ALAN PARADISE July 18, 2022 All Feature Vehicles

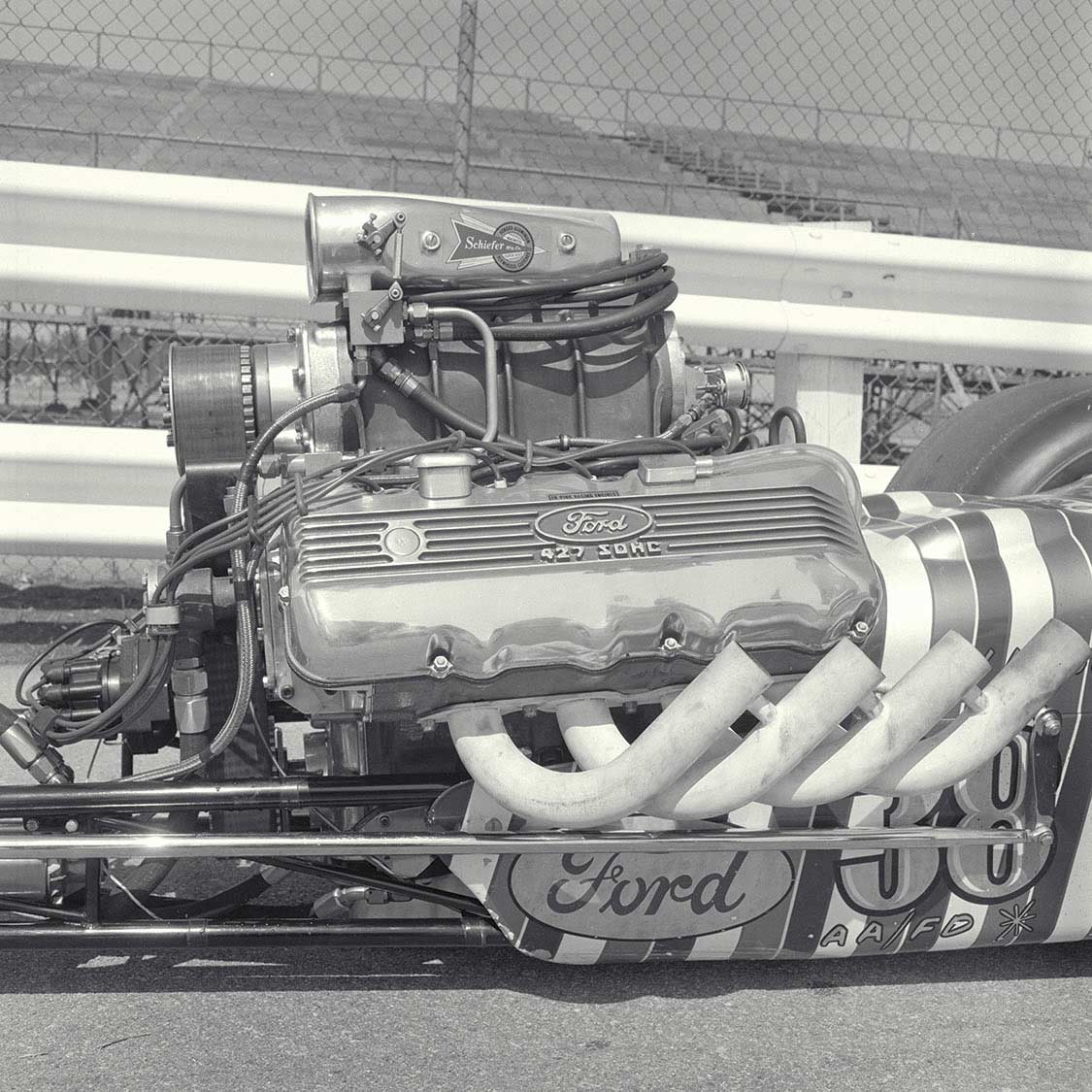

Forced induction using a supercharger is not a new concept. In fact, superchargers have been used on production-based cars since the ’30s. However, to performance geeks, superchargers are often referred to as “blowers.” That brings to mind the massive GMC 6-71 or 8-71 ribbed boxes atop the engines of Top Fuel dragsters and Funny Cars. There is also the image of the same type of detuned and polished units on mega-buck street rods or protruding out of the hoods of Pro Street cars; you know the ones, built to impress and intimidate.

