Ken McCoy August 24, 2023 Buyer’s Guides

Growing up in Jefferson City, Missouri, Chris Bedsworth wasn’t your typical millennial. He didn’t spend hours after school playing video games or listening to new-age pop music. Most of his free time was devoted to working at a local car wash and mowing lawns. He was determined to save that hard-earned income to purchase his dream ride: a classic GM truck.

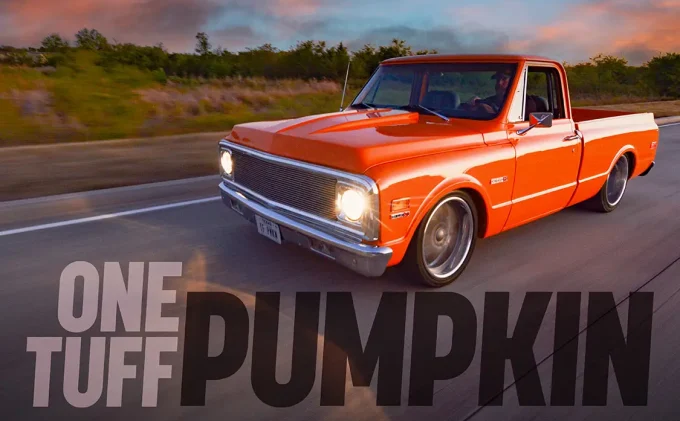

When he turned 15, his dad, Larry, helped the young man find the freedom of transportation. Chris found a bright orange 1972 Cheyenne and fell in love. It was a well-maintained longbed rolling on wide rally wheels. Under the hood, a small block had been built with more power than he probably needed but certainly wanted. The vintage hauler was used for transportation to school, hunting and fishing trips, and hauling loads for his dad’s woodshop.

Despite his love for the truck, Chris had to make a tough decision when he graduated from high school. He knew it would be too costly to provide daily transportation when he went off to college. With deep regrets, he sold the C10 and focused on acquiring an education. His high school crush was gone but never forgotten.

Fast forward 15 years, and the desire to relive the exhilaration of those youthful days resulted in a search for his old truck. Unfortunately, it proved to be elusive. Chris did, however, find a similar replacement. The ’72 Cheyenne featured here is a shortbed, but the color match was close enough to win him over.

His college education led him to a career as an insurance adjuster in Fort Worth, Texas. That success would allow him to take this build to a level he had long dreamed of. Chris wanted a truck that would go fast and look great doing it. Encouraged and assisted by a group of good friends, he began the tedious process of building a Pro Touring terror.

His college education led him to a career as an insurance adjuster in Fort Worth, Texas. That success would allow him to take this build to a level he had long dreamed of. Chris wanted a truck that would go fast and look great doing it. Encouraged and assisted by a group of good friends, he began the tedious process of building a Pro Touring terror.

The existing orange paint on his latest acquisition was in great condition, so it was buffed to a brilliant shine. A plan was formulated to focus on a total transformation of the drivetrain. An LS3 was procured as the starting point for creating the power he felt would be necessary to accomplish his goals.

The stock 6.2 block was bored to accommodate Darton 4.1 sleeves. Those larger holes were filled with a set of DSS Racing flat-top pistons netting a 11.5 to 1 compression ratio. Down below, SCAT “Pro Series” connecting rods swing on a balanced Callies stroker crankshaft. Brian Tooley Racing grinds a cam specifically for a stroked LSx. He supplied the stage-three kit with matching hydraulic rollers. The block was topped with a set of aluminum heads that Ron Warrick at Vector Performance massaged extensively.

After porting and polishing, Ron filled the holes with BTR valves, springs, and retainers. The top end was finished off with a port-matched LS3 intake breathing through a 92mm throttle body. A set of LSA 52# injectors fed by Holley fuel rails provides large doses of premium gas. Once the fuel mixture is squeezed and fired, it exits through Doug Thorley Tri-Y headers. Spent gases are moved rapidly through a 3-inch exhaust quieted to a mild rumble by Borla XL mufflers.

To endure an estimated 600 horsepower with tons of torque that the stroker motor was capable of producing, a pro-built transmission would be required. Cameron Powers at CPR Transmission was called on to blueprint a GM 4L80 with premium quality parts. The case was gutted, and then a Jake’s Performance 258mm torque convertor was secured to the flexplate using ARP bolts. This turns a TCI billet input shaft connected to a roller bearing hub. Borg Warner high-energy clutches engage the gears controlled by a B&M manual valve body.

Power is sent downstream through a Precision Shaft Technologies 4-inch aluminum drive shaft coupled to a custom-made rearend. Boar’s Nest Fabrication built a 9-inch trussed housing and filled it with a Wave Trac differential spinning Moser 3.50 gears. Strange Engineering 35 spline heat-treated alloy axles complete the bulletproof package.

With the ability to go forward rapidly, attention was directed toward turning and stopping. A Unisteer rack-and-pinion with a reduced lock-to-lock ratio replaced the factory steering box. Ridetech provided a MuscleBar to minimize body roll and maximize driver input.

