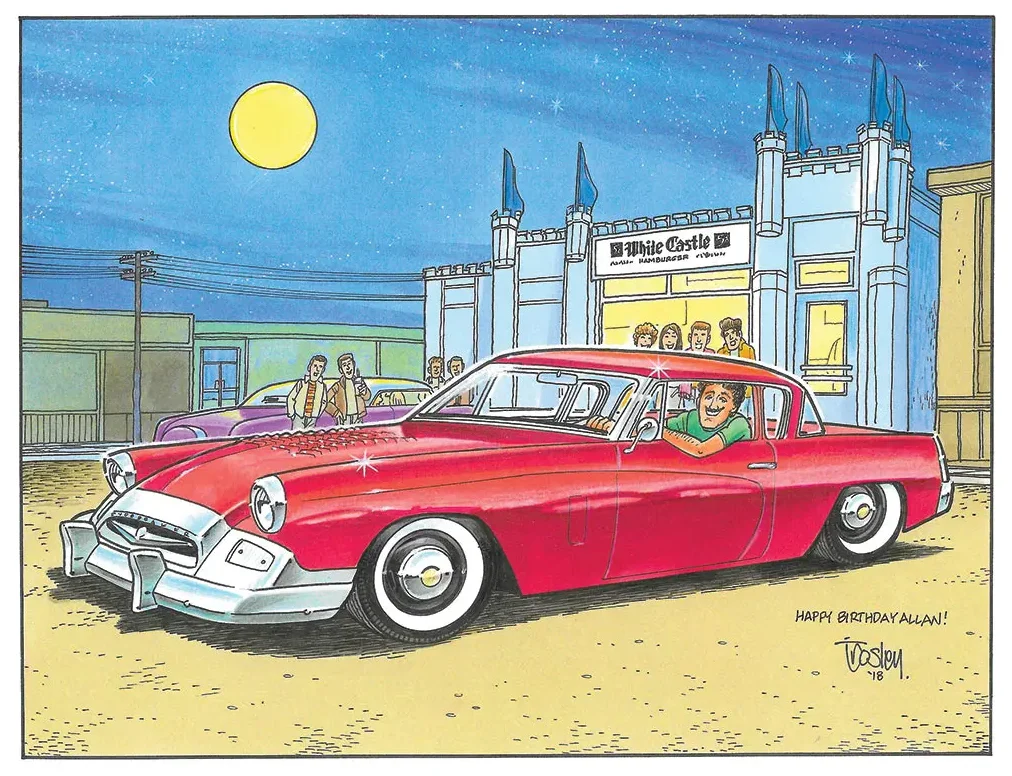

T: It’s so cool to receive a bent up photo of somebody’s Dad’s High School ride and graduation picture and then putting together a drawing of him in front of a hamburger joint where he hung out as a teen. We often get a note from the dad who gets it as a gift telling us how much he digs it.

Another really popular request is the Custom CARtoons Covers featuring your car and your special blurbs… or the drag race that never happened between you and your buddy with you winning by half a car! We also do Car Club logos as well as Car Show T-shirt art.

Often I’ll get a Custom Car Portrait request from someone who has just acquired his dream ride or one from someone who let his get away. I also did quite a few car portraits of the cars destroyed in the recent fires of California. It’s great to be able to preserve memories … new and old for someone.

D! You are so crazy-busy. In addition to the personal commissions, give our readers a sense of the other types of projects you accomplish.

T: I presently produce a full page-color cartoon for STREET TRUCKS magazine, a two page ‘KRASS & BERNIE’ feature every month for CAR CRAFT magazine, and an episode of ‘DEUCE & PINSTRIPE’ and a how-to drawing lesson ‘TROSLEY’S SKETCHBOOK’ for the all-new CARtoons Magazine.

D! What’s next?

T: We just put together Book Two of our continuing KRASS and BERNIE Series 1980 – 1985 and have few new T-shirts coming. More of the same, of course! Keep your eye on georgetrosley.com for our Limited Edition prints, t-shirts, books and other cool stuff!

D! Super-cool. Thank you!

