What is, hands down, your ultimate dream truck? A new Ford Raptor or Bronco? An all-original Ford Highboy? Or maybe even a souped-up late ’80s or early ’90s mini-truck?

We’ve seen a lot of cool trucks in our days, and in impressive forms at that. But when it comes to some of the most-notable and memorable in our minds, it’s the trucks you don’t see many of on the road that stand out, especially when taken to levels that some may scratch their heads at.

One such truck is this beauty—a 1966 Ford F-250 crew cab named “Blue” by builder and owner Kyle Delfel. A fabricator by trade, Kyle certainly knew how to take this truck from stock to stunning, giving it a new life as a one-of-a-kind performance machine while allowing the truck’s old-school charm to continue to shine through!

Owner of DelFAB in Snohomish, Washington, Kyle has built some incredibly impressive trucks in his career—just check out the cover feature from the Summer 2024 issue of F-Series Builder’s Guide. Kyle’s retro-inspired 2023 F-350 single cab conversion speaks for itself when it comes to showcasing Kyle’s talents. But if you’re more of an all-around old-school Ford fan, which Kyle clearly is, this ’66 is truly one for the books.

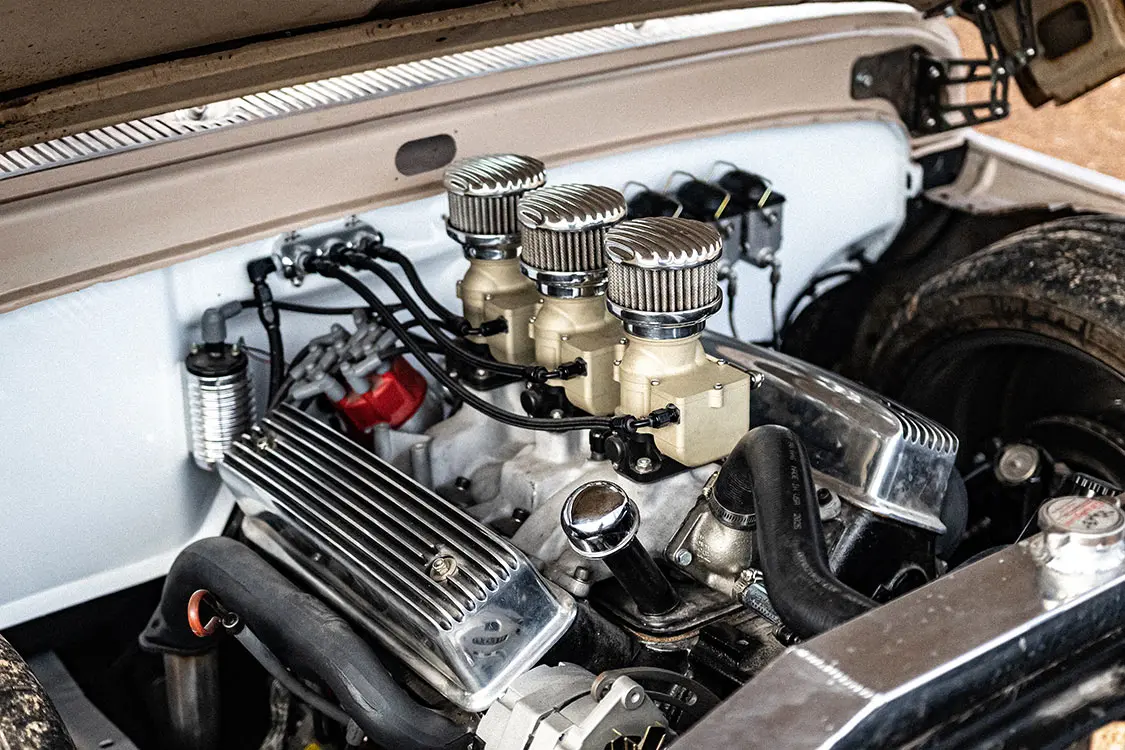

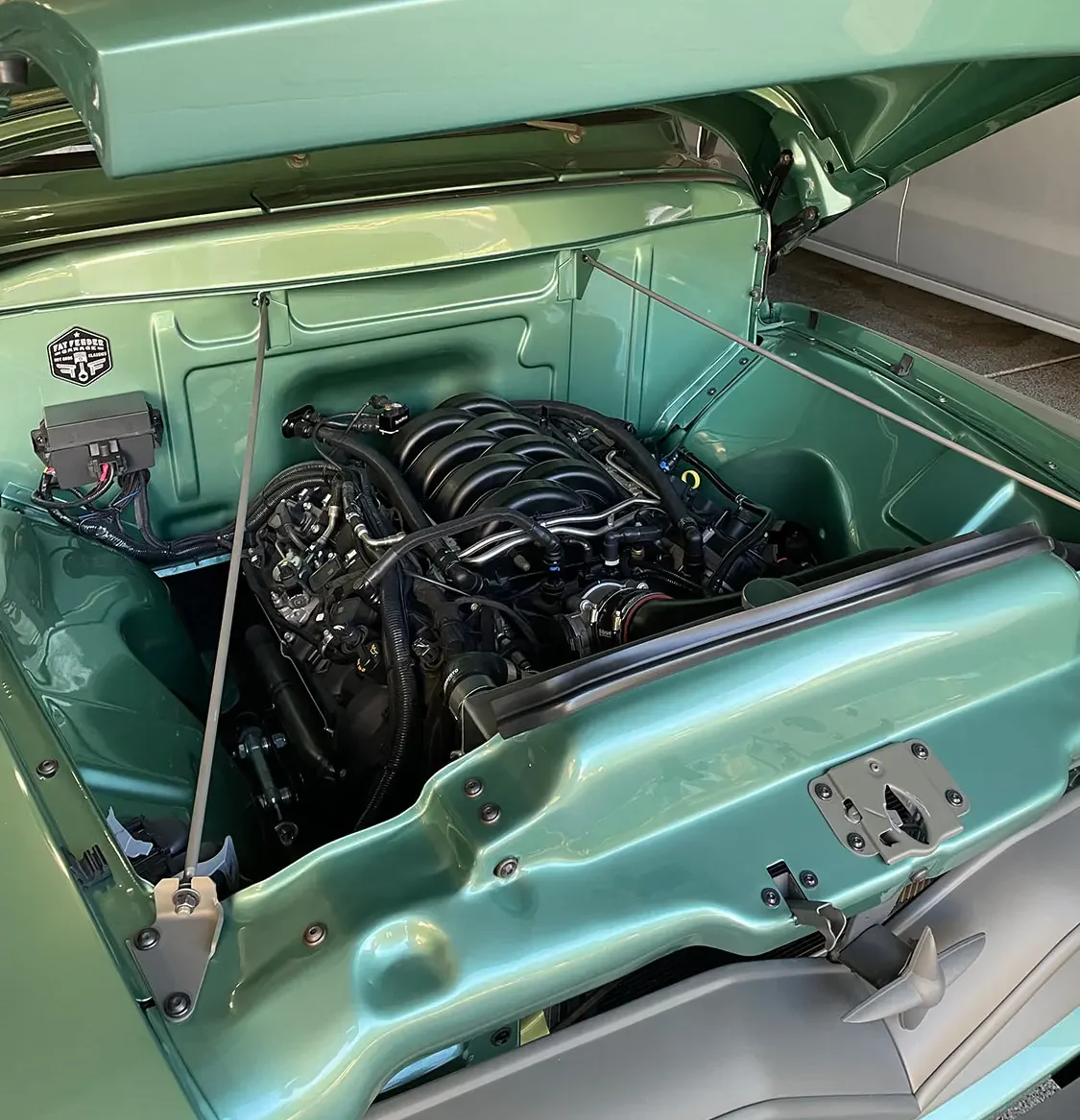

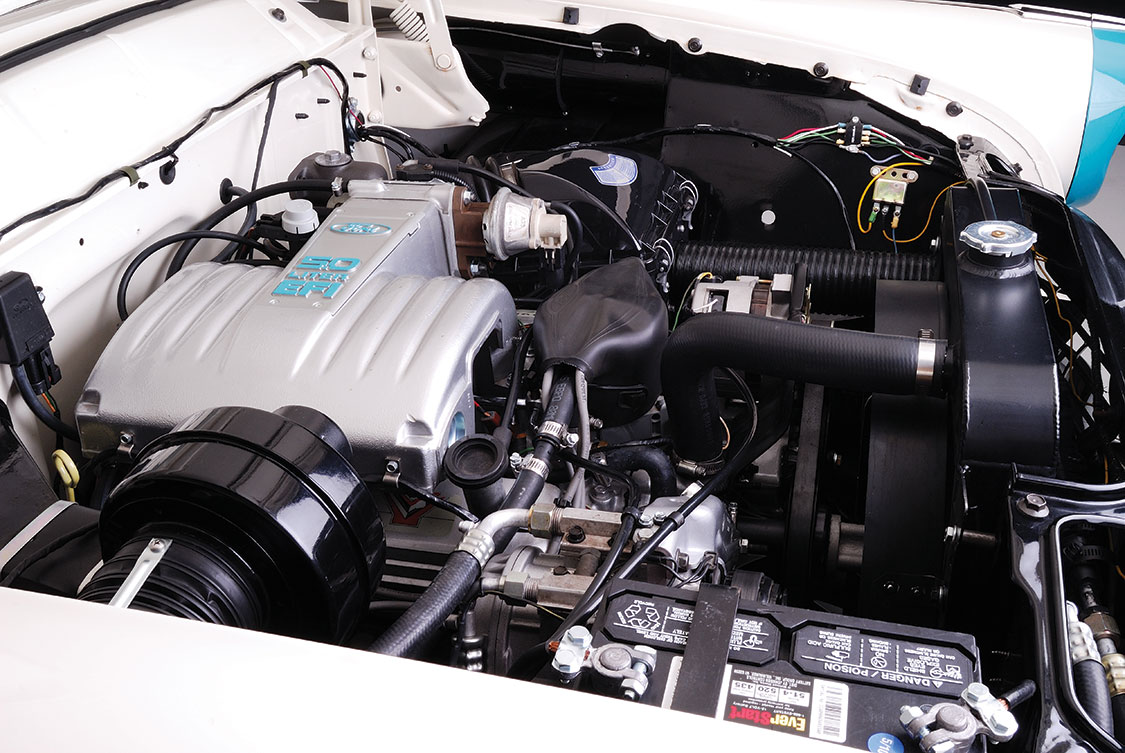

“That beautiful beast you see under the hood is a 2022 Ford Performance 7.3L Godzilla V-8—one of the baddest naturally aspirated performance engines Ford has come out with to date.”

When we asked Kyle why he wanted to build this particular truck, we got a pretty standard answer— “Because it’s my dream truck.” But it was what he continued on with that really drove it home: “This truck has been in my family for five years and my kids and I have made some great memories in it.”

Started in 2021, the truck’s build was set to be a challenge from the start. While the crew cab had the look Kyle was after, it didn’t exactly have everything his dream truck should feature. So he did what he knows best—to fabricate, retro-fit, and outright transform the four-door into the epitome of a classic Ford enthusiast’s ultimate old-school-meets-new-school truck package!

One of the most appealing parts of this build for Kyle was the truck’s original four-door crew cab body. Painted Arcadia Blue from the factory and never touched since, even with touch-up paint, the condition of this F-250’s metal skin is incredible, and it was of the utmost importance to maintain throughout the build process. After all, it was the love of classic Ford trucks that inspired this build in the first place.

Not wanting to add anything crazy or take away anything from that old-school charm, Kyle opted to add just a couple things to make his truck stand out. One of those is a fully custom, serial-numbered canopy and TrailCap topper Kyle had specifically made for the truck. The only other body modifications are the added KC HiLiTES 7-inch Gravity LED headlights, a Pro6 light bar mounted with custom billet mounts atop the front bumper, and two Flex ERA 4 lights out back.

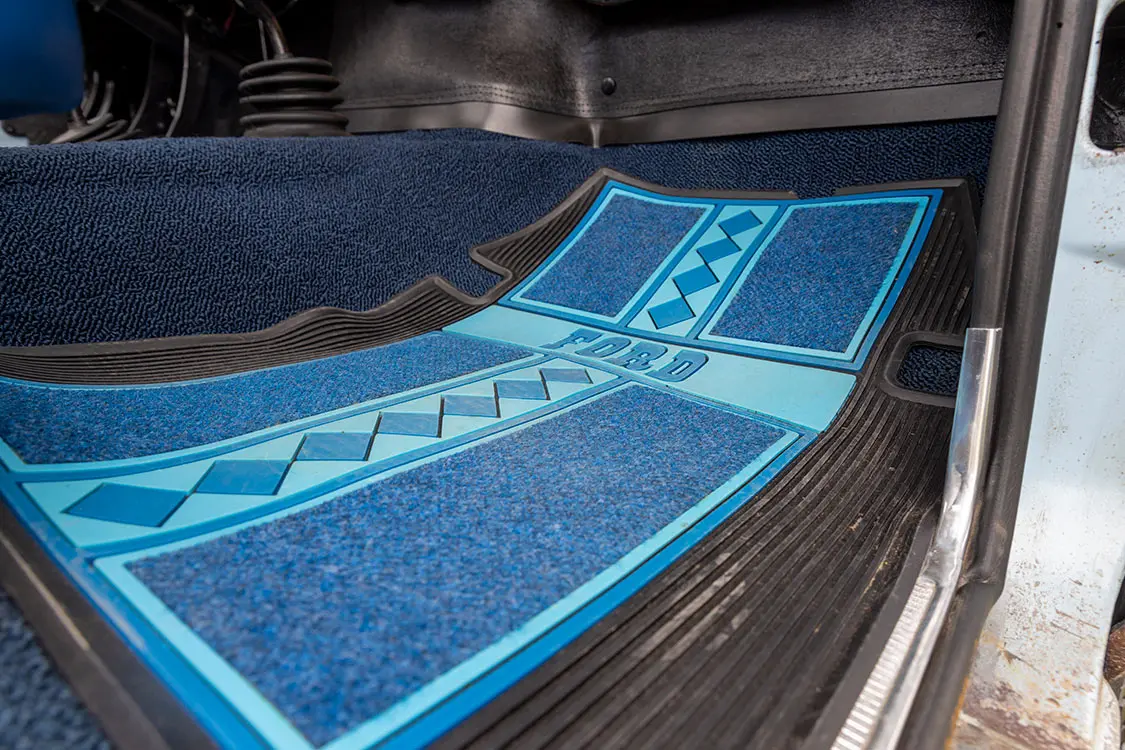

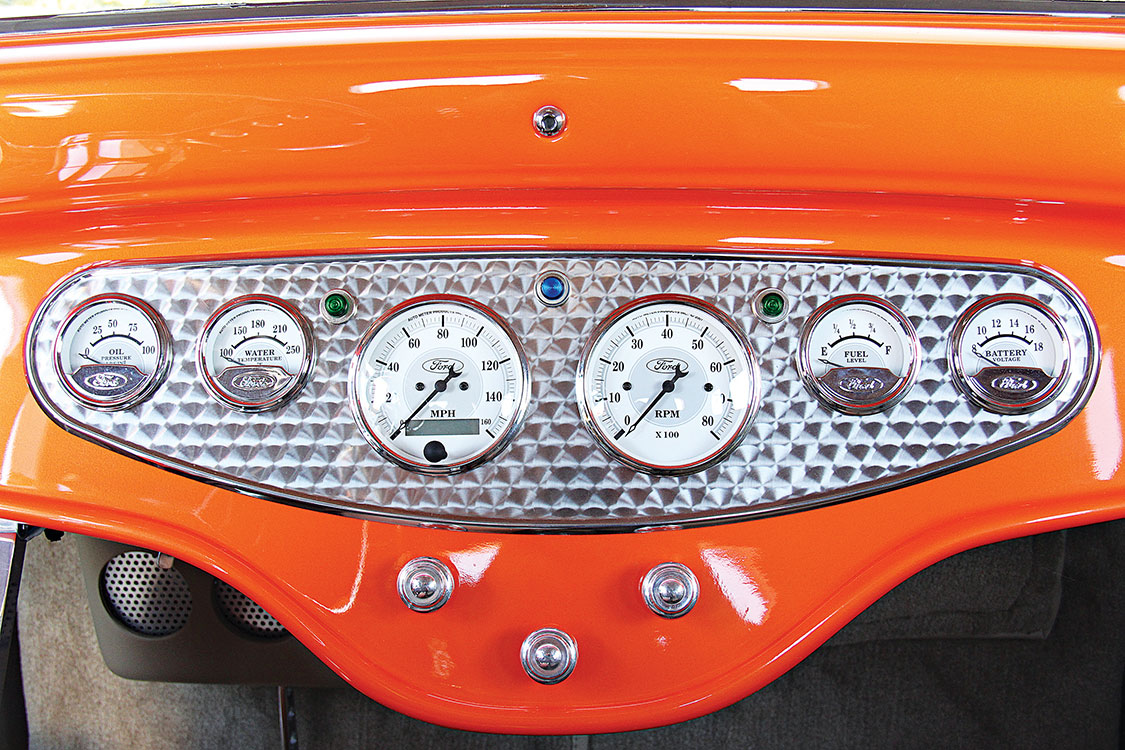

Inside, the truck’s interior is likewise very classic feeling, from the factory seats reupholstered to their current blue by the original owner three months after truck was bought new, to the stock gauges in the dash, albeit modified for the modern powerhouse lurking under the hood. The interior also features drive-by-wire throttle and reverse controls for a more modernized driving experience, mounted under the dash and controlled by the truck’s original gas pedal, as well as a gun rack mounted over the rear window.

