During my time at The Vault, a classic car dealership situated in Jackson, Mississippi, I embarked on my journey with a 1969 Subaru 360. This peculiar car stands out among the array of rare and expensive classics and exotics that graced the shop. As I juggled being a full-time nursing student, my boss, JD Pass, accommodated my schedule, allowing me to work around classes and clinical commitments. This unique flexibility enabled me to nurture my passion for classic cars and mechanics while pursuing my education.

My association with The Vault extended throughout my time in nursing school and continues sporadically to this day, with occasional visits to lend a hand in the shop. Amidst a treasure trove of automotive wonders, the little 1969 Subaru 360 caught my attention. It arrived at the shop with a dormant engine and ineffective brakes. This modest and unassuming car would soon become one of my favorites.

Upon completing nursing school and finding myself with disposable income, an opportunity presented itself on the Facebook Marketplace—a project car, a 1969 Subaru 360, in need of revival. After parting with $1,200 and undertaking a four-hour road trip, the little car became part of my life. At the outset, my intention was to restore the original motor or locate a suitable replacement engine. Yet, the scarcity of hard-to-find components for the original powertrain led me down a different path.

In my Uncle Earl’s workshop, which housed dormant Taylor Dunn and EZGO vehicles, my quest for an alternative solution began. These neglected electric vehicles became my experimental ground. A journey of trial and error ensued, eventually giving rise to what I now refer to as the Electric 360.

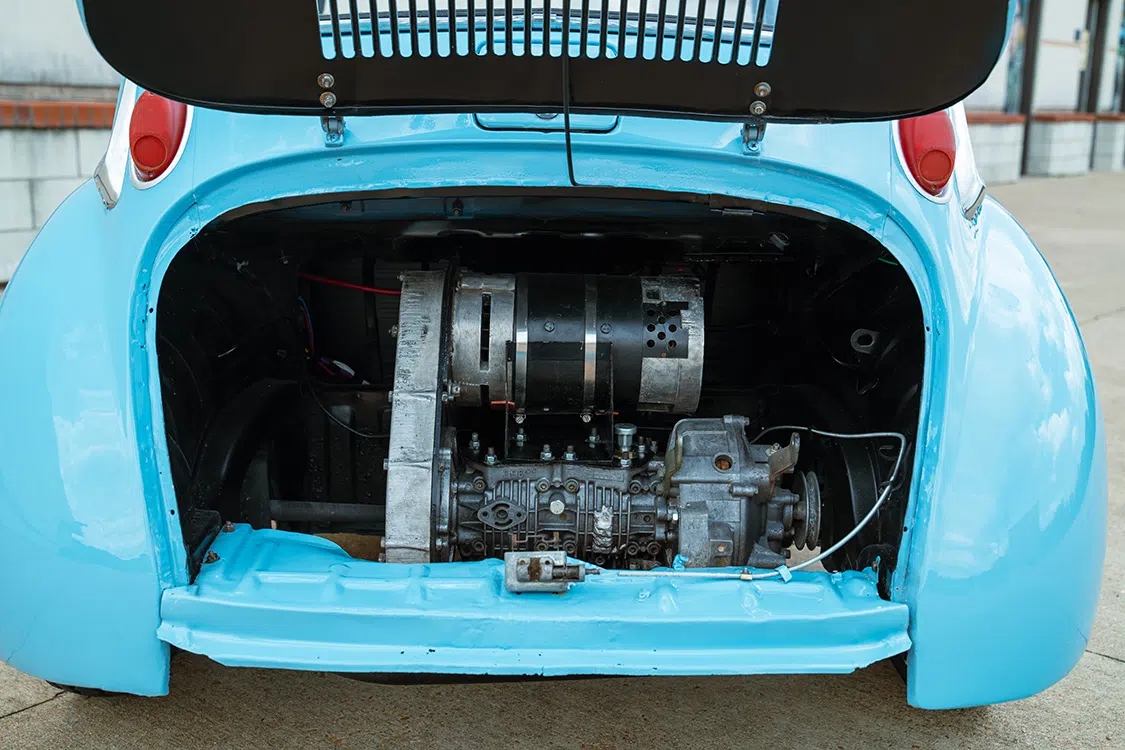

The original Subaru 360 engine presented a plethora of issues—missing parts, bent rods, and a piston with a hole, among others. Salvaging the crankshaft bearings and removing the piston rods marked the starting point. The electric motor took the place of the cylinders, connected by a chain to the crankshaft. The motor mounting plate, sourced from the Taylor Dunn, was meticulously aligned with the Subaru block. Custom-made sprockets from Motion Industries in Jackson, Mississippi, upheld a 1:1 ratio between the motor and the crankshaft. A specially crafted bracket supported the electric motor’s weight, occupying the space previously reserved for the cylinders. Retaining the rest of the Subaru drivetrain maintained the car’s original essence.