For street use, the over-the-top, race-ready units are neither useful nor practical. On the street, for every day (or at least once a week) properly engineered and installed units have the ability to deliver reliable performance without compromising engine durability. This has become evident by the recent presence of factory-installed superchargers on “showroom” models offered by not one, but all three domestic makers: Ford, GM and Chrysler.

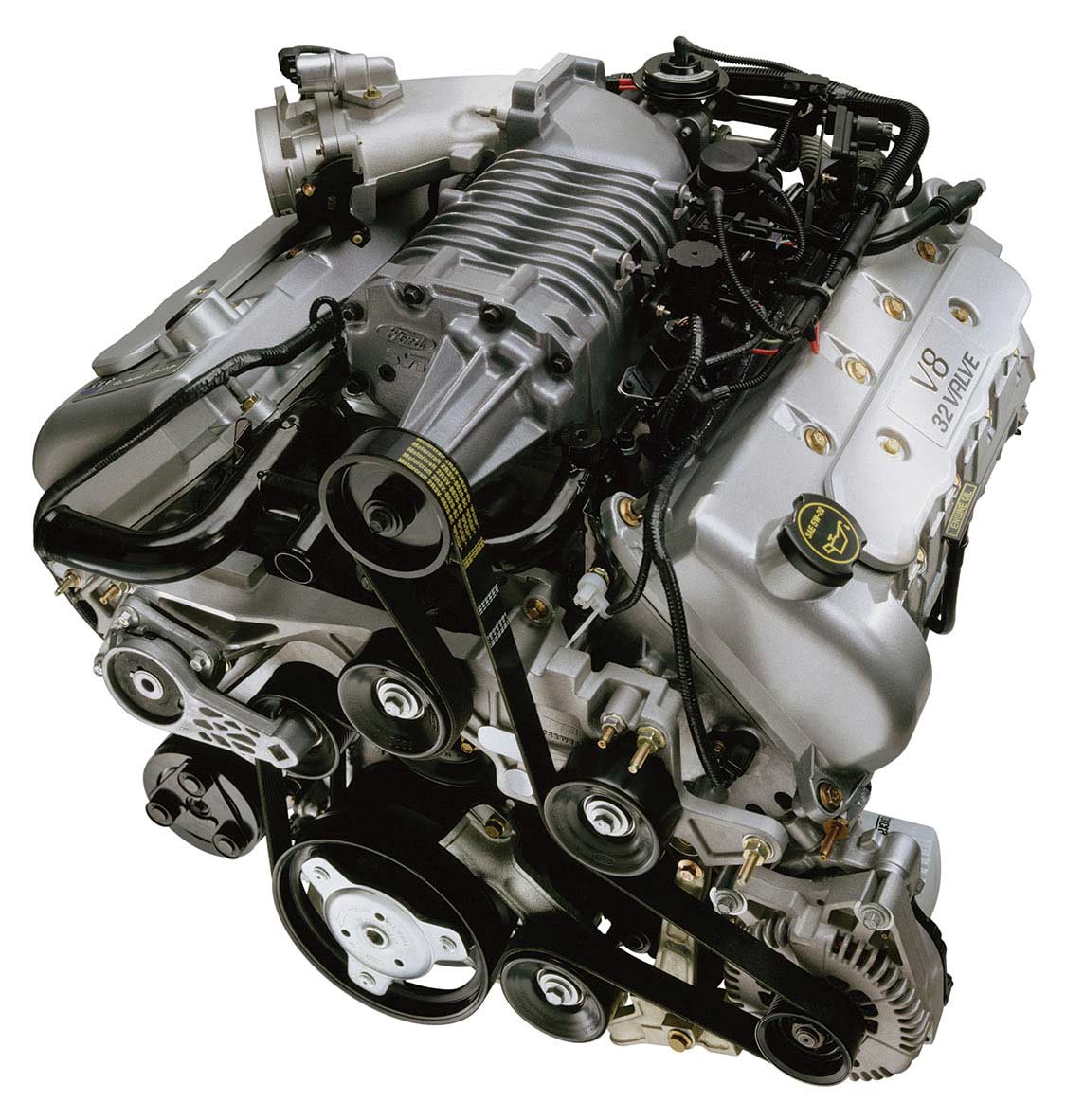

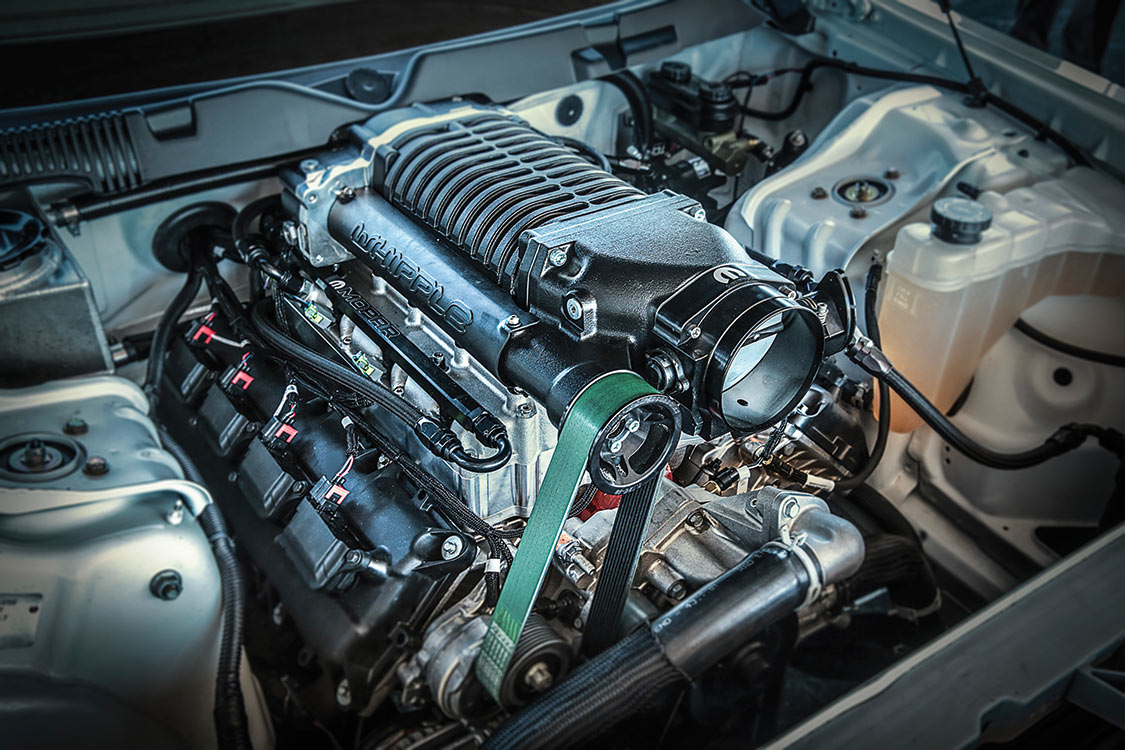

Mustang, Camaro, Challenger, Charger and Corvette as well as selected Cadillac models are available with superchargers. What has made this possible is the development of modern technology to deliver major punch in smaller capacity units. This has made reasonable and manageable power while offering very little risk.

The application of choice is no longer just the classic Roots configuration supercharger. Centrifugal and twin-screw superchargers are also a part of the new car and aftermarket scene. The differences between these configurations are dramatic in both packaging and performance, and the choices can seem overwhelming. Before the differences can be appreciated, however, some basic explanations and definitions are in order.

A supercharger helps the engine produce more power by compressing the air charge going into the combustion chamber. Because the displacement of an engine is fixed, the only way to get more air/fuel mixture into the cylinder space is to compress it and force it in place. The supercharger is actually nothing more than a glorified air compressor. There is, however, no correlation between a supercharger and an air compressor you might have in your garage.