Everything looks and feels (and even smells) like a vintage Ford. But like we said before, there’s something not so vintage lurking under the F-250’s factory skins.

Now, you didn’t think we’d be featuring a virtually stock 1966 Ford F-250, did you? While cool in their own right, we strive to take things a level or two beyond factory F-Series trucks around here. And what Kyle stuffed under this classic Ford’s hood certainly took it up a notch.

That beautiful beast you see under the hood is a 2022 Ford Performance 7.3L Godzilla V-8—one of the baddest naturally aspirated performance engines Ford has come out with to date. This bad boy bone stock is good for over 430 horsepower and 475 lb-ft of torque. That’s over double what any factory engine configuration the 1966 Ford F-250 could have come with would have produced.

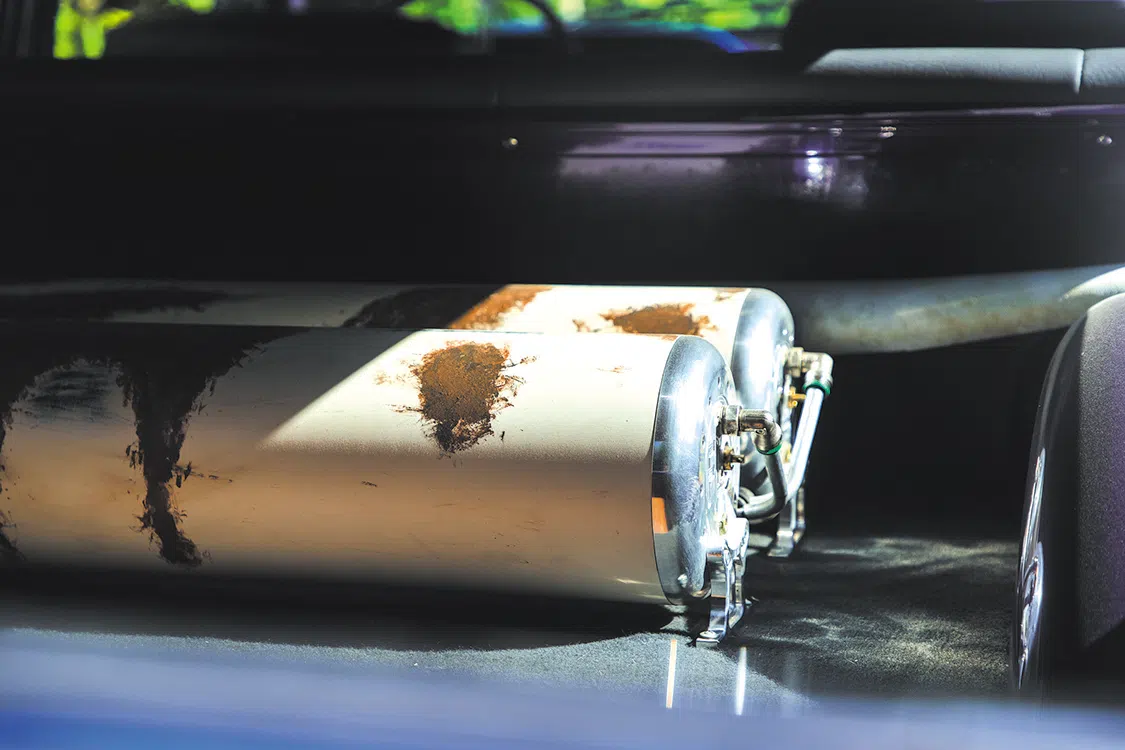

To that, Kyle added Fat Fender Garage headers, as well as a fully custom 4-inch exhaust that he fabricated using a Super Duty muffler and resonator. The engine is expertly wired with a Ford Control Pack, and is fed by a stock fuel tank, modified to allow for an Aeromotive Stealth intake pump, plumbed with DelFAB custom stainless fuel lines.

Backing the Godzilla is a 2022 Ford 10R140 10-speed automatic transmission with gears selected via a factory ’66 Ford automatic shifter inside the cab, which was modified specifically for the upgraded setup. Behind the 10-speed sits a divorced 205 transfer case from a 1975 Ford F-250 4×4 featuring a 1.96:1 low-range ratio, tied to the transmission by a custom intermediate driveline from Drivelines NW. Up front, the truck features a rebuilt Snow Fighter high-pinion Dana 60 front axle out of a 1979 F-350, while out back is a rebuilt Dana 60 rear axle out of a 1975 F-250. Both are spun by custom drivelines from Drivelines NW.

Up front, the Dana 60 is fitted with 4.11 gears, while out back, 4.10 gears help the truck with even quicker acceleration. The rearend also features a limited-slip differential. All drivetrain assemblies on the truck were fully rebuilt, powdercoated, and outfitted with all-new hardware.

Planting the truck to the ground are 16mm-backspaced SuperLug tires with 9.00/16-inch sidewalls, wrapped around 16-inch non-split 1966 F-250 factory wheels. Brakes on the truck are stock to the axles, but are tied into the build with a 1979 Ford F-350 master cylinder and DelFAB custom stainless steel brake lines.

You’ve got to have a hearty foundation when you’re building a classic truck with a Godzilla powerplant, so Kyle retrofitted the truck’s frame with 1975 Ford F-250 Highboy 4×4 components, as well as outfitted the Ford with Deaver front and rear leaf springs, Fox 2.0 remote reservoir shocks both front and rear, and a Fox 2.0 stabilizer.

Kyle also borrowed the Highboy’s steering box for the project and had it rebuilt by Red-Head Steering Gears. The truck also makes use of a Stearman Cycle electronic power steering system, which was modified to clear the engine.

The truck’s suspension is topped off with a custom DelFAB 6-inch lift.

Just like with the driveline assemblies, all of the chassis and suspension components were powdercoated—“and every leaf spring, every bracket, every bolt replaced,” Kyle adds.

Kyle’s vintage crew cab is one gorgeous build that perfectly meshes old-school cool with modern performance. While Kyle told us if he had to do it over again he would keep the Coyote V-8 he originally had under the hood instead of Godzilla-swapping it, we wouldn’t change a thing about this build. Not that Kyle seems to want to trade it in any time soon, specifically telling us this truck is not for sale—ever!

Suspension & Chassis

Wheels & Tires

Engine & Drivetrain

Body & Paint

Interior & Stereo

When Caleb Rennekamp isn’t running around with his mini-Highland cows on his Florida ranch, he can be found running Shifted Industries, a brand most of us know as one of the meccas for all things trucks. For those unaware, Shifted Industries has been a large supplier of parts since June of 2014 providing high-end parts such as forged wheels, full lift kits of any size, interior and exterior lighting, performance parts, as well as almost every type of exterior piece you could ever want. How did it all begin? Well, look no further than his 2009 Harley Davidson Ford F250. What started as an obsession of vehicles as a young child grew far beyond that—a hobby of toying with vehicles, both his and his friends, which snowballed into him building his own F250 for SEMA in 2011.

Realizing the potential to make something out of the SEMA opportunity, Caleb threw on the first ever set of forged 24×14- inch wheels on a truck (American Force Shifts), partnered with a handful of awesome companies, and made a huge impact on the scene. Caleb instantly knew he could fill a gap in the form of bridging the many truck parts companies directly to the consumer via one concise site—Shifted Industries. Fast forward to 2024, and this F250 is still just as beautiful as it was in 2011, albeit with quite an extensive list of changes and upgrades since then.

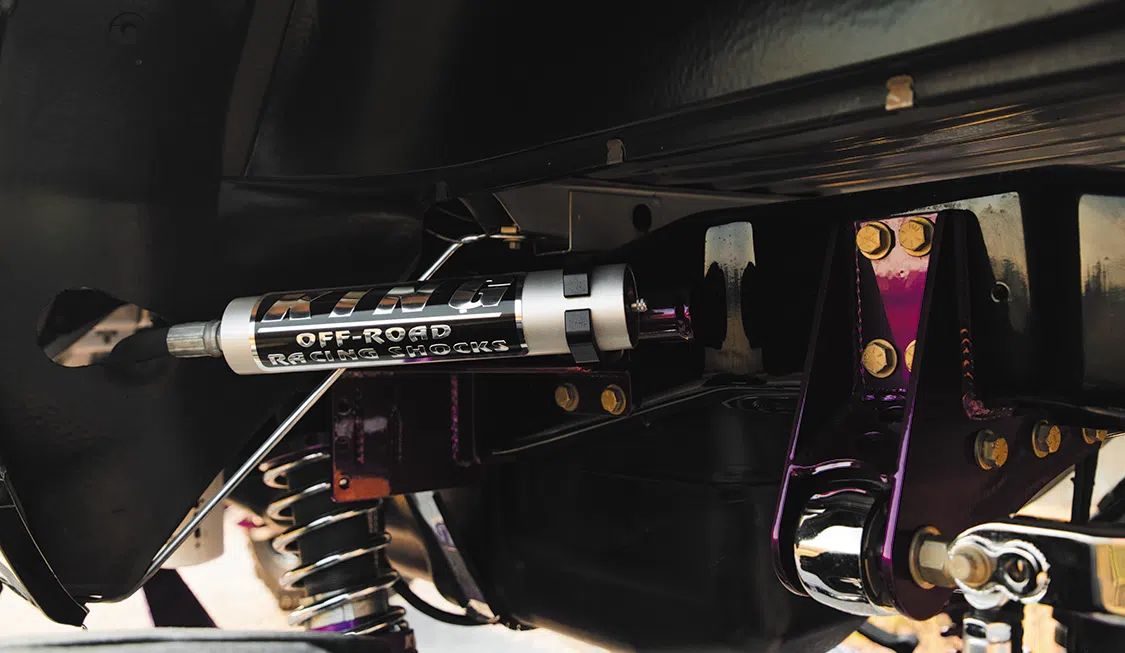

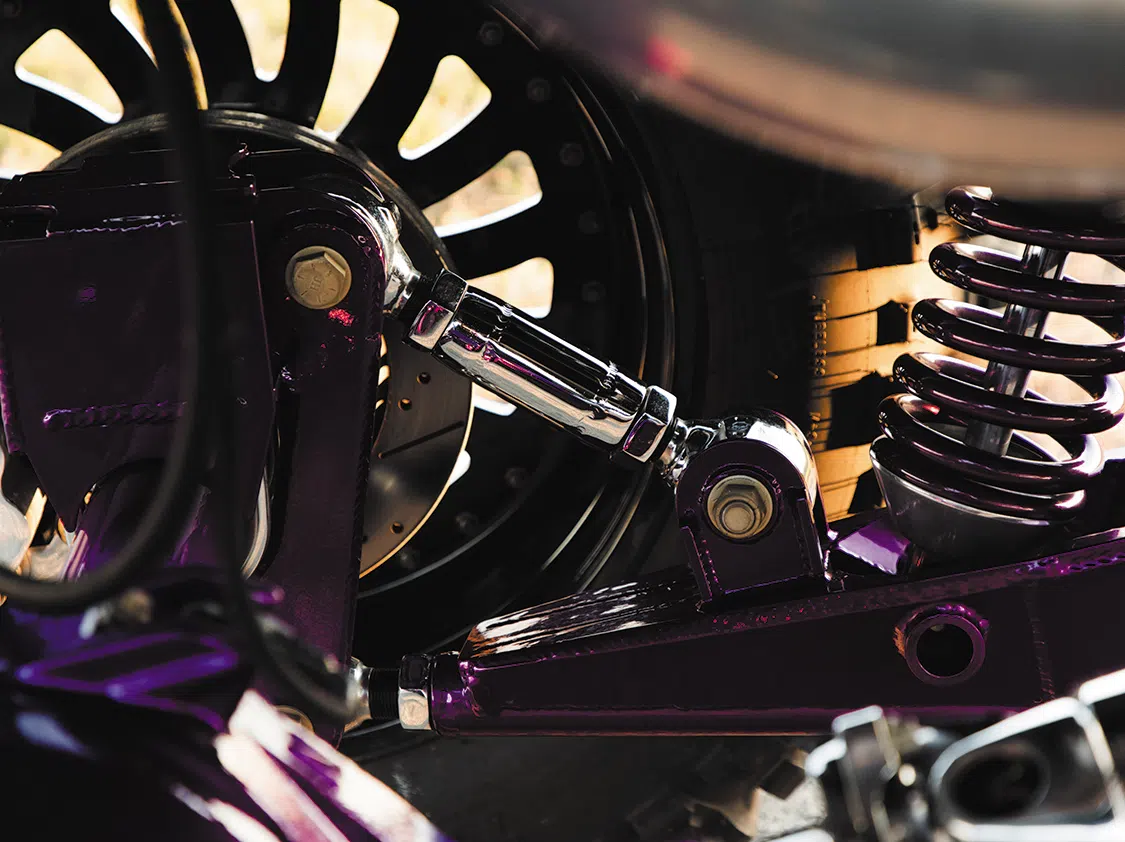

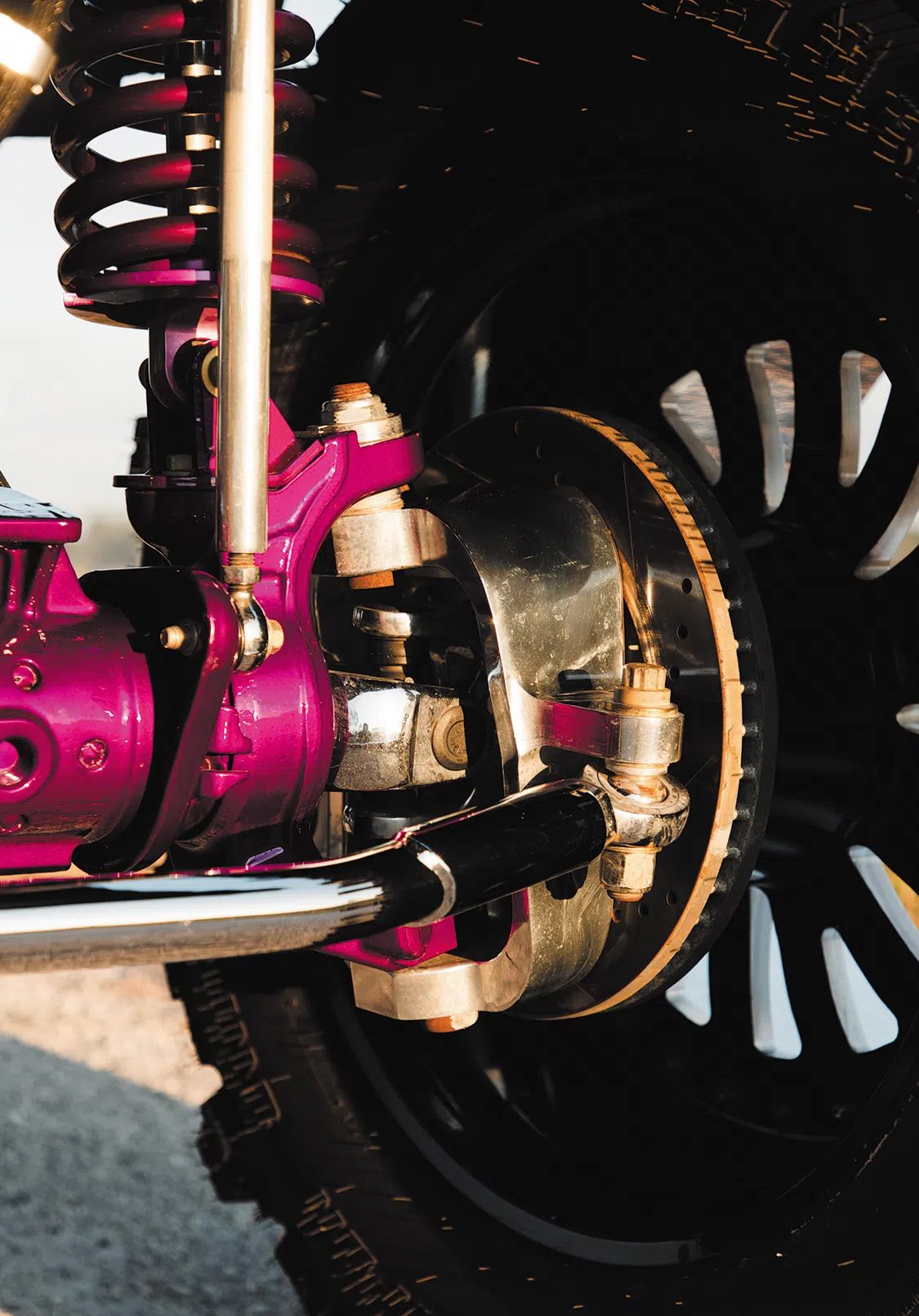

For starters, the truck was taken down to the frame to smooth and paint the entire chassis which was done by Caleb in his shop. He then threw it on a 16-inch long travel Precision Metal Fab lift complete with King 3.0 coilovers, which are all of course powder coated, or chrome plated. A closer inspection will reveal that even all of the hardware has been chrome plated as well, including the smoothed FK rodends and 3.0 Ballistic joints and bushings. It really is quite the spectacle, hanging out under the truck on the photoshoot was like being a kid in a toy store. No matter where you looked there was something to hold your attention. The steering was upgraded with a Precision Steering Components Ram Assist stabilizer, which, you guessed it, has been chrome plated! Now of course the wheels were given the over-the-top treatment.; The very rare two-piece 24×18 American Force MP Series Octane wrapped in 44 inch Interco Boggers have black faces, polished windows, polished lips and purple hardware.