Come See Us At This Year’s Overland Expo West, May 17-19 In Flagstaff AZ.

Corona, CA — aFe POWER is proud to announce its inaugural exhibit at the 2024 Overland Expo West May 17-19 held at Tuthill County Park, Flagstaff AZ.

Overland Expo® is the premier overlanding event series in the world—offering on-site camping, 400-plus exhibitors, specialized classes taught by the world’s leading experts alongside a professional-level trade show that brings together all the camping and vehicle and motorcycle equipment and services you need to Get Outdoors.

aFe’s 20 x 40 booth footprint will be at space P40, near the Navajo Ramada section. Come by to check out our trail-ready vehicles, the latest product displays and speak with our knowledgeable staff to find out how to get more power and performance from your rig. From intakes and exhausts to suspension and sliders, take advantage of at-show specials on aFe products, apparel and much more.

We will also be offering free giveaway items as well as customer sign-ups for the latest product updates, specials, and events. We look forward to seeing you there May 17-19 in Flagstaff, AZ.

About aFe POWER:

advanced FLOW engineering (aFe Power) is a premier designer and manufacturer of automotive performance upgrade systems and components. Current product lines include cold air intake systems, high-performance direct fit and universal air filters, exhaust systems, intercoolers, electronic modules, suspension, accessories and more. aFe is passionate about providing the most compelling, innovative, and highest-performing products that are designed, built, and tested in the USA. aFe POWER was founded in 1999 and has headquarters and manufacturing facilities in Corona, California, USA

For more information about aFe POWER, visit afepower.com.

For more information about Overland Expo West, visit overlandexpo.com/west/.

