Commuting can really wear a person out. Day in and day out, putting in miles to and from work, driving around town to errands, then back home just to repeat it all again the next day. What could make all those things worse you ask? Paying for the gas it takes to do it all, especially when you happen to be purchasing that gas in California. Standard gas is over $5.00 a gallon right now in the Golden State, so any commute can become an expensive way to live. These are some of the biggest reasons that Peter Tran decided to buy his Tesla Model 3. Being able to cut gas prices completely out of his equation, it really helped out in his daily life.

Peter, like most of us, does not want to drive a car that blends in with the rest of the world. He wanted different, special, and one of a kind. He did not want to own just another Tesla in a California parking lot.

However, Peter, like most of us, does not want to drive a car that blends in with the rest of the world. He wanted different, special, and one of a kind. He did not want to own just another Tesla in a California parking lot.

How can someone achieve that you ask? Well, let us explain the process it took to stand out from the crowd. Let’s start with the ride height. No one likes wheel gap. There is a reason you do not see any Tesla’s rolling around on 33×12-inch billets, so on the ground is the only way to do it.

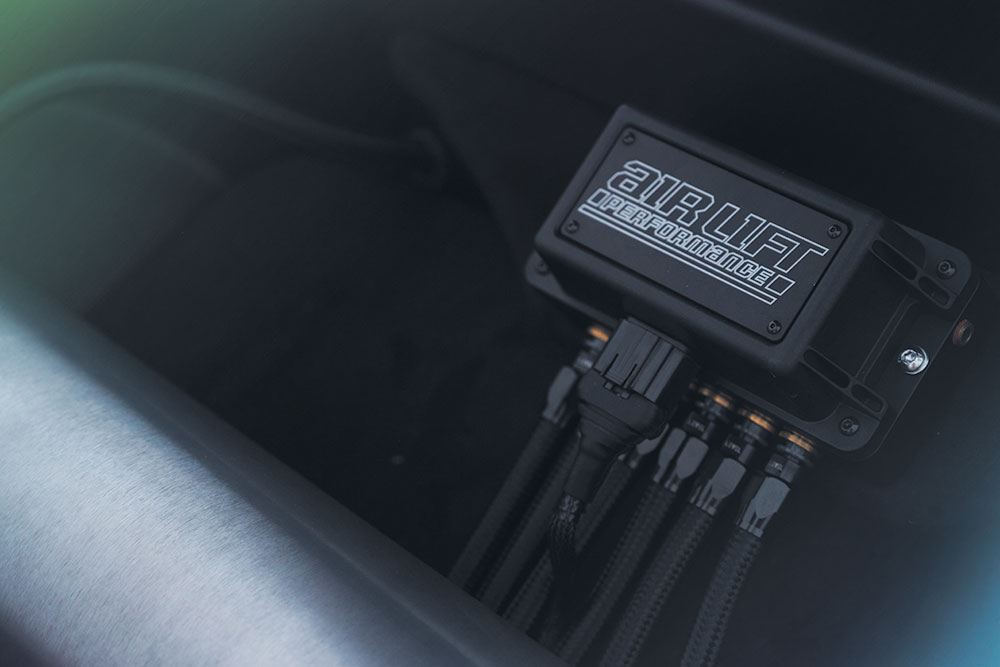

Very few people take enjoyment in the stress of driving low on coilovers. The static-height scraping, front-lip destroying rough ride, and considerable stress that can come with it, was not for Peter, so bags were the way to go. Getting a full Airlift suspension kit front to back, as well as Airlift 3H air management for controlling it all provided all the ease of use a driver could ask for from a modified car. From the smooth ride it provides to height presets and monitoring his corner to corner PSI, it was the only choice as far as he was concerned.

Now for the other details of the exterior. To make sure it never looks stock, first up for installation was a full Vorsteiner body kit. This kit gives a little extra attitude and flare to just about every side and corner of the whole car, really “sports” it up also for lack of a better term.

As seen in the shoot in front of you, Peter’s Tesla was fully wrapped in a color named Super Gloss Metallic Midnight Gold. There is a lot of depth to the color and depending on the time of day or even shadows, the car can look very different angle to angle.

When asked if he has advice for people who may want to try and replicate a build like is, he said this, “Buy nice or buy twice.” (and we could not agree more!)

There was no stopping there though. To finish setting off that look, a staggered set of aggressive spec RSV Forged 20-inch wheels were fitted and aligned into place. The staggered depths and custom offsets provided perfect fitment while driving or when laid out flat.

There are a few more changes to this Model 3, but we will let you try and spot them and consult the tech sheet if you cannot track them down yourself. When asked if he has advice for people who may want to try and replicate a build like is, Peter said this: “Buy nice or buy twice.” (and we could not agree more!)

Peter wants to give a special shout out to his sponsors: Rad Rides, Airlift, Adams Polish, RSV Forged, VIP Modular, ESD, Levvel Air, Mai Mobile Tint, and 1Clear Bra.

Peter already has some other builds in the works, EV and gas powered, so keep your eyes peeled to our various publications and you may just run into a few of the others sooner than you think!

Peter Tran

Motor / Drivetrain

Chassis/Suspension

Wheels, Tires & Brakes

Body/Paint

Interior

Thew’s a new Goodwood Hill RECORD. After 23 years Nick Heidfeld’s Timed Shootout record in the McLaren MP4/13 has been broken. F1 and IndyCar star Max Chilton’s new 39.08 second run in the incredible McMurtry Speirling fan car has knocked over two seconds off that time. It’s also taken the Outright Hill record from the Volkswagen ID.R. Romain Dumas’ time of 39.9 seconds was smashed earlier in the day in practice, and a further 0.1 seconds in the Timed Shootout.

Is this the best Goodwood run you’ve ever seen?

The Future of Motorsport Power presented by DHL #FOS #Goodwoodrecord #McMurtry #gw_dhl

Official Website ? http://www.goodwood.com/grr/

Facebook ? http://www.facebook.com/goodwoodrrc

Instagram ? http://www.instagram.com/goodwoodrrc/

Twitter ? http://www.twitter.com/goodwoodrrc

SUBSCRIBE for more racing cars, supercars, new car reviews, historic motorsport and Goodwood event coverage ? http://bit.ly/GoodwoodTV

Buy your Goodwood Event tickets ? http://bit.ly/GWBuyTickets

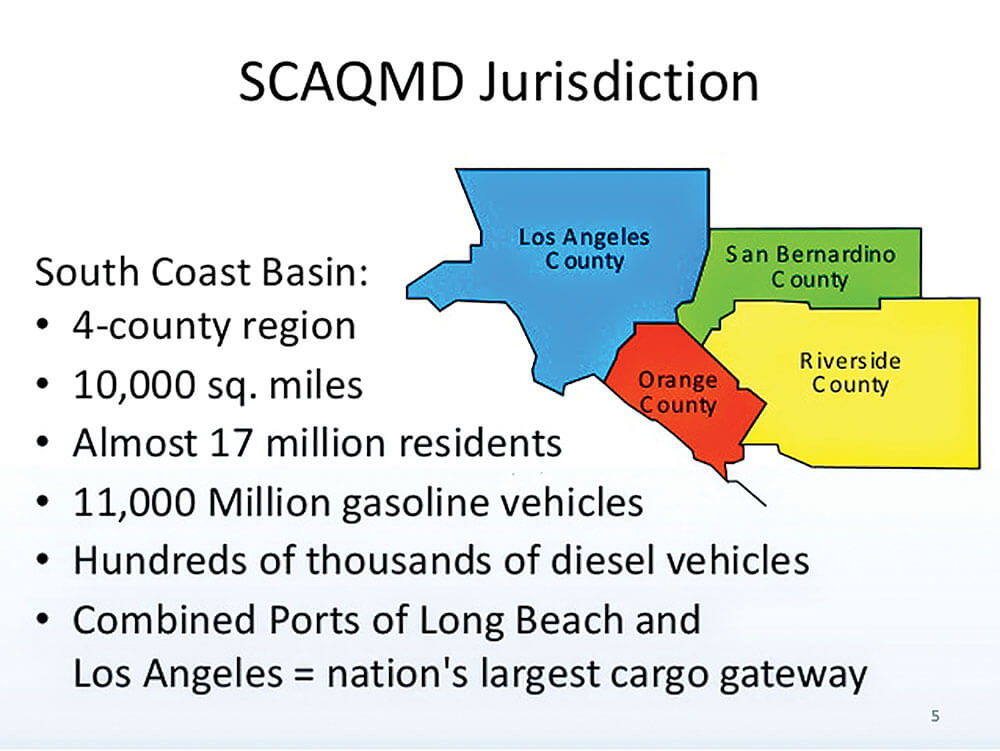

The Holley High Voltage Experience debuted at Sonoma Raceway in Northern California. The location proved especially fitting given its proximity to California’s capital, Sacramento, where the state’s laws are passed. As most everyone knows, California is especially stringent when it comes to emissions laws, but EV swaps offer additional hope to California performance enthusiasts. Since EVs have zero tailpipe emissions, they are exempt from smog testing, meaning that it’s now possible to EV swap your ride and have it exempted from future tests.

Teslas dominated the first-ever event from a numbers standpoint, but that was to be expected considering Northern California is Tesla’s home turf. Unlike events featuring internal combustion engines, Holley’s High Voltage Experience was relatively quiet. Between the occasional gusts of wind, one could hear the screeching of tires and, of course, the whir of electric motors. As someone who is accustomed to electric vehicles, it’s still wild to see cars going fast without the noises normally associated with speed!