The 6.4 engine has been entirely built up by Performance Machine & MFG. They coated and de-lipped the pistons, put in ARP bolts and head bolts, a polished crank, and bored the motor by .020 inches. There’s a stage 2 Comp Cams camshaft with 188-inch lift and 206-inch duration. The factory heads have been ported and polished, the factory intake has been ported, and it has an Industrial Injection fuel injection system paired with a FASS fuel system. A gnarly compound turbo kit featuring a 59mm and a 76mm turbo fills up the engine bay, getting properly cooled by a Mishimoto radiator and a Spearco Intercooler. A Zex Pro Street nitrous kit finds itself under the center console for whenever you want a powerful shot of juice to drag anybody. Caleb had ATF Speed throw in an ATF Speed 5r110 transmission with a Suncoast Performance torque converter to properly put the power down, and those too have been given the full powder coat treatment to match everything else.! A billet input shaft, billet output shaft, and a billet overdrive planetary plus a polished front and rear drive shaft with solid billet flanges make literally every single visible component ridiculously shiny and clean. Stopping this monster is a set of brakes from SSBC USA with EBC rotors, and those too match the suspension!

The interior has also been entirely swapped with Tuscany leather seat covers made by Katzkin. A full Rockford Fosgate blow-through sound system featuring four 12-inch Rockford subs was thrown under the rear seat, all done by Travis Horton at A1 Car Stereo. There is also an incredible custom center console that houses the nitrous bottle, with an iPad for a screen and even a PS3 tucked underneath in the rear of the console!

Caleb says that while he absolutely adores the truck, he does have a slight regret for letting it get to this point. The intention for the truck was supposed to be just an 8–10-inch lift on 37-inch tires. Clearly, it went far above that bar, but the reception from people, even to this day, reminds Caleb why he loves it. They tell him that his truck is what got them into trucks to begin with, which is only further proof that Shifted Industries was the right dream to chase all those years ago.

It’s always amazing to see what true automotive artisans can pull off with old, rusted-out vehicles. Top-tier shops with the right combination of craftspeople and a collective hopeful outlook can make miracles happen. Classic Car Studio of Brentwood, Missouri, has proven it is indeed one of nation’s elite automotive restoration businesses, as documented in the TV series “Speed is the New Black,” which showcases some of CCS’s most celebrated accomplishments. Shop owner Noah Alexander and his crew have shown the world the high-caliber results they routinely pull off with nearly all types of vehicles, from vintage muscle cars to classic trucks and everything else in between.

The last episode of “Speed” aired back in 2018, but that didn’t stop the CCS crew from doing what they do best even after the cameras stopped rolling. In fact, the show created new opportunities for the shop to take on with more clients with larger ideas to help push the boundaries of creativity. While the base level result of any project that carries a CCS stamp of approval is of an elevated pedigree, it’s still possible for a blinding burst of excellence to outshine all expectations.

The most recent vehicle to create such brilliance happens to be a crew cab 1956 Ford F-600 that exudes a sinister sense of sophistication that will no doubt sear a lasting spot in the memory of most custom truck fanatics.

“Classic Car Studio of Brentwood, Missouri, has proven it is indeed one of nation’s elite automotive restoration businesses…”

The F-600 was beat when came to CCS due to it living the hard life of a family farm truck. Its dull red paint was fitting of a near-70-year-old industrial workhorse, and the amount of rust and crud that fell from it with every movement was concerning to say the least. There wasn’t a whole lot that would be salvaged from the ’56 Ford carcass except for the cab, so its come-as-you-are condition wasn’t a deal-breaker at the end of the day. The imagined vision of what the truck could look like presented a level of potential that far surpassed the restrictive nature of its weathered shell.

The factory chassis had served the F-600 well throughout its years of dedicated labor, but so much more was in store for it with its scheduled reincarnation. Once the OE frame was removed from under the cab, it was loaded on the first truck headed to the scrapyard. CCS resident fabrication gurus Scott France and Mark Siddle designed an all-new, one-off foundation for the Ford that features a front Porterbuilt dropmember sub-frame complete with tubular control arms and Detroit Speed rack-and-pinion steering. The back of the chassis was outfitted with a Porterbuilt 4-link kit as well as a narrowed 14-bolt rearend. Air ride was always in the cards for this project, and to allow the ’56 to boast a fully adjustable ride height, Goodyear ‘bags along with Accuair air-management components and Viair compressors were properly plumbed and wired.

Another inclusion that was planned well before the project begun was maintaining the F-600’s rear dually wheel setup. Even though the truck’s frame was designed to lay flat on the ground, it still is very much a big truck that can still roll on big wheels. Nothing short of 22.5-inch Alcoa semi wheels (which were all turned down to 22-inch diameters) would do. Late-model 1-ton GM power brakes were also incorporated to into the chassis to bring the hefty F-600 to a controlled halt. Things were looking up at this point, but there was another factor baked into the new frame that would soon reveal what else Scott and Mark had cooking.

“CCS resident fabrication gurus Scott France and Mark Siddle designed an all-new, one-off foundation for the Ford…”

The chassis was outfitted with a body mount configuration much different than the factory F-600’s frame to accommodate a one-off crew cab that features a rear set of “suicide” doors and reinforced fabrication throughout, a handmade roof, floor, custom valance and grille section, and everything else imaginable. Not only was the quad cab specially designed for the project, but so was the bed that features unique rounded corner panels matched the cab for a façade that naturally flows from front to back. A curved opening was then cut into the bed floor to accept a slab of exotic zebrawood, which gives the truck that extra touch of class.

“A curved opening was then cut into the bed floor to accept a slab of exotic zebrawood, which gives the truck that extra touch of class.”

Once the exterior metal work was complete, CCS’s team of expert bodyworkers joined the project to adequately massage the truck’s exterior surface before the paint process could commence. While that was going on, Scott and Mark began test fitting the Cummins 24-valve 6.7L engine delivered from D&J Precision Machine. Now, the size of the diesel mill required some consideration on where to place it inside the bay. Once the right position for the engine was decided on, the guys began configuring a new firewall and series of paneling that would soon envelop all sides of it.

The owner of the F-600 selected Area 51 Blue—a factory Ford paint color to cover the exterior of the of the truck. Even though the hue is a more contemporary selection used on late-model Bronco and pickups, it looks right at home on the ’56. Soon after the paint dried and the multiple layers of clearcoat were buffed to a mirror-like shine, fabrication and interior work immediately began within the confines of the newly expanded cab. Scott and Mark fabricated a custom center console and metal dash with an opening designed specifically to house a Dakota Digital gauge cluster. A custom bronze paint was then used to cover the dash, upper halves of the inner doors and pillars, as well as the console, steering wheel, and so many other smaller accessories.

Next, CCS’ in-house upholstery specialist Laura Semaan began heavily upgrading the Snowden seat bases. The foam was meticulously shaped to give the exact form she was after. Exquisite seat covers were then sewn together with chocolate colored Relicate leather skins that proved to be the perfect finishing touch for the front buckets and rear bench seat. To further promote the interior’s cohesiveness, Laura also fabricated matching door panels complete with zebra wood inserts, which can now be found all throughout the F-600’s exterior and interior landscapes. A network of Kicker audio components was wired and stashed behind the rear seating area, and a one-off sub enclosure lurks below. Old Air Products climate control was also added to the list of in-cab amenities to ensure a pleasurable drive during all weather conditions.

The summation of the F-600’s fabrication phases have been wildly underestimated here. An estimated 8,500 hours has been invested into the entirety of this project, which has spanned the course of just over three years. Every aspect of this truck is simply mind-blowing, and it’s apparent that there was never even a murmur of the word “shortcut” anywhere in its vicinity. There is a reason why the moniker given to this vintage Ford pickup has stuck, and there is no argument of it reigning as the current kingpin of the custom truck scene.

Owner

Engine & Drivetrain

Dodge ECU

Chassis & Suspension

Wheels, Tires & Brakes

Body & Paint

Interior & Stereo

Photos by Solomon Lunger

Crawl over rocks, speed through the desert sand, and take a beating over long stretches of often off-camber, rolling divots in the form of “whoops” all while trying to follow a specified route between Point A and Point B and do so as quickly as possible—that’s what racing in Mexico on the Baja Peninsula is like. If this sounds like a good time, you’re in good company, including that of off-road aficionado Jerry Souza of Gilroy, California.

There are a handful of very well-known races that take place on the Baja Peninsula every year, every one of them having their challenges, as well as amazing aspects. For Jerry, it was all about racing the NORRA 500 and he needed the perfect rig to do so. Enter this gorgeous 1976 Ford F-250 crew cab.

OK, so we may be getting ahead of ourselves a bit—let’s rewind. Jerry’s original purpose for building this truck was to have a rig he could take off-road, whether that was weekend wheeling or attending various off-road events. But he didn’t want just any old truck. He had his heart set on a classic, built to be as capable off-road as it was on pavement. Three and a half years of work and we’re looking at that very truck.

“For Jerry, it was all about racing the NORRA 500 and he needed the perfect rig to do so.”

Building a capable off-road truck is more than just slapping on a lift and some sticky tires. Rather, every aspect of the build has to be weighed against how you want that truck to perform and on what kind of terrain, how you’re going to keep from breaking just about every mechanical component possible, and how you’re getting home at the end of the day safe and sound. Therefore, many people start with the chassis.

To achieve his ultimate build, Jerry opted to stick with the Ford’s original frame to start things off, but he had it cut and notched by M-Fab. A cage was then integrated into frame that goes throughout the truck for added rigidity and safety.

“… every aspect of the build has to be weighed against how you want that truck to perform and on what kind of terrain, how you’re going to keep from breaking just about every mechanical component possible, and how you’re getting home at the end of the day safe and sound.”

From there, M-Fab added Eibach springs and King shocks dialed in by KDM on all four corners to give the truck longer wheel travel while increasing the ride quality substantially from what the truck boasted stock. A Red-Head F150 ported steering box and PSC hydraulic-assist steering stabilizer were also added, boosting the handling of the truck tenfold.

Under the truck you’ll find 17×8.5-inch Method MR704 wheels wrapped in differing rubber depending on the situation, with Jerry going back and forth between 40×13.5×17-inch Toyo MT tires, and the pictured BFGoodrich Mud-Terrain T/A tires.

Looking for some decent power to push this beast forth, Jerry went against the purist grain and outfitted the truck with a 2008 GM 6.2L V-8 he salvaged from a junkyard. To that, he added custom 1 7/8-inch headers and a custom 3-inch exhaust system with side dumps, as well as a Speartech harness before handing it over to ZMOD Performance for the perfect tune. Other than that, the engine is as it came from the factory, fed by a Fuel Safe fuel cell behind the truck’s cab.

Tied to the 6.2L V-8 is a CBR-cooled 2012 GM 6L90 transmission touting heavy-duty NP205 transfer case with a Offroad Design Magnum underdrive, adding up to a 5.33:1 final low-range drive ratio. This low gear is the perfect “crawl gear” for Jerry’s off-road adventures, while hardy Tom Wood’s front and rear driveshafts give the truck’s drivetrain extra fortification for the same task.

As far as the axles go, Jerry also went tough here, with a 2014 Ford F-350 Super Duty Dana 60 in the front, and a 2014 Ford F-350 shaved Sterling 10.5 in the rear. Both axles are equipped with 4.88 gears and electronic lockers for targeted dual wheel rotation at the touch of a button.

Ford Super Duty brakes both front and rear give the truck some powerful stopping power, fed by a GM Hydroboost master cylinder and upgraded with a proportioning valve and line lock.

“Tied to the 6.2L V-8 is a CBR-cooled 2012 GM 6L90 transmission touting heavy-duty NP205 transfer case with a Offroad Design Magnum underdrive, adding up to a 5.33:1 final low-range drive ratio.”

While Jerry built his truck to be highly capable off-road, he also wanted it to stand out in a crowd. Thus, using his automotive painting skills to his advantage, Jerry gave his truck a one-of-a-kind look, featuring Ford Vineyard Yellow paint with custom black and white “cartoon-like” accents.

A 1975-1977 Ford F-Series grille, custom tube bumpers and rock sliders, and a custom integrated spare tire rack over the truck’s bobbed bed add to the build’s rugged appearance. Cutout wheel wells make for better tire clearance as well as less rubbing and denting of body panels from off-road shenanigans. Speaking of off-road shenanigans, Jerry’s upgraded lighting system, which includes 7-inch KC HiLiTES Gravity LED Pro headlights, a KC light bar above the truck’s cab, and 30 rock lights throughout the body help light the way for just about any after-dark adventure Jerry may want to go on, including those races in Baja we spoke about earlier.

Inside, the truck is just as custom, with brown and tan PRP suspension seats, as well as a matching center console, door panels, and dash, bringing the old-west vibe of the truck’s exterior from outside in. As discussed before, an M-Fab rollcage is continued throughout, while a full Rugged Radios communication system with headsets guarantees proper communication between the driver and the passenger, whether they are out night wheeling, enjoying an event, or racing in Mexico. Other interior features include AEM Electronics digital gauges, a MOMO California Wood Heritage steering wheel, and an on-board refrigerator/freezer.

Purpose-built and gorgeous all in one package, Jerry’s vintage crew cab is one impressive truck, so much so that in 2023, Jerry and his team raced the NORRA 500 and pulled out a third-place finish in their class in the truck’s first race. If that isn’t a testament to the capability of this truck and its owner, we don’t know what is.

1976 Ford F-250 Crew Cab

Owner:

Chassis & Suspension:

1976 Ford frame cut and notched by M-Fab, Custom integrated cage, 144-inch wheelbase, Custom 3-link suspension lift by M-Fab, Eibach front and rear springs, King front and rear shocks, custom tuned by KDM,Red-Head F-150 ported steering box, PSC hydraulic-assist steering stabilizer

Wheels & Tires:

17×8.5-inch Method MR704 wheels, 40×13.5×17-inch Toyo MT tires; BFGoodrich Mud-Terrain T/A tires, 4.25-inch backspacing front and rear

Engine & Drivetrain:

2008 GM 6.2L V-8, Custom 1 7/8-inch headers, Custom 3-inch exhaust system with side dumps, GM E38 ignition, ZMOD Performance tune, Speartech wiring harness, Fuel Safe fuel cell

On-board ARB air compressor, 2012 GM 6L90 transmission, 14×16-inch CBR transmission cooler, Heavy-duty NP205 transfer case with an Offroad Design Magnum underdrive adding up to a 5.33:1 final low-range drive ratio, Tom Wood’s front and rear driveshafts, 2014 Ford F350 Super Duty Dana 60 front axle, 2014 Ford F350 shaved Sterling 10.5 rear axle, 4.88 front and rear gears, Electronic lockers both front and rear, 2014 Super Duty brakes front and rear, GM Hydroboost master cylinder, Proportioning valve and line lock

Body & Paint:

1975-1977 Ford F-Series grille, Custom tube bumpers, Custom tube rock sliders, Custom spare tire wrack integrated into the rollcage, Cut-out wheel wells, Bobbed bed , 7-inch KC HiLiTES, Gravity LED Pro headlights, KC HiLiTES light bar, 30 KC rock lights, Ford Vineyard Yellow paint with black and white “cartoon-like” accents, all done by Jerry

Interior & Stereo:

Custom brown and tan upholstered PRP suspension seats, Matching brown and tan center console, door panels and dash, M-Fab roll cage, AEM Electronics digital gauges, MOMO California Wood, Heritage steering wheel, Full Rugged Radios communication system with headsets, On-board refrigerator/freezer

Get the Latest Gear!

