Step one was to rewind the front of the 1999 Suburban back to 1993 pace truck standards with a few upgrades. After a quick call to LMC Truck, the crew had all the necessary conversion parts, including a grille shell, billet insert, lower grille filler, turn signal lamps, side marker lamps, front fender extensions, and the correct front bumper. At some point in its life, Brik Yrd had been converted with a 1993 GMC grille with the correct lower grille filler and fender extensions and a smooth, front work-truck bumper with no strips or guards. This is a simple conversion. All OBS grilles are interchangeable from OBS ’88-’98 with the correct corresponding year’s parts. Follow along as the team brings Steve’s vision to reality.

How many of you wanted a Red Ryder BB gun after “A Christmas Story” appeared on TV when you were a kid? It was one of the most influential movie scenes in the ’80s, and to this day it still plays nonstop during the holiday season.

Few things stick around for that long and still hold sentimental value to millions of people around the country. Show anyone in your family a picture of a stock ’88-’98 GMT400 truck, and we promise at least one of them has a great story involving one of them. Either it’s your grandpa who used one as a farm truck his whole life and watched the sunset in it with his wife for the past 30 years, or it’s your mom who met your dad in their parent’s work truck on a Friday night. Everyone has a memory that involves this all-American Bow Tie, and this particular shortbed is no different.

Dylan Eaton from Spring Hill, Florida, grew up with this exact truck—well, a stock daily-driven version of it at least. His dad picked it up from the dealership new in 1989 and drove it until 2008 when he gave it to Dylan. This was the first truck Dylan ever owned, and he wanted to prove he cared about it as much as his dad did. Now after a little over eight years and around $25,000 dollars or more, Dylan is proud to tell the story of this long-time family member. He knew the path he wanted to take when he started customizing. A daily driven, big power, thick tire street machine. Nothing more and nothing less. He wants to jump the truck at any time and have a strong crank. No special fuel and no pre-charging, just a ready and reliable show truck.

Because it was so well maintained since its time on the showroom floor, the exterior of the truck only needed some fresh paint and a few simple upgrades. A Street Scene front grille with billet inserts was installed, the factory bumpers were shaved and painted, the bed rail stake holes were shaved, and a steel roll pan was welded and smoothed in. Finally, the whole truck was painted Viper Red by Donnie Peake of Peake’s Autobody Inc. To get the stance correct, Dylan and his dad installed a 5-inch front and 7-inch rear suspension drop that included DJM Control Arms, Belltech coil springs, new spindles, a rear flip kit, C-notch for the rear frame rails, and Belltech Street Performer shocks. They also bolted on a 1.375-inch front sway bar with polyurethane bushings and body mounts as well as a Calvert Racing Caltrac bar.