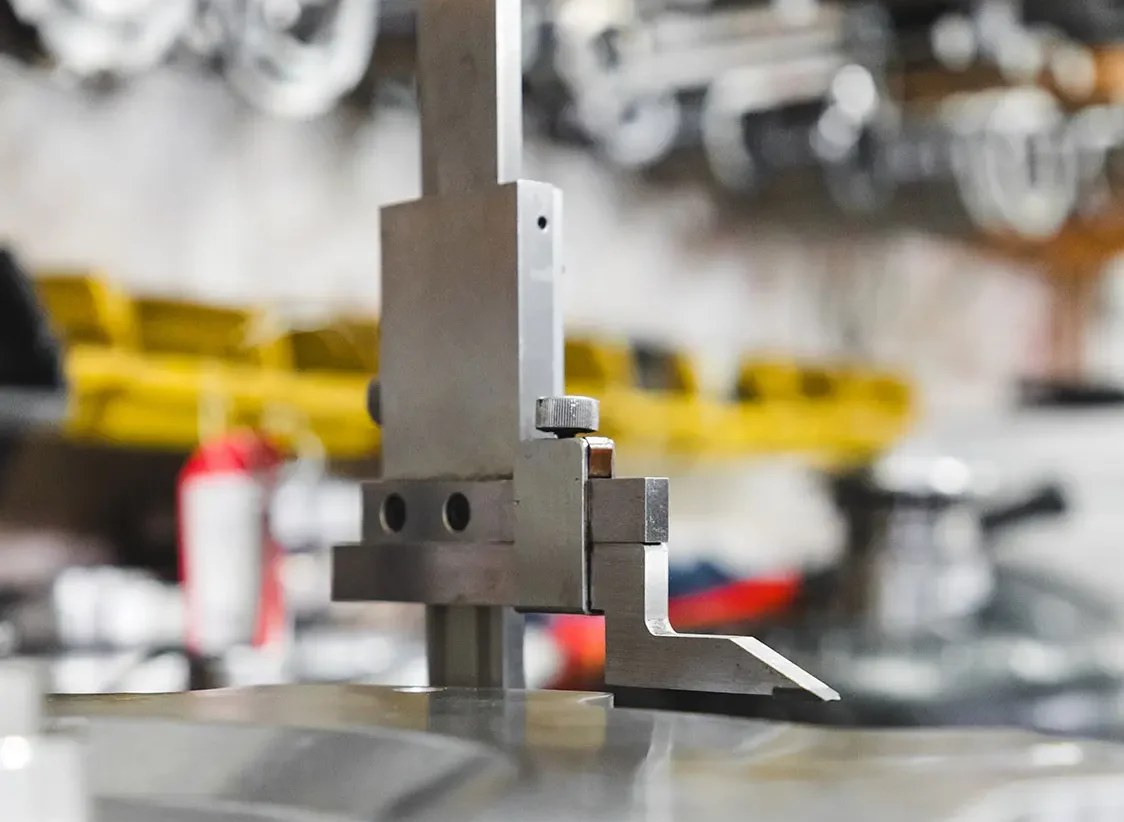

Hello, Diesel World readers! We’re in Deland, Florida, at FTI Performance to get a glimpse behind the scenes at how a 47RE/RH torque converter is built by one of the best in the industry!

This is a part that just about everyone needs for their upgraded transmission build, but most don’t necessarily get to see an inside look as to how it’s actually put together.

And we’re done!

In the previous Backcountry Skills, we delved into tire CPR 101, reviewing techniques and equipment for repairing basic punctures, broken valve stems, and how to dismount a tire from its wheel. But what do you do if a commie rock, branch, or whale bone slashes a gash in your sidewall? This issue recently landed front and center during a run guide for Sierra Trek on the Fordyce Creek Trail, a route that surpasses the Rubicon in technical challenges. Most participants were running 38- to 40-inch tires, didn’t carry a spare, and one of them had a run-in with the aforementioned foe. This month we are diving deep into our bag of tricks and exploring ways to bring an ostensibly dead tire back to life, albeit temporarily, and get you off the trail. what do you do if a commie rock, branch, or whale bone slashes To keep the attorneys at bay, we need to emphasize that the following are for emergency trail fixes only, are not approved by the DOT for on-road use, and the repaired tire should only be used at very slow speeds.

TIP: Per the U.S. Department of Transportation, shoulder and sidewall repairs are not permitted for vehicles driven on public roads.

Now that we’ve covered the ‘Don’t try this at home’ disclaimer, there are several options for resuscitating a flatlined tire; traditional interior patches, surgical stitching, or a combination of the two, each of which will require removing the tire from the rim. The third, which we will get to in a moment, is a new product from GlueTread.

TIP: Be sure to fully remove the membrane from the interior work area prior to applying a patch.

If welding with batteries is the Holy Grail of backcountry repairs (see Backcountry Skills #1, Tread Jan/Feb 2023), stitching a badly torn sidewall is a close second. The Extreme Outback Products and Power Tank kits include waxed sail thread and stainless-steel wire respectively, but if you are in a pickle, this type of surgery can be accomplished with bailing wire, tire plugs, and silicon. For this exercise we cut a 2.5-inch slice in the middle of the sidewall and went with the in-a-pickle scenario. You will find the process is akin to suturing up a laceration in your buddy’s leg…but with a little less finesse.

Whichever method you use (wire or thread, silicon or patch) sidewall flex can be detrimental to this type of repair. Reinflate to the point that sidewall flex under a load is limited, but not to the point that the repair area bulges much (psi will depend on tire, wheel diameter, vehicle weight, and so on). So, it’ll hold air under a great load—though the bailing wire fix might have slow leaks, so you should swap it out for the spare, if you carry one. This Frankenstein fix will not be pretty, but it should get you off the trail or provide a spare if things go pear-shaped…again. If you must use it, avoid rubbing the subject tire against rocks, tree branches—anything.

TIP: When stitching, be sure to cover the plugged area and suture holes with silicon from the inside.

TIP: Inflate a stitched tire only enough to eliminate most sidewall flex.

I met the GlueTread crew at the 2022 SEMA Show, and while I was skeptical about ‘super gluing’ an external patch for trail use, I listened to their pitch. While I’ve not personally trail tested this product, my buddy Tyler Laursen (of MORRFlate systems) recently slashed all four tires on his rig, repaired them with GlueTread, and drove the Rubicon Trail. Is this the miracle drug that renders dismounting tires a thing of the past?

TIP: For best results, be sure to precisely follow GlueTread application instructions.