Greetings Gearheads,

I have some hot news that’s burning rubber right off the printing press. Motortopia just dropped a fresh line of branded TREAD apparel—from tees to hoodies, we’ve got you covered. Get yourself some gear that screams “off-roader” louder than an engine redlining in a deep mud hole.

But hold on to your lug nuts; it’s not just about looking the part. We’re cranking out new apparel across all Motortopia brands. From the trail-savvy TREAD magazine to the hot rods of the streets, we have something for everyone.

Here’s the deal—you’re not just reading about rides; you are the people behind the wheel in those rides. Log onto Motortopia.com, upload your rig, and add your event to the latest online directory of automotive get togethers. Whether it’s an off-road expedition, a national expo trade show, a simple car and truck show, or even a pulse pounding side-by-side drag race, Motortopia is where you need your rig and event listed for the automotive world to see.

This is where the rubber meets the digital road, and it’s time to show off your ride.

Stay Dirty Out There,

Chris Hamilton

Motortopia Gearhead-in-Chief

Editor’s Note: A version of this article appeared in TREAD Mar/Apr 2024.

Photos by Emma Sauve

ProTech Industries has worked hard to put itself on the map as a go-to builder/provider of custom truck flatbeds and accessories. The Vancouver, Washington, company has been creating its own line of products since 1980, steadily increasing its number of offerings throughout the years.

The name of the game in marketing is getting your product in front of as many qualified eyes as possible, which means appealing to your target audience. Protech’s client base is people who drive their trucks for a living, meaning that it had to have one hell of an impressive (and eye-catching) truck to show off its wares. To that end, it doesn’t get much more impressive than a classic heavy-duty rig, especially a classic ‘55 F-600!

Now, there are different ways to get things done, and that certainly applies here. The in-house fabrication crew had a few competing ideas on a general look for the truck, but they all agreed on this: it had to be lifted, mean, and ready to work. Eventually, the best ideas out of the bunch were arranged into a game plan, and everyone started building!

As stout as the Ford’s original chassis and suspension were, they were a bit archaic to say the least—especially since the final product would end up with a shortened wheelbase, and the ride would likely be unbearable at that point. Plus, any excuse to ditch the F-600’s “widow-maker” split rim wheels is a good one. It just made sense to swap over to something newer, so a complete ‘96 F-350 chassis (complete with 7.3L Powerstroke diesel) was located and put to use under the F-600 cab. Obviously that required some work on its own, but it was by and large much better than dealing with the almost 70-year-old suspension and crusty Y-block. Before they called the running gear “done,” however, the guys at ProTech dropped off the Powerstroke at Portland Engine Rebuilders, where it was bored .020 over, studded, and given upgrades such as bronze valve guides, Carrillo rods, Mahle oversized pistons, and 205cc Stage 3 injectors by Irate Diesel. Once the long block was back from PER and set back into place between the frame rails, Ian Morton at ProTech built a custom exhaust, which exits the fenders and runs underneath the doors.

The engine wasn’t the only thing to get beefed up more than the “add protein” option in the Subway app. A Superlift 6-inch suspension lift was bolted on to clear the 35-inch BFG KO2 tires and 20×11 Detroit Steel Wheel D-Town wheels, and because any 4×4 truck looks better lifted—let’s face it. With the chassis and suspension now complete, the custom ProTech flatbed platform was attached, complete with toolboxes, rear folding steps, and Miller Trailblazer 325 Diesel welder. Showpiece or not, this truck is ready to make money!

And while the majority of the ProTech staff and crew’s time would be spent showing off the company’s parts, it was equally important to make sure that anyone driving the Ford would be comfortable enough to drive the rig long distances whenever needed.

A TMI bench seat made quick work of filling that requirement, and a backup camera screen in the rearview mirror keeps tabs of any obstacles. The Forever Sharp steering wheel provides a lot more room than the giant original wheel, making it easy to load snacks into the cab for those cross-state trips, and the Classic Instruments gauges take care of reporting back to the driver at a glance.

After a year and a half of build time, the F-600 was ready to show off, making its debut at NTEA’s Work Truck Week convention in 2022, and then following up with SEMA 2022 and 2023. With plenty of miles now under its belt and tons of interest at every event it goes to, we bet this truck is going to be the centerpiece of ProTech’s marketing efforts for quite a while!

ProTech Industries

Suspension & Chassis

Wheels & Tires

Engine & Drivetrain

Body & Paint

Interior & Stereo

Investing time and money on building a custom vehicle can be somewhat of a slippery slope. Depending on the vehicle and its condition, that investment can be doomed from the start—financially speaking, anyway. Practicality also comes into play as a make or break factor at the end of the day. As long as there is a good time and sense of accomplishment at the center of the project, however, there can still be a great deal of success to be had with it. There is a balance to be met, and that balance is different for each and every one of us—especially if family life can benefit greatly from putting together a custom tailored ride.

Recently, we were lucky enough to catch up with Kodie Paxton, and her husband William “BJ” Boden from Temperance, Michigan. Both are definitely not newcomers to custom automotive culture, as they own and operate their own shop called Acme Gas and Oil. BJ has been in the scene a long time now, and he has a couple absolute killer builds (both Fords) to his credit. One is a slammed and show-worthy ’84 Bronco II that is hard to forget once you’ve seen it. The other is also low, a cool-as-hell ’85 Ranger that also boasts custom paint, a full interior and a whole lot more.

While both of BJ’s previous builds share a similar mid-1980’s vintage along with heavy street truck styling cues, there is one glaring difference that sets them starkly apart—the Cummins 4BT turbo-powered engine underneath the Ranger’s hood. While the Bronco’s 1949 Ford Flathead V8 is an amazing piece of machinery in its own right, the Ranger’s power plant does pique our interest a tad bit more. This does happen to be a diesel-centric publication, after all.

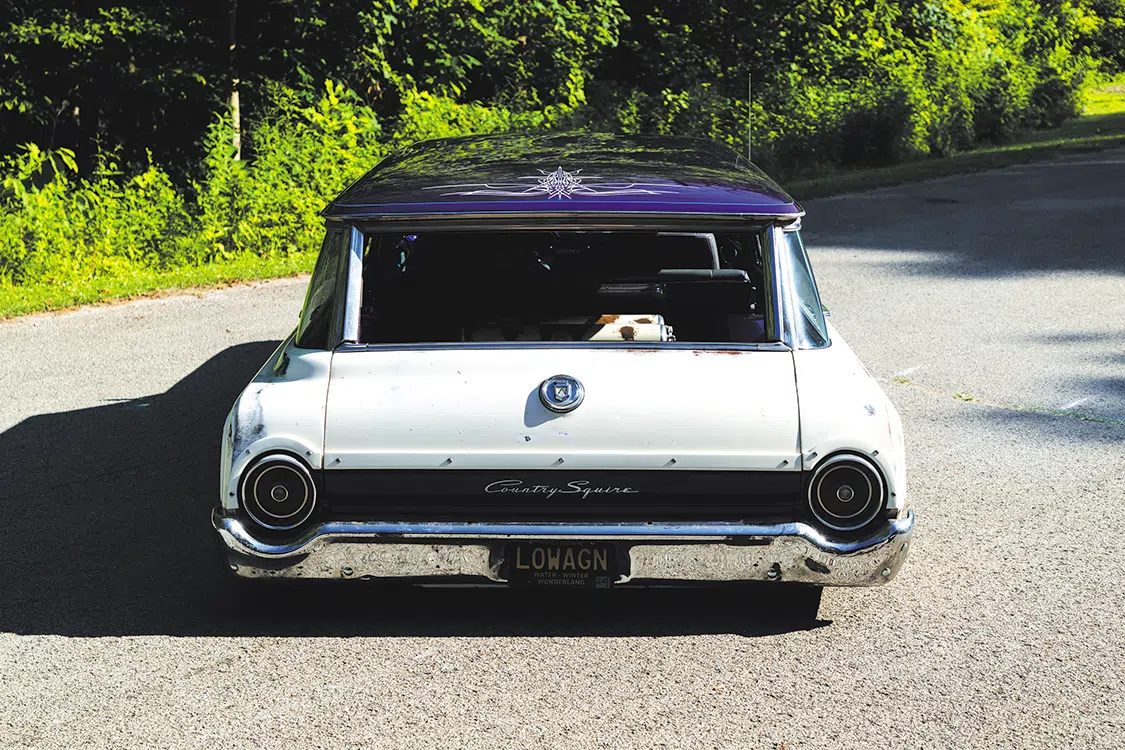

Another similarity the Bronco and Ranger share is Kodie’s love for both of them. When the time came for the two to take on yet another project vehicle, they placed their growing family at the heart of the build and found something that they can all enjoy and fit inside comfortably at the same time. The vehicle they chose is a step away from their previous two, but it’s just as cool. BJ picked up a 1962 Ford Galaxie Country Squire wagon as a surprise for Kodie, and boy, she was surprised to see it for the first time parked in their shop. The plan was to give the car the full treatment, which included running with another truly stellar engine specimen, which has become somewhat of a requirement for any of BJ’s builds.

With some help from Kill Devil Diesel (KDD) in Poplar Branch, North Carolina, BJ was able to lock down a 2006 6.0L Ford Powerstroke that was fully loaded with KDD’s own machine work and components. A ton of other performance parts, including two very special additions, were also added to the lineup.

Now, before we get too far ahead of ourselves, Kodie and BJ wanted to make sure that we get one thing clear. The two Borg Warner turbochargers featured on the Powerstroke are in fact a compound turbo setup and not a twin turbo configuration. The difference is notable, as the first turbo in line feeds the other with boosted air in a compound layout instead of the two turbos operating independently in a twin scenario. Mistaking the two, or just assuming that two turbochargers naturally translates to twin turbos is an honest oversight for those not in tune with it all, but a little bit of explanation does go a long way.

A fully built 1997 Dodge NV4500 transmission from SuperStick was ordered and put into place to take full advantage of the 900hp at the rear wheels as well as the 1700 ft-lbs of torque that the Powerstroke produces. That substantial amount of power would soon be a blast to experience once the rest of the wagon project evolved.

The next phase of the build would be one of the most transformative for the Country Squire. With the expertise that BJ has with custom chassis systems, a full one-off frame was put together for the wagon using 2×3 and 2×4 square tubing throughout. Since BJ’s forte with severely lowered suspension setups is well proven and documented in his previous builds, he was fully motivated to follow suit with this project. A combination of Air Lift air bags, a 3H air management system, and dual Viair 444C compressors were plumbed to create a fully adjustable ride height. QA1 adjustable shocks have been put into place to promote ideal ride quality, and a hand-built IRS system was created to round off the custom chassis highlights. It’s a shame that this chassis is hidden underneath the car, because it really is a work of purpose-built automotive art.

To set off the wagon’s newfound low-slung chassis just right, Kodie and BJ selected a one-off set of 20×9 and 20×11 Detroit Steel Ambassador wheels that were wrapped in Nitto NT555 G2 performance rubber. To bring the car to a controlled halt, PowerStop front and Wilwood rear braking components were bolted up and finished off with steel braided lines.

Natural patina is a sacred thing among the classic vehicle crowd. It’s almost like embracing the ‘wisdom’ that gray hair brings. When the wagon found its way to Kodie and BJ, it had quite a bit of rust along the top portions of the doors and the entire hood that they weren’t interested in painting over. These worn portions were encapsulated in layers of clear coat to preserve the patina look while ensuring it doesn’t turn into any real damage to the metal down the road.

Custom paint was still as important in this build as saving the patina was, so Detroit Chris “The Mad Professor,” Mike Kluczynski, and James Rivers helped out by applying the custom candy paint that BJ mixed to the roof and along both sides of the car. Shannon Best at Best Built Customs applied airbrushed wood grain graphics to the sides, and Todd Hanson at Hanson Graphix then stepped in to pinstripe the hell out of the wagon to add some old school flavor.

Don Steinman joined the project by fabricating a custom floor pan in order to lay down wood flooring inside of the wagon—definitely a cool alternative to rolling out replacement carpet. Pete’s Auto Upholstery and Trim in Taylor, MI reupholstered a set of 2006 Lincoln MKZ bucket seats, along with a factory rear bench, center console and door panels too. The dash was painted and pinstriped to match the wagon’s exterior, a fresh set of Dakota Digital gauges were wired in, and a Mooneyes steering wheel was mounted to fully upgrade the entire command center.

Kodie and BJ started ripping into the wagon at the start of 2019 and finished it up at the tail end of 2021—not bad considering the struggle of getting parts in hand during this prime time portion of the pandemic lockdown. Every penny and minute spent whipping the car into shape has been well worth the effort, since the Galaxie is now a means for creating unforgettable memories together with their children. A wagon by nature has always been thought of as a vessel for promoting wholesome family values since their release decades ago. This is what motivated BJ to grab one for his wife and kids, but of course he couldn’t imagine doing it any differently than how it came out.

Owner

Kodie Paxton

Temperance, MI

Engine & Drivetrain

Chassis & Suspension

Wheels, Tires & Brakes

Body & Paint

Interior & Stereo

There’s no better truck story than one that centers around the life-long learning journey of a grounded, self-taught auto fabricator. Shannon Manley of Penton, Colorado, has been teaching himself the ins and outs of keeping his 1969 F-100 on the road since he was a very young teenager. His dad instilled a passion for cars and trucks at an early age, and his neighbors were always working on their hot rods in their driveways. These two influences during his formidable pre-teen years lit the fire underneath Shannon to get his hands on a vintage project of his own by any means possible.

“My mom and stepdad surprised me with my old ’69 F100 back when I had just turned 13,” Shannon recalls. “It had a stepside bed, was riding at stock height, it had lots of broken parts, a rusted 223 straight-6 under the hood, and a three-on-the-tree that required a screwdriver to start it, but it was my first love. Just having the truck there to tinker with was a huge experience for me. Since I had little to no guidance, I had to figure things out for myself.”

It was during this sink-or-swim learning period when Shannon proved to himself that he was able to troubleshoot and fix a lot of things on his old Ford.

It was during this sink-or-swim learning period when Shannon proved to himself that he was able to troubleshoot and fix a lot of things on his old Ford. Wiring and other minor mechanical repairs, as well as figuring how to make the truck move and stop were all newly gained skills that compelled him to go to school to learn what he needed to go out and take on mechanic jobs. Ultimately, he wanted to dive deeper into auto education, so he took more courses to learn to customize cars the way he always wanted to do. A stint at a local hot rod shop gave Shannon the hands-on training that gave him the tools and confidence to open his own shop a few years down the line—Pot O’ Gold Kustoms in Colorado Springs.

With all the paying customer work that started walking through the door, Shannon did his best to spend as much time as possible with his F-100. It has seen various stages throughout the years, but it wasn’t until very recently when he made a big push to do some very cool things that had been on his to-do list for a while.

“I always wanted to change up the balance/symmetry of the body lines,” Shannon states. “The stepside bed just wasn’t cutting it. I even tried a ’64 fleetside bed but it still didn’t look right to me. During my search for the perfect fit, I got lucky and found the current unibody bed at a local salvage yard for a whopping $50!”

Soon after finding the bed, Shannon stuck gold once again by finding a set of matching unibody doors as well as a big back window that would finally give his F-100 the aesthetic he was after.

The caliber of custom vehicles that Shannon sees at Pot O’ Gold are usually higher-end rides that receive full painted finishes. While most of these cars and trucks tend to be show pieces that don’t get a whole lot of road time, Shannon wanted to drive his truck as much as possible whenever it was ready to roll again.