The rad thing about being on the ground floor of the EV explosion is that there’s a lot of ingenuity going on at this stage of the industry’s development. An eclectic array of motor setups were present at the event, with plenty of direct drive and transmission-driven vehicles to check out and steal ideas from. And, everyone at the event was more than happy to discuss everything electric and tips for building your own electric vehicle.

Of course, what everyone really came to see was the action, and you could also participate if you wanted to! From road course racing to drifting and even some off-road shenanigans, you could find plenty of ways to have fun, and thankfully plenty of charging stations were available to top off your batteries between sessions.

In addition to Holley, several well-known electric builders and shops were present to show off their talent. Salvage 2 Savage, Rich Rebuilds, and even Bisi Ezerioha of Bisimoto was there with his insane Porsche 935 K3V widebody/slantnose beast. Even Ford Performance was in attendance, racing its Cobra Jet 1400 Mustang on the drag strip and displaying its F-100 Eluminator pickup. Not to be outdone, Current Technology brought out its insane EV dragster to lay down some rubber on the strip.

The Holley High Voltage Experience was an impressive event to attend, and it’s obvious that the next one will be even bigger. We’d suggest going to www.holleyhighvoltage.com now and scooping up some tickets for Round 2, which is taking place on July 9-10. Tickets will only be sold online, so go get yours today!

Of course, what everyone really came to see was the action, and you could also participate if you wanted to! From road course racing to drifting and even some off-road shenanigans, you could find plenty of ways to have fun…

When: July 9-10

Where: Sonoma Raceway, Northern California

Cost: $25/day; $20/day active military discount; kids 16 and under free

Info and Tickets: www.holleyhighvoltage.com

Have an EV you’d like to test on the track? Sign up your vehicle for one of these events!

Check out www.holleyhighvoltage.com for more information.

We added a Leveling Kit to the all new 2022 Ford F-150 Lightning! In addition to that we added a set of 34″ Nitto Ridge Grappler tires and Black Rhino Wheels! The F-150 Lightning has a completely different suspension compared to a normal F-150. However we noticed that the front struts are very similar to the 2022 F-150 with an Internal Combustion Engine. The ReadyLift Leveling kit fits on the Ford F-150 Lightning!

Leveling Kit – https://www.readylift.com/2-0-leveling-kit-ford-f-150-2021.html

“This is Town and Country TV! We’re just a bunch of “car guys” who started this channel over twelve years ago as a way to showcase awesome vehicles and teach people the correct way to customize them. We are passionate about all makes and models and love providing our viewers with honest reviews and virtual test drives. Make sure to subscribe to our channel! You will be glad you did!”

When Rob Ward of Gilbert, Arizona, decided he needed a new toy, he decided to do something really different. Turning a classic heavy sled of American power and steel into a green, efficient, battery powered vehicle is just about as different as you can be! The choice for Rob was a 1966 Cadillac De Ville. This body of De Ville was built from 1965-1968, and most were featured with a 429 cubic inch, 7.0-liter V-8, weighing in at a stout 4,534 pounds. Crazy that back then, you got all that style, size, and power for around $5,500 fully loaded, right?

Well, as you can assume, that’s a little bit less than Rob has invested into his redesigned Cadillac, affectionately dubbed “dEVille”. Mr. Ward is the CEO and founder of a company named Legacy EV, and so he thought, why not practice what he preaches when it comes to the drivetrain? (While we have not actually confirmed this with him… surely there is a way he could write this off on his taxes as a business expense, right?? A promotional/display car for his company’s products and services sounds logical to us. For your sake Rob, we hope you wrote this off on your taxes. Either way, we are very happy you built it.) In just an eight-month time span, Rob and his crew fulfilled his vision for the once gas guzzling Cadillac to now have an updated and fully battery powered drivetrain.

As you can see, this modern twist on the Cadillac has not been completely forced into the future, which we love. Retaining almost all the era’s original and correct looks from the interior of the car to the body, it is truly the best of both worlds, old and new. From the custom door panels with an updated stereo to the subtle LED headlights and taillights, the Legacy EV team played it pretty cool with any changes they made to the naked eye.

The all-red interior and matching convertible top ties perfectly into the custom-made engine cover, as well as also contrasting beautifully with the Bright White paint laid down by Burges Customs. One of the wild things people do not always remember with EV cars is the weight that comes along with their batteries and motors. Building the De Ville in this manner was probably the only way possible to make this car even heavier than it was originally built, but now it has no footprint verses the gas and oil consumption beast it was before the swap.

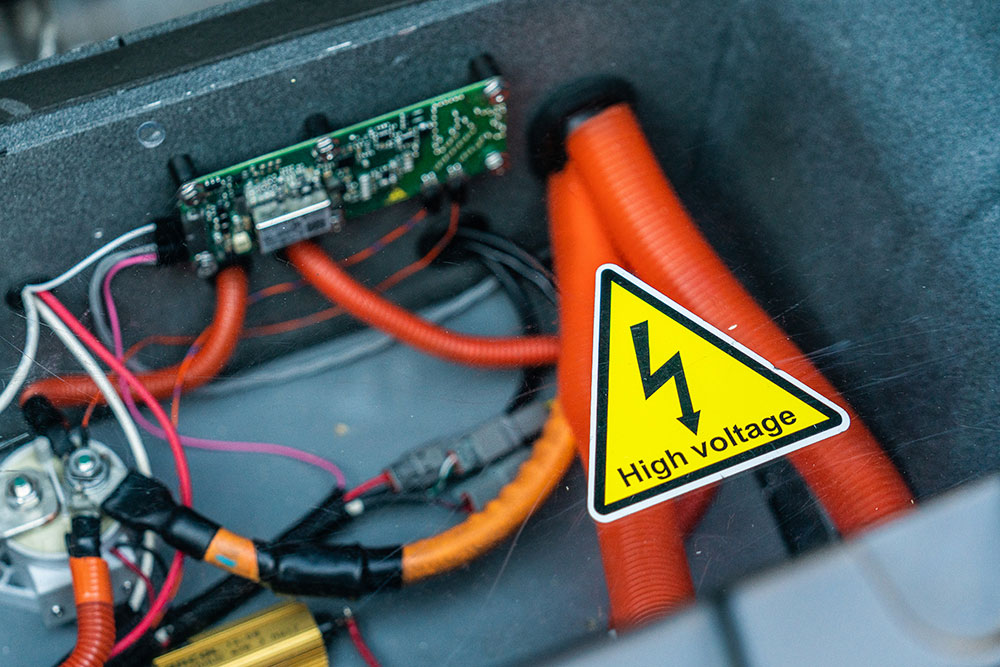

One of the biggest struggles in not only this EV build, but most EV builds, is space (and we are not talking about how to pull an Elon and launch your EV into outer space). We are talking space for batteries, space for the motor (or in this case three motors), and the logistics of fitting all of these things into spaces that were not originally built for them.

…all the weight and power needs to find a healthy balance to distribute it properly for the most efficient, and the most fun, you can have with your finished project.

Luckily, this is a Cadillac, so the engine bay, trunk, and car in general are built with an excess of extra room for the parts it was originally created with. Initially, Rob and his team were pretty concerned with these challenges. However, as things came together, the issues began to fade away and parts fell into place.

When asked what some of the biggest lessons Rob and his team learned during the Eville De Ville build were, this is what he said: “As a team we learned more about how to properly weight a vehicle during this build.”

Which makes a lot of sense, because all the weight and power needs to find a healthy balance to distribute it properly for the most efficient, and the most fun, you can have with your finished project.

Owner

Rob Ward

Motor / Drivetrain

Chassis/Suspension

Wheels, Tires & Brakes

Body/Paint

Interior

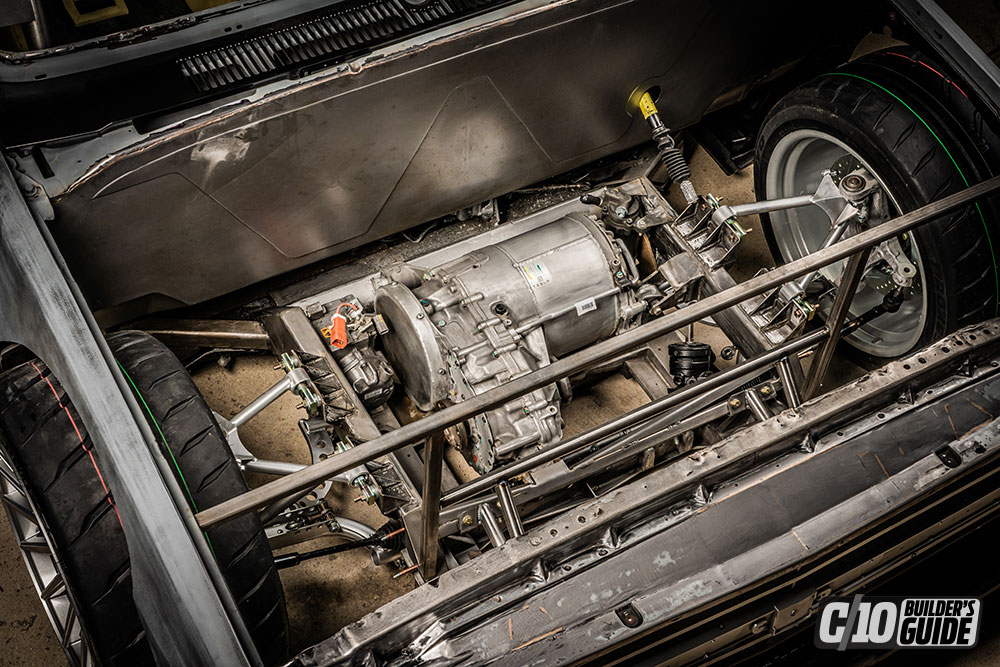

In a scene dominated by LS engine swaps, the C10 community is faced with very few motor upgrades that receive commanding attention, though the tried-and-true 350 or something along the lines of an LT mill are readily available and reliable. Of course, there are other alternatives to these selections, but one particular path has been disregarded as a legitimate source for power and torque—electric!  That’s right. It is possible to build and drive a C10 without a gas-guzzling engine underneath the hood. All we needed was for someone to come out and prove to us that assembling the parts and fabricating the install is feasible, even though the entire process may still sound as foreign as building a spacecraft. But have no fear, and wait to cast any and all doubts until after you take a good look at what has been made possible in the wonderful world of custom pickup trucks.

