Tom Wilson June 06, 2022 All Feature Vehicles

Needing gas money to get around, Barrett Lash arranged two private races in his stripped 1966 Plymouth Fury. On the second of these wins, his date—thoughtfully perched atop a piece of cardboard where the passenger seat once took up weight and peering through the holes where the glovebox and heater core used to be—inquired if blue flames in the engine compartment were normal.

We’d think the time to inquire about normalcy may have already transpired, but then, not much about Barrett and Patty Lash’s path to the exquisite 2009 SRT8 Challenger in front of you would pass for normal. That first date—yes, it was a first date—turned into the third win of the evening for Barrett when he and Patty eventually married. Turns out it would take more than a couple of street races and a few blue flames from a failing alternator to scare her off. In fact, Barrett says Patty is the competitive one and she’s been behind his car projects all the way.

That first date—yes, it was a first date—turned into the third win of the evening for Barrett when he and Patty eventually married.

Barrett’s early intoxication with fast Mopars—he’s been a pentastar guy from the get-go—was intentionally shelved as he reached his working years. Learning from textbooks was never Barrett’s strong suit—he’s dyslexic—and early on made the conscious decision to become an independent businessman by hands-on experience. So, when most youth were still trying to figure out how they were going to score that 750 Holley double-pumper of their dreams, Lash realized that if he set aside his speeding ticket habit and applied himself to a successful business career he could eventually buy any car he wanted. The result was decades of grinding hard work building a distributorship and culminated by the purchase of Folex, the maker of advanced cleaning agents he was distributing.

“David ate Goliath,” is how Lash explains it.

Thus realizing his Horatio Alger plan, Lash has been able to indulge in modern Mopars with considerable intent. With the means to collect as well as build, Lash’s Challenger story actually starts with a pair of SRT8 Chargers and a numbers matching, collectible SRT8 Challenger too clean to cut up into a custom. So Lash traded his ’07 Charger for the bright silver metallic Challenger in the photos to reach his starting point. His plan was, and is, to carefully build the Challenger into the performance stratosphere; a car with mega power that would be both a challenge to build and drive well.

A man of the street, Lash may have 1700-hp dreams, but they no longer include stripped interiors and jungle-gym roll cages. The silver Challenger is to be all a streetcar can be. Clean, driveable, looking mean in a factory-built sort of way, and above all with hand of God power. Smart enough not to build more than he can drive, Lash has also wisely chosen to make the Challenger’s development a learning journey for himself as he revisits and exceeds the performance of his youth.

With the means to collect as well as build, Lash’s Challenger story actually starts with a pair of SRT8 Chargers and a numbers matching, collectible SRT8 Challenger too clean to cut up into a custom.

“Working for the big companies you need the [school] credentials. But on your own, you learn that every decision matters,” says Lash. “That is literally how we looked at this car. Every single step is deliberate, to learn how to do it again. I didn’t want to be that guy who builds it and runs it into a tree.”