My foray into electrical engineering was aided by rewiring the entire vehicle harness, a task facilitated by my father’s background as an electrical engineer. A 36V to 12V converter powered a fuse block that controlled the lights, signals, and wipers. With the back seat removed, I constructed a frame to house the batteries and essential controls, expertly upholstering a box to conceal them. Sheetmetal repairs and extensive bodywork occupied three years, culminating in a satisfying paintjob. Reassembly proved more straightforward, and the transformed car emerged in all its glory.

Through constant research during the build, I identified potential upgrades for future street legality. While this venture was undoubtedly marked by trial and error, it has shown me the remarkable potential of electric conversions.

Over the past three years, the car has been showcased as a “work in progress” at numerous local car exhibitions, including the Southlife Car Show in Pearl, Mississippi. The vehicle has garnered a local following due to its unconventional charm and evolving transformation. This weekend, the car will make its debut as a completed project at the same show where it initially captured public attention.

Notably, the car’s presence extended to television, featuring on “Stacy David’s Gearz.” This platform spotlighted the car’s gradual evolution, an inspiration for others to embark on their garage-based projects. My Subaru 360’s potential to encourage others to pursue their automotive dreams is a rewarding outcome.

Reflecting on the build process, wiring emerged as the simplest task. Drawing from my familiarity with electrical systems and old cars, I managed the 36V motor circuit akin to a golf cart setup and the 12V circuit for lighting and wipers. Electrical complexities were mitigated by my upbringing and experience, streamlining this aspect of the conversion.

Although time was a formidable adversary, the journey was sustained by support from fellow Subaru 360 owners and invaluable assistance from my dad, Uncle Earl, and Dan Dearman.

While the present build might rely on outdated technology, the potential for modernization looms large. Visualizing the car with modern batteries, motors, and controls ignites excitement for a future upgrade. However, budget constraints temporarily temper such aspirations. The gradual evolution of EV technology will hopefully pave the way for more accessible upgrades, enabling projects like mine to reach new heights.

A fervent advocate of home-based innovation, I encourage others to embark on their own creative journeys. Whether transforming a dilapidated go-kart, rusted car, or forgotten dirt bike, the magic lies in making disparate elements harmonize. Drawing from personal experiences and the philosophy of building championed by figures like Stacy David, I champion the idea that the pursuit of a project need not be constrained by its shine or cost. Witnessing individuals derive pride from their creations, irrespective of their scale, is immensely rewarding.

Perseverance and embracing trial and error form the cornerstone of successful projects. Venturing beyond factory specifications demands a blend of courage and patience. The “Keep It Simple Stupid” approach guided my project, promoting a focus on fundamental simplicity. With each step taken, knowledge expands, and capabilities grow. Initiating with manageable undertakings paves the way for improvements and innovations over time.

Richard Rieger II

Motor & Drivetrain

Battery System & Charger

Chassis/Suspension

Wheels, Tires & Brakes

Body/Paint

Interior

Special Thanks

Richard Rieger, Earl Scallorn, Dan Dearman, Roddy Merritt, Zack Munger, Sylvia Rieger, David Rieger, Frances Rieger, Jackie Scallorn, Cody Russell

What factors contributed to the eventual resurgence of interest and appreciation for the Subaru 360 as a classic vehicle?