That’s right. It is possible to build and drive a C10 without a gas-guzzling engine underneath the hood. All we needed was for someone to come out and prove to us that assembling the parts and fabricating the install is feasible, even though the entire process may still sound as foreign as building a spacecraft. But have no fear, and wait to cast any and all doubts until after you take a good look at what has been made possible in the wonderful world of custom pickup trucks.  Robert Ward is a car guy through and through, and while he can appreciate the magical scent of high-octane gasoline, he also appreciates the fact that the appeal of electric vehicles is still not far off on the distant horizon—it’s here now. Consumers are ready to climb aboard the next phase of transportation as seen in the rise of non-gas vehicles such as Tesla and other offerings from major auto manufacturers, and what Robert hopes is that builders and customizers will be the next ones to hop on the trend as well. But hopes and dreams aren’t all he is banking on. Robert has gone all-in as CEO of Legacy EV, a distribution company that specializes in converting gasoline-powered cars and trucks into modern electric vehicles. And to get the show started, he has set out to create an all-electric, show-worthy Chevy C10 that operates just as smooth as it looks.

Robert Ward is a car guy through and through, and while he can appreciate the magical scent of high-octane gasoline, he also appreciates the fact that the appeal of electric vehicles is still not far off on the distant horizon—it’s here now. Consumers are ready to climb aboard the next phase of transportation as seen in the rise of non-gas vehicles such as Tesla and other offerings from major auto manufacturers, and what Robert hopes is that builders and customizers will be the next ones to hop on the trend as well. But hopes and dreams aren’t all he is banking on. Robert has gone all-in as CEO of Legacy EV, a distribution company that specializes in converting gasoline-powered cars and trucks into modern electric vehicles. And to get the show started, he has set out to create an all-electric, show-worthy Chevy C10 that operates just as smooth as it looks.  “This truck here is one of the first of its kind,” he said. “It runs on two motors and has instant torque from 0 RPM. It’s a blast to drive and proves that that electric vehicles aren’t all slow-moving and boring.” Robert will be the first to admit that putting together all the individual components for an electric motor swap can be tedious and is one of the sole reasons a lot of builders haven’t flocked to this route yet. To alleviate some of the headache that goes into a job of this nature, Legacy EV is now able to take all the guesswork out of the equation—and it’s because of the success of this C10 project that this level of assurance is possible.

“This truck here is one of the first of its kind,” he said. “It runs on two motors and has instant torque from 0 RPM. It’s a blast to drive and proves that that electric vehicles aren’t all slow-moving and boring.” Robert will be the first to admit that putting together all the individual components for an electric motor swap can be tedious and is one of the sole reasons a lot of builders haven’t flocked to this route yet. To alleviate some of the headache that goes into a job of this nature, Legacy EV is now able to take all the guesswork out of the equation—and it’s because of the success of this C10 project that this level of assurance is possible.  “We have a full support team of expert engineers that has helped get our mission rolling,” Robert said. “We’ve gone through the process and know what is needed to mount the electric motors and how to get the gearing right. Actually, the conversion is a lot less work than you’d think, as it gets rid of about 3,000 existing components and then only installing about 36 electric ones.”

“We have a full support team of expert engineers that has helped get our mission rolling,” Robert said. “We’ve gone through the process and know what is needed to mount the electric motors and how to get the gearing right. Actually, the conversion is a lot less work than you’d think, as it gets rid of about 3,000 existing components and then only installing about 36 electric ones.”  To get the non-gas-powered ball rolling, Robert brought the C10 to Ridgefield, Washington, where his other venture, Old Town Auto, is located. OTA is a full fabrication and restoration shop that Robert oversees, which made for a smooth ride during the course of the electric C10 build. It was there that the majority of the work was done to the ‘ol Chevy. From the engine conversion to the air-ride suspension, interior, and body and paintwork—it was mostly all done in-house.

To get the non-gas-powered ball rolling, Robert brought the C10 to Ridgefield, Washington, where his other venture, Old Town Auto, is located. OTA is a full fabrication and restoration shop that Robert oversees, which made for a smooth ride during the course of the electric C10 build. It was there that the majority of the work was done to the ‘ol Chevy. From the engine conversion to the air-ride suspension, interior, and body and paintwork—it was mostly all done in-house.  Now, the first thing that sends folks for a loop with the electric motor conversion is the engine bay. It currently sits empty and has been carpeted and finished to serve as a trunk. The components that power the truck now take up residence underneath the custom flush-fit fiberglass bed cover. The concept is different, we will say that about the conversion, but it works, and that’s all that matters.

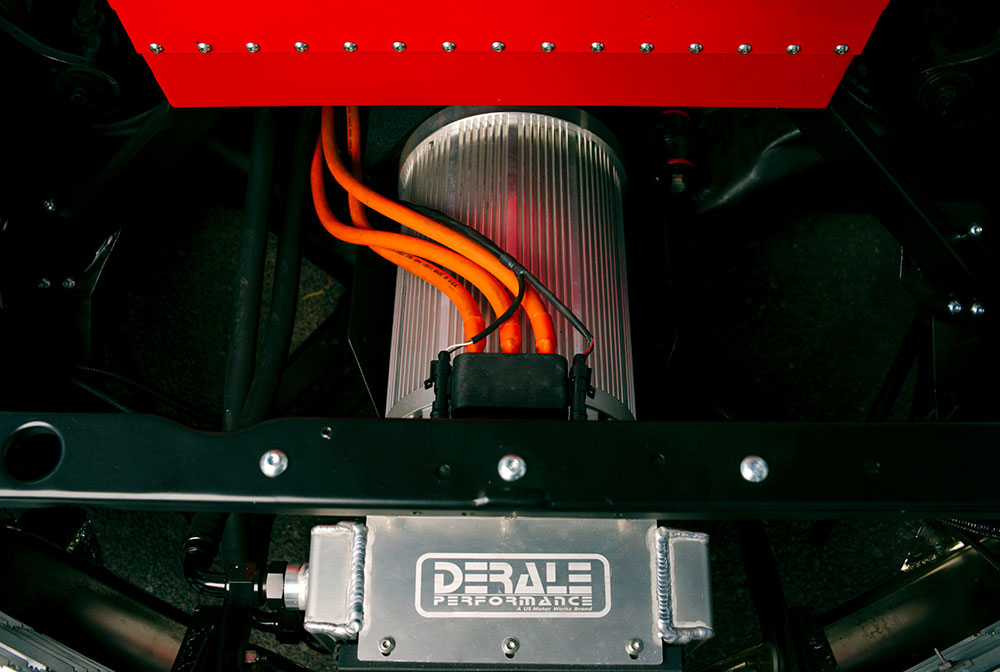

Now, the first thing that sends folks for a loop with the electric motor conversion is the engine bay. It currently sits empty and has been carpeted and finished to serve as a trunk. The components that power the truck now take up residence underneath the custom flush-fit fiberglass bed cover. The concept is different, we will say that about the conversion, but it works, and that’s all that matters.  This ’71 C10 is powered by two 2020 NetGain 3-phase electric motors, complete with a Legacy EV 3.1 kit to make the conversion possible. While this information might not mean much to many people out there at the moment, hopefully it will start to hold more value and actually click to more customizers out in the field. The LS1 wave took time to build into what it is today, and in some respect, Robert is hoping the same will happen with the rollout of easily accessible electric setups.

This ’71 C10 is powered by two 2020 NetGain 3-phase electric motors, complete with a Legacy EV 3.1 kit to make the conversion possible. While this information might not mean much to many people out there at the moment, hopefully it will start to hold more value and actually click to more customizers out in the field. The LS1 wave took time to build into what it is today, and in some respect, Robert is hoping the same will happen with the rollout of easily accessible electric setups.  These types of systems have come a long way, and there are still plenty more variables to work out based on the many specific needs from individual builders. Robert’s truck isn’t currently outfitted with an air conditioning system, but it can be done, so he might add it later on down the line since he’ll be making the permanent move down to Arizona where Legacy’s HQ is located. AWD is a question that he gets asked about quite often, and that can be accomplished with the addition of a third motor. And while electric motors generally run almost silently, enthusiasts who are used to the rumble of heavily modified combustion engines may feel like something vital is missing. Even though this C10 is able to roast tires like a beast, it is a different type of beast that needs some time for truck fans to understand what it is, and what it isn’t, and Robert fully acknowledges that.