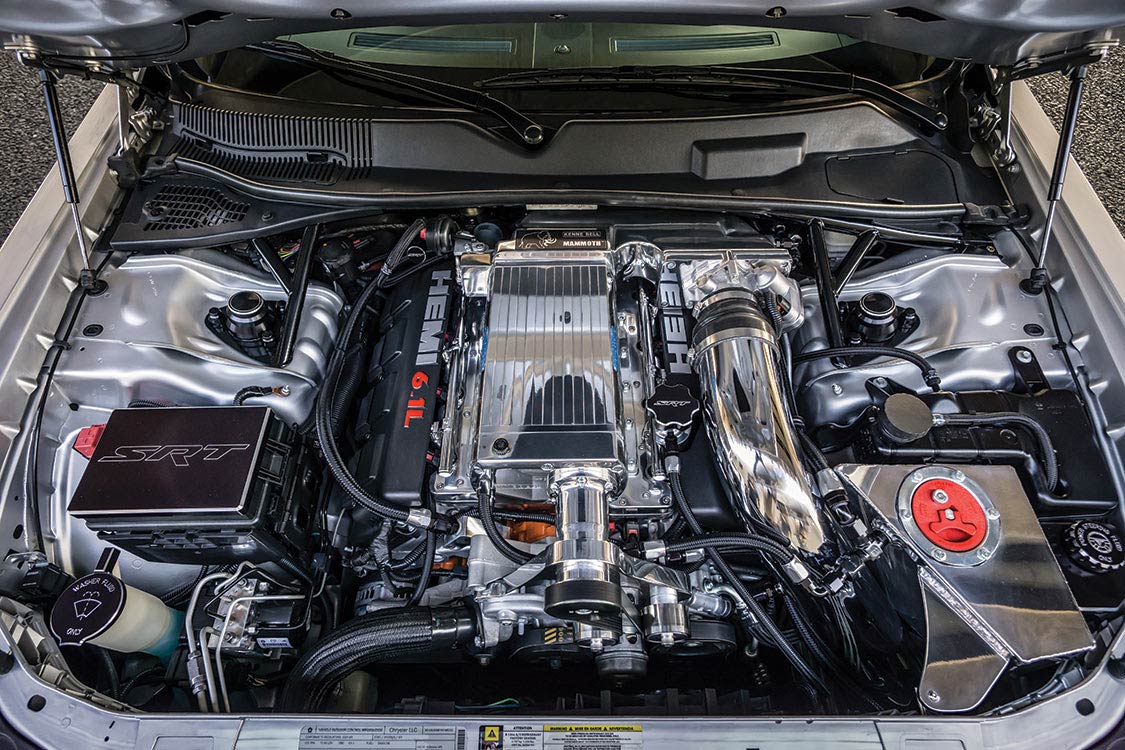

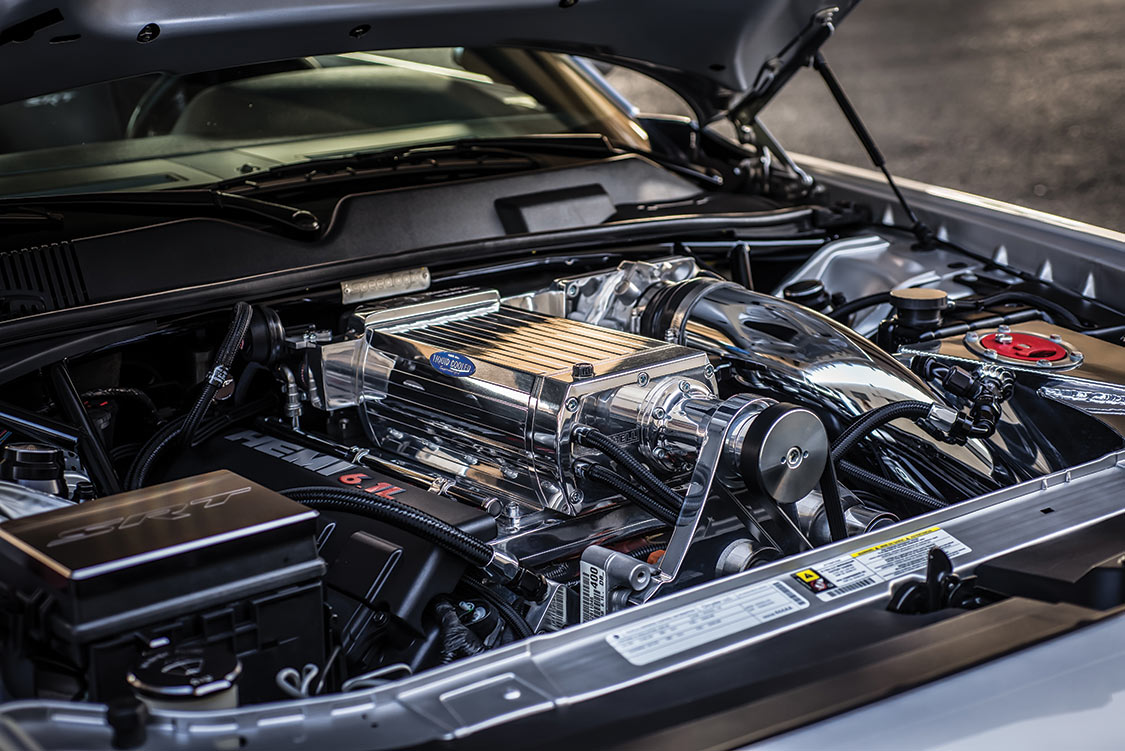

Avoiding trees was easy enough given Lash began with a set of lowering springs and drag radials for play days at the track. Quickly comfy with the Challenger naturally aspirated, Lash soon began getting it into the form seen in our photos. The engine is internally stock save for the camshaft, but has been augmented by a Kenne Bell 2.8-liter twin-screw supercharger with the Liquid Cooling option. Adam Montague at the memorably named Spankin Time Performance in San Bernardino, California, handled both the blower’s mechanical installation and electronic tuning. Located just a few miles from blower maker Bell, tuner Montague is a regular with their potent Lysholm screw huffers and has extensive tuning experience with them on many applications running everything from California rot-gut pump gas to “corn” ethanol blends up to E85, to race gas.

Something of a get acquainted tune, good for 510 hp at the tires with 7.6 lb. of boost. near the limit with pump gas but hardly working the 2.6 Kenne Bell, which is efficient making boost well into the teens.