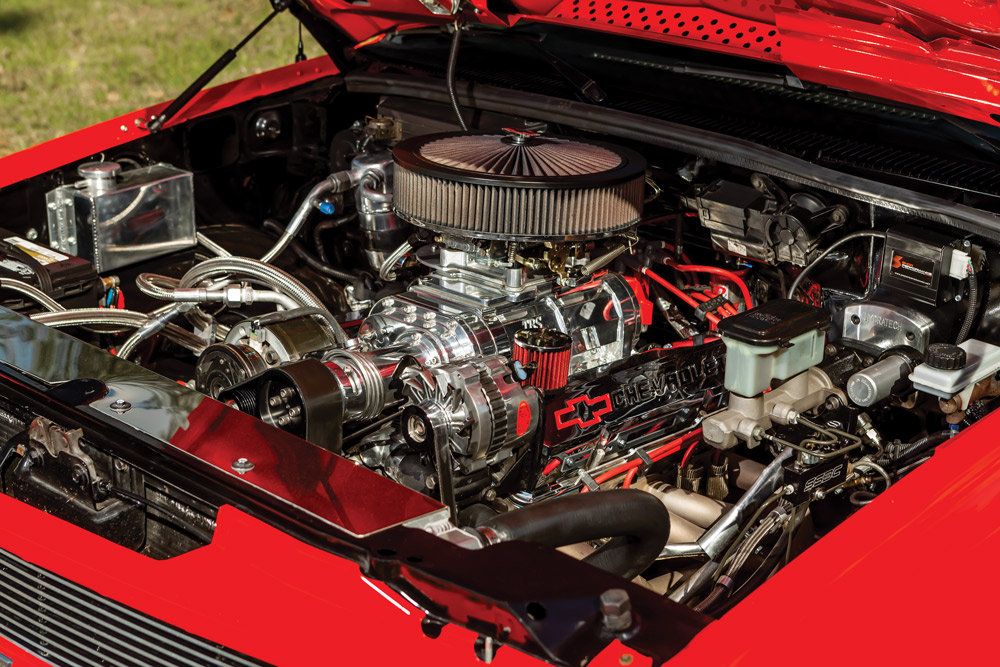

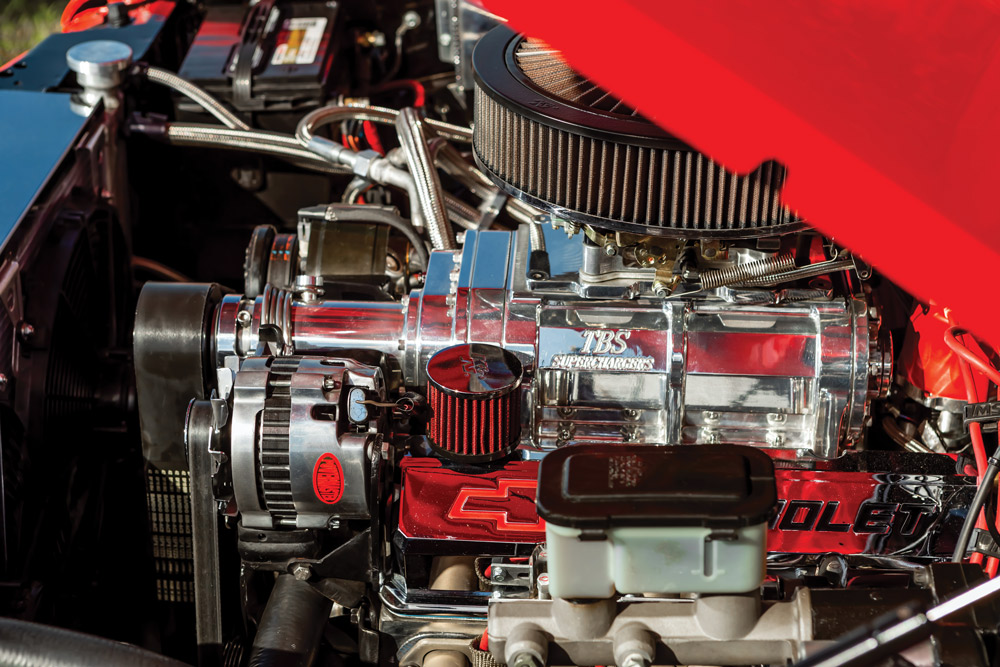

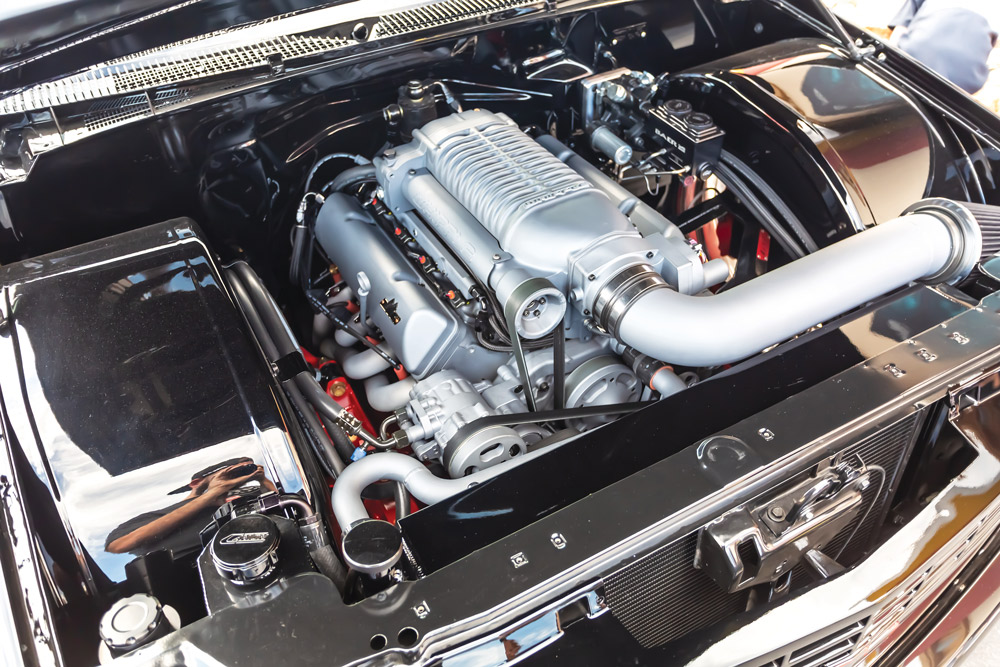

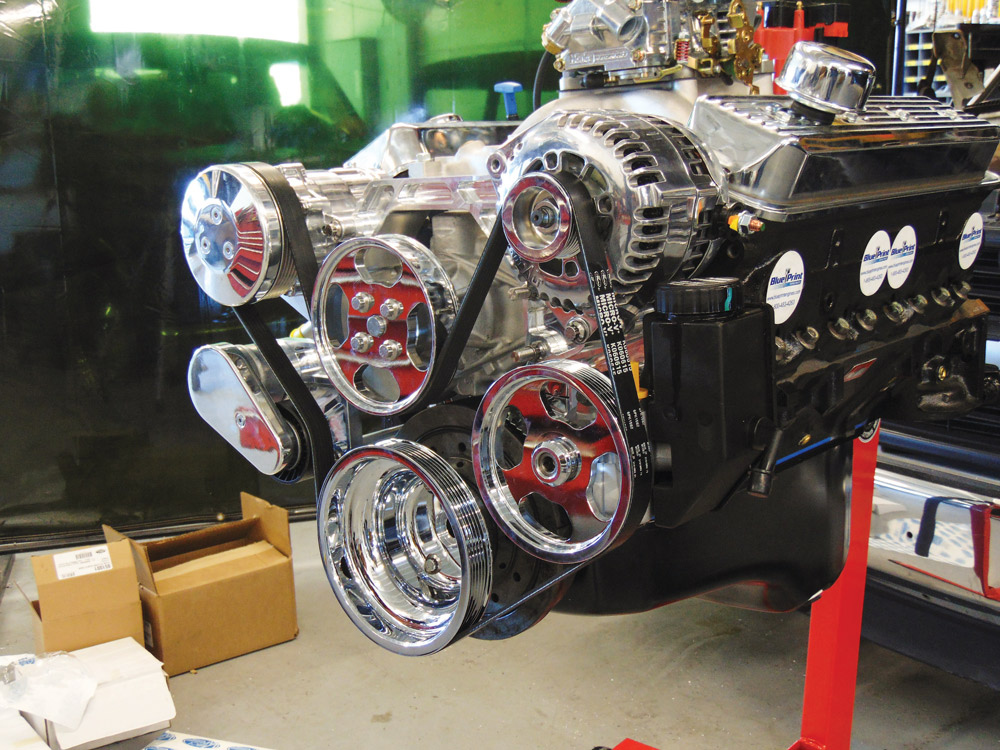

The power plant on this sweet OBS is an ’87 GM roller block SBC 355ci V-8 built by Mark’s Performance and Machine in New Port Richey, Florida. The block was balanced, blueprinted, decked and line honed. It was also bored 0.030 over and has a Pro Meth methanol injection system. Eagle connecting rods, Comp Cams nx276hr camshaft, JE Pistons, Total Seal rings and King bearings complete the internals, and it’s all bolted together with ARP bolts and studs. Under the block is a Morosso oil pan. Topping off the engine build are Air Flow Research Eliminator 180cc heads, a polished 192-intake 16-rib supercharger from The Blower Shop, a Devane “Weekend Warrior” 930cfm carburetor, and Hooker Headers. These bolt up to Hooker Max Flow mufflers and flow out the back of the truck. An MSD ignition keeps the timing in check and an American Powertrain “White Lightning” Tremec 5-speed transmission with hydraulic throwout bearings and a SPEC Type 3 clutch wrap up the drivetrain.

All this power is sent back to the 14-bolt 5-lug 454SS rearend with 3:73 gears. Some 17-inch American Racing Torq Thrust 2 wheels are at each corner with a 17×7 up front and 17×9.5 in the rear. The Michelin Pilot Sport 4s tires give Dylan the traction he needs and the SSBC Big Bite brakes stop him when he steps on the pedal. The SSBC rear disc brake conversion and SSBC adjustable proportioning valve give him all the braking power he needs for this beast of a truck.

This truck is on every grown kid’s Christmas list, and you don’t have to worry about shooting your own eye out with a truck like this—although you may break a few necks when you drive by.

Truck Specs:

Dylan Eaton

’89 Chevy Cheyenne C1500

Spring Hill, Florida

Chassis/Suspension

Engine/Drivetrain/Performance

Wheels/Tires/Brakes

Body/Paint

Interior

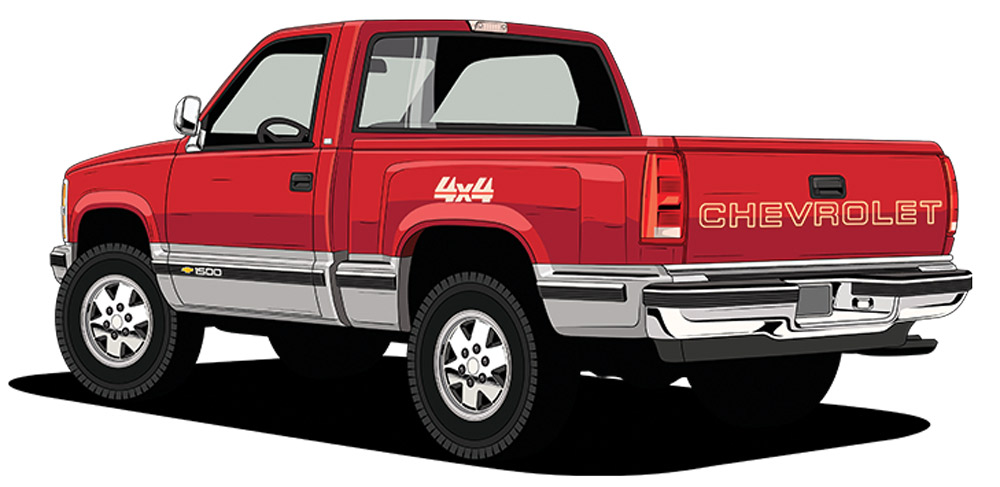

In my opinion, 1988 was the exact year that jump-started the street truck era with the release of the all-new re-designed GM trucks commonly known as the “OBS” (Original Body Style, Old Body Style). This redesign by GM officially made a truck more than just a tool on the farm. It sparked the creation of an entire culture of automotive enthusiasts, and the street truck/sport truck movement was born. The GMT400 is said to have influenced GM designers long after they were no longer produced, and for good reason! We believe to this day they are the best-looking trucks on the road, we may be a little biased though!

Over its more than 10-year span of production, these trucks just got better and better in terms of design, comfort, reliability, power and safety. Although GM made a ton of changes both cosmetically and mechanically to the GMT400 trucks, we’ll hit the high points of the changes made throughout the years. We wanted to break down all the biggest and best changes between the ’88-’94 and ’94-’98 trucks. So let’s dive deep into the timeline of this timeless truck.