I’ve learned a lot since that commie push rod confrontation back in the `80s, and I am always impressed when someone comes up with a better mousetrap. After drilling, slicing, and dicing our test dummy tire, it begrudgingly held air for several days. Not bad! As for my crewmate’s GlueTread repair on the spareless Sierra Trek vehicle, he finished the trail and was having coldies with us around the fire in basecamp that night. If you follow the instructions, this stuff is pretty darn amazing.

Whether it’s stitching, patching, plugging, or super glue, pick your poison, get the gear, and practice, practice, practice in the comfort of your garage. Next time one of your buddies finds themselves in a tire pickle, you’ll be the hero of the day.

See you on the trail,

Chris

Extreme Outback Products:

www.extremeoutbackproducts.com

Power Tank:

www.powertank.com

GlueTread:

www.gluetread.com

Editor’s Note: A version of this article appeared in TREAD Nov/Dec 2023.

Eddie Motorsports newly designed Kinetic hood hinge features form and function in a CNC precision machined T-6061 billet hinge. The new Kinetic hinge is a custom alternative to the inferior O.E. stamped steel hinge. Mounting points are designed with larger mounting areas machined in for more adjustment over stock hinges to get a perfect hood gap. Sealed bearing and stainless hardware ensure long lasting performance and smooth operation. CNC machined windows add to the distinctive look of the Kinetic hinge. Available for these popular applications: 67-69 Camaro / Firebird, 64-67 Chevelle. 63-67 Impala and 64-67 GTO / Cutlass. Can be customized in any one of our available finishes from raw machined or any one of our Fusioncoat colors. Sold as a pair with vehicle specific gas charged struts and stainless mounting hardware.

PerTronix has an expanded line of popular Flame Thrower Coils with offerings for late-model GM, Chrysler, and Ford applications. Superchargers, turbochargers, and nitrous all increase the demand on the ignition system. Whether it’s a performance application with add-ons or an increase in power for the stock ignition, Flame Thrower coils won’t disappoint. We’re offering 12 fitments that are available in single coil or 4, 6, or 8 packs depending upon the application.

A new MagnaFlow catalytic converter will make those issues go away and keep your vehicle emissions-compliant without compromising exhaust flow and performance. Features include:

For over 50 years, Leather Honey has been making the best leather care products, including Leather Honey Leather Conditioner, the #1 best-selling leather care product on Amazon.

Leather Honey penetrates deep to protect new leather and rejuvenate dry leather and old leather. This non-toxic leather conditioner has no silicone, solvents, or animal products. It is also non-sticky and completely odorless, which makes it perfect for your car, motorcycle, RV, etc.

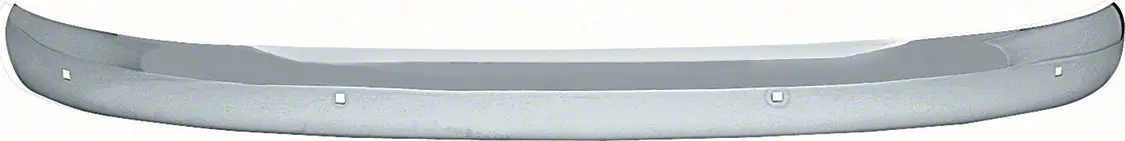

Classic Industries new OER Premier® reproduction of the chrome front bumper designed for use on 1947-55 Chevrolet and GMC truck models. This “show quality” bumper can also be installed as a rear bumper on panel truck models. This bumper is designed exclusively for the restorer who demands the best the market has to offer. Each bumper features superior triple chrome plating that exceeds OE standards. Also features original-style contours and pre-drilled mounting holes. Replace your old or worn-out original bumper with this “show quality” reproduction.