The resurgence in interest and appreciation for the Subaru 360 as a classic vehicle can be attributed to several key factors. Firstly, there is a growing sense of nostalgia in the automotive community, particularly for modern Japanese classics. As enthusiasts and collectors become more interested in the origins and early models of now-popular brands, vehicles like the Subaru 360 gain prominence. The 360 holds a special place as it marked the beginning of Subaru’s automotive journey, making it a cornerstone of the brand’s history. Moreover, the shift in perspective regarding the Subaru 360’s initial flaws plays a significant role. What were once seen as shortcomings are now viewed more affectionately as charming quirks of a young brand finding its footing in the automotive industry. This change in narrative transforms the car from a historical footnote to a symbol of humble beginnings, adding to its allure. Comparative rarity and increasing monetary value also contribute to the Subaru 360’s rising status. When placed alongside other microcars from its era, which now fetch high prices on the collector’s market, the Subaru 360 stands out as relatively undervalued. This perceived value for money sparks additional interest from collectors looking for unique pieces at lower prices. Additionally, the car’s portrayal in media and advertising subtly suggests a luxurious or niche appeal, potentially aligning it with elite hobbies and lifestyles, such as yachting. This association could drive its desirability among affluent collectors. In summary, a mix of historical significance, a reevaluation of its initial market reception, comparative affordability, and strategic positioning in the marketplace contribute to the Subaru 360’s resurgence as a beloved classic car.

How did the Subaru 360’s marketing and sales strategies evolve over time, and what impact did they have on its success?

The Subaru 360, initially launched, was marketed as an affordable and economical vehicle ideal for the masses. Over the years, its promotional strategies adapted to changing market demands and increasingly focused on highlighting its compact size and efficiency in urban environments. Despite these efforts, the car didn’t achieve significant success initially, largely due to its perceived underperformance and safety concerns compared to more modern vehicles of the time. It was only decades later that the Subaru 360 began to be appreciated for its historical significance and innovative design, earning it a nostalgic reverence which improved its reception and underscored its impact on the automotive industry. This belated recognition has shown how pivotal yet ahead of its time the Subaru 360 was in influencing small car design and urban mobility.

What were some of the challenges and criticisms faced by the Subaru 360, especially in relation to safety and power?

The Subaru 360 faced significant scrutiny and criticism when it was introduced to the American market, particularly concerning its safety features and engine performance. One major automotive publication reviewed the vehicle unfavorably, noting that it failed to meet the expectations for acceptable safety and performance standards on U.S. roadways. The review highlighted that the car’s maximum speed capabilities were substantially lower than its competitors: it struggled with sluggish acceleration, taking over 37 seconds to reach 50 mph, a stark contrast to similar era cars like the Volkswagen Beetle. In terms of safety, the vehicle’s structural integrity and design raised alarms. Its light weight allowed it to bypass certain federal safety regulations, raising concerns about the outcome of potential collisions with larger, heavier vehicles—a frightening prospect given the era’s vehicle sizes. Additionally, issues such as doors that could unexpectedly open when subjected to strong winds further underscored the car’s inadequate safety measures. Even the car’s braking and suspension systems, while somewhat effective, contributed problematic dynamics during normal driving conditions, such as excessive diving during braking. These issues combined to create a driving experience that could feel unstable and unsafe. The car’s maintenance and operation also posed challenges for American drivers. It required a specific type of two-stroke motor oil, which was not widely available, and demanded adherence to a stringent break-in protocol that capped speeds at 45 mph for the first 1200 miles. Moreover, the fuel efficiency was notably less than advertised, performing poorly in comparison to its stated mileage, particularly when driven under typical American driving conditions rather than the less demanding urban environments for which it was originally designed. Ultimately, the accumulation of these concerns led to recommendations for revising safety standards to eliminate loopholes that allowed such vehicles to be exempt from rigorous safety testing and regulations.

How did the Subaru 360’s design and engineering contribute to its performance and appeal?

The Subaru 360 was a significant model in automotive history, primarily because of its innovative design and engineering features that directly contributed to its performance and broad appeal. Introduced as the first mass-produced Kei car in Japan, its design was tailored to meet urban transportation needs economically. The car was exceptionally light, a critical factor in enhancing its efficiency and agility, thanks to the use of a thin steel monocoque chassis combined with a lightweight fiberglass roof. This reduced weight allowed the small, 356cc two-stroke twin engine, producing only 16 horsepower, to deliver sufficient performance for the vehicle’s urban role. Additionally, the engineering of the Subaru 360 included a sophisticated suspension system featuring four-corner independent torsion bars. This setup was not only advanced for its time but also crucial for improving the ride quality and handling of the car, making it more comfortable and safer to drive. The integration of finned brake drums attached directly to 10-inch steel wheels also pointed to an innovative approach to simplifying brake cooling and reducing unsprung weight—further boosting its performance capabilities. Thus, the Subaru 360’s design was structured not just for basic transportation but engineered to provide a remarkably balanced blend of performance, practicality, and affordability, which was instrumental in its success and popularity, helping it dominate the Kei car segment during its production years.