These types of systems have come a long way, and there are still plenty more variables to work out based on the many specific needs from individual builders. Robert’s truck isn’t currently outfitted with an air conditioning system, but it can be done, so he might add it later on down the line since he’ll be making the permanent move down to Arizona where Legacy’s HQ is located. AWD is a question that he gets asked about quite often, and that can be accomplished with the addition of a third motor. And while electric motors generally run almost silently, enthusiasts who are used to the rumble of heavily modified combustion engines may feel like something vital is missing. Even though this C10 is able to roast tires like a beast, it is a different type of beast that needs some time for truck fans to understand what it is, and what it isn’t, and Robert fully acknowledges that.  Even though Robert and his team can boast about being one of the first in the C10 community to successfully pull off a full-electric motor conversion, there are other underlying reasons that fueled the project. Legacy EV’s mission statement plainly encourages honoring the past while protecting the future, which directly translates to equating an electric-powered vehicle, new or retrofitted, to a sustainable, climate-friendly necessity. To help others get there easier with their car or truck of choice, Legacy offers their expertise in selecting and delivering the correct components required for a complete conversion during one conversation, rather than having to spending months acquiring piece by piece from different sources that may or not jive well together.

Even though Robert and his team can boast about being one of the first in the C10 community to successfully pull off a full-electric motor conversion, there are other underlying reasons that fueled the project. Legacy EV’s mission statement plainly encourages honoring the past while protecting the future, which directly translates to equating an electric-powered vehicle, new or retrofitted, to a sustainable, climate-friendly necessity. To help others get there easier with their car or truck of choice, Legacy offers their expertise in selecting and delivering the correct components required for a complete conversion during one conversation, rather than having to spending months acquiring piece by piece from different sources that may or not jive well together.  “We understand that there are enthusiasts out there who have been trying to convert vehicles over to electric but have been discouraged by one thing or another, but we’re here to turn that around,” Robert said. From parts, support and all-important peace of mind, Robert, along with the rest of the Legacy and Old Town Auto teams are looking to play a crucial role in developing the new wave of custom EV builders. There is an alternative solution to fuel that works, and while the demand may not be overwhelming at this very moment, all trends in the industry point to things picking up sooner rather than later.

“We understand that there are enthusiasts out there who have been trying to convert vehicles over to electric but have been discouraged by one thing or another, but we’re here to turn that around,” Robert said. From parts, support and all-important peace of mind, Robert, along with the rest of the Legacy and Old Town Auto teams are looking to play a crucial role in developing the new wave of custom EV builders. There is an alternative solution to fuel that works, and while the demand may not be overwhelming at this very moment, all trends in the industry point to things picking up sooner rather than later.

OWNER Robert Ward Legacy EV 1971 Chevy C10 Tempe, AZ Engine

Chassis

Wheels, Tires & Brakes

Exterior

Interior

Legacy EV is the market leader in aftermarket EV applications. Legacy offers fully integrated EV systems from top manufacturers, certified EV technician training programs, and EV design consultation for businesses around the world. With support from Legacy EV, builders around the world are becoming more confident with the transition to Electric Vehicles.

Building a custom Electric Vehicle (EV) doesn’t have to be complicated. Conversions simply require the right components and proper training. The Legacy EV team has developed a growing network of authorized installers around the world through their custom EV training platform. When you buy a kit from Legacy EV you are not only getting the best parts available, but also the best training and build-support from the most experienced EV experts.

As the world transitions to electric powered vehicles, automotive shops now need access to parts and knowledge to build and repair EVs. To that end, Legacy EV developed fully integrated EV conversion kits and established relationships with best manufacturers across the EV industry in order to provide the one stop solution for EV kits, components, and build support to auto shops across the world.

We have resigned to the fact that the EV (Electric Vehicle) is the way of the future, much like the occasional plant-based meat. And just as the odd one of those “better than beef burgers” can actually be better than the original, the next generation of EVs holds infinite promise.

The problem is that some of them have been nothing but promises.

This week, Ford announced a fully EV version of North America’s bestselling vehicle, the F-Series pickup truck. Based on this promotional video, Ford knows how to make trucks look impressive. They did not miss a beat with this one.

So where is the Tesla Cybertruck that promised to revolutionize, well, trucks? It is 550 days since Elon Musk held his Cybertruck press briefing, showing off the next generation’s features and, it seems, bulletproof-ness, of Cybertruck. But in those 550 days, not a single Cybertruck has been built. Not. One.

While the announcement of the Lightning has many fans lauding the emergence of Ford on the EV truck scene, some argue that the better value will be the Cybertruck. They point out that for “only” $70,000 a Fully loaded Cybertruck will get you 500 miles of range and a 0-60 in under 3 seconds, and 14,000 pounds of towing capacity. Conversely, for $90,000 a fully loaded F-150 Lightning has only 300 miles of range, goes from 0-60 in about 4.5 seconds (still seems pretty darn fast to me), and has only 10,000 pounds of towing capacity.

That may very well be accurate, but there is a very large but: The actual starting price for a not-very-loaded Lightning will be right around $40,000, right in the wheelhouse of the American truck buyer. And boy, do we buy trucks.

Ford has done one thing exceptionally well over the years: build cars and trucks. In fact (maybe sit down before you read this fact), Ford F-Series pickup trucks are second only to iPhones in sales. So, we know the Lightning will actually get built.

While Tesla and its legion of followers (“Muskrats” is your author’s preferred descriptive term of choice when their online behavior is less than stellar) are great at promoting the still-fictitious Cybertruck, the Lightning release announcement is garnering reviews like this one, from Input:

“No, we haven’t driven the F-150 Lightning yet, but yes, we’re going to call it one of the most important steps in America’s move to electrification nonetheless. The gas-guzzling F-150 is America’s favorite truck. It has been for more than four decades. The Lightning looks just like it, but promises better acceleration off the line, the option to keep your house powered in a blackout, and has all of the brand recognition and loyalty Tesla’s Cybertruck will need generations to accrue (assuming it does at all). Ford’s calling the F-150 Lightning “the truck of the future,” but what’s more exciting is it might turn out to be “the truck of the present” instead.”

This is really the issue: Tesla knows that part of their game is trading on speculation. Their Cybertruck sales contract is remarkably well done, essentially promising nothing from a legal perspective.

“You understand that Tesla may not have completed the development of Cybertruck or begun manufacturing Cybertruck at the time you entered into this Agreement and so we do not guarantee when your Vehicle will actually be delivered.”

In other words, you get the Cybertruck when you get the Cybertruck.

Further, if you think that putting down your $100 and pre-ordering the Cybertruck gives you any legal rights aside from an ability to one day being able to actually configure and order your truck, you’re also wrong:

“Limitation of Liability. We are not liable for any incidental, special or consequential damages arising out of this Agreement. Your sole and exclusive remedy under this Agreement will be limited to reimbursement of your Pre-Order Payment.”

John Lawlor, a Fort Lauderdale, Florida, personal injury lawyer, offers this sobering perspective on the wisdom of not rushing a new truck to market, no matter how much the public is demanding it.

“As someone who has represented many people injured by trucks, it makes sense not to rush a new design to market. Safety always has to be a priority for the manufacturer, especially when there’s an expectation that so many of these new vehicles will be on our roads.”

The good news is that the Cybertruck doesn’t seem to be rushing. This week’s news might light a fire under Tesla’s production process, as Ford’s announcement represents what Tesla likes the least—a massive incumbent drafting behind them in the home stretch of a race. With that comparatively low base price, Lightning is going to sell like electric-powered hotcakes. And while Tesla critics point out that it will be 2022 until Ford can get the Lightning to market, whether Tesla can get you behind the wheel of your Cybertruck before then remains to be seen.

About Aron Solomon: Aron Solomon is the Head of Digital Strategy for Esquire Digital and an adjunct professor of business management at the Desautels Faculty of Management at McGill University. Since earning his law degree, Solomon has spent the last two decades advising law firms and attorneys. He founded LegalX, the world’s first legal technology accelerator and was elected to Fastcase 50, recognizing the world’s leading legal innovators.

Aron is not a car guy, unless a borderline unhealthy obsession for old Swedish cars that need to be held together by a makeshift exoskeleton counts. And he has yet to develop a taste for electric cars. He thinks they sound creepy. They sneak up on you like oversized golf carts. He prefers the mature feline hum of a 30-year-old diesel engine, the kind of machine that says we ain’t getting there fast but not much is going to prevent us from the journey.

What if we said someone is swapping out the combustion engine in an old classic farm truck for a new fully electric Tesla motor. Pretty cool, but you’ve heard that one before, right? That’s what Mike Rolleri and the crew at Salvage to Savage thought when they were planning their next big build. So, when someone mentioned adding a second Tesla motor in the front, brainpower overtook horsepower and the excitement built up faster than the price tag, which is going to be massive at this end of this build. Do you think that factor even once left a doubt in Mike’s mind? With this one, money doesn’t exist, and only the absolute best will be considered. On top of all that, Mike decided it would be a good idea to film it all and share the progress a few times per week on their quickly growing YouTube channel. Based on the soaring numbers their videos get, we would say it was possibly his best decision to date, but we are media makers also, so we can relate!

This single location speed shop is based in Boca Raton, Florida, and they are always looking to push the boundaries. Here’s their motto: “We are misfits, proud to stand out from the crowd on a daily basis. We are fast flyers, ass kickers, name-takers, and heartbreakers.” With a tagline like that, their work must be good. The completion goal for this build is SEMA 2021 and, based on their current progress, it looks like they will make it with time to spare. The project has had a few unexpected issues when it came to understanding how to operate an all-wheel drive powered truck, but after making some very valuable relationships in the EV world, Mike’s team cleared the problem path and are now on their way to victory.