OBS refers to Chevy C/K trucks that were manufactured by General Motors between the years of 1988 and 1998. Marketed under the Chevrolet and GMC brands, the C/K series included a wide range of vehicles including a chevy truck and two SUV models. While most commonly associated with pickup trucks, the model line also included medium-duty and heavy trucks. “C” denoted a two-wheel drive; “K” denoted four-wheel drive.

There were eight different versions of the C/K line for 1988: Fleetside Single Cab, Fleetside Extended Cab, Fleetside Crew Cab and Stepside Single Cab models, each in either 2WD or 4WD drive-lines. Three trim levels were available for these trucks including Cheyenne, Scottsdale and Silverado.

There were eight different versions of the C/K line for 1988: Fleetside Single Cab, Fleetside Extended Cab, Fleetside Crew Cab and Stepside Single Cab models, each in either 2WD or 4WD drive-lines. Three trim levels were available for these trucks including Cheyenne, Scottsdale and Silverado.

Over its more than 10-year span of production, these trucks just got better and better in terms of design, comfort, reliability, power and safety.

The Work Truck (W/T) was introduced in 1988, which featured a single cab long bed with Cheyenne trim and a new grille with black bumpers. Check out a tech article for this Chevy!

The Work Truck (W/T) was introduced in 1988, which featured a single cab long bed with Cheyenne trim and a new grille with black bumpers. Check out a tech article for this Chevy!

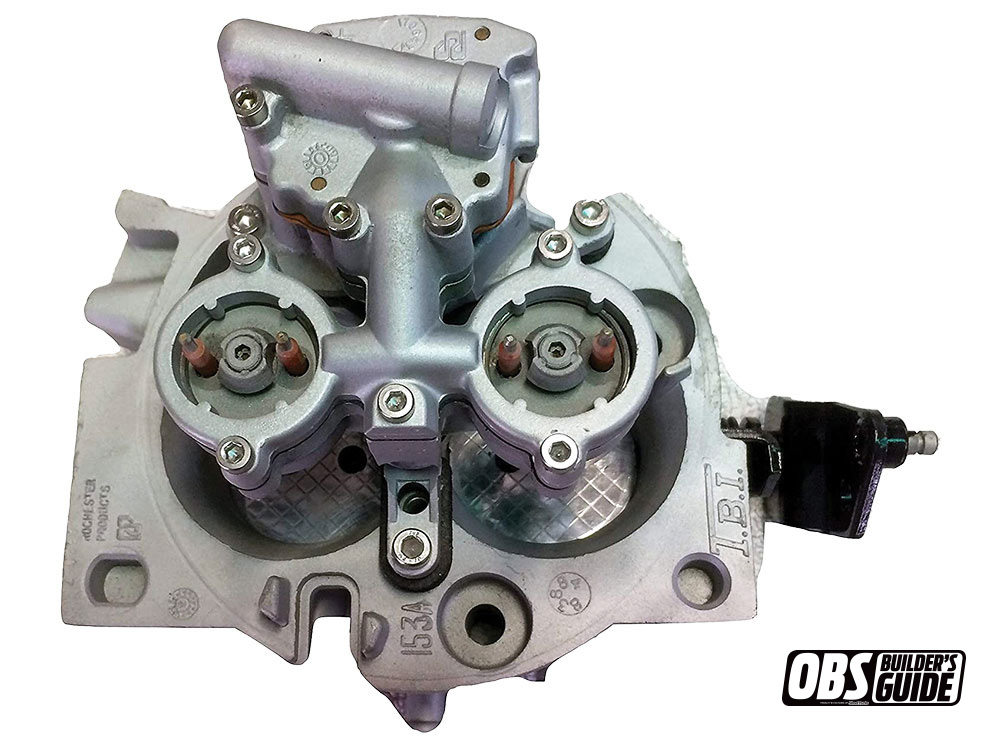

Throttle body(TBI) fuel injection was used on ‘88-’95 gas engines.

Throttle body(TBI) fuel injection was used on ‘88-’95 gas engines.

In 1998, to circumvent the rise in auto thefts, GM introduced the Pass Lock II system with a “security” light on the dash to the 88” to 98″ Chevy Trucks.

In 1998, to circumvent the rise in auto thefts, GM introduced the Pass Lock II system with a “security” light on the dash to the 88” to 98″ Chevy Trucks.

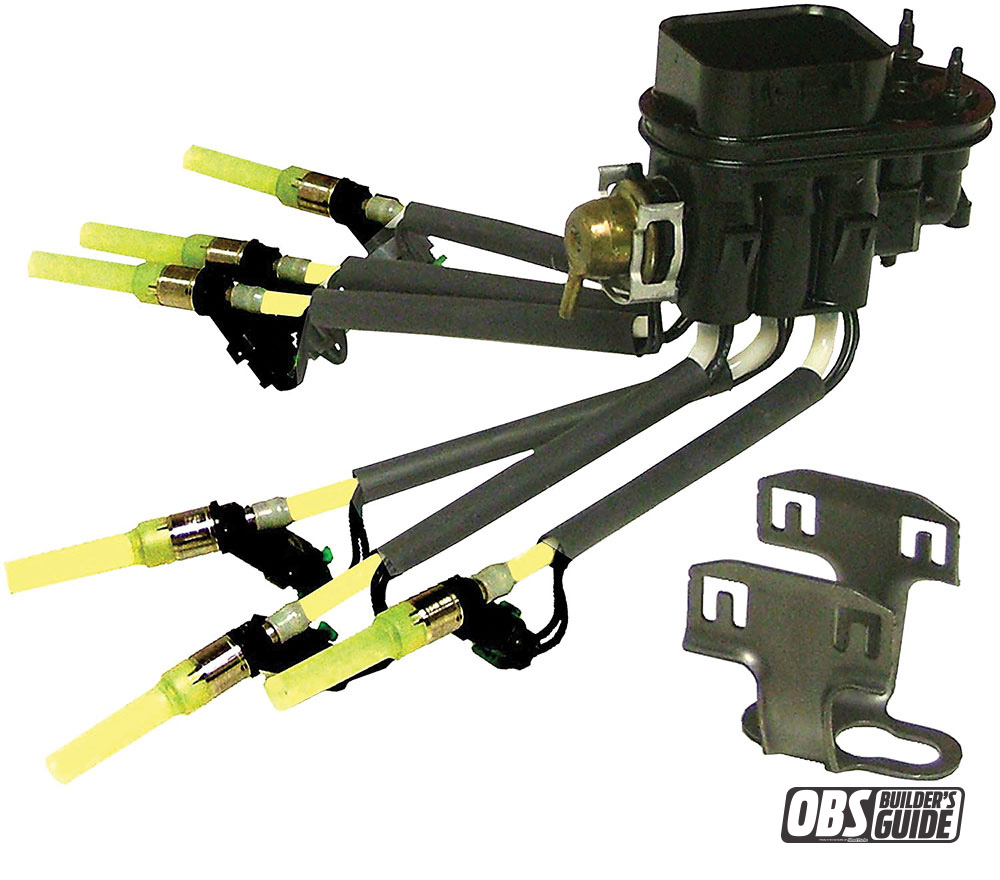

CPI (central point injection) was used on the ‘96-’00 4.3L-V6, 5.0L-V8, 5.7L-V8

CPI (central point injection) was used on the ‘96-’00 4.3L-V6, 5.0L-V8, 5.7L-V8

1997 was to be the last year the C/K Silverado would display “CHEVROLET” on the tailgate

1997 was to be the last year the C/K Silverado would display “CHEVROLET” on the tailgate