What were the unique features and specifications of the Subaru 360 that set it apart as a Kei car?

The Subaru 360, introduced as Subaru’s initial vehicle and a pioneer in Japan’s Kei car segment, was noted for its unique design tailored for affordability and urban utility. Originating in 1955 when restrictions limited Kei cars to engines of no more than 360 cubic centimeters, the Subaru 360 quickly became a staple in this category. Its design included several features that were quite advanced for its era and set it apart within the Kei car market. One of the notable aspects of the Subaru 360 was its lightweight construction, which was critical given its small engine size. The car utilized a thin steel monocoque chassis combined with a lightweight fiberglass roof, which significantly reduced its overall weight. This design choice not only enhanced fuel efficiency but also compensated for the car’s modest power output from its 356cc two-stroke vertical-twin engine, which produced only 16 horsepower. Furthermore, the Subaru 360 was equipped with a sophisticated suspension system, featuring independent torsion bar suspension on all four corners. This provided a smoother ride than what was typical in many other small cars of the time. Additionally, the vehicle was designed with unique finned brake drums that were mounted directly onto the 10-inch steel wheels, an arrangement that helped with both weight reduction and brake cooling. Overall, the Subaru 360 was an ingeniously engineered vehicle that combined cost-effectiveness, practical engineering, and innovative features to dominate the Kei car market from 1958 through 1971, with nearly 400,000 units sold. These characteristics ensured its success and enduring legacy within the automotive industry.

Las Vegas is known for its glitz and glamour, but hidden among the neon lights and bustling streets is a ground-breaking masterpiece turning heads in the local car scene and EV modification world. Meet “Karma,” a 2020 Tesla Model Y brought to life by the visionary builder Brett Hunsaker.

Brett has always been drawn to pushing the limits of automotive customization. So, with a background in mini-trucks and lifted rigs, he set out to infuse that unique style into an electric vehicle. And from the moment he laid eyes on a Tesla Model Y, he knew it would be the perfect canvas for his project.

As the saying goes, Rome wasn’t built in a day, and the same can be said about Brett’s remarkable build. The project began before the Tesla even arrived, albeit initially on a way less extreme level of modifications. With a few parts patiently waiting at home, Brett eagerly anticipated the moment he would be united with his ride. Little did he know at the time just how much this project would snowball.

Originally intended to be a slightly modified practical work car, it quickly became apparent that driving a close-to-stock vehicle was not in Brett’s DNA. Instead, the desire to transform the car into something unique and reflective of his style took hold. So, less than a 1,000 miles after taking delivery, the Las Vegan decided to go “all-in,” including dropping the Y to the ground with a never-seen-before air-ride setup.

Some might question why Brett chose a Model Y for his ambitious build, given the perception that SUVs inherently differ from more road-focused counterparts such as the Model S Plaid or Model 3 Performance. However, Brett is quick to dispel this notion. In his eyes, the Y is not fundamentally different from the 3; it does share a majority of parts—yet the Model Y, in general, had then been significantly less modified, especially in the air-ride department.

Karma is based on the Performance version of the Model Y, sporting a dual-motor setup; it delivers an insane 393kW/527hp and 660Nm/487 lb-ft. With a lightning-fast acceleration time of just 3.5 seconds from 0 to 60 mph, it merges the worlds of electrification, cool family wagon capabilities, and exhilarating performance.

From the moment you see Karma, you’re captivated by its brushed black steel wrap, meticulously applied by the talented hands of Mario Baratta at Madhouse Customs.

Every element of Karma’s exterior has been carefully curated to perfection, including the tinted headlights, Hansshow taillights, sleek carbon-fiber hood, and unique one-off honeycomb vinyl design on the glass roof—stunning from the inside and slightly reducing sunlight exposure—perfect for the Nevada desert climate.

But Karma’s beauty isn’t just skin-deep. Brett turned to the skilled team at Shawn Robinson’s Old Man Customs for the chassis and suspension modifications to ensure the perfect balance between style and functionality. They worked tirelessly to create a unique setup, allowing Karma to be the first Model Y to lay its body on the ground. It consists of an Air Lift Performance air-ride system paired with Air Lift shocks, MPP upper control arms, and a custom sway bar—they guarantee an unrivaled smooth ride and superb control on twisty roads just outside Sin City. Last, hidden in the frunk, we find a custom-painted FLO air tank to match the wheels. It sits on custom fabricated mounts and is coupled to two Viair 480 air compressors, wrapped in the same vinyl as the car’s exterior.