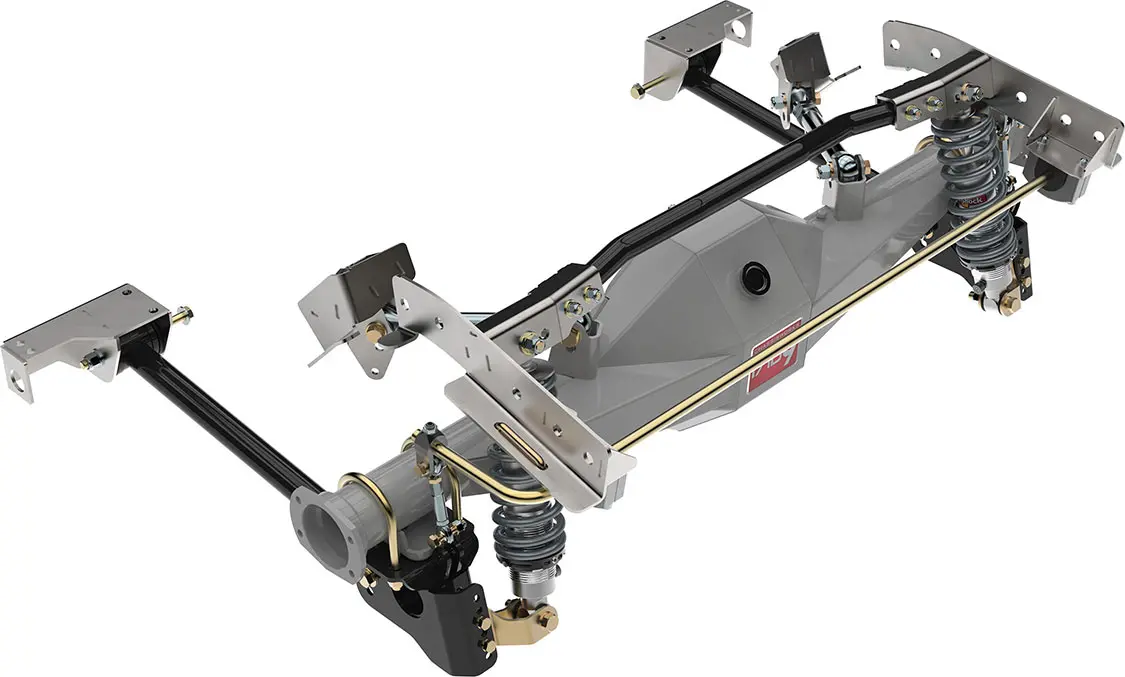

With adjustable suspension geometry and the option to choose between coil-over or air-spring shocks, this suspension upgrade offers enhanced control and stability on the road. The triangulated 4-link design offers improved traction and handling, making it an excellent choice for drivers looking to enhance their driving experience. The suspension can also be used with either a leaf-spring rearend housing or a fabricated Ford 9” housing from Total Control Products.

The Third Brake Light Antenna Mount from Bullet Proof Diesel is simple to install and can be done with a minimal number of tools.

Easy To Install

No Large Hole To Drill In The Top Of Your Cab

Patented Design

2021-2023 Ford Bronco With 35” Tire or 37” Tires

235 Series Premium Nylon Braided Hose and 205 Series Stainless Braided Hose have a dual-layer inner tube of Epichlorohydrin (ECO) and Fluoroelastomer that is compatible with E85, methanol, and gasoline. They also have a full stainless steel underbraid layer. The 235 Series Hose has a black braided nylon cover, and the 205 Series hose has a stainless steel braided cover.

How’s it going everybody! I’m Devan Ence, the new Editor-at-Large for the F-100 Builder’s Guide. I have been a Ford truck nut since I was a little kid. Some of my earliest memories are riding around in our 1976 F-250 Highboy with my dad listening to Dan Fogelberg as we headed into the hills to round up cows. The dash of that truck and time spent in that passenger seat made a lasting impact on me. I still have that truck, and now I’m getting to make memories with my son while he sits in that same passenger seat.

Some of my earliest memories are riding around in our 1976 F-250 Highboy with my dad listening to Dan Fogelberg as we headed into the hills to round up cows.

I am super humbled to have the opportunity to be the editor of the F-100 Builder’s Guide and I look forward to bringing you a ton of rad content of the classic trucks we all love and the new Ford trucks we all drive daily! There are some awesome builds in this issue, and we can’t wait to show what’s coming in the future! See you again soon.