The supercharger is Actually nothing more than a glorified air compressor. There is, however, no correlation between a supercharger and an air compressor you might have in your garage.

The supercharger only helps with power increases because compressed air alone does not produce power. Fuel is where the energy is stored and, efficiency being equal, the only way to get more power is to burn more fuel. A higher air density in the combustion chamber allows this to happen.

There is a good deal of misconception regarding supercharged engines. The most horrific is the belief that a supercharger can fatally damage an engine. This, for the most part, is not fact. First, let us assume some parameters: a healthy engine, reasonable amounts of boost, correct fuel and ignition management and proper installation. That might seem like a great deal of assumptions; however, on all factory-installed applications these aren’t assumptions at all. Also, aftermarket kits, especially those engineered and offered throughout the past 10 years, have highly effective safeguards. With these parameters in place, there is no reason a supercharged engine should suffer any premature damage. The load a supercharger creates on the engine’s internal components is not increased significantly enough to cause catastrophic failure. In fact, in many engines, the highest loads are seen when the piston reaches top dead center (TDC) and the connecting rod is under tension. In this instance, the supercharger has the effect of actually reducing load as the pressurized air in the combustion chamber acts counter to the load generated by the decelerating piston.

There can be problems, however, if detonation is allowed to occur. Detonation, simply put, is caused when the octane rating of the fuel affects the ability of the unburnt end gases to resist spontaneous auto-ignition. If auto-ignition occurs, it results in an extremely rapid pressure rise, as both the desired spark-initiated flame front, and the undesired auto-ignited end gas fumes expand. A combined pressure peak arrives slightly ahead of the normal operating pressure peak, leading to a loss of power and eventual overheating. The end gas pressure waves are superimposed on the main pressure wave, leading to a colliding pattern of pressure that oscillates in the chamber, resulting in that dreaded knocking sound.

Detonation can be avoided using one or all of the following: conservative boost pressure, inter-cooling, water injection and fuel with a higher octane fuel rating. Supercharging, when done properly, will not damage your engine.

There are several different types of superchargers that can be placed into two categories: fixed-displacement and centrifugal.