To visually slam the Y even more, Brett opted for bumper lips and extensions, all wrapped in body color with a bright copper strip adorning the rear spoiler and side camera covers. Of course, a genuinely great car deserves equally impressive wheels, and Brett didn’t disappoint. Karma proudly rolls on custom-made, two-tone, 21-inch Electric Performance rims wrapped in Michelin Pilot Sport 4 tires, which provide excellent grip. The stock Brembo performance brakes have been meticulously painted in the striking copper hue. They are highlighted by BlamfLED off-road lighting wheel rings. For good measure, Brett coupled the latter with Lighting Trendz underglow and lights.

Stepping inside Karma reveals an interior that seamlessly blends luxury and innovation. Andrew Evens, Mike Rios at Fabricated LV, and Mario at Madhouse Customs worked their magic to transform the interior into an ultra-bright cocoon. The stock front seats received additional white leather back panels for a monochromatic finish, perfectly matching the center armrest, dashboard finisher, and the plethora of painted plastic trims. Door card inserts, ceiling, and pillar trims were elegantly wrapped in white suede. Then comes the piece de resistance: the custom-made steering wheel from Unleashed Customs. It sports white perforated leather and forged carbon and perfectly complements the interior’s flashy-yet-classy ambiance.

Karma’s interior isn’t just about comfort; it’s a symphony of sound. Brett spared no expense in creating an audio system that surpassed expectations. Two 10-inch Wolfram Audio subs, housed in a custom-tuned box, deliver chest-thumping bass, accompanied by a Wolfram 3500.1 sub amp and two Arc Audio 4-channel amps. In addition, the Audio Control DSP 810, housed in a custom-lit, molded amp rack, ensures precise control over every note, even when cranked to 11.

Karma has already left an indelible mark on the modified OEM EV scene. Unforgettable experiences and numerous appearances at prestigious events have marked the journey of this unique EV build. Brett has showcased his creation at the Tesla Takeover twice in California, the Lone Star Throwdown in Texas, and multiple shows in Utah. However, it is in Las Vegas where his masterpiece has left an enduring mark, racking up an impressive collection of awards, including the coveted “Best of Show.” This build has also garnered recognition at Mint Truck style shows, securing multiple top 50 and 30 medals.

Coming from a background rooted in mini-trucks, Brett aimed to infuse that distinct style into a Tesla, creating a one-of-a-kind fusion. However, as with any ambitious project, challenges were bound to arise. Brett’s passion, dedication, and the support of his club affiliation, Relaxed Atmosphere, became his best allies in overcoming these obstacles. The audio system design and installation were particularly tricky.

Along the way, Brett discovered some invaluable tips. Planning and anticipating potential issues proved instrumental in avoiding costly and time-consuming rework. The importance of doing things right the first time, even if it meant a slightly higher initial investment, became evident as he encountered the complexities of redoing certain aspects—then again, haven’t we all over the years?

Brett emphasizes the significance of having a clear end-goal in mind. Undertaking substantial modifications as a collective effort, rather than piecemeal changes, helps streamline the process and ensures a cohesive final product. In addition, it is crucial to pay attention to how each modification affects the overall functionality of the vehicle. He has certainly perfected the art of modifying a Tesla.

Like What You See? Pre Order This Magazine Issue Now!

https://engagedmedia.store/product/ev-builders-guide-print-subscription/

Owner: Brett Hunsaker

Motor & Drivetrain

Battery System & charger

Chassis/Suspension

Wheels, Tires & Brakes

Body/Paint

Interior

Sponsors and Special Thanks:

In a scene dominated by LS engine swaps, the custom truck community has very few attention-commanding motor upgrades, though the tried-and-true 350 or something along the lines of an LT mill are readily available and reliable. Of course, builders can find other alternatives to these selections, but many have disregarded one particular path as a legitimate source for power and torque—electric!

That’s right. It is possible to build and drive a truck without a gas-guzzling engine underneath the hood. All we needed was for someone to come out and prove to us that assembling the parts and fabricating the install is feasible, even though the entire process may still sound as foreign as building a spacecraft.

But have no fear! Wait to cast any and all doubts until after you take a good look at what has been made possible in the wonderful world of custom pickup trucks.