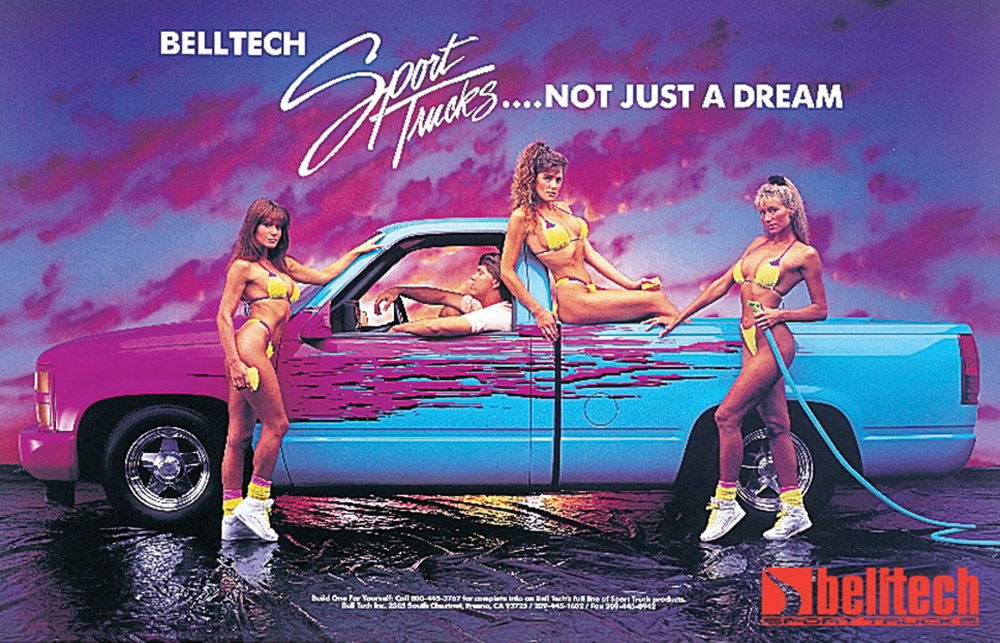

When it comes to lowered trucks, the stance is everything! Without the proper stance, the truck will not look good or handle correctly. One company has been getting it right since 1983—Belltech.

Belltech was at the forefront of the sport truck craze in the early ’90s building parts for none other than the GMT400 trucks. The launch of the drop spindle allowed people to lower their trucks while maintaining front-end geometry. They also addressed the rest of the suspension with shackle kits, flip kits and lowering coil springs. All of these components resulted in a ride quality that hadn’t been realized before now.

We recently picked up a 1996 GMC Sierra C1500 as a project truck. It was a bit rough around the edges but had great bones and potential. A little elbow grease and replacing a few things such as the carpet and body side moldings had the truck looking much better than when we bought it. The next step was to address the suspension, brakes and wheels.

To get the stance and look we wanted, we reached out to our friends at Belltech and Ridler wheels. We knew we wanted it to be low, but didn’t want to lay frame. The folks at Belltech recommended a 4/6 lowering kit with their Street Performance shocks part #688SP. We chose the new Ridler 606 gray with milled spoke wheels wrapped in Toyo rubber to round out the look we were after.

While we were tearing into the suspension, we also decided to upgrade the brakes and steering components. We chose drilled and slotted front rotors and a rear disc conversion from Little Shop Manufacturing. To ensure the truck steered straight and true, new steering components and balljoints were in order from Proforged.

All of these parts combined are going to create a truck that handles as well as it looks. Lets dive into what it takes to istall a 4/6 lowering kit from Belltech.

Check out other Belltech lowering tech installs click here!

Sources

Belltech

www.belltech.com

800-445-3767

Ridler Wheel

www.ridlerwheel.com

866-894-3351

Proforged

www.proforged.com

866-464-6553

Little Shop Manufacturing

www.littleshopmfg.com

A DRIVER. Every custom truck enthusiast must have one. The driver is the truck that gets mobbed on the daily work commute and usually gets put through the paces on the weekend hauling the “show truck” around. The driver is never left alone for long, however. It always starts out innocent enough with a drop kit or airbag suspension setup, wheels and tires, and maybe some upgraded audio and simple exterior bolt-ons, but that only lasts so long. Pretty soon, the custom truck freak’s desire to take the build further and further takes over, and what was once the driver becomes yet another show truck. So much for self-restraint!

Mike Barcia out of Tampa, Florida, bought a driver back in January 2001 to tow his full custom Isuzu show truck. The driver came to him in the form of a trade where Mike gave up the title to his bagged ’90 C3500 and some cash for the ’96 four-door that would eventually become No Compromize.

Mike Barcia out of Tampa, Florida, bought a driver back in January 2001 to tow his full custom Isuzu show truck. The driver came to him in the form of a trade where Mike gave up the title to his bagged ’90 C3500 and some cash for the ’96 four-door that would eventually become No Compromize.

After a weekend of de-grampifying the OBS Crew, Mike set about getting it on the ground. Set up with full air-ride suspension, the truck’s stock black paint eventually gave way to a full color change with a crisp and clean two-tone with traditional flames heating up the beltline coupled with billet interior accents, ear pounding audio and deep detail under the hood. It didn’t take long before the driver became another show truck. So, Mike decided to take the dually off the road and show circuit and build the most radical custom 1-ton on the planet. The Isuzu was sidelined and the dually became the popular girl getting all of the love and attention.

After a weekend of de-grampifying the OBS Crew, Mike set about getting it on the ground. Set up with full air-ride suspension, the truck’s stock black paint eventually gave way to a full color change with a crisp and clean two-tone with traditional flames heating up the beltline coupled with billet interior accents, ear pounding audio and deep detail under the hood. It didn’t take long before the driver became another show truck. So, Mike decided to take the dually off the road and show circuit and build the most radical custom 1-ton on the planet. The Isuzu was sidelined and the dually became the popular girl getting all of the love and attention.

It was February 2003 when Mike and friend and fellow Negative Camber club member Robbie Taylor tore the truck down to perform a traditional 4-inch body drop on it. After the rockers were kissing the Florida asphalt, the truck looked cool but Mike thought, “It’ll just be another bagged and bodied dually with nice paint and a stock frame under it.” So, the decision was made to go for broke and have a full custom chassis built. Also being a fan and regular attendee of ISCA World of Wheels car shows where the best of best show up to compete, Mike knew that if he wanted to play on that level with the truck, then he had to bring his A game.

It was February 2003 when Mike and friend and fellow Negative Camber club member Robbie Taylor tore the truck down to perform a traditional 4-inch body drop on it. After the rockers were kissing the Florida asphalt, the truck looked cool but Mike thought, “It’ll just be another bagged and bodied dually with nice paint and a stock frame under it.” So, the decision was made to go for broke and have a full custom chassis built. Also being a fan and regular attendee of ISCA World of Wheels car shows where the best of best show up to compete, Mike knew that if he wanted to play on that level with the truck, then he had to bring his A game.