This single location speed shop is based in Boca Raton, Florida, and they are always looking to push the boundaries. Here’s their motto: “We are misfits, proud to stand out from the crowd on a daily basis. We are fast flyers, ass kickers, name-takers, and heartbreakers.” With a tagline like that, their work must be good. The completion goal for this build is SEMA 2021 and, based on their current progress, it looks like they will make it with time to spare. The project has had a few unexpected issues when it came to understanding how to operate an all-wheel drive powered truck, but after making some very valuable relationships in the EV world, Mike’s team cleared the problem path and are now on their way to victory.

…after making some very valuable relationships in the EV world, Mike’s team cleared the problem path and are now on their way to victory.

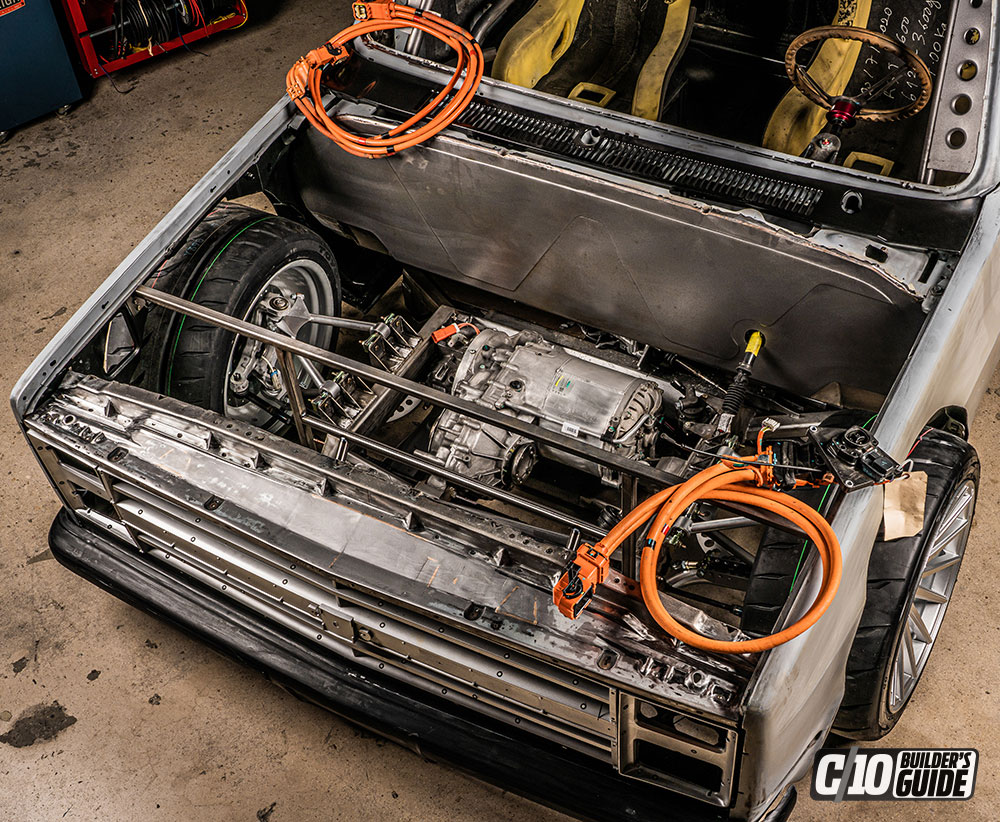

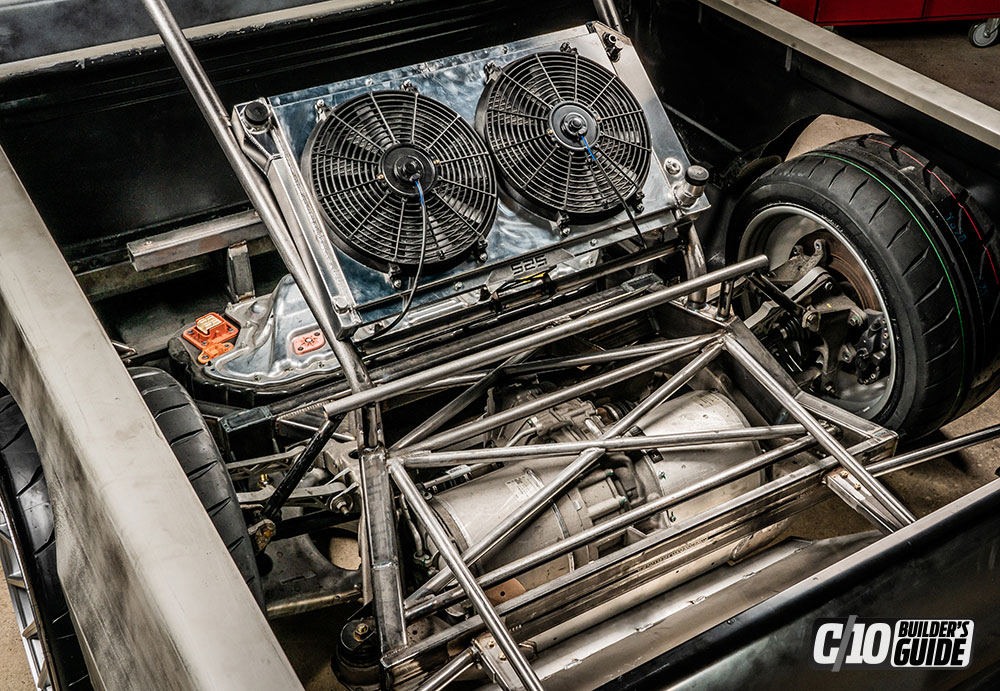

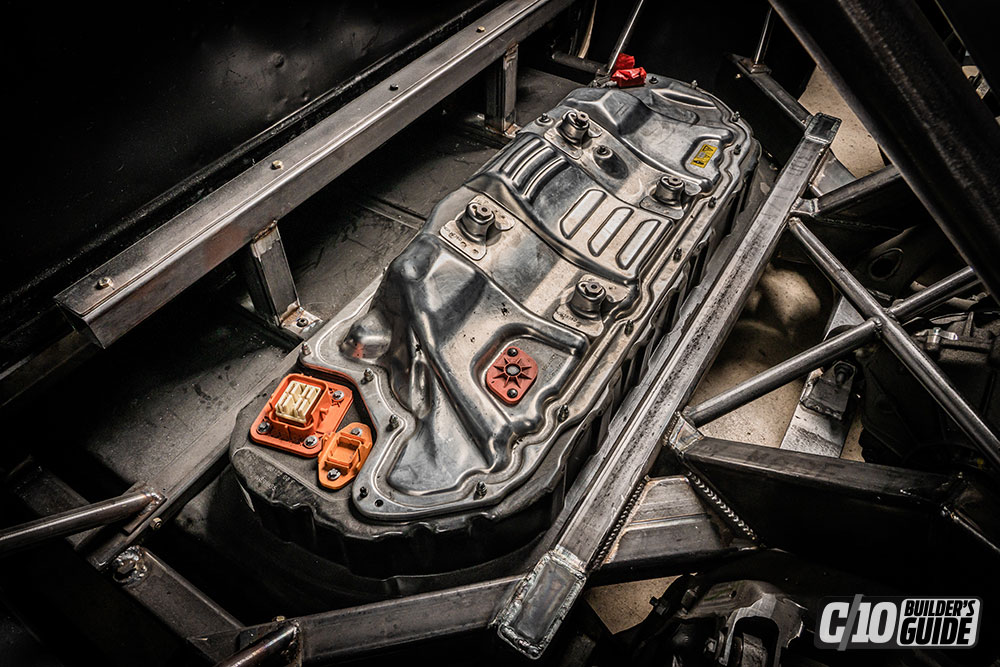

The Tesla motors are from 2017 Model3 vehicles and are the large range units. The original specs for this motor were 220 miles of range, a 0-60 time of 5.6 seconds and a top speed of 130 mph. Now imagine two of those powering an Army Green 1985 Chevy C10 truck. It’s going to be wild! The truck will need multiple coolant radiators and fans from Mishimoto to keep temperatures in check, and all the fitting and hoses came from Earls and Holley Performance. The chassis wiring harness is from Street Smartwire Power Control. A Tesla gear reduction and custom built 1500-hp half-shafts from the Driveshaft Shop transfers the power to the wheels. Wilwood front brakes and Tesla rear brakes bring the truck to a stop along with a Tesla master cylinder. All this technology and engineering can’t go onto that old Chevy frame, so the Salvage to Savage crew built an all-new chassis with a 117-inch wheelbase. The suspension components are comprised of parts from a C6 Corvette, Tesla Model3 along with springs from Belltech Suspension.

Toyo R888 tires reside at all four corners and protect those amazing 20×12 Finspeed wheels from touching the ground. New body panels from Auto Metal Direct were a no-brainer, but even some of those parts would get the custom treatment as well. The fenders were cut, and an all-carbon fiber wide body is going to be installed. Door handles from a Nissan GTR will be a trick addition, and a big window kit will give it a cool custom detail not many will notice. Finally, to top off all the madness, the truck body will be will be combined from front to back to create one long unibody. We can’t wait to see it!

Toyo R888 tires reside at all four corners and protect those amazing 20×12 Finspeed wheels from touching the ground. New body panels from Auto Metal Direct were a no-brainer, but even some of those parts would get the custom treatment as well. The fenders were cut, and an all-carbon fiber wide body is going to be installed. Door handles from a Nissan GTR will be a trick addition, and a big window kit will give it a cool custom detail not many will notice. Finally, to top off all the madness, the truck body will be will be combined from front to back to create one long unibody. We can’t wait to see it!