“I wasn’t too interested in spending a lot of time cleaning and polishing the truck,” Shannon admits. “I just wanted to stay focused on enjoying it. To help with this, I planned on leaving the original patina on the bed and hood, and my daughter Rayna and I then painted the rest of the truck to match the weathered appearance. The result looks great, and it makes for very worry-free maintenance.”

The truck has seen various ride height levels throughout the years, but to achieve its current stance, Shannon entrusted a Scott’s Hot Rods front suspension kit and an AVS rear 4-link setup to help provide a more aggressive altitude as well as an elevated ride quality than before. Full air ride allows for height adjustability to give the truck all the room it needs to fully function while in motion—plus, there’s nothing cooler than being able to air an old truck out on the ground. A tall rear frame notch had to be fabricated in order to fit the Ford 9-inch pumpkin, but Shannon made quick work of that before ordering the perfect set of wheels to blend in with the truck’s developing style.

“Detroit Steel has been a reliable source for me over the years,” he says. “I have used their wheels on multiple projects at the shop, and I knew they would look right at home on this truck. They set me up with a pair of 20×8 units for the front and 22×9 for the rear, and even drilled them for me so I could run the set of caps I wanted.”

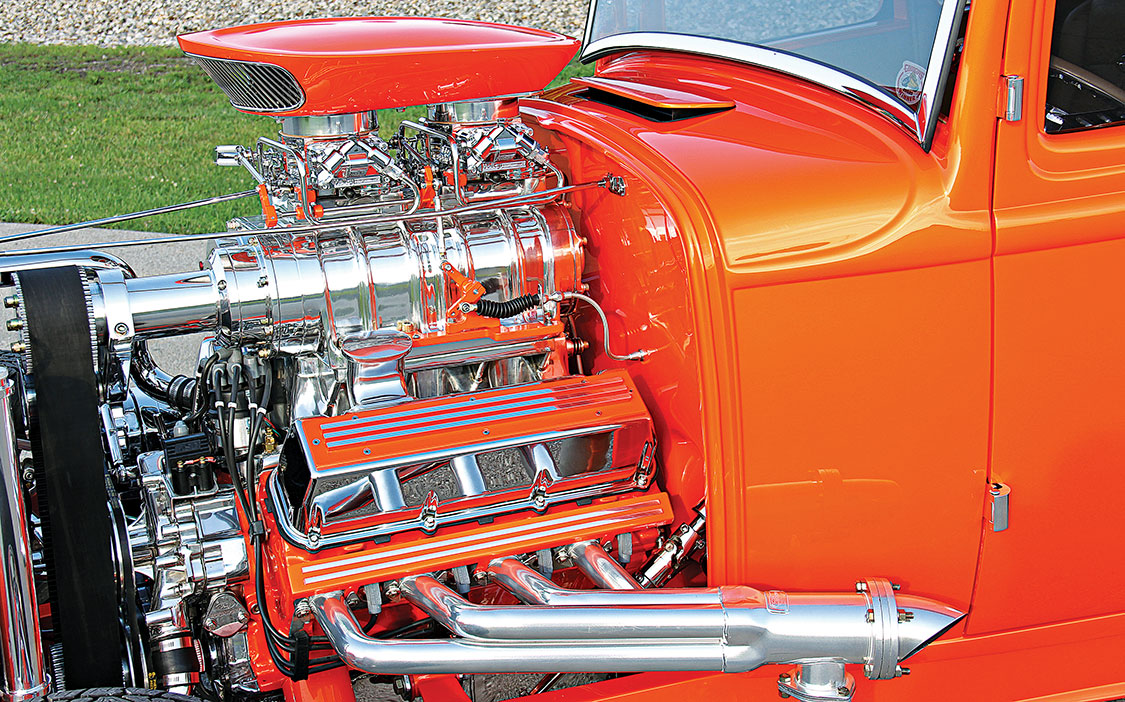

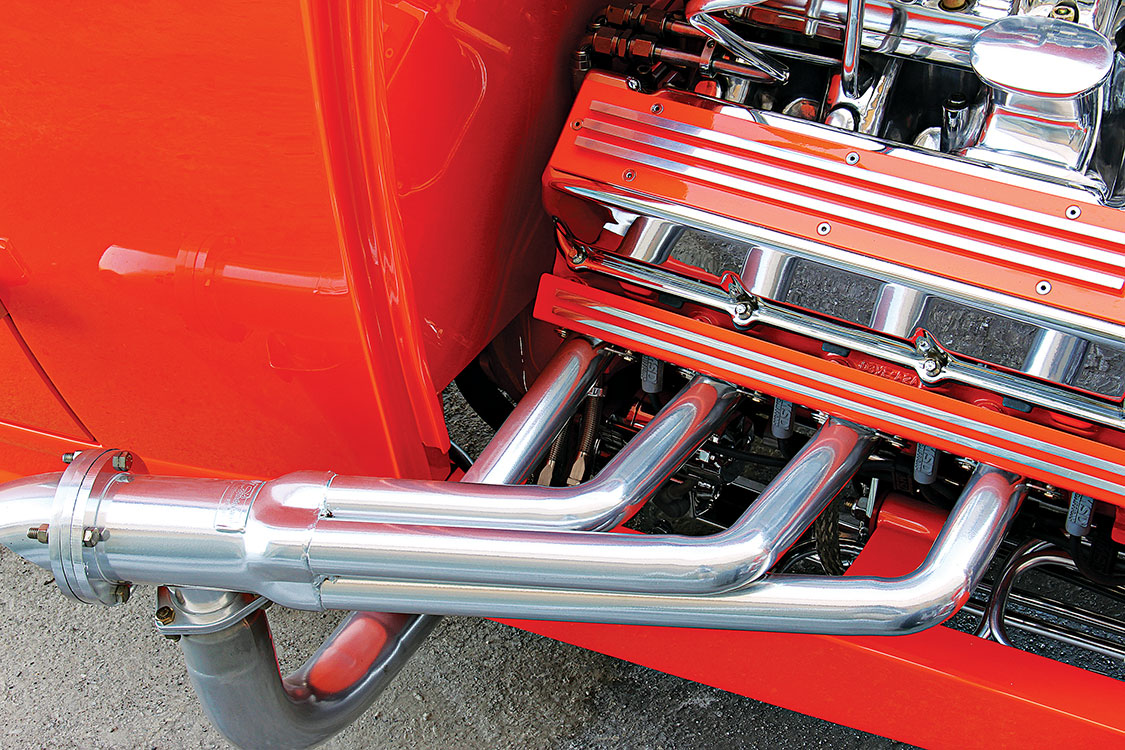

Since Shannon’s main concern with the truck was to drive the hell out of it once it was completed, his next move was to set his sights on getting a fresh engine prepped for it. While a modern engine may have been an easier option to run with, he instead decided on rebuilding a tired ‘63 Y Block 292ci that he already had in his possession. Eddie’s Hot Rod Shop in Canon City, Colorado, went through the entire engine before topping it off with parts from OTB Gear and Spotlite Kustom Accessories, along with a Fenton intake manifold and headers to keep the mill looking vintage. Shannon also wanted something reliable for the engine’s fuel delivery, so he had it hooked up with Autotrend EFI to promote that jump-in-and-go feeling whenever he felt like going out for a cruise.

Although Shannon has an affinity for the look of natural patina, he wanted a much more polished atmosphere inside the cab. Dominic Olson at Big O Fabrications in Colorado Springs reworked a set of Ford Galaxie bucket seats and a center console from a Mercury Comet, and then finished them off in luxurious white leather and excellent stitchwork. Dakota Digital gauges, a Speedway Motors steering column and CON2R steering wheel all came together to upgrade the F-100’s cockpit while lending a clean vintage appearance to the command center. Shannon admits that the cab space is still a work in progress, but it has come a long way so far and will be heading further in the direction of providing a true VIP experience to its occupants.

After a long eight-year process of getting the completely truck show worthy, Shannon set the grand unveiling at Lone Star Throwdown 2023.

“I have been driving the wheels off of it since,” he adds. “While it’s nice to be able to finally enjoy my F-100 on the road, what I like most about it is the growth it represents for myself and my shop. I have also loved having my family involved during the entire process. I must take the opportunity to give a huge thank you to my wife April and son Liam for the metalwork, my son Tyler for the brake, wiring and fuel help, Damien for the suspension and steering assistance and my daughter Rayna for the paintwork. And to all the other shops and suppliers that helped make this possible, I couldn’t have done it without you.”

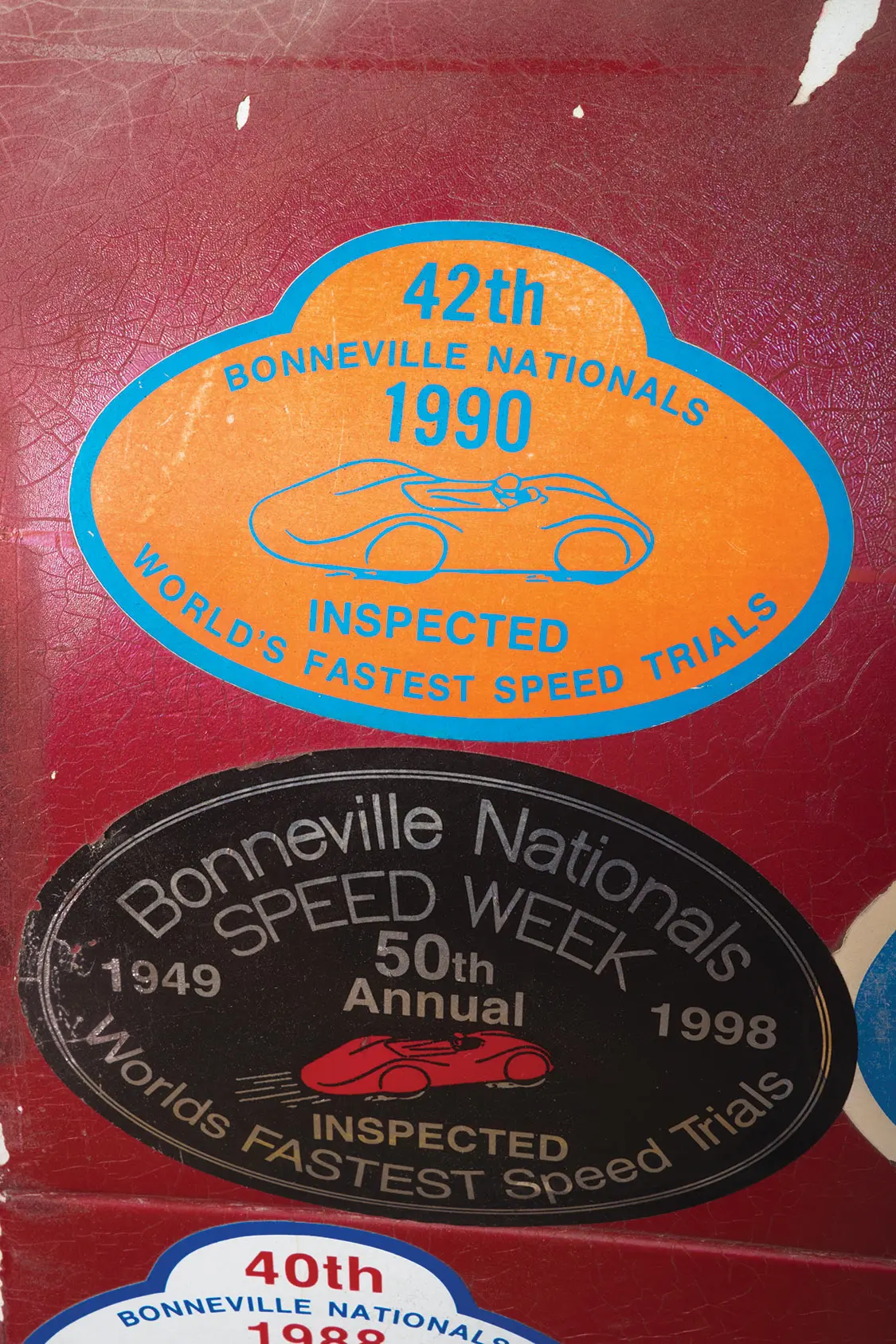

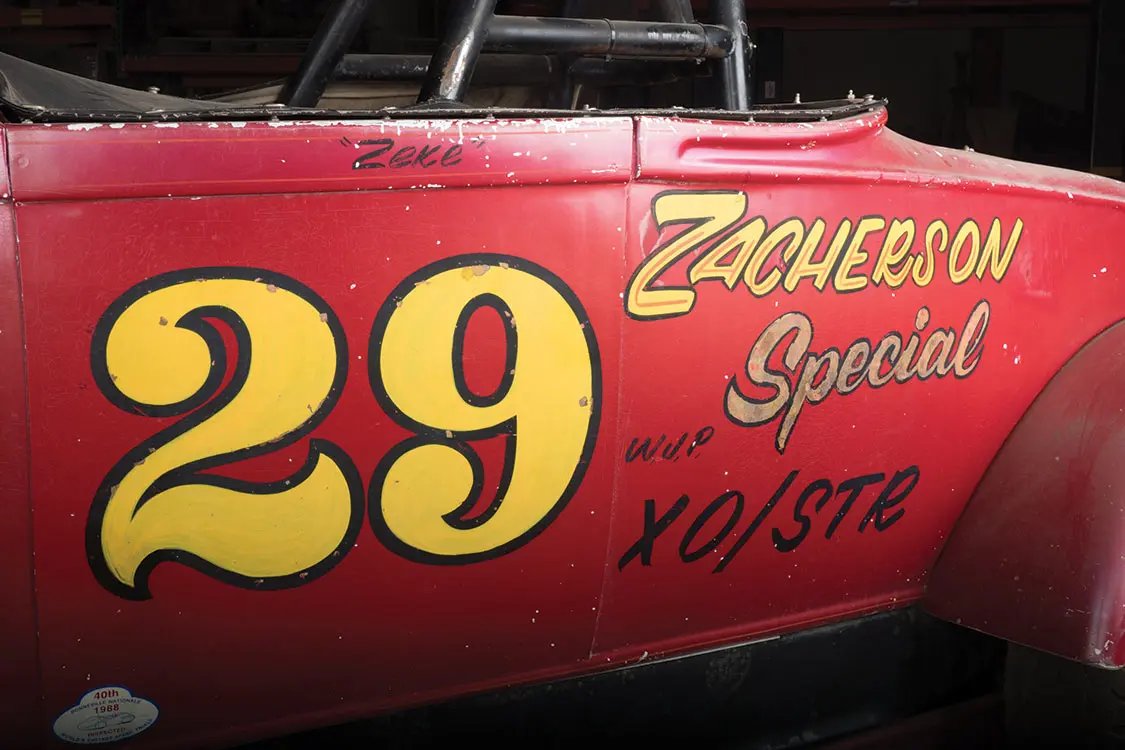

Zeke Zacherson’s ’29 roadster was part of the retro movement at Bonneville before there was a retro movement at Bonneville. Zeke chose to do battle in a class designed specifically for engines designed before 1959 at a time when the latest and greatest engine technology was all the rage. His ’29 Ford roadster is an icon of the return to the roots of hot rodding.

THE HISTORY OF LAND SPEED RACING AT BONNEVILLE IS ALSO A HISTORY OF HIGHEST-PERFORMANCE ENGINES AT THE TIME.

Fashion trends come and go in a flash. The must-have outfit for spring is no longer acceptable come fall. The same can be said for engine choices at Bonneville, although the trends on the salt follow a much longer cycle. The history of land speed racing at Bonneville is also a history of the highest performance engines available at the time. Interest in land speed racing was huge in the ’50s and ’60s, with advancements in automotive technology pushing records higher and higher. By the mid-’70s the automotive world shifted emphasis from performance to economy, and this malaise had crept into the scene at Bonneville. Participation dropped off to all but a few die-hards running their cars using the latest technology. Fewer still looked back in time to nearly forgotten engine designs. When Zeke acquired the Bonneville veteran roadster he became one of those few.

Zeke caught “Salt Fever” in the mid-’70s when a friend let him drive a small-blockpowered roadster. After hitting 149-mph, Zeke was hooked and vowed to return with his own car. Previously the governing bodies had seen an opportunity to bring more competitors to the start line by creating a new class for older engine designs. Zeke seized this opportunity by retuning to the salt with his street-driven ’38 Chevy sedan converted to race car duty and managed to set a couple of records. Armed with knowledge gained setting the XXO/Sedan class records and hungry for more, Zeke started looking for a car to compete in the Roadster body class (Bonneville classes are divided by engine type/displacement and body style).

FEWER LOOKED BACK IN TIMETO NEARLY FORGOTTEN ENGINE DESIGNS. WHEN ZEKE ACQUIRED THE BONNEVILLE VETERAN ROADSTER HE BECAME ONE OF THOSE FEW.