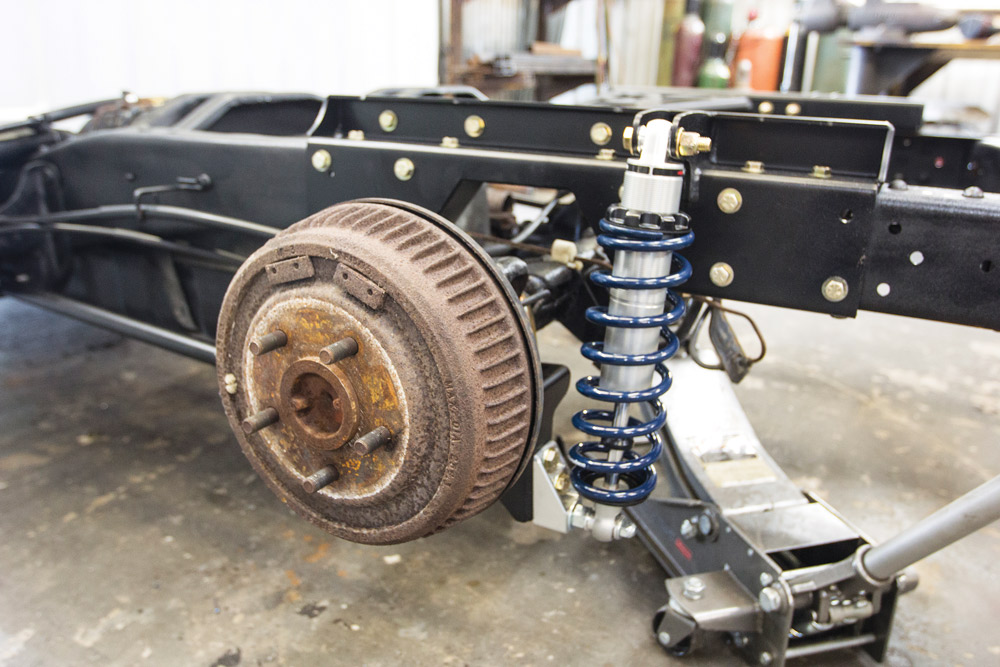

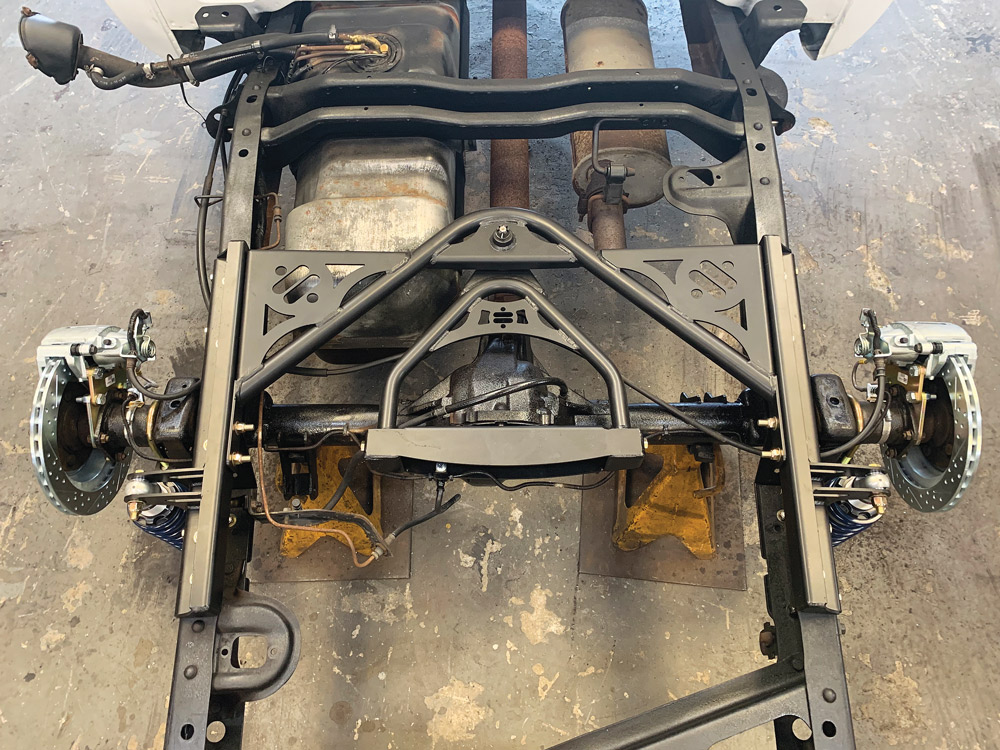

Enter Jimmy Graham of Jimmy’s Rod N Customs in Edgewater, Florida. Jimmy hand built and fabricated a oneoff custom chassis equipped with a custom built four-link rear suspension. The leadingedge underpinnings feature custom front suspension and shock hoops built from scratch. Not only is the chassis of No Compromize a work of fabrication and design art, but the depth of detail is unmatched.

Enter Jimmy Graham of Jimmy’s Rod N Customs in Edgewater, Florida. Jimmy hand built and fabricated a oneoff custom chassis equipped with a custom built four-link rear suspension. The leadingedge underpinnings feature custom front suspension and shock hoops built from scratch. Not only is the chassis of No Compromize a work of fabrication and design art, but the depth of detail is unmatched.

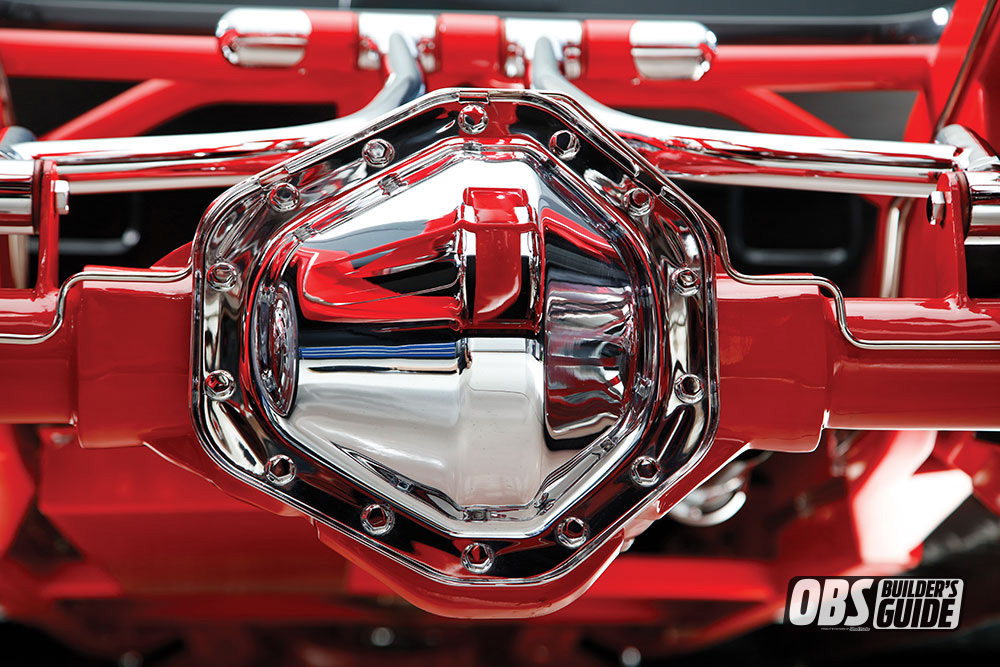

After Jimmy finished fabbing up the ultimate bones and suspension, Mike took special care to grind smooth all unnecessary roughness, such as the factory ridges on top of the rear differential where the axle tubes meet the pumpkin. Mike and Gerald Ashe welded up all of the seams and grinded all the welds baby butt smooth. Friend and fellow NC club member David “Double D” Dekorver bodyworked the frame before Chris Bareswilt covered the chassis and suspension components in Euro Red. The frame and suspension were painted as opposed to powdercoated for a superior finish, and then Mike wet sanded and polished to perfection.

After Jimmy finished fabbing up the ultimate bones and suspension, Mike took special care to grind smooth all unnecessary roughness, such as the factory ridges on top of the rear differential where the axle tubes meet the pumpkin. Mike and Gerald Ashe welded up all of the seams and grinded all the welds baby butt smooth. Friend and fellow NC club member David “Double D” Dekorver bodyworked the frame before Chris Bareswilt covered the chassis and suspension components in Euro Red. The frame and suspension were painted as opposed to powdercoated for a superior finish, and then Mike wet sanded and polished to perfection.