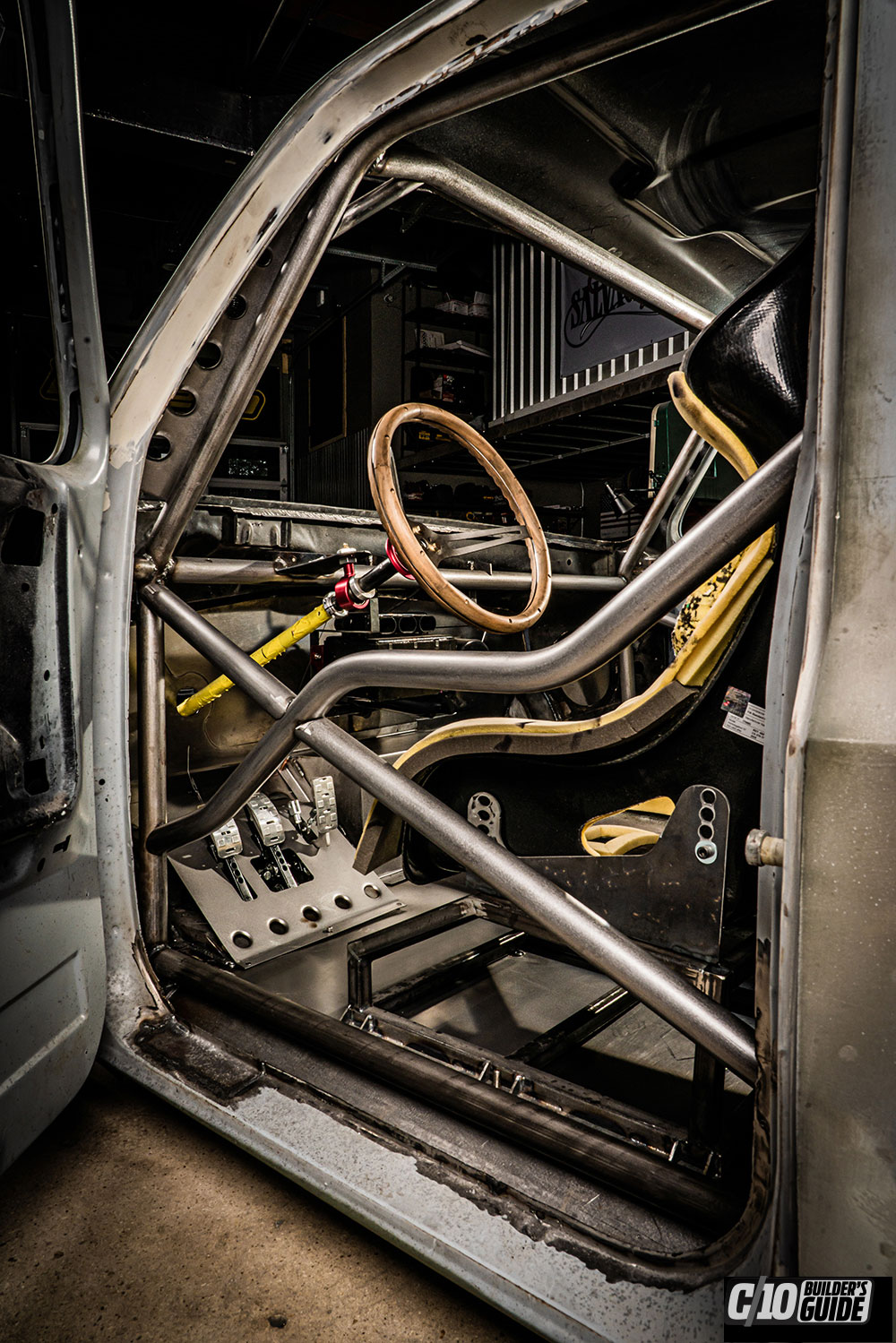

Rounding off the list of major mods are the interior upgrades. A 1 5/8-inch chromoly roll cage was built to perfection and a custom carbon fiber dash and door panel combo was formed in house. Billet Restomod A/C vents and controls along with a Haltech IC7 gauge panel and a Status steering wheel is all that they need to cruise.

“Nothing is impossible,” says Mike, and after this ambitious undertaking, it’s clear that there is a new talent in town.

And just like MMA fighter Conor McGregor once said, “They’re not here to take part, they’re here to take over!”