Montague first set up a simple 8 lb. of boost tune along with an oversized custom ice water cooler reservoir for the intake air, plus his mildest blower cam and a dual bypass for the most stock-like throttle feel. Something of a get acquainted tune, this was good for 510 hp at the tires with 7.6 lb. of boost. This is near the limit with mediocre pump gas but hardly working the 2.6 Kenne Bell, which is efficient making boost well into the teens. As always, Spankin Time paid close attention to the intake air temperature with the Hemi. These large engines easily make excellent power when boosted, but aggressively pull ignition timing as intake air temperature rises, hence the larger capacity 1.5-gal. charge cooler tank for faster chills at the track.

With the engine producing respectable power, Lash turned to presentation and Portland, Oregon’s, master body man, Bill Hall. He started with a thorough detailing of the car’s inevitable mass production grade paint, and then got down to business with the Mopar T/A hood and scoop. Sold as a cosmetic add-on, Hall turned the scoop into a functional unit aimed at either simply cooling the blower by ducting air over it, or acting as a proper ram air scoop at a later date. This required adding aluminum and reengineering the scoops fastening to the hood, not to mention integrating the paint. As usual with such involved bodywork when executed by pros, the scoop looks like Dodge grew it there. Its low, wide standoff design harkens to the original muscle car era when Dodge engineers led the way in transferring aerodynamics from planes to Detroit iron and plays a large part in Lash’s Challenger’s factory ethos.

Underneath, Lash moved to a more robust and adjustable suspension. Eibach adjustable front upper control arms and KW V-2 springs and adjustable dampers replaced the simple lowering springs during a trip to Ding’s Auto in Vancouver, Washington. Ding’s also replaced the wimpy stock Dodge cowl brace with a proper Speedlogix front shock tower brace.

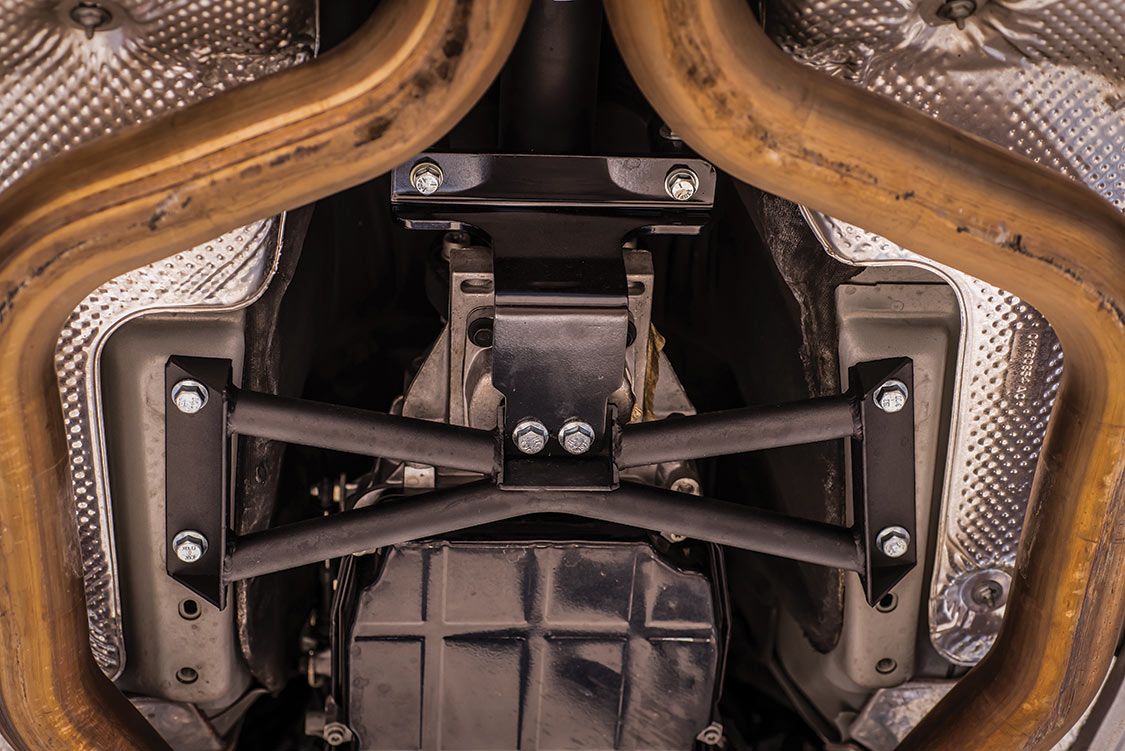

In back, the excellent Razors Edge billet aluminum adjustable control arms were fitted by Bill Brink at So-Cal Speedshop Northwest in Tualatin, Oregon. Actually, this was just the beginning of Brink’s handiwork on the Challenger as he also fabbed custom subframe connectors, coaxed a Razors Edge 4-point, low-profile, rear shock tower brace into position in the trunk, installed a Razors Edge X-shaped transmission brace and driveshaft loop, plus massaged the rear inner wheel wells for worry-free drag radial clearance.