To keep things extra clean and smooth, all of the wiring was run through the frame rails, the air compressors were plumbed into the chassis tubing, and all of the chromed stainless bolts were clocked the same direction for that extra touch of ISCA detail. Polished stainless hard lines handle fluid transfer to the brakes and transmission, while a fully polished 3-inch stainless exhaust system built by Jimmy Graham with one-off billet chrome plated exhaust hangers built by Tom Hingle of Billet & Acrylic Fantasies kick out the octane cocktails. Cruising juice is housed in a custom aluminum fuel cell built by Jeff Davy of Devious Customs. The factory rearend was shortened 9 inches and stuffed with shortened Franklin axles while the first set of 24-inch Raceline Ratchet polished wheels mounted on Toyo rubber. Mike even sanded the side walls down for a smooth no-letter look. For an extra touch, Mike reached out to Kennedy Brown from Fat Dog Designs in Jonesboro, Arkansas, to machine one-off billet floating logo No Compromize center caps.

To keep things extra clean and smooth, all of the wiring was run through the frame rails, the air compressors were plumbed into the chassis tubing, and all of the chromed stainless bolts were clocked the same direction for that extra touch of ISCA detail. Polished stainless hard lines handle fluid transfer to the brakes and transmission, while a fully polished 3-inch stainless exhaust system built by Jimmy Graham with one-off billet chrome plated exhaust hangers built by Tom Hingle of Billet & Acrylic Fantasies kick out the octane cocktails. Cruising juice is housed in a custom aluminum fuel cell built by Jeff Davy of Devious Customs. The factory rearend was shortened 9 inches and stuffed with shortened Franklin axles while the first set of 24-inch Raceline Ratchet polished wheels mounted on Toyo rubber. Mike even sanded the side walls down for a smooth no-letter look. For an extra touch, Mike reached out to Kennedy Brown from Fat Dog Designs in Jonesboro, Arkansas, to machine one-off billet floating logo No Compromize center caps.

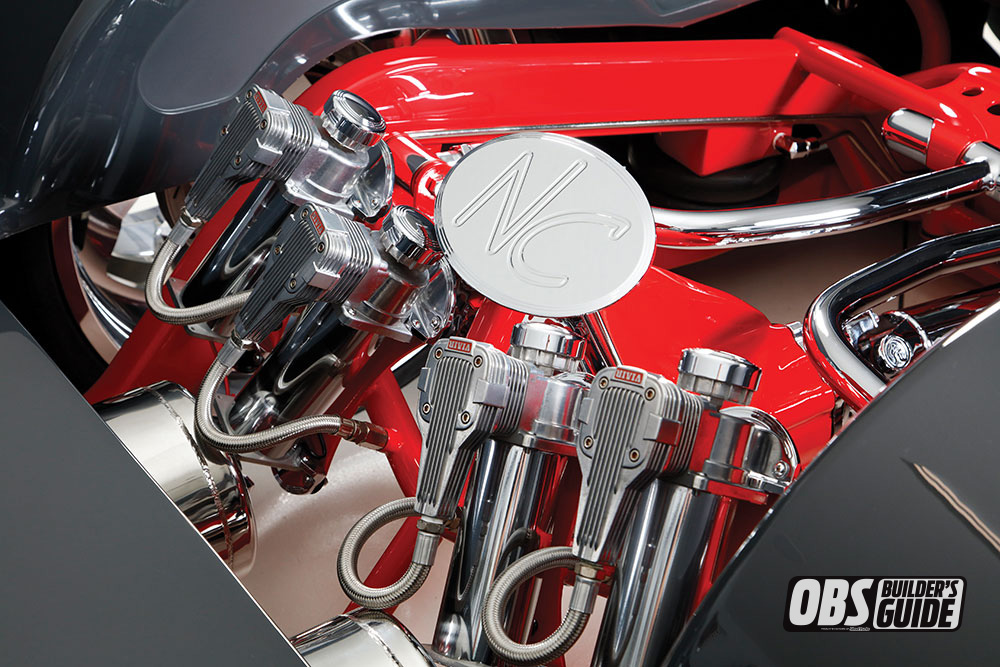

The truck comes to a halt with one-off billet 4-piston calipers and custom slotted and drilled rotors by Aerospace Engineering. Slam Specialties Slam Bags get the meticulously detailed underpinnings on the ground while air management from Accuair sends lift and drop commands from Mike’s itchy trigger fingers. Viair compressors re-supply the tanks.

The truck comes to a halt with one-off billet 4-piston calipers and custom slotted and drilled rotors by Aerospace Engineering. Slam Specialties Slam Bags get the meticulously detailed underpinnings on the ground while air management from Accuair sends lift and drop commands from Mike’s itchy trigger fingers. Viair compressors re-supply the tanks.

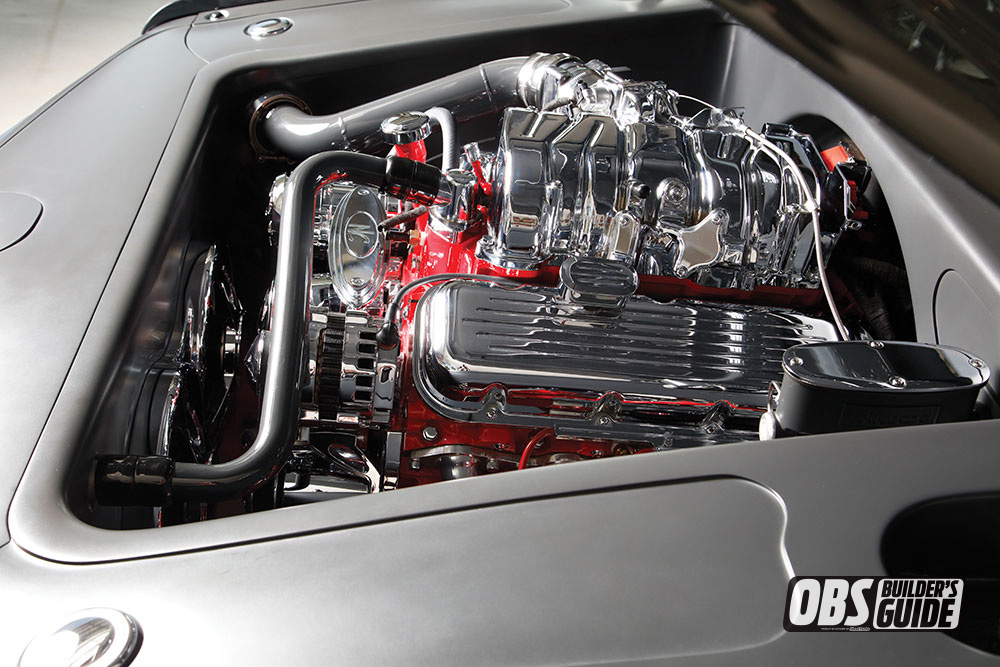

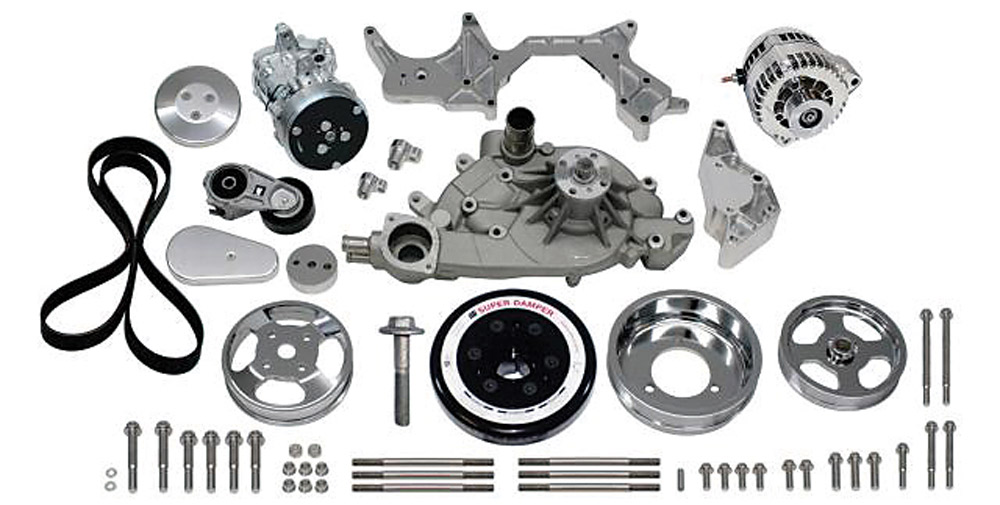

The factory big block, while mechanically stock, has a bit more bite with a March Pulley Set, Edelbrock Headers and 3-inch custom built stainless exhaust. Making the most noise under the hood is the deep detail, including the smoothed block and heads, paint-matched block, and all of the chromed and polished accents. Mike wanted the world’s finest chrome, so he reached out to Steve from Advanced Plating in Tennessee to get that accomplished. Billet Specialties valve covers cap off the valve train in style, while a custom-built radiator from Performance Rod and Customs keeps the BBC’s operating temps in check. A Wilwood master cylinder kicks fluid to the custom machined calipers allowing them to bite down on the slotted and drilled rotors.