The roadster Zeke found had started life as a magazine project feature. Frank Oddo, a long-time automotive journalist and hot rodder, built the #29 roadster in the mid-’70s while documenting the build for series of articles in Street Rodder magazine. Once completed, Frank took it to Bonneville and went faster than 180 mph with a blown small-block Chevy V-8, from the legendary Bonneville figure Bruce Geisler, under the hood. The project and story complete, the car was sold to Lloyd Arnold, who replaced the potent small-block with a four-cylinder Pinto engine. Lloyd campaigned the car off and on until selling it to Zeke in 1983.

Zeke set about tearing the car down to the bare frame and replacing the four-cylinder plant with a GMC 302-ci inline six-cylinder engine acquired from Clifford Performance, a leading supplier of inline six-cylinder performance parts. The 302-ci GMC truck engine, originally fitted to 2.5-ton military trucks affectionately known as Deuceand- a-Halfs, had proven a potent hot rod engine in the early-’50s, powering the first car to break 150 mph on the drag strip and setting many land speed records. In stock trim, the engine was good for about 150 hp with solid low-end torque. This rivaled the newly introduced Ford Y-block V-8 and Chevy small-block V-8, although the inline six-cylinders were soon eclipsed once hot rodders realized the potential horsepower lurking in the V-8 motors. While the truck engines were praised for their sturdy blocks and nearly indestructible nature, they belonged to a family of engines that had its roots in the ’20s and carried with them a power-robbing head port design.

The venerable truck engine sported “siamesed” exhaust and intake ports in the head. Cylinders 2 and 3 and cylinders 4 and 5 shared a single exhaust port, while cylinders 1 and 6 enjoyed their own. The picture on the intake side was even worse where only three ports were shared between each pair of adjacent cylinders. Compounding this further, the stock intake manifold design favors the middle intake port, delivering less fuel and air to the front and rear cylinders.

ONCE COMPLETED, FRANK TOOK IT TO BONNEVILLE AND WENT FASTER THAN 180 MPH WITH A BLOWN SMALL-BLOCK CHEVY V8, FROM THE LEGENDARY BONNEVILLE FIGURE, BRUCE GEISLER, UNDER THE HOOD.

Wayne Horning, a mechanical engineer at Lockheed Aircraft, recognized these shortcomings in the late- ’30s and drew up plans for a better-breathing head. While World War II put a hold on his plan to hot rod the Chevy sixcylinder, soon afterwards he produced heads that did away with the antiquated port design.

Other manufacturers took up the cause of the inline engine, notably Howard Johansen of drag and land speed racing fame. He produced cross-flow heads with 12 ports, one port for each intake and exhaust valve, that boasted 1 hp per cubic inch of displacement in street trim.

THE VENERABLE TRUCK ENGINE SPORTED “SIAMESED” EXHAUST AND INTAKE PORTS IN THE HEAD.

Zeke collected a couple of Howard 12-port heads throughout the years and chose to run them on his 302 GMC motor. He fitted the engine with a Howard 380 cam and 14:1 compression pistons to match. Then he fabricated his own intake and backed up the revived mill with a 1955 Chevy three-speed transmission and Ford 9-inch rearend with .325 gears. He then updated the roll cage to meet new regulations from the SCTA (Southern California Timing Association, one of the governing bodies of land speed racing) and removed nearly 1,100 pounds of lead that had been bolted to the frame in an effort to gain rear wheel traction. The fiberglass body had been stretched 11% in the hood but retained an original grille shell per SCTA rules.

In this configuration, he went to Bonneville and quickly set records. Another rule change split the use of specialty and stock heads into separate classes, and Zeke set records in both in the same day by changing heads. Zeke took the roadster to run at El Mirage dry lake bed in Southern California and set a record using a stock head on the GMC 6, but the governing body at the race would not certify it since he was not a member of one of the clubs that run the event.

The #29 Zacherson Special even made a couple of appearances on the drag strip. Zeke and the car became a fixture at Bonneville throughout the years, setting records from the mid-’70s until the late-’90s. Pictures of the car have graced four calendars and even the pages of an ’80s issue of Penthouse magazine.

The retro craze that Zeke helped usher in took a firm grasp of the minds of Bonneville racers. Interest in the roots of land speed racing and hot rodding is stronger now than ever before. Flathead V-8, vintage inline four- and six-cylinderpowered cars now attract more attention than their modern counterparts in the Bonneville staging lanes.

THE RETRO CRAZE THAT ZEKE HELPED USHER INTOOK A FIRM GRASP OF THE MINDS OF BONNEVILLE RACERS. INTEREST IN THE ROOTS OF LAND SPEED RACING and hot rodding is stronger NOW than ever before.

Eventually both Zeke and the roadster started to grow long in the tooth. What once was a vanguard of a retro movement on the salt became just another old race car, so Zeke hung up his helmet. When Joe Fazio, owner of SoCal Speed Shop Sacramento, heard that the #29 Zeke Zacherson Special was available for sale he jumped in to preserve this piece of land speed racing history. It now resides in Joe’s collection waiting for its next chance to bring the roots of hot rodding to yet another venue.

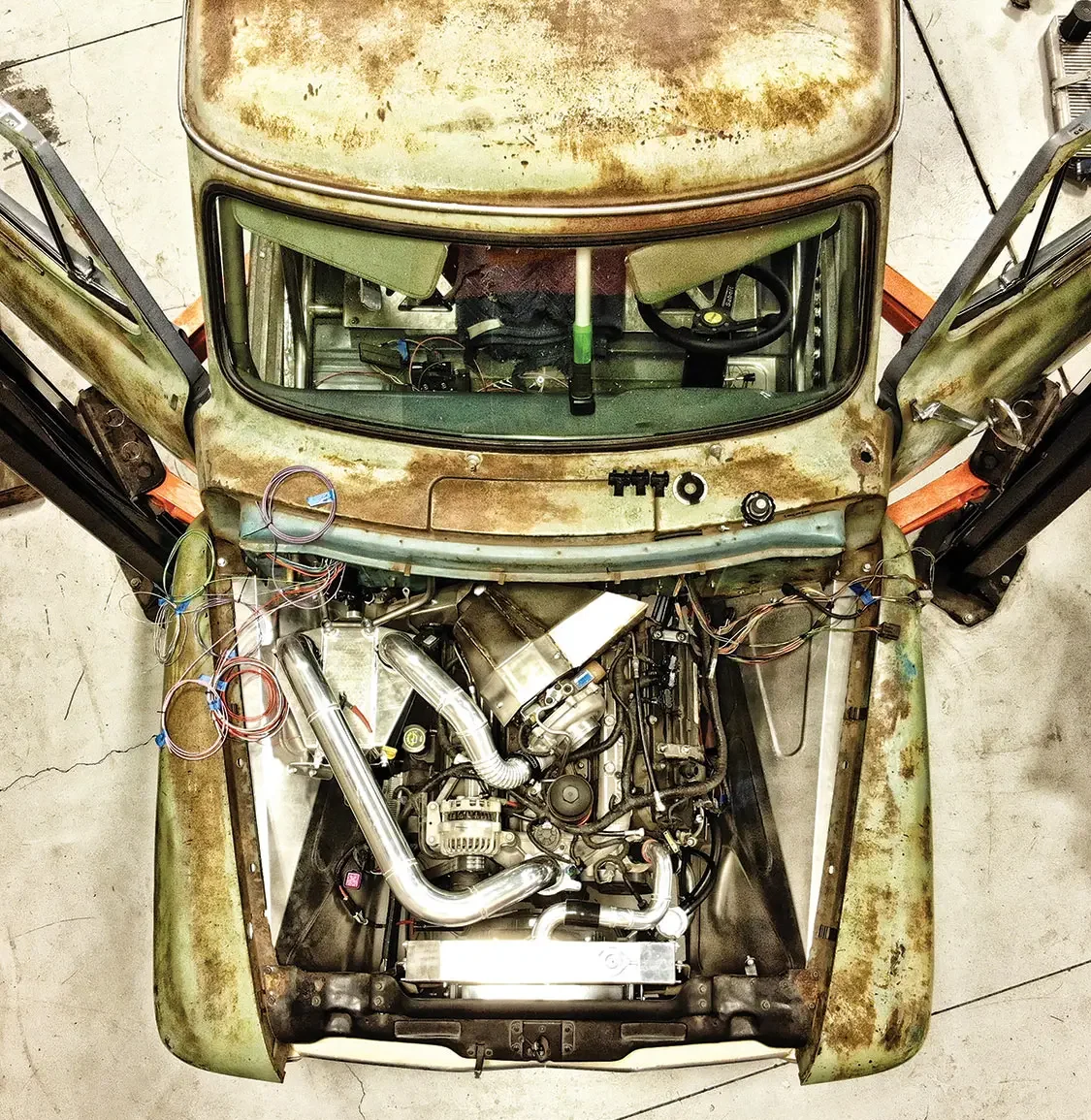

Engine swaps are all the rage these days and we’ve seen builds from every end of the spectrum. From the no expenses spared, top of the line performance builds for competition use to the low budget, do whatever it takes for as little money possible to get it on the street kind of conversions. But this one, this old Ford F100 build falls somewhere in the middle, tipping a little heavy to the ‘not cutting any corners’ side of the scale. For Clay of Riffraff Diesel in Eagle Point, OR this build was more than just putting together a cool conversion project you could show off to your buddies. This project was about learning something new, applying knowledge you already had, while brining that nostalgic feeling from years gone by back into your life.

Riffraff Diesel has focused its entire business structure around supporting the 7.3L and 6.0L Power Stroke platforms and has become well known within the industry for just that. With well over a decade of experience in those two perspective fields of study, the team at Riffraff has learned a thing or two about Power Strokes. They continue to push the boundaries with products engineered specifically for the 1994-2007 Ford diesel markets. From basic problem solving aftermarket products to fully custom machined competition based parts, they really do it all from mild to wild. So, this truck, dubbed Pigpen, it was about building something to showcase products, a shop truck, a fun weekend hotrod, and a truck Clay and his wife could just enjoy having around.

While the truck qualifies as a show piece in our eyes, Riffraff never built the truck with those intentions. It was built to showcase their products and abilities sure but being able to drive the truck without worry of it getting dirty was just as important.

Coming from automotive families, Clay and his wife both have a strong connection to old cars and trucks, old 50’s Ford trucks to be more specific. In fact, throwing it back to when they first started driving, a modified F100 was the first thing they drove to high school. So, building a truck like this checked just about every box for them. As you can see, attention to detail is something the Riffraff group takes seriously, and they weren’t afraid to throw some new flare into an old worn out patina’d Ford. It shows wear and rust where it should, with classy styling ques and what definitely could be considered a jewelry box under the hood.

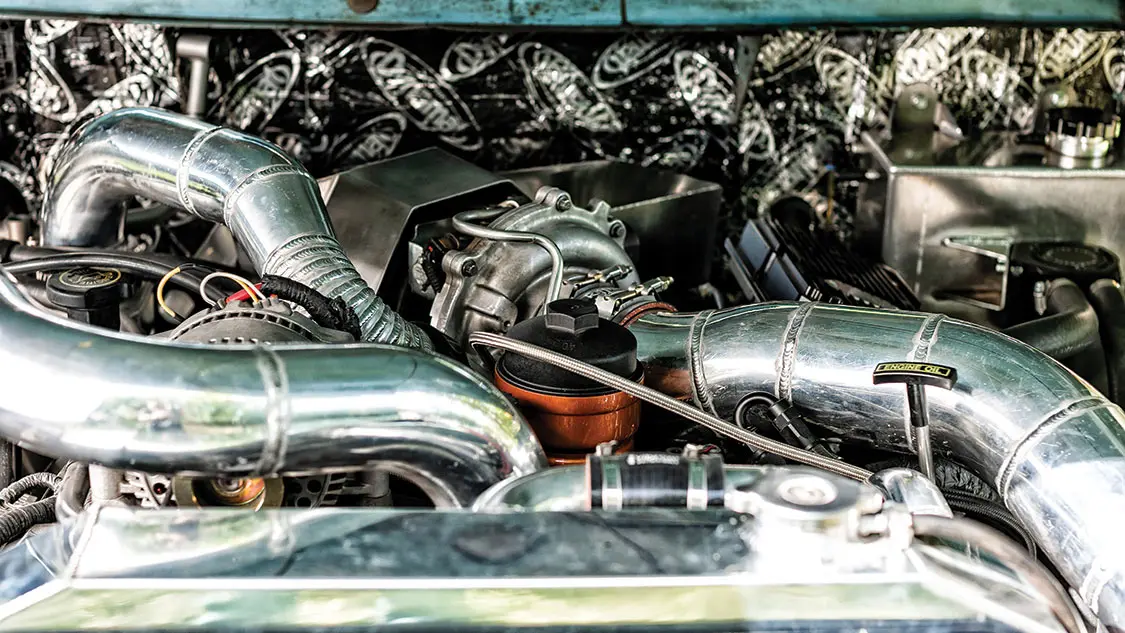

For power, the 6.0L Power Stroke engine has been completely rebuilt from the pan up. The factory block, crankshaft, and rods were used, but Riffraff delipped and fly cut Mahle pistons were used along with a Stage 2 Killdevil camshaft. The factory cylinder heads were cleaned up with all new parts and porting from Steel Dust Machine of California. Smith Brothers pushrods help maintain solid valvetrain performance under high RPM and elevated boost pressures. For fueling, Full Force Diesel 205cc 30% over injectors were installed along with a Terminator Engineering T500 high pressure oil pump and Riffraff’s own lift pump and complete fuel system from tank to engine.

For boost, the truck runs a 68mm VGT Stage 3 turbocharger from KC Turbos pulling through a hand fabbed intake setup built by LYFE Motorsport. LYFE also handcrafted the intercooler tubes and core for maximum flow and cooling potential in the smaller engine bay of the F100 truck. O’Dawgs high flow cast intake manifold helps with distribution to the cylinders and Riffraff has even thrown in a couple stages of nitrous just for good measure. For exhaust, factory manifolds were replaced with pieces from Steed Speed, a 4” downpipe splits into 3” duals further down the chassis.

Transferring power is 5-speed 5R100 transmission built by John Wood Automotive with multiple internal upgrades to handle the horsepower that engine creates. Modified valve body, triple disc torque converter and a sprinkling of billet parts ensure it’ll plant 700+ horsepower without breaking a sweat. The truck its on matte grey Forgeline 18” wheels with 265/45 rubber up front and massive 295/40’s out back.

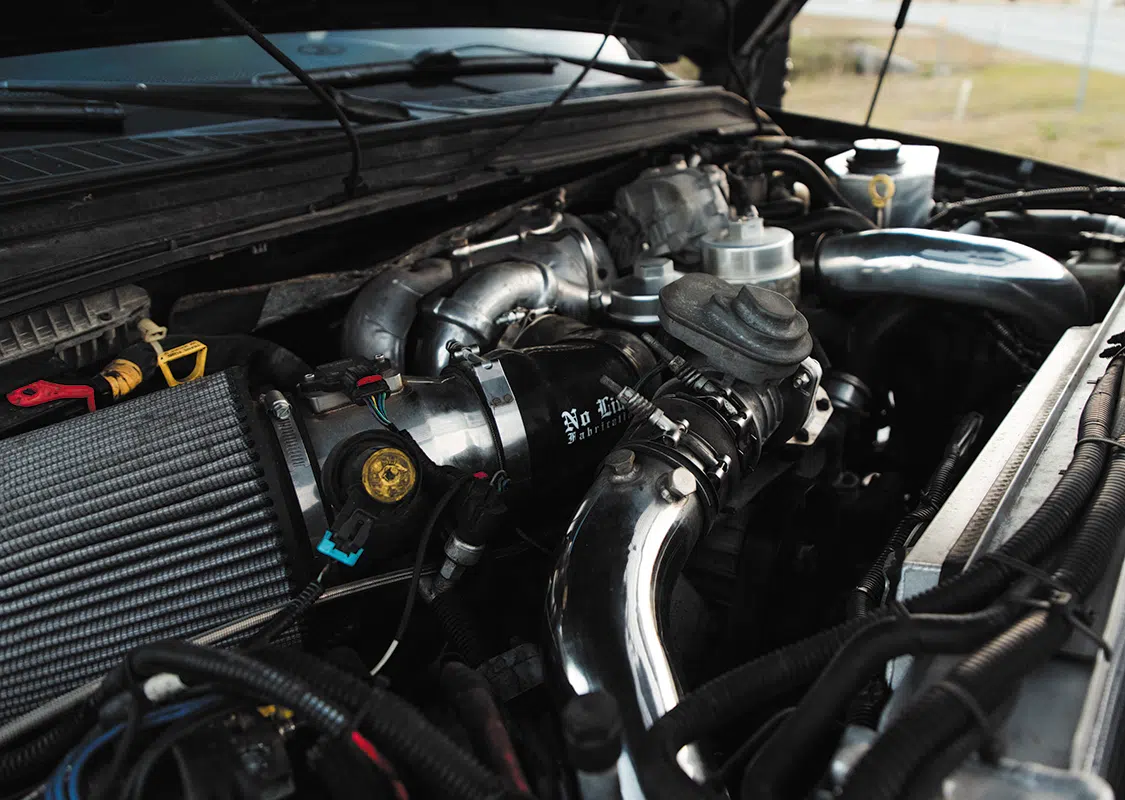

Since the original frame and suspension were never designed to handle this kind of power or weight, it was completely scrapped and replaced with a Big 10 chassis from No Limit Engineering which allowed for much easier assembly and better end results when cruising or rallying the truck. The standard chassis was upgraded in specific places to better handle the torque and extra up front weight from the 6.0L diesel. A roll cage was also fabbed up by LYFE Motorsport just in case Clay ever gets the hankering for a road race or quarter mile pass.