None of these jobs were eased by Lash’s requirement that everything look as factory as possible. This includes under-car, where the subframe connectors started out as readily available round-pipe aftermarket parts, which were discarded because they hung down too low and could be seen. They were replaced by lower-profile rectangular tubing fabricated by So-Cal for a close-as-possible fit, including trimming and refitting Dodges’ stock plastic under-car trim panels. Widening the rear wheelhouses was another case of alternately welding in custom pie-shapes here and shrinking metal there to build in place something that looked stock but was a little larger. Care was required when welding these and the sub-connectors as the complete interior was still in the car, so Brink had to watch where he pointed the welder in case he smoldered the carpet.

In the trunk, the 4-point frame brace was not an exact fit in Lash’s Challenger, so it took some blacksmith coaxing. More to the point, Lash’s requirement that the brace penetrate the carpet without cutting slits in the fabric meant he had to gut the trunk and rear seat to take up the carpet so it could be holed to slip over the brace tubing, then the brace’s final build could take place in the car. Fitting the transmission brace and then integrating a driveshaft loop was another study in massaging aftermarket pieces until they fit on Lash’s car, but as add-ons this was relatively easy, out-in-the-open work, and the somewhat custom installation is expected when working with mass-produced chassis.

Once the under-car gear was fitted, So-Cal spent a couple of days setting the ride height exactly so and re-gaining the stock alignment settings. This is always tedious as it takes a few hours for the springs to settle to their final height. Plus the offset bolts used to restore the proper rear camber setting in the Mercedes-sourced IRS are a trial fit proposition and are designed to be installed with the IRS cradle dropped away from the chassis. So-Cal scraped a few knuckles working successively different offset bolts with the cradle in position thanks to the aftermarket suspension bits. Crowning this tedious exercise, Brink ultimately found the available offset bolts didn’t offer enough adjustment, so he had to fabricate those as well.

No doubt sensing the extra traction from the drag radials, the original 5-speed, Mercedes-sourced NAG 1 automatic transmission soon took a powder with the engine set at 8 lb. of boost. Knowing he was going to need a built gearbox eventually, Lash put in a call to Paramount Performance Products for a replacement transmission capable of laughing off the then current power and handling a whole lot more. Using a NAG 1 Stage II valve body, Mercedes internals and as many clutch packs as they could stuff in, Paramount paired the new transmission with a 3200-rpm stall lockup torque converter. Lash’s go-to guy for all his regular maintenance, Troy Ding at Dings Auto, performed the installation.

A Challenger/Jeep SRT8 specialist, Ding has been working on his own transmission controller since working on Lash’s. He notes the Challengers are large, heavy cars with an IRS and when given more power can be tough to launch consistently at the strip. Wheel hop is an issue—notably so with manual transmissions and not so much with the automatics—but it can be controlled with the right spring rate and zeroing in on the shock valving. Ding will no doubt have another round of this on Lash’s Challenger when he steps up to a 9-in.-based G-Force replacement rear end, but we’re getting ahead of ourselves there.

For now, Lash has stepped up his combination to 10 lb. of boost plus an appropriately more aggressive tune e-mailed in from Montague at Spankin Time. This requires more octane, but blessed with easy access to non-ethanol laced gasoline, Lash adds a can of Torco octane booster to every tank to blend his own cost-effective high-octane pump gas. Bell has tested octane boosters and says the Torco juice is a rarity in that it actually boosts octane a meaningful amount and the now-rare alcohol-free gas is a beautiful starting point. Without a dyno session, the exact horsepower is an unknown, but Montague guarantees it’s 590 to 605 rwhp from previous experience, so call it 600 hp at the tire or 700 at the flywheel. Whatever the number, this is definitely a happy spot, as Lash reports that he has 19,000 miles on the clock and drives the Challenger every sunny day when he’s at his Portland, Oregon, home. Now fitted with 3-piece Forgeline wheels, and dressed with Billet Specialties caps and other trim, the Challenger is fast, handsome and reliably ready for duty—but you know more is on the way.

Without a dyno session, the exact horsepower is an unknown, but Montague at Spankin Time guarantees it’s 590 to 605 rwhp from previous experience, so call it 600 HP at the tire or 700 at the flywheel. Whatever the number, this is definitely a happy spot…

As we go to press, a G Force 9-in. rear end, carbon-fiber driveshaft and aluminum block are on Lash’s shop floor. A 4330 vacuum remelt crankshaft is being milled by Winburg Cranks and a humongous 4.7-liter Kenne Bell blower is in the works, along with an aluminum block, Mahle pistons, Carrillo rods and all the rest of the top-tier parts needed for an all-out engine. The combination will be corn-fed on E85 fuel and the power will be far into the 4-digits, an exclusive neighborhood in the motorsports hobby, but one Barrett—and we think Patty, too—have definitely anticipated.