The factory big block, while mechanically stock, has a bit more bite with a March Pulley Set, Edelbrock Headers and 3-inch custom built stainless exhaust. Making the most noise under the hood is the deep detail, including the smoothed block and heads, paint-matched block, and all of the chromed and polished accents. Mike wanted the world’s finest chrome, so he reached out to Steve from Advanced Plating in Tennessee to get that accomplished. Billet Specialties valve covers cap off the valve train in style, while a custom-built radiator from Performance Rod and Customs keeps the BBC’s operating temps in check. A Wilwood master cylinder kicks fluid to the custom machined calipers allowing them to bite down on the slotted and drilled rotors.

When building a truck of this caliber, getting it this low and expecting it to compete and win on the extremely competitive indoor show circuit, you have to pull out all of the stops. Modifications lead to more modifications to achieve the right fit, the right look, the right form and most importantly the right function! Not only does No Compromize have a detailed to the nines, full-custom chassis, but the envelope was deeply modified as well, demanding a mountain of metal work from the firewall forward.

When building a truck of this caliber, getting it this low and expecting it to compete and win on the extremely competitive indoor show circuit, you have to pull out all of the stops. Modifications lead to more modifications to achieve the right fit, the right look, the right form and most importantly the right function! Not only does No Compromize have a detailed to the nines, full-custom chassis, but the envelope was deeply modified as well, demanding a mountain of metal work from the firewall forward.

Blending classic CK lines with more modern Silverado styling, Mike opted to go with a ‘06 Chevy cat-eye front end. Sounds simple, right? But this mod combined with Mike’s obsession to go over the top turned into a five-year fabrication adventure just to make it seamless. Jimmy’s Rod ‘N’ Custom knocked it out of the park again with hammer bending all of the edges for a clean, smooth look. The front fenders were sectioned and lengthened in the front to make them flush with the ’06 Silverado bumper. On the backside, the ’06 fender is joined with the ’96 fender, and the wheel opening had to be cut, sectioned and massaged to make the lines flow proportionately. Moving up, the hood was lengthened on the backside by 10 inches and the windshield wiper cowl area was removed. The side curves of the hood were cut off so that when the hood was opened a clean fender line was achieved. The hood top body lines were then rebuilt and moved in 2 inches per side. The bottom side of the hood was hand built with a bead-rolled insert added for a smooth look and to gain clearance between the top of the intake and the base of the hood. The ’06 Silverado bumper top was chromed and the lower half sectioned and extended by Gerald Ashe so the bottom sat flush with the tarmac when the truck is laid out.

Blending classic CK lines with more modern Silverado styling, Mike opted to go with a ‘06 Chevy cat-eye front end. Sounds simple, right? But this mod combined with Mike’s obsession to go over the top turned into a five-year fabrication adventure just to make it seamless. Jimmy’s Rod ‘N’ Custom knocked it out of the park again with hammer bending all of the edges for a clean, smooth look. The front fenders were sectioned and lengthened in the front to make them flush with the ’06 Silverado bumper. On the backside, the ’06 fender is joined with the ’96 fender, and the wheel opening had to be cut, sectioned and massaged to make the lines flow proportionately. Moving up, the hood was lengthened on the backside by 10 inches and the windshield wiper cowl area was removed. The side curves of the hood were cut off so that when the hood was opened a clean fender line was achieved. The hood top body lines were then rebuilt and moved in 2 inches per side. The bottom side of the hood was hand built with a bead-rolled insert added for a smooth look and to gain clearance between the top of the intake and the base of the hood. The ’06 Silverado bumper top was chromed and the lower half sectioned and extended by Gerald Ashe so the bottom sat flush with the tarmac when the truck is laid out.

Even before paint was laid down, the engine compartment alone was a work of art in and of itself, with a custom bead-rolled firewall, custom core support and core support bead-rolled sheetmetal cover and bead-rolled fender wells. The radiator and power steering caps were all frenched into the sheetmetal work as well as the hood hinge pockets. To take it one step further, Mike wanted custom billet hood hinges, but he had no clue what he was getting himself into. After commissioning four different machine shops and delaying the build for over a year, Bobby McCurdy finally saved the day. Bobby designed and cut a set of one-off custom billet hood hinges like no other. The truck is basically a highend turn table street rod with a bed on it.

Even before paint was laid down, the engine compartment alone was a work of art in and of itself, with a custom bead-rolled firewall, custom core support and core support bead-rolled sheetmetal cover and bead-rolled fender wells. The radiator and power steering caps were all frenched into the sheetmetal work as well as the hood hinge pockets. To take it one step further, Mike wanted custom billet hood hinges, but he had no clue what he was getting himself into. After commissioning four different machine shops and delaying the build for over a year, Bobby McCurdy finally saved the day. Bobby designed and cut a set of one-off custom billet hood hinges like no other. The truck is basically a highend turn table street rod with a bed on it.

After Jimmy finished the work on the front clip and the engine compartment, it was time to get the cab and bed slick and smooth. Starting with the bed, the fuel door, stake pockets, tailgate handle and taillights were all shaved. A motorcycle style fuel cap was added to the top of the bed rail while one-off custom taillights by Greening Auto were frenched in for stylish stopping. A custom roll pan was built, and the dually fenders were raised 2 inches so the 24-inch Raceline would tuck. Jimmy fabricated new bead-rolled sheetmetal to the front outside bulkhead of the bed, and the factory dually fender marker lights were shaved in favor of custom one off machined replacement. Jimmy kept the tools burning by fabricating a push-button tailgate handle on the inside of the tailgate, rounding all four corners of the inside of the bed, building bead-rolled interior sheetmetal inserts inside the inner bed sides, and building widened bead-rolled inner wheel tubs. It didn’t stop there. The welder kept on blazing with a custom raised and smoothed bed floor panel, both top and bottom, smooth sheetmetal on the inside of the tailgate and bead-rolled billet oval No Compromize insert into the tailgate.

After Jimmy finished the work on the front clip and the engine compartment, it was time to get the cab and bed slick and smooth. Starting with the bed, the fuel door, stake pockets, tailgate handle and taillights were all shaved. A motorcycle style fuel cap was added to the top of the bed rail while one-off custom taillights by Greening Auto were frenched in for stylish stopping. A custom roll pan was built, and the dually fenders were raised 2 inches so the 24-inch Raceline would tuck. Jimmy fabricated new bead-rolled sheetmetal to the front outside bulkhead of the bed, and the factory dually fender marker lights were shaved in favor of custom one off machined replacement. Jimmy kept the tools burning by fabricating a push-button tailgate handle on the inside of the tailgate, rounding all four corners of the inside of the bed, building bead-rolled interior sheetmetal inserts inside the inner bed sides, and building widened bead-rolled inner wheel tubs. It didn’t stop there. The welder kept on blazing with a custom raised and smoothed bed floor panel, both top and bottom, smooth sheetmetal on the inside of the tailgate and bead-rolled billet oval No Compromize insert into the tailgate.