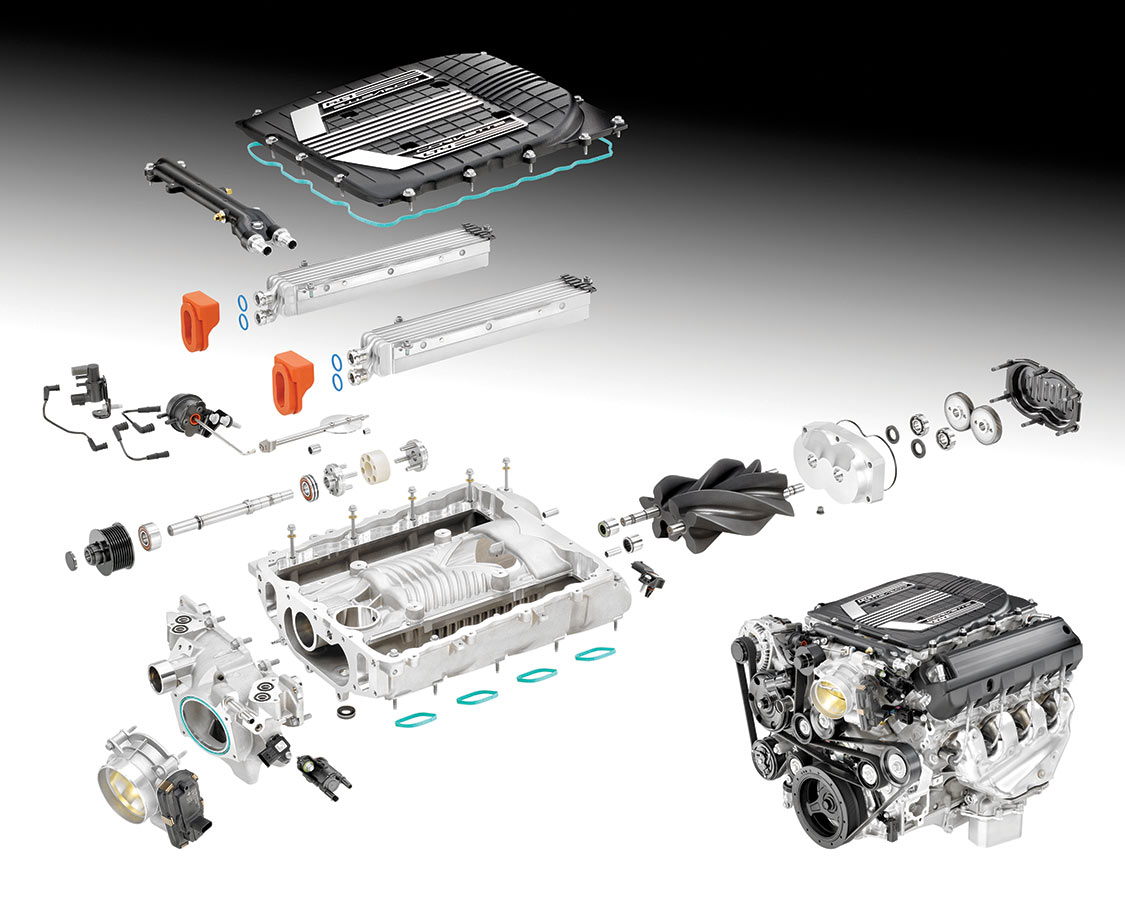

Fixed-displacement superchargers (Roots and twin-screw) move a fixed amount of air during each cycle, like those manufactured by Eaton, Whipple and Kenne Bell. They also prevent the air from flowing backward through the system. Centrifugal superchargers, such as those from Paxton, Garrett and ProCharger, on the other hand, act more like a squirrel-cage blower, flinging the air into the sides of the compressor housing and using the inertia of the moving air molecules to do the compressing. Centrifugal compressors are not considered fixed-displacement because the amount of air they compress with each revolution varies with rpm, and it’s possible for air to reverse its flow through the compressor. So we have two fundamentally different methods for supercharging an engine. Which is best is a matter of application.

The Roots supercharger is the oldest and simplest of the fixed-displacement superchargers. Francis Roots invented the design in the 1860s for use in blast furnaces. It consists of two, intermeshing, counter-rotating rotors. The rotors trap air from the inlet between the rotor cavities and the supercharger housing. As the rotors spin in opposite directions from the center out to the edge of the housing, air is moved to the outlet side of the housing. It’s important to note that no compression is taking place within the rotor system. It simply moves air from one side of the housing to the other. Compression occurs when the air, which was taken from the inlet at atmospheric pressure, is forced into a container (intake manifold) that has a finite volume.

The Roots supercharger makes peak boost at very low rpm, and on many applications you can feel the benefit in as little as 2,000 engine rpm. This makes it an ideal candidate for small engines that need an infusion of power in the lower end of the power band. Durability is also enhanced by this slow-rotating trait.

The Achilles’ heel of the Roots supercharger is thermal efficiency. A Roots compressor produces a lot of heat. Its use, however, is widespread due to the reliability and level of development. This is why OEMs use the Roots supercharger. Ford has been using Eaton Roots units for more than a decade on SVT Mustang, Lightning and GT models.