OWNER

Michael Rolleri

Engine

Suspension

Exterior

Interior

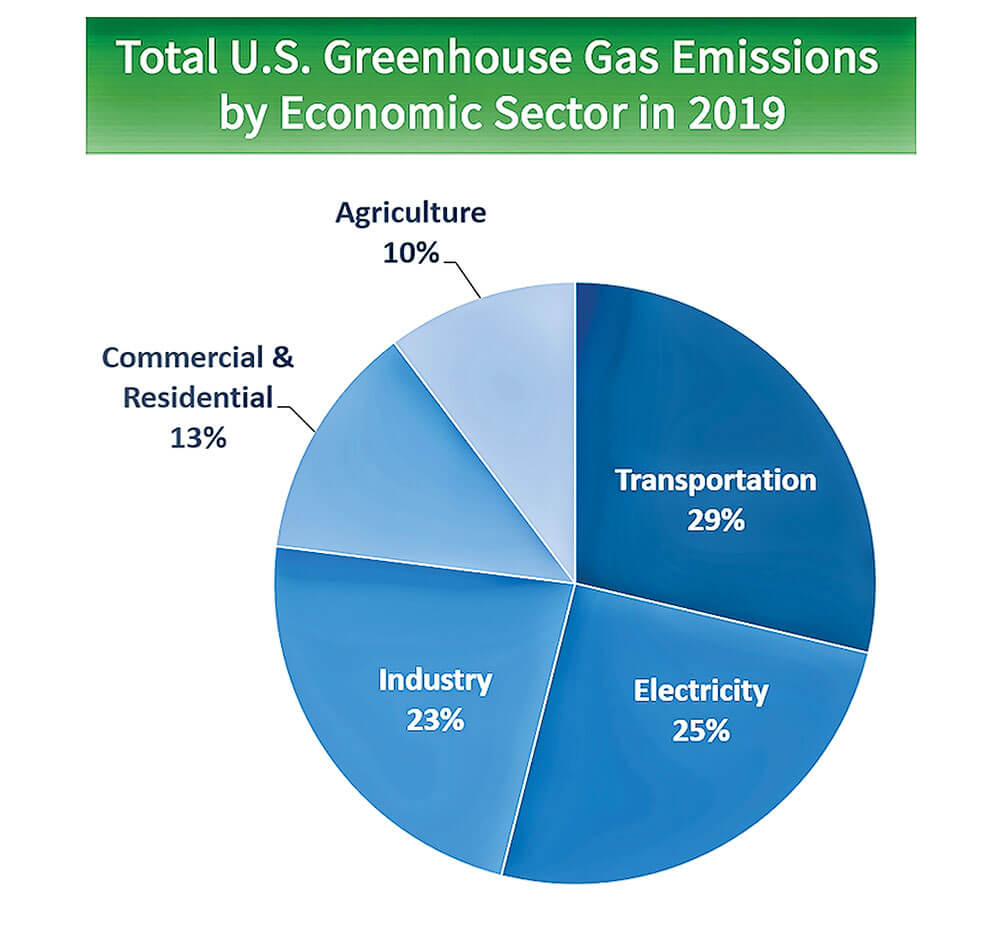

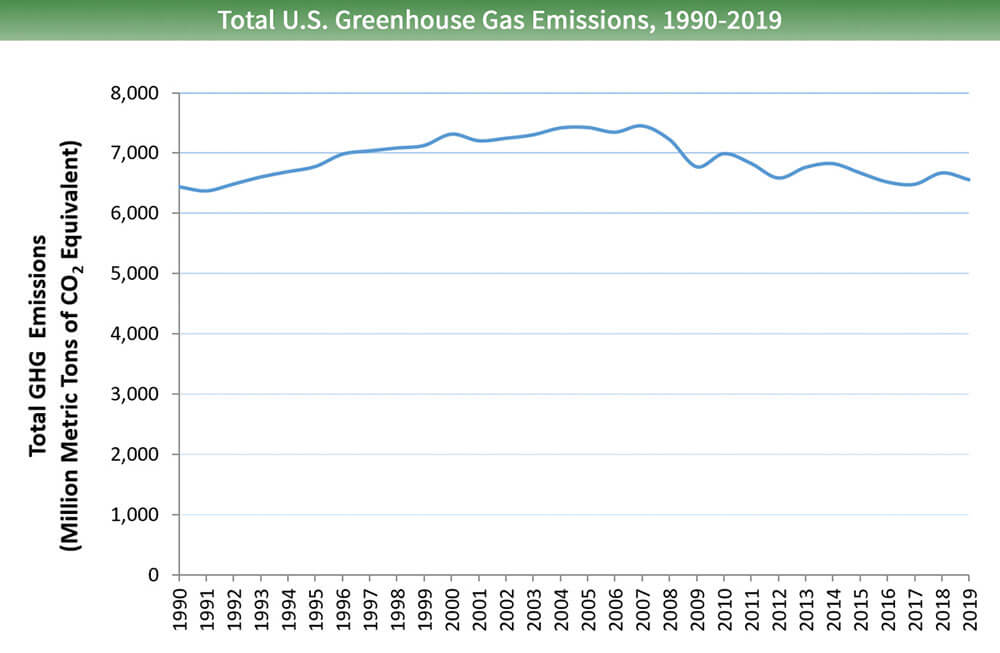

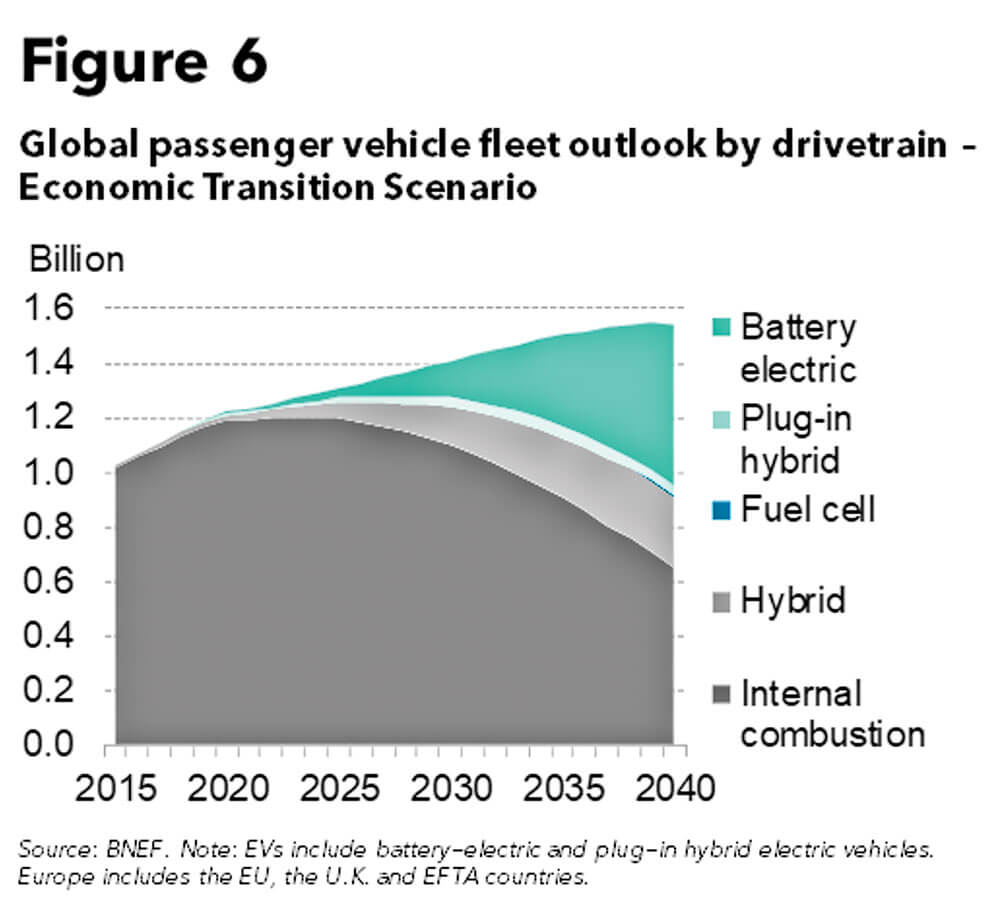

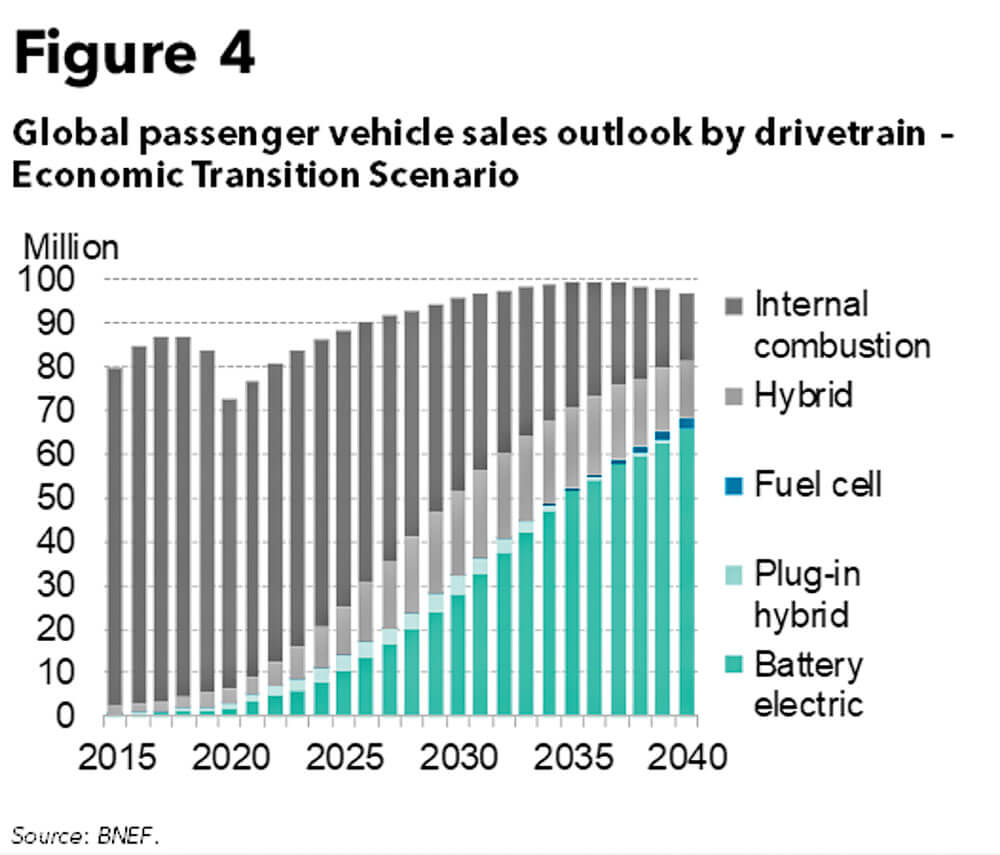

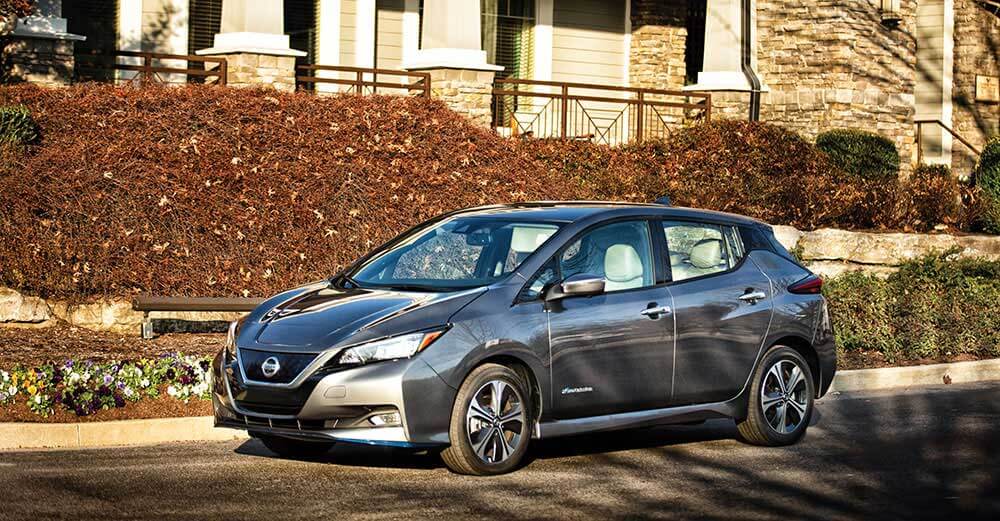

The whole world is going electric, or so we’re told. But the reality is that while the world may eventually switch to 100-percent electric passenger vehicles, it’s not going to happen overnight. In fact, you’re likely going to see diesel, gasoline, and hybrid-powered vehicles dominate U.S. roadways for at least another two decades. So why all the hype about battery electric vehicles (BEV’s) in recent years? Long story short, BEV technology—and in particular battery technology—has come a long way, and practically improves on a daily basis. Sprinkle in a little “zero emissions” make-believe, emphasize the obvious reduction in dependency on foreign oil, get every OEM automaker onboard, and you’ve got a full-blown BEV movement.