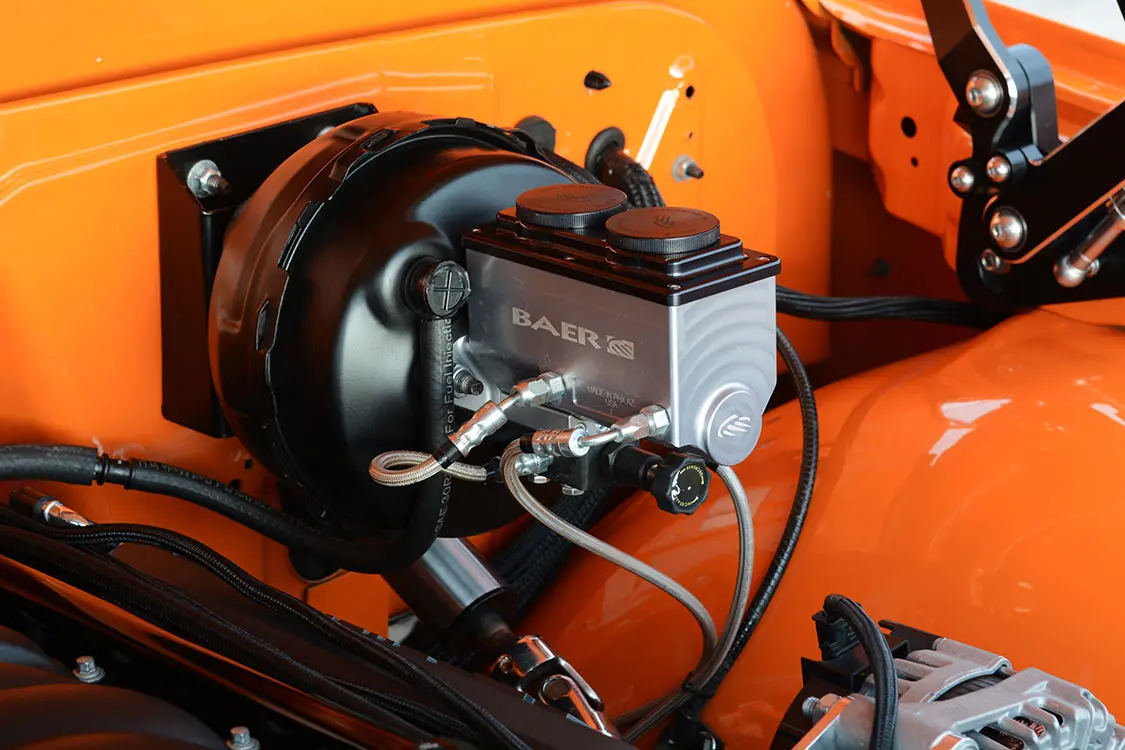

Chris fabbed a bracket to mount a Baer dual diaphragm booster to the smooth firewall. Stainless braided lines were routed to Baer 13-inch slotted rotors with T4 calipers in front. The big brakes are mounted on Ridetech spindles and control arms are supported by QA1 double adjustable coilover shocks.

Porterbuilt Fabrications’ inner frame stiffener was combined with a PB Fab 4-link and C-notch to reduce chassis flex and improve suspension articulation. Another pair of QA1 double-adjustable coilovers were hung in back. Rear braking is provided by Baer 12-inch slotted rotors with SS4 calipers.

With the suspension in place, a fresh set of wheels were needed. Chris Coddington at Hot Rods by Boyd suggested his Crowbar-Pro Bar wheels. With the suspension in place, a fresh set of wheels were needed. The charcoal centers are accented with a polished outer lip. In front, a pair of Nitto 295/35/20 went on 20×8.5 with a 315/35/20 on 20×12 fill up the rear tubs.

Chris fitted the custom bed wood to a tilt- floor frame made by Riggs Fabrication and then covered the gaps with smooth Mar-K polished stainless bedstrips.

To maximize performance when at the drag strip, Chris switches to tires and wheels that are better suited for straight-line performance. In front, he runs RC Component “Fusion” 17×4.5 with Mickey Thompson Sportsman 28X6.00R17LT. Out back, he runs a matching set of RC Component “Fusion” 15×10 with bead locks. Tires are sticky Mickey Thompson ET Street Radial Pro P315/60R15.

Part of what makes a Pro Touring truck appealing is an interior designed to be comfortable while keeping the occupants safe. A perimeter roll cage was precision bent by Wright Fabrication and tucked tightly out of sight. A pair of late-model Silverado buckets seats, door panels, and console were covered with black vinyl and combined with perforated inserts by PG Auto Upholstery of Haltom City, Texas. A Momo steering wheel was wrapped to match the seats and door panels, and then mounted onto an Ididit tilt column. Behind the wheel is a Dakota Digital VHX cluster surrounded by a Ring Brothers billet bezel. Vintage Air controls the temperature via Restomod Air billet ducts.

The original Delco radio was replaced with a Kenwood multimedia system. It is now the source for audio entertainment as well as navigation. An Audison SR5 amp produces 550 watts of crystal-clear power sent through five channels. Up front, Hertz Audio separates are tucked behind custom grilles to provide the mids and highs. In back, a Hertz 10-inch sub fills the cab with low-frequency bass.

As the project neared completion, Chris considered his options to fill the open bed floor. He recalled a load of walnut wood he had hauled home from the mill back in his high school days. His father had saved it for decades waiting for the perfect opportunity to use it. Larry skillfully crafted the hardwood planks in his wood shop and then sealed them with a satin finish. Chris fitted the custom bed wood to a tilt-floor frame made by Riggs Fabrication and then covered the gaps with smooth Mar-K polished stainless bedstrips. The three-year project was almost complete.

When contemplating a name for his bright orange build, he recalled showing a drawing of his old truck to his dad years ago. Mr. Bedsworth had teased his son about the color, calling it “The Great Pumpkin.” Chris defended his pride by proclaiming it to be a “Tuff Pumpkin.” That may have been an overstatement back then, but clearly this tribute to his high school crush is one TFPMKN.

Everyday Wheels

Drag Wheels