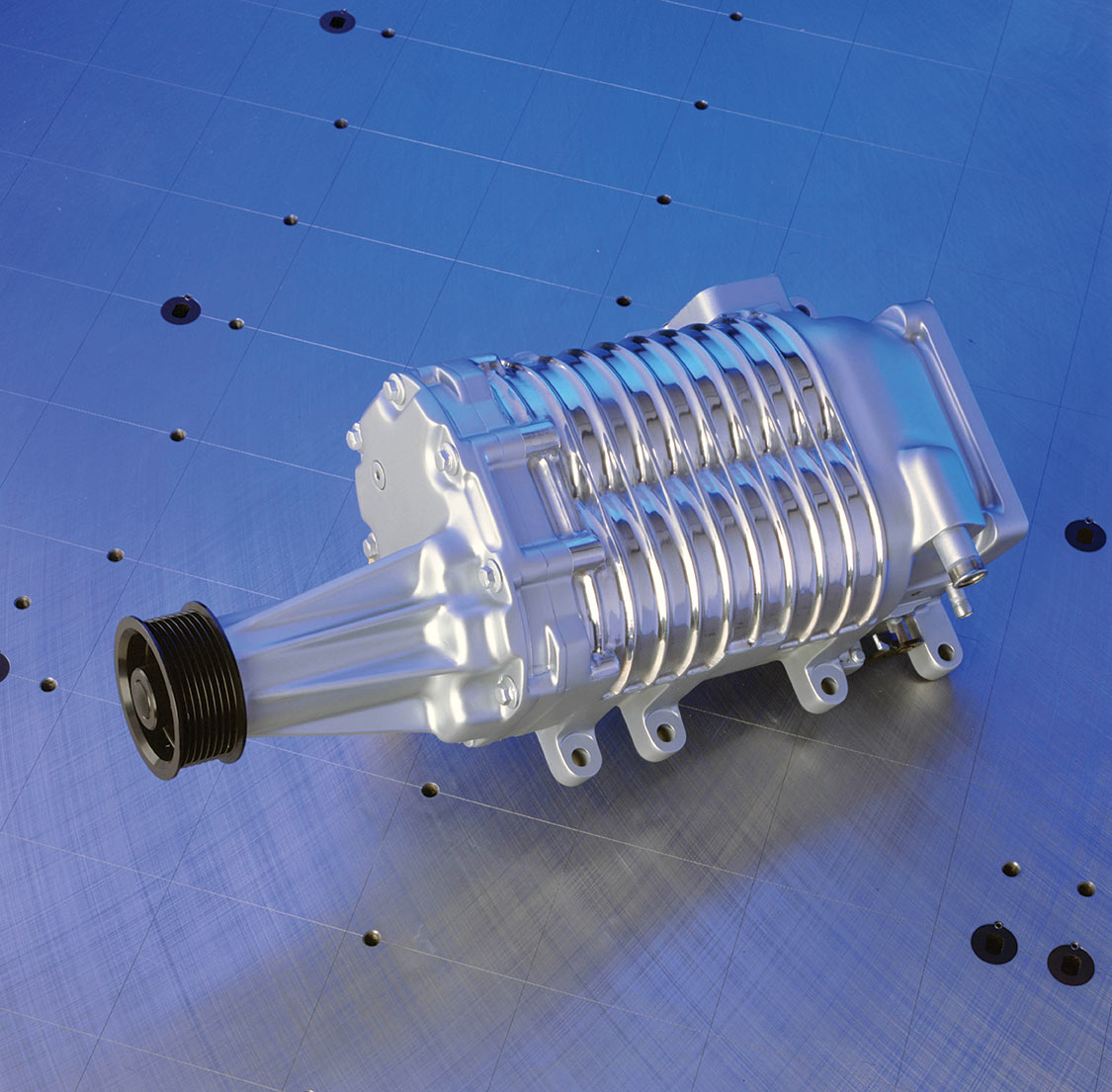

The twin-screw supercharger is a more recent iteration of the Roots design. Some performance gurus believe it is more advanced in terms of design and efficiency. It is also one of the most difficult units to manufacture. Tolerances are critical and the components have difficult shapes to form. The twin-screw design is more efficient and can produce significantly less heat than a Roots compressor; thus, it requires less power to drive it.

Our superchargers have evolved alongside our engines, and no matter which option you choose, your right foot will be sure to thank you. Choose wisely and go fast.

It works by meshing two counter-rotating screws inside a casing. Air becomes trapped between the casing and the screw lobes and is pushed forward toward the discharge port. The intermeshing screws are formed so that the volume between them diminishes as they rotate. This means that the twin-screw design compresses the air before it reaches the discharge port rather than after it like in a Roots supercharger.