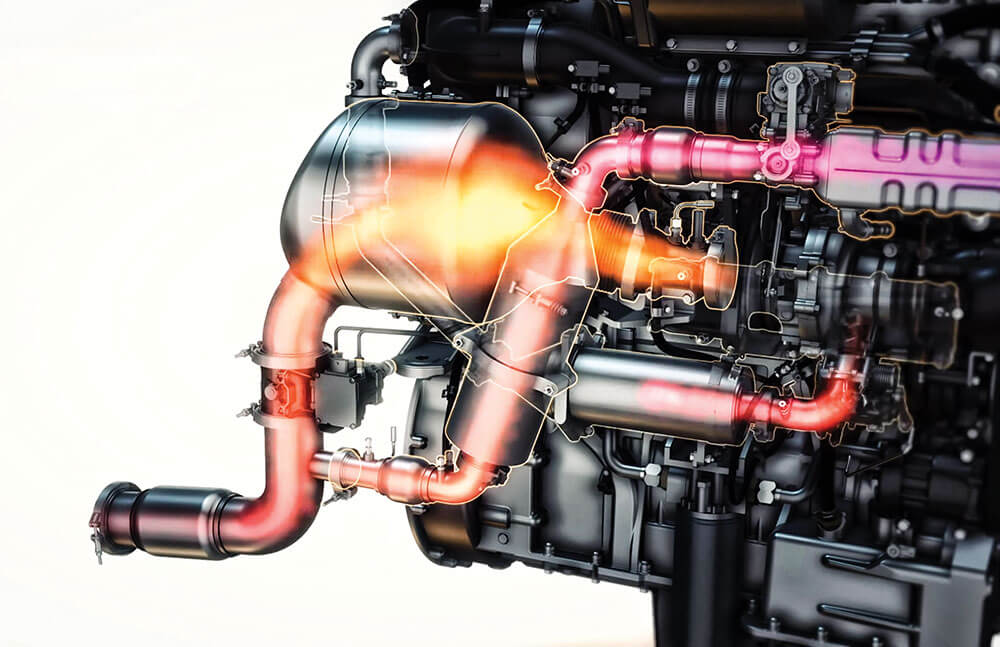

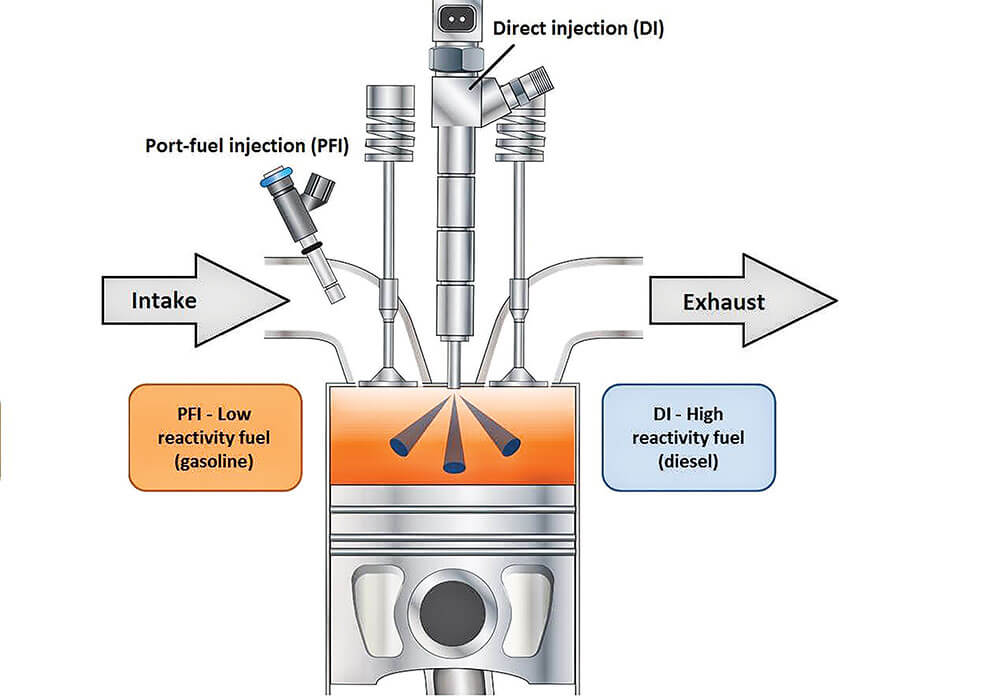

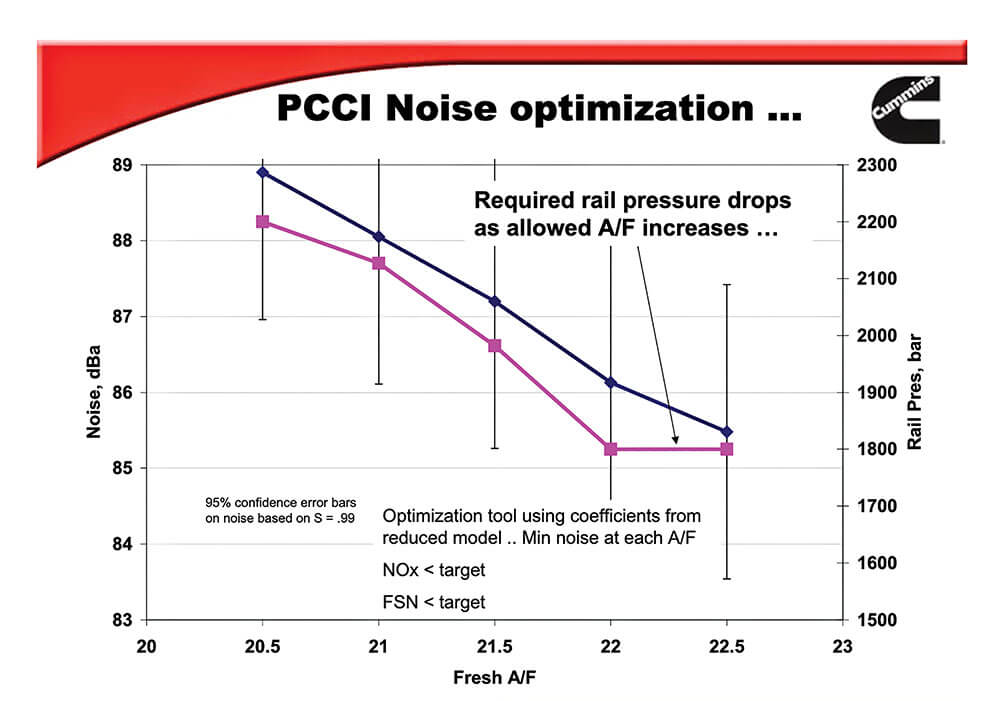

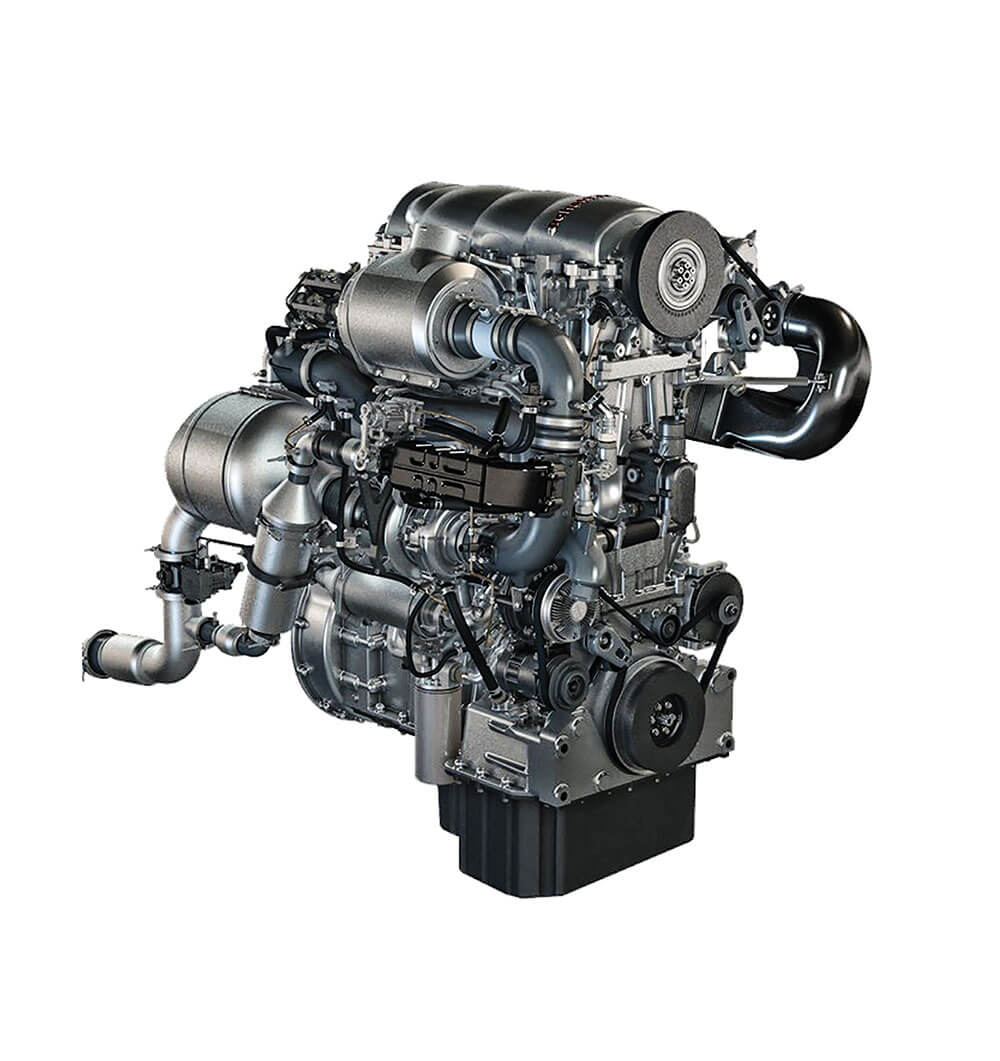

If only it were that cut-and-dried. Beneath every electric headline and glamor shot there are a lot of items going undiscussed. Among them are the BEV’s range and charging disadvantages, the fact that they’re cost-prohibitive for many Americans, shift greenhouse gas emissions from the tailpipe to the power plant, and lack the same type of 100-year infrastructure internal combustion engines (ICE’s) enjoy at the present time. Beyond that, all the advancements made in internal combustion engines (ICE’s)—especially diesel technology—over the years is being ignored. Not here. In the following pages we’ll spell out just how far diesel emissions have come, shine a light on all the modern BEV’s shortcomings, and make a case as to why diesel and gasoline will continue to co-exist with electric for years to come.

BLOOMBERGNEF

about.bnef.com

SAE INTERNATIONAL

www.sae.org

TESLA

www.tesla.com

UNITED STATES DEPARTMENT OF ENERGY

www.energy.gov

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY

www.epa.gov