While the truck qualifies as a show piece in our eyes, Riffraff never built the truck with those intentions. It was built to showcase their products and abilities sure but being able to drive the truck without worry of it getting dirty was just as important. The truck gets driven to and from work on the regular, and you’ll see Clay cruising through town frequently with one of his boys riding shotgun. On the chassis dyno the truck laid down a solid 735hp on fuel and 954hp on a shot of spray, but is still an incredibly reliable daily driver, that’s more than a handful in a lower sub-600 horsepower tune. You’ll definitely be thankful for the massive Wilwood brake calipers and PRP race seats with 5-point harnesses anytime you bring this thing up on full boost out on the street. We aren’t sure how it got the name PigPen or why it stuck but who really cares what you call it, it’s a beautiful build and a complete riot on the street.

In the quiet corners of Preston Hawkins’ shop, nestled beneath the soft glow of hanging workshop lights, rests a relic of the past: a 1971 Ford F-250 that carries with it the scars and stories of a bygone era. But this isn’t just any truck to Preston—it’s a testament to his passion for automotive revival, a journey that began with a simple text message and ended with the resurrection of a forgotten classic.

The saga of the F-250 didn’t begin with Preston actively seeking it out. It found him—a stroke of fate orchestrated by a friend’s text message about a neighbor’s bumpside that was possibly for sale. Intrigued, Preston asked for pictures, and once he saw it, he felt an instant connection. The decision was swift—he would rescue this forgotten truck.

Just 5 miles from his house, Preston laid eyes on the truck for the first time just hours later. Its body, surprisingly unmarred by the passage of time, captured his heart. The deal was sealed, and in July of 2021, the F-250 found its way to its new home.

Before Preston’s skilled hands got to work on it, the F-250 had weathered 25 long years abandoned in a field, gaining a distinguished patina that hinted at its former glory. Remarkably, though, it had almost no rust or dents. Once a two wheel-drive truck, Preston breathed new life into it, transforming it into a four wheel-drive behemoth with an original Highboy chassis and running gear, a decision that paid homage to its heritage.

Just 5 miles from his house, Preston laid eyes on the truck for the first time just hours later. Its body, surprisingly unmarred by the passage of time, captured his heart.

Preston had a vision. He wanted more than just a relic—he wanted a trusty sidekick that combined Ford heritage with the convenience of some modernity. With its upgraded power brakes and power steering seamlessly integrated to work alongside the 390 big block and 4-speed NP435 manual transmission (bolted up to an NP205 transfer case), the F-250 now boasted both brawn and ease, a blend of old-school charm and contemporary comfort.

But Preston was determined to take it a step further. The engine, although in fine operating condition, didn’t quite meet his standards. So, he tore it down and rebuilt it, every part meticulously machined to perfection by Troy’s Engine & Manufacturing including boring it out .030, bringing the block to 401 cubic inches. He then followed that up by restoring the rest of the truck’s drivetrain and suspension, including the brakes, axles, and hubs. After all, it wasn’t just a mechanical restoration—it was a labor of love, and this truck deserved the best.

Every step of this journey was a cherished chapter for Preston. The underside was now fortified, bedlined, and chipguarded, a shield against time’s relentless march. He planned on covering lots of miles over the years, so he didn’t want to leave anything to chance. A set of 255/85R16 Toyo Open Country M/T tires provide an aggressive yet manageable grip both on and offroad, while making the truck look damned good in the process.

Inside, Preston revamped and mechanically refurbished with fresh sound deadening, a new steering wheel from LMC, an internally restored Philco stereo, and new vinyl upholstery by Aaron Hill.

In Preston’s hands, this F-250 ceased to be a mere vehicle. It became a canvas, a testament to his craftsmanship, a living testament to his dedication. With every rev of the engine, every turn of the wheel, it carries forward not just its own legacy but also the indomitable spirit of its caretaker—a man bound to his truck by more than just bolts and metal, a man who found a companion in the heart of a classic Ford, and in return, breathed life into a forgotten hero of the roads.

TRUCK SPECS

OWNER

Preston Hawkins

CHASSIS & SUSPENSION

WHEELS & TIRES

ENGINE & DRIVETRAIN

BODY & PAINT

INTERIOR & STEREO

Trucks that are handed down through one’s family are an extra kind of special. Sure, any old truck is going to have some history to it, but one that’s been passed down has your history—and the history of your predecessors—permanently ingrained its soul. Yes, trucks have souls. You grew up riding shotgun, you possibly got to help out with an oil change or two, and you definitely got to play in (or even ride in) the bed! One way or another, that history lives on in these old machines.

Sharma Mulqueen holds those memories close to her heart, having ridden along in her dad’s ’55 F-100 as a kid—and even before that when it was her grandfather’s truck! The truck remained stock for the first 65 years of its existence, so you may be wondering how it ended up in its current state. Well, here’s the loose chain of events that led to the transformation of this F-100.

Sharma’s grandparents bought the truck in 1959 to serve as a daily driver and occasional errand runner. Her grandfather drove it all the way through the early 1980s, and then gave the truck to her dad. He used it as a work truck, so it was treated as such, and was then eventually stuffed in the garage where it began its next chapter as a storage container and oversized junk drawer.

The truck remained stock for the first 65 years of its existence, so you may be wondering how it ended up in its current state.

Both Sharma and her grandfather would occasionally ask her dad when he would get around to fixing it back up, but it would never get any further than a shrug of the shoulders. Finally, in 2019, he conceded that he would likely not be restoring it, so Sharma politely asked for the keys and decided to make it a project of her own.

Everything began with the simplest of intentions: Get the truck back on the road, with Sharma’s son Declan eventually getting the keys as long as he put in some sweat equity. With some additional help from Sharma’s husband Keith, the family got the truck running and stopping again, and everyone was excited to have it back on the road.

But what now? While everyone in the family was a gearhead to varying degrees, they knew that they wouldn’t be able to get the truck where it needed to be on their own. And as important as the truck was, especially to Sharma, they wanted to make sure that everything was done right and to a level that was deserving of a treasured family heirloom.

Well, that’s where Jason Noble and his crew at Fat Fender Garage came in. As the name of his shop implies, Jason is no stranger to F-Series trucks—especially ones that turn heads—and he happened to be local to the Mulqueen family, so it definitely couldn’t hurt to just stop by and see what FFG could do for the Sharma’s Ford. After a detailed consultation, Sharma and Jason had a game plan (and budget) on paper, and the old F-100 was dropped off for some FFG magic.

The foundation of the truck is a TCI air-ride chassis, which Keith had previously bought for Sharma for her birthday. Wait, what? Spouses, take note! Anyway, with the complete rolling chassis finished off with the addition of a 2019 Gen 3 5.0L Coyote engine and 10-speed 10R80 transmission, the Fat Fender crew was able to focus on the body, massaging each panel to perfection before the custom-mixed green pearl BASF paint was applied. Rather than go with standard chrome or painted trim, pieces such as the grille and FFG billet door handles were finished with Cerakote.

Interior appointments were kept simple and elegant, but they include everything expected of a truck that was built to drive anywhere in comfort. Restomod Air climate control, a Focal audio system, Dakota Digital RTX Retrotech gauges, and a Sparc steering wheel just in front of the white leather bench seat give Sharma everything she needs, whether driving to a local show or across Arizona.

Everything began with the simplest of intentions: Get the truck back on the road, with Sharma’s son Declan eventually getting the keys as long as he put in some sweat equity

The best was saved for last: Right before Sharma was scheduled to pick up the truck from Fat Fender Garage, the fresh 20-inch Schott Drift wheels and Sumitomo tires were bolted on over the Wilwood brakes—an amazing finishing touch that complemented the rest of the F-100 brilliantly.

So you may have noticed by the title of the story that the truck is named “Blue Thunder,” and you would be right to wonder why the heck that is. After all, the truck is very much green! The answer is simple enough: the truck was Ford Waterfall Blue for the better part of seven decades, and so that’s what the family has always called it, and that’s what they’ll continue to call it for generations to come!

OWNER

Sharma Mulqueen

CHASSIS & SUSPENSION

WHEELS & TIRES

ENGINE & DRIVETRAIN

BODY & PAINT

INTERIOR & STEREO

From Sept. 21-23, 2023, the Sevierville Convention Center in Tennessee became a haven for Ford enthusiasts as it played host to the 46th F-100 Supernationals and All Ford Show. Under the new management of the Blackwell Brothers, this year’s edition unveiled innovative changes, making the show grander than before.

A notable shift was observed in the division of the 1967-1972 truck class due to an overwhelming 170 trucks in last year’s event. The division now recognizes trucks from 1967-1969 separately from those from 1970-1972. Another significant introduction was the recognition of four “Patina” classes.

The much-anticipated F-100 Takeover “Night Out” event marked its debut this year, treating participants to a delightful evening at the Hard Rock Café followed by a scenic cruise. The raffle of a roaring 351W performance-built engine became an instant highlight, with a lucky couple from Kentucky clinching the prize.

This year’s event surpassed previous records with 560 registered trucks and a few cars, marking the highest attendance at this venue. The swap meet doubled in size, and an estimated crowd of 6,000 relished the three-day spectacle. A single truck club’s contribution? Over 60 trucks!

Blessed with splendid weather, the event felt less like a truck show and more like a vast family gathering. With the bar set high, plans for next year’s show are already in motion, promising even more enhancements.

It’s 1973, and President Richard Milhous Nixon is reelected to a second term and suspends offensive action in North Vietnam, ultimately ending the U.S.’s involvement in the Vietnam War. It wouldn’t be long, however, until he is caught in the middle of the infamous Watergate scandal. His presidency would be cut short the following year when he is impeached and removed from office.

In the musical world, DJ Kool Herc introduces hip hop to the world from Sedgwick Ave. in the Bronx. Elvis Presley’s popularity holds steady, with his televised concert in Hawaii attracting more viewers than the Apollo moon landings, though the event is censored in communist Eastern Bloc countries. Meanwhile, The Godfather wins an Academy Award for Best Picture, but horse head aside, it’s The Exorcist that disturbs audiences like no film before it with the most disgusting display of pea soup to date.

Federal Express begins operations, delivering 186 packages on its inaugural day. We’re guessing that the number of packages they were supposed to deliver was much higher. On a broader scope, rising inflation and the oil crisis take their toll on the economy in big ways, causing layoffs in associated industries.