The twin-screw supercharger combines efficiency with the ability to create high levels of boost. It too is a fixed-displacement design.

A centrifugal supercharger looks and acts like a squirrel-cage blower, which is related to your common household blow dryer. After drawing the air molecules into the center of the supercharger compressor, it throws them outward, into a supercharger scroll. The supercharger scroll acts as a chamber to collect the air molecules and channel them toward the supercharger discharge tube so they can be forced into the engine’s air intake. The diameter of the scroll increases as it moves further away from the center of the supercharger, which slows the flow of the air while increasing the pressure.

The centrifugal supercharger compresses the air primarily at the point when the air leaves the supercharger impeller and is forced into the supercharger scroll. At this point the air is pushed through a venturi-shaped bore. The compression peaks at the apex (narrowest point) of the venturi before passing into the scroll for discharge. This compression method allows the centrifugal supercharger to deliver a fairly high degree of thermal efficiency, however, in order to produce significant amounts of boost, the centrifugal supercharger impeller must spin at a very high rate of speed. In fact, the amount of boost produced by a centrifugal supercharger is proportional to the square of its impeller speed, which enables the centrifugal supercharger to make very high amounts of boost in the upper half of the engine’s power band. This makes the centrifugal supercharger a less desirable application that requires high torque at low engine rpm.

The term inter-cooler is technically a misnomer commonly applied in forced induction applications. The official term for cooling the air charge after the compressor before the engine is after-cooling. Inter-cooling refers to a charge-cooler located between two compressors, such as with many aircraft applications. Misuse of a word as common as “inter-cooler,” though, isn’t easily remedied, and here we are. At least you know what you’re supposed to say. A charge-cooler is a device that cools the air charge going into an engine; specifically an after-cooler cools that charge after it is supercharged but prior to reaching the intake manifold. Technically, an inter-cooler does the same thing after one compressor before another. Of course, if you classify the internal combustion engine as a compressor rather than a pump, the term inter-cooler could be used with minimal stretching.

After-coolers have a variation on the traditional concept, where the functional simplicity of using ambient air to cool the intake charge is traded for the more mechanically complex but easier to fit (typically) closed-loop water cooling. It’s a confusing tradeoff, air-to-air after-coolers have few moving parts but more high capacity tubing and can suffer excessive boost surge or frictional losses due to the lengthened charge tube and large internal volume of the air-to-air cooler’s core (between supercharger and manifold). Air-to-water after-coolers (though they can use other cooling mediums besides water) have more parts: pump, charge cooler, tubing, reservoir and radiator, but all of these items are relatively small or replace parts already in the supercharger’s system. Being pump driven, an air-to-water after-cooler can temporarily keep charge temperatures down while the vehicle is motionless, though like an air-to-air after-cooler the radiator that cools the water is most effective with air flowing through it. This brings up another question: Does the radiator being used to cool an air-to-water after-cooler merely create a redundant need for more air-based cooling (actually being air-to-water-to-air), rather than provide an alternative? Turns out water will absorb more heat with less temperature rise than air, so it is a more effective cooler, and the radiator on an air-to-water charge-cooler can be smaller, thus reducing the need for the massive airflow exposure required by an air-to-air cooler.

Supercharger efficiency and design has evolved since the days of the gigantic Roots blower. More efficient Roots configurations, high-tech and high-efficiency twin-screw designs and affordable centrifugal options all will make more power, it just happens in different ways. Modern engines are designed close to the edge of their performance envelope. Rather than being overbuilt, they are built to achieve projected performance with optimum reliability. Unfortunately for the performance enthusiast, this means that easy power enhancements are few and far between. Airflow in the heads cannot be improved by hogging out material because that material just isn’t there like in the days of old. The refinement of a factory engine, however, is much higher than it was in the old days and big leaps in power are no longer convenient. Supercharging is one of the most effective ways of making said leap. Luckily, our superchargers have evolved alongside our engines, and no matter which option you choose, your right foot will be sure to thank you. Choose wisely and go fast.