Robert Ward is a car guy through and through, and while he can appreciate the magical scent of high-octane gasoline, he also appreciates the fact that the appeal of electric vehicles is still not far off on the distant horizon—it’s here now. Consumers are ready to climb aboard the next phase of transportation as seen in the rise of non-gas vehicles such as Tesla and other offerings from major auto manufacturers. What Robert hopes is that builders and customizers will be the next ones to hop on the trend as well.

But hopes and dreams aren’t all he is banking on. Robert has gone all in as CEO of Legacy EV, a distribution company that specializes in converting gasoline-powered cars and trucks into modern electric vehicles. And to get the show started, he has set out to create an all-electric, show-worthy Chevy C10 that operates just as smooth as it looks.

“This truck here is one of the first of its kind,” he said. “It runs on two motors and has instant torque from 0 RPM. It’s a blast to drive and proves that that electric vehicles aren’t all slow-moving and boring.”

Robert will be the first to admit that putting together the individual components for an electric motor swap can be tedious and is one of the sole reasons a lot of builders haven’t yet flocked to this route. To alleviate some of the headache that goes into a job of this nature, Legacy EV is now able to take all the guesswork out of the equation—and it’s because of the success of this C10 project that this level of assurance is possible.

“We have a full support team of expert engineers that has helped get our mission rolling,” Robert said. “We’ve gone through the process and know what is needed to mount the electric motors and how to get the gearing right. Actually, the conversion is a lot less work than you’d think, as it gets rid of about 3,000 existing components and then only installing about 36 electric ones.”

To get the non-gas-powered ball rolling, Robert took the C10 to Ridgefield, Washington, where his other venture, Old Town Autos, is located. OTA is a full fabrication and restoration shop that Robert oversees, which made for a smooth ride during the course of the electric C10 build. It was there that the majority of the work was done to the ‘ol Chevy. From the engine conversion to the air-ride suspension, interior, and body and paintwork—it was mostly all done in-house.

Now, the first thing that sends folks for a loop with the electric motor conversion is the engine bay. It currently sits empty and has been carpeted and finished to serve as a trunk. The components that power the truck now take up residence underneath the custom flush-fit fiberglass bed cover. The concept is different, we will say that about the conversion, but it works, and that’s all that matters.

This ’71 C10 is powered by two 2020 NetGain 3-phase electric motors, complete with a Legacy EV 3.1 kit to make the conversion possible. While this information might not mean much to many people out there at the moment, hopefully it will start to hold more value and actually click to more customizers out in the field. The LS1 wave took time to build into what it is today, and in some respect, Robert is hoping the same will happen with the rollout of easily accessible electric setups.

These types of systems have come a long way, and there are still plenty more variables to work out based on the many specific needs from individual builders. Robert’s truck, for instance, isn’t currently outfitted with an air conditioning system, but it can be done, so he might add it later down the line since he’ll be making the permanent move down to Arizona where Legacy’s HQ is located. All-wheel-drive is a feature that he gets asked about quite often, and that can be accomplished with the addition of a third motor.

And while electric motors generally run almost silently, enthusiasts who are used to the rumble of heavily modified combustion engines may feel like something vital is missing. Even though this C10 is able to roast tires like a beast, it is a different type of beast that needs some time for truck fans to understand what it is, and what it isn’t, and Robert fully acknowledges that.

Even though Robert and his team can boast about being one of the first in the C10 community to successfully pull off a full-electric motor conversion, other underlying reasons have fueled the project. Legacy EV’s mission statement plainly encourages honoring the past while protecting the future, which directly translates to equating an electric-powered vehicle, new or retrofitted, to a sustainable, climate friendly necessity.

To help others get there easier with their car or truck of choice, Legacy offers its expertise in selecting and delivering the correct components required for a complete conversion during one conversation, rather than having to spend months acquiring piece by piece from different sources that may or not jive well together.

“We understand that there are enthusiasts out there who have been trying to convert vehicles over to electric but have been discouraged by one thing or another, but we’re here to turn that around,” Robert said.

From parts, support and all-important peace of mind, Robert, along with the rest of the Legacy and Old Town Autos teams, are looking to play a crucial role in developing the new wave of custom EV builders. An alternative solution to fuel that works does exist, and while the demand may not be overwhelming at this very moment, all trends in the industry point to things picking up sooner rather than later.

Owner

Robert Ward (Legacy EV)

Engine

Chassis

Wheels, Tires & Brakes

Exterior

Interior