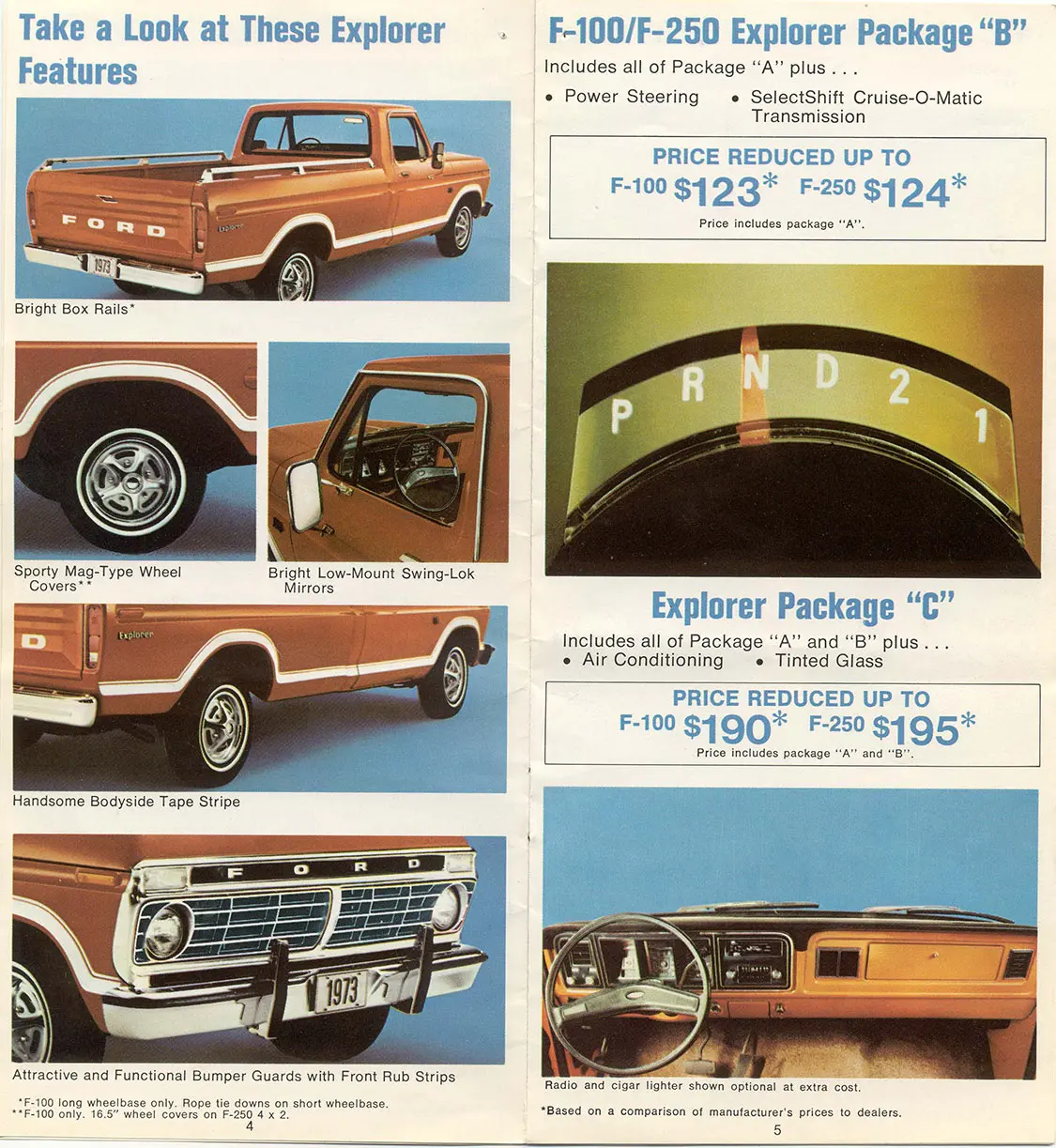

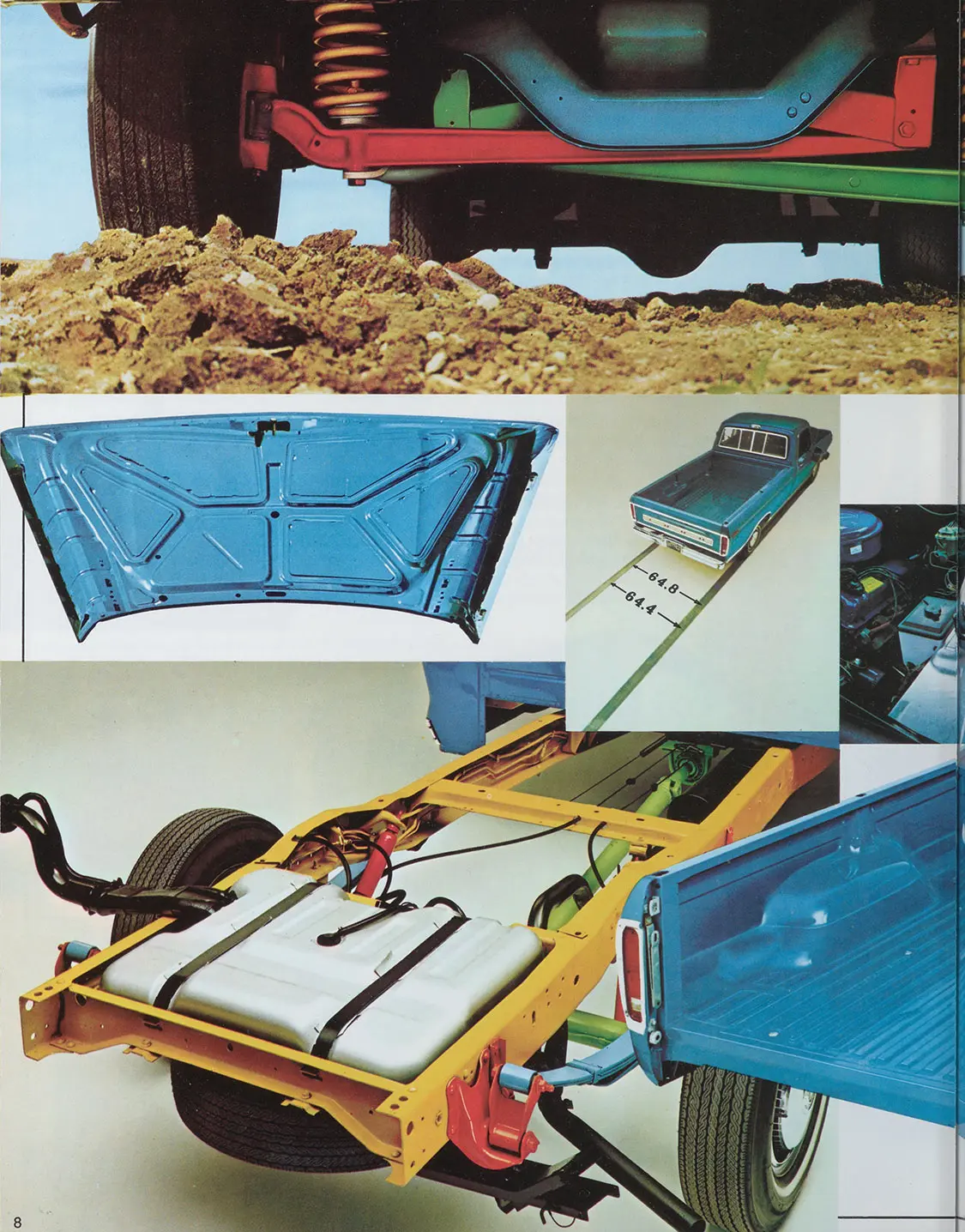

For Ford trucks, this would also be a year of change. The redesigned F-Series would go through a series of updates and would be the last generation to be based on the 1965 chassis design, although it now rode on a longer wheelbase.

The new F-Series was not as drastic a change as with generations before it, but it was definitely a fresh take on Ford’s popular pickup line, especially with the addition of the crew cab. The dramatic beltline was inverted, or “dented,” to juxtapose against the previous “bump” in the sheetmetal, and surrounding sheetmetal was resculpted, with galvanized steel being used in key places to reduce corrosion. Curved side glass was a new feature, as was slightly tilted rear glass (to minimize rearview reflections at night).

The redesigned F-Series would go through a series of updates and would be the last generation to be based on the 1965 chassis design, although it now rode on a longer wheelbase.

Inside, A/C vents were now an integrated part of the dashboard assembly instead of under-dash add-ons, and there was now room for a larger glovebox thanks to the heater blower being relocated to the engine compartment. Another major change was that the fuel tank was now located under the truck instead of inside the cab.

Two-wheel drive trucks now also came standard with disc brakes, and the rear axle was widened a total of 4 inches to more closely match the front track width. The ’73 model year also saw the introduction of the F-350 V-8, which featured a longer wheelbase and heavier duty suspension. A variation for the F-350, the “Super Camper Special,” added provisions for slide-in campers.

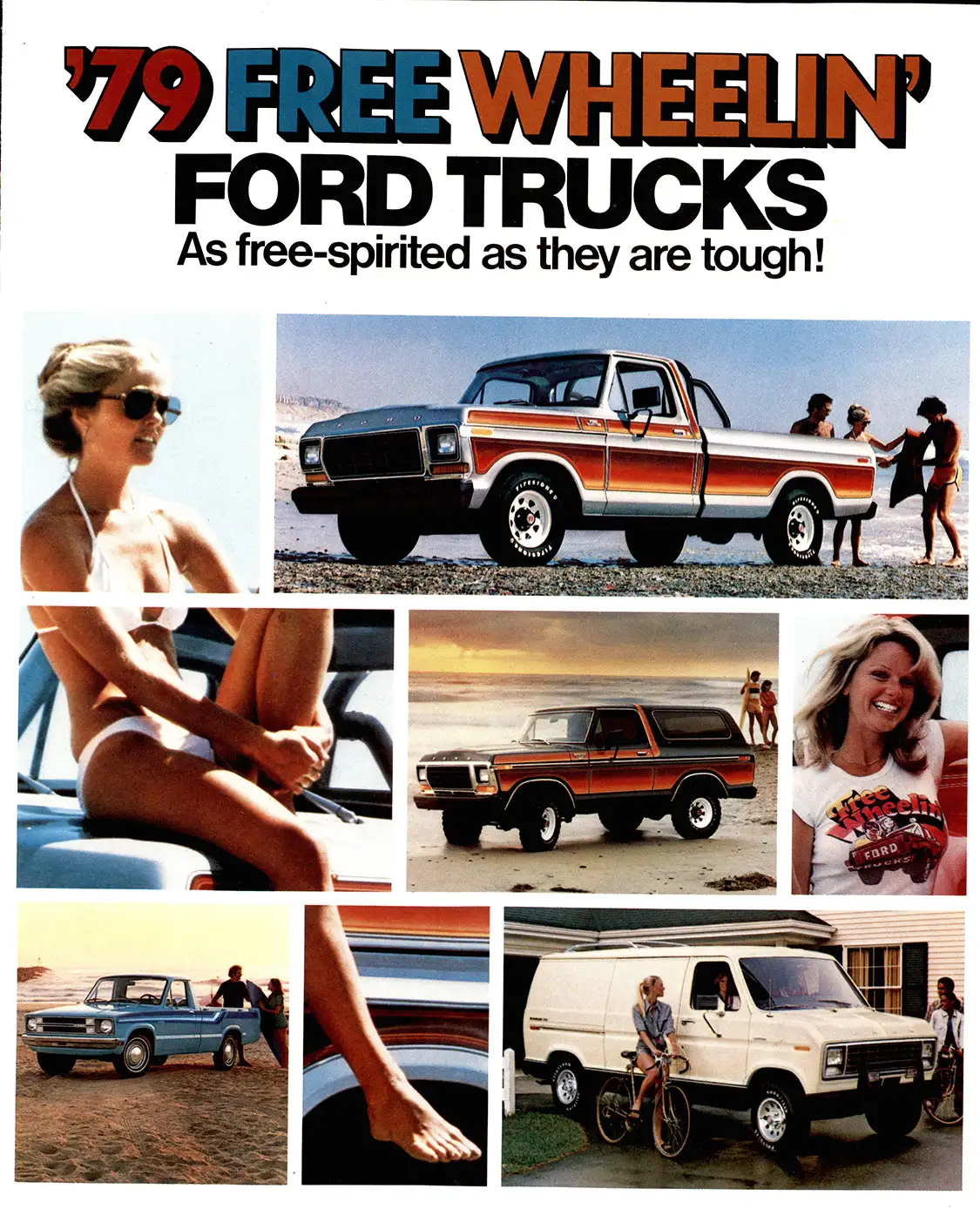

The year 1974 was a big one as well, with the SuperCab (extended cab) F-Series hitting the market, and the ’75 model year trucks could be had as a heavier, heavy-duty F-150.

As emissions laws become more stringent, the F-150 put itself in a different weight class, which eased certain restrictions that were mandated on lighter duty F-100s.

All years of the F-Series, up until the ’77 model year, could be had with the 240 or 300 cubic-inch inline sixes, the 302 V-8 Windsor, a 360 or 390 FE V-8, or the large 460 385-series V-8. Choices for ’77-’79 models consisted of the 300 CID I-6, the 302 Windsor, the 351M V-8, 460 385-series V-8, or the 400 CID V-8.

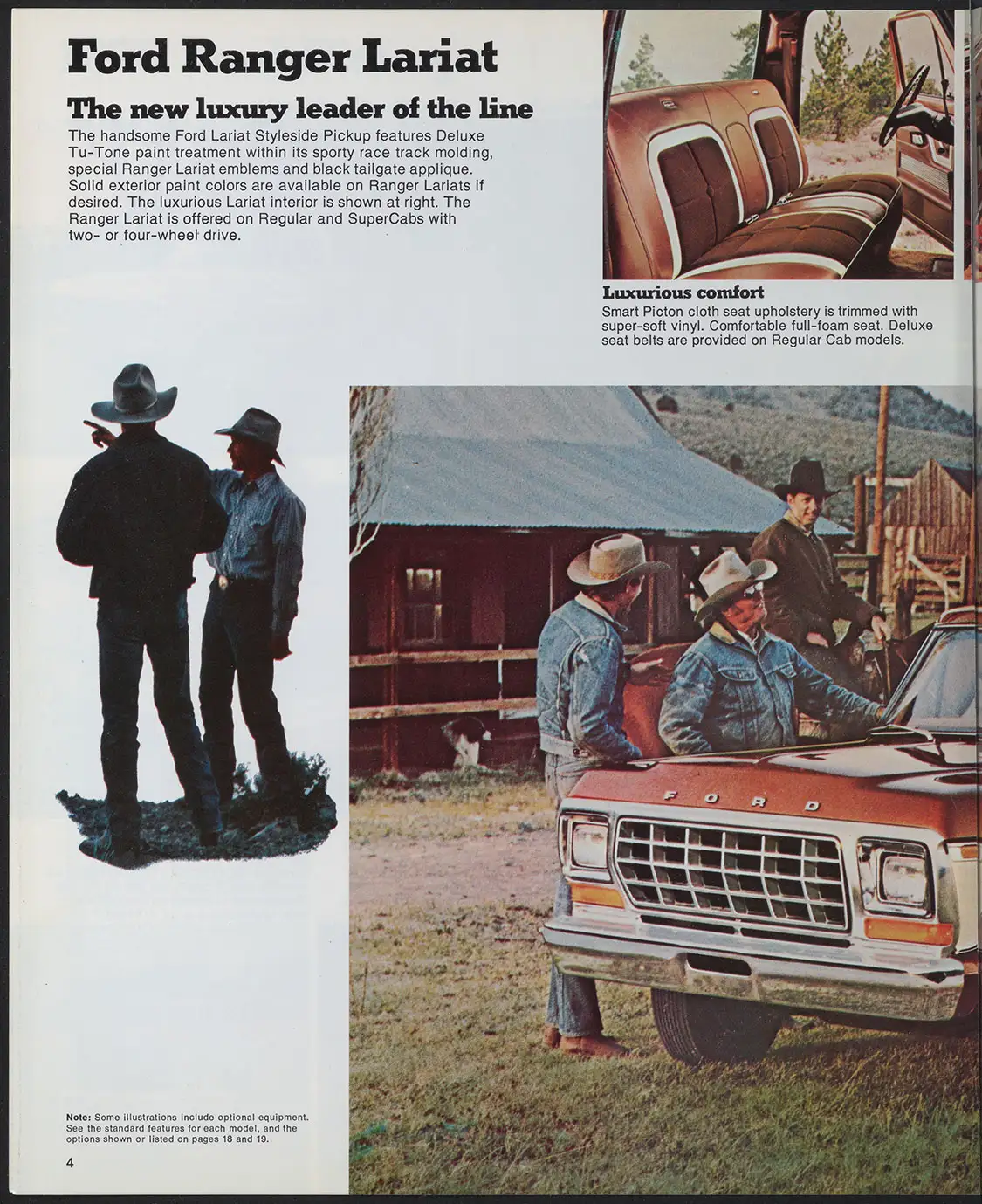

When the ’76 models arrived at dealerships, they featured an updated grille, while ’77s received even more exterior trim updates. Completely redesigned grilles appeared in 1978, both for the Custom trim and the Ranger/Ranger XLT/Ranger Lariat trim levels, which could now be optioned with rectangular headlights. They became standard for 1979.

Over the course of its run, the “dentside” Ford trucks became more refined, while also becoming much tougher in all the right places, making it a bestseller year after year. And, of course, we love how great they look when given a custom touch!

We hope you’ve enjoyed this series of retrospection on the Ford F-Series over the past few issues of F-100 Builders Guide and we hope to bring more series like this to you in the near future! As always, thanks for the continued support from the Ford Motor Company Archives for providing us with these amazing historical documents and images to share with you!

Over the course of its run, the “dentside” Ford trucks became more refined, while also becoming much tougher in all the right places, making it a bestseller year after year.

This mad contraption is the new Supervan.

The fourth time in the last 50 years that Ford has gone insane (in a very good way) and decided to fit an insane powertrain in the back of a Transit. This time, it produces 2.000 hp and 1.328lb-ft or 1.800 Nm and, you guessed it, it’s fully electric. Enjoy the vidéo

Source: Top Gear Magazine

Admit it. There are times when you’d love to own a vintage car as a daily driver, like a driver-quality 1965-66 First Gen Mustang. But you’re not sure if you could actually live with it, without modern conveniences like air conditioning and cruise control and the reliability and fuel economy of a modern-day car.

And what if you wanted something a little more “vintage,” like a car that you remember from a now-distant childhood, a 1954-59 full-size Ford, for instance. That crossed the mind of Southern Californian Gary Richards, who during the last 15 years, has built seven such hybrids, including this ’56 Ford Crown Victoria coupe.

Richards grew up in the Midwest—the St. Louis area to be exact—and still has ties to the area. After serving a stint in the Army from 1963 to 1965, he entered the workforce as a mechanic for a number of Ford dealers in Missouri before moving to the Golden State in 1975. In California, he worked for Peterbuilt and a succession of Ford dealers that included Corwin Ford in Orange and Citrus Motors in Ontario. In 1996, he started working on his passion for vintage cars, focusing his attention on 1954-59 full-size Fords and Mercurys, replacing tired drivetrains with modern Ford OHV SOHC and DOHC V-8 and four-speed overdrive automatic transmissions.

The very first was a ’55 Ford Customline (see sidebar, pg. 80), which was his daily driver for many years before he sold it to a ’50s Ford enthusiast back in Missouri. This first in a series, which now includes seven completed builds since 1998, served as his proof of concept.

When Richards first embarked on this modernization program, he concentrated locating his donor cars from insurance auctions. While Ford Crown Victorias are more plentiful, Richards believes that Mercurys, and especially Lincoln Continental Mark VIIs, make the best donor cars. “I look for the kinds of cars that have been in rear and side-impact crashes,” says Richards. “Then I look at interior condition, which gives a good indication on how well the previous owner took care of the car. While mileage can be important, the ‘grandma car’ factor really is so much more important.”

Richards noted that when he started doing these conversions back in the late ’90s, these donor cars were plentiful at auctions, not so today. “I’ve turned to venues like Craigslist,” says Richards. “Lincoln hasn’t built a Mark Seven since nineteen ninety-two, and the Mark Sevens are among my favorites as a choice for a donor vehicle. The Mark Sevens are equipped with their own version of the Mustang’s five point zero HO motor and can be installed in any nineteen fifty-four to nineteen fifty-nine Ford with far less difficulty than the modular motors that followed. And if the climate control or the air suspension systems give out, often they are sent to the boneyard prematurely.”

Since the Customline, Richards has built the following cars. All are equipped with Ford’s four-speed automatic overdrive transmissions and a variety of aftermarket air conditioning systems. Most were also equipped with power steering and cruise control. Some have braking systems updated with front disc brakes.

When asked to bullet point what he looks for in a donor car, Richards listed these qualities.

Surprisingly, overall mileage doesn’t often factor into his purchase decisions, since there are many cars available with fewer than 100,000 miles on the clock. He would rather have a high-mileage car that has been well maintained than a low-mileage car that shows signs of abuse.

From the list of cars Richards has built, many Ford products are suitable, including the more sophisticated 4.6L modular motor cars, but he’s found that the 5L HO-motor-equipped Lincoln Mark VIIs usually make the best donor cars. The later modular motors are wider and are best suited to the 1957-59 cars, which have a wider engine compartment than the pre-1957 cars.