Ever since the truck came off the road and was torn down in ’03, the color of choice for the modified metal was to be red. When it came time for the metal work to be body worked and covered in color, Mike delivered the truck to Justin and Eli Griffin at Twin States Rod Shop in Meridian, Mississippi. Once the truck was arrow straight, smooth and ready for color, it was time for the booth and the ultimate decision on color. Since the chassis was already red and Mike wanted it to stand out, it was decided that the body better be an opposing color. BASF RM products were custom mixed to come up with the custom color nicknamed “SEMA Gray,” and the truck was coated from nose to tail and roof to rocker and the liquid art buried in RM Glamour clear coat.

Ever since the truck came off the road and was torn down in ’03, the color of choice for the modified metal was to be red. When it came time for the metal work to be body worked and covered in color, Mike delivered the truck to Justin and Eli Griffin at Twin States Rod Shop in Meridian, Mississippi. Once the truck was arrow straight, smooth and ready for color, it was time for the booth and the ultimate decision on color. Since the chassis was already red and Mike wanted it to stand out, it was decided that the body better be an opposing color. BASF RM products were custom mixed to come up with the custom color nicknamed “SEMA Gray,” and the truck was coated from nose to tail and roof to rocker and the liquid art buried in RM Glamour clear coat.

Completion of the metal work, body work and paint led to wiring before the truck was delivered to the upholstery and audio shop for threads and sounds. Justin and Eli Griffin installed a Painless Performance wiring harness to connect all of the electrical dots and a custom motor wire harness from Tempe Speed & Performance to get the bigblock cranking.

Completion of the metal work, body work and paint led to wiring before the truck was delivered to the upholstery and audio shop for threads and sounds. Justin and Eli Griffin installed a Painless Performance wiring harness to connect all of the electrical dots and a custom motor wire harness from Tempe Speed & Performance to get the bigblock cranking.

No head turning, jaw dropping and awardwinning custom show truck is complete without a double throw down interior and some tunes to pummel ear drums. Aaron Markwell, Jesse Johannesen and the team of Innerworx in Sarasota, Florida, got down on the cabin of No Compromize with the entire interior inner structure built out of ABS plastic and then cut, shaped, layered and routered out to perfection. Innerworx built the custom dash, door panels, center console, overhead console and the seats. A total of 11 hides of Relicate Napa saddle leather were used to wrap the full custom interior. Mushroom Versaweave textile carpet covers the cab floor. Complementing the supple leather and smooth street rod sculpted styling of the threads is a Flaming River steering column topped by a custom machined 15-inch billet steering wheel. Vintage Air climate control keeps show cruising temps in check while Classic Instruments gauges provide accurate reporting on the big blocks behavioral patterns. Further accenting the cruising chamber are a variety of billet dress-up items from Clayton Machine Works. To finish off the interior, Mike had Jeff Bertrand of J&B Microfinish in Pontiac, Illinois, machine custom billet seat recliner handles to match the door handles, while Tony Pasquini of Automods in Sarasota, Florida, performed the interior leather laser engraving NC logos throughout. Tom Hingle of Billet and Acrylic Fantasies in Vero Beach, Florida, designed and machined more than 100 unique custom billet parts placed carefully and strategically throughout the build to add class and detail at every turn. A keen eye will note the “NC” engraved throughout the billet accents signifying two things—the truck’s name, No Compromize, and Mike’s truck club, Negative Camber.

No head turning, jaw dropping and awardwinning custom show truck is complete without a double throw down interior and some tunes to pummel ear drums. Aaron Markwell, Jesse Johannesen and the team of Innerworx in Sarasota, Florida, got down on the cabin of No Compromize with the entire interior inner structure built out of ABS plastic and then cut, shaped, layered and routered out to perfection. Innerworx built the custom dash, door panels, center console, overhead console and the seats. A total of 11 hides of Relicate Napa saddle leather were used to wrap the full custom interior. Mushroom Versaweave textile carpet covers the cab floor. Complementing the supple leather and smooth street rod sculpted styling of the threads is a Flaming River steering column topped by a custom machined 15-inch billet steering wheel. Vintage Air climate control keeps show cruising temps in check while Classic Instruments gauges provide accurate reporting on the big blocks behavioral patterns. Further accenting the cruising chamber are a variety of billet dress-up items from Clayton Machine Works. To finish off the interior, Mike had Jeff Bertrand of J&B Microfinish in Pontiac, Illinois, machine custom billet seat recliner handles to match the door handles, while Tony Pasquini of Automods in Sarasota, Florida, performed the interior leather laser engraving NC logos throughout. Tom Hingle of Billet and Acrylic Fantasies in Vero Beach, Florida, designed and machined more than 100 unique custom billet parts placed carefully and strategically throughout the build to add class and detail at every turn. A keen eye will note the “NC” engraved throughout the billet accents signifying two things—the truck’s name, No Compromize, and Mike’s truck club, Negative Camber.

For cruising beats, Mike went with all Sony components featuring three-way speakers up front, two 10-inch subwoofers in the center console and a sixchanel Bluetooth amplifier with DSP sending the signals.

For cruising beats, Mike went with all Sony components featuring three-way speakers up front, two 10-inch subwoofers in the center console and a sixchanel Bluetooth amplifier with DSP sending the signals.

No Compromize was a 15-year journey in the making from the time Mike tore it down until the day it rolled into the SEMA Show in November 2018. His commitment to the level and quality of the build is self-evident in the finished product. Mike is thankful for the help and support of his wife, Heather, and daughters Madison and Brooke Barcia for allowing him to pursue his dream. Mike would also like to extend his deepest appreciation for the hard work and dedication of the build team, including Justin Griffin, Eli Griffin, Gauge Griffin, Jimmy Graham, Aaron Markwell, Jesse Johannesen, Chris Bareswilt, Gerald Ashe, David Dekorver, Robbie Taylor, Efrain Ramos, Tony Pasquini, Cody Holmes, Chris Douglass, Joe Griswold, Alex Madrigal, Kennedy Brown, Bobby McCurdy, Jeff Bertrand, Andre Brown, Chris Rawlins, Matty Barkley, Anthony DeMichael, Chuck Scheer, Bryan Perreault, Danny Terneus and CJ Fayet. Bad ass trucks, family and friends— what it’s all about!

TRUCK SPECS

Mike Barcia

1996 Chevy C3500 Dually

Tampa, Florida

Negative Camber

Chassis/Suspension

Engine/Drivetrain/Performance

Wheels/Tires Brakes

Body /Paint

Interior

Miscellaneous Custom Tricks

One of the most important things you can hold onto are friendships. Friendships help you build character, define who you are and help you along the way through trials and tribulations. Those friendships often influence your hobbies and interests as you learn about new things and cultures. Since their time in middle school, Robert Walden and his friend Kyle Boring have been close. Although they had different lives and interests, they remained very close.

Kyle got involved in the truck lifestyle and Robert began a career in the pharmacy industry. Oftentimes, Robert would see the trucks Kyle was around and absolutely loved the style and look of them. Kyle was building a 1994 Chevy C1500 and had just added a bodydrop but got distracted by some other projects and set it aside. For about a full year, Robert would ask if he could purchase the Chevy before Kyle finally agreed. Robert had never owned any custom vehicle so Kyle was hesitant at first but figured he would lend a hand.

Kyle got involved in the truck lifestyle and Robert began a career in the pharmacy industry. Oftentimes, Robert would see the trucks Kyle was around and absolutely loved the style and look of them. Kyle was building a 1994 Chevy C1500 and had just added a bodydrop but got distracted by some other projects and set it aside. For about a full year, Robert would ask if he could purchase the Chevy before Kyle finally agreed. Robert had never owned any custom vehicle so Kyle was hesitant at first but figured he would lend a hand.

Robert brought the truck home in pieces—a rolling frame, a cab and lots of other small parts. The frame was painted a bright red, and then tires and wheels with the ’bags were installed. Robert’s friend Wesley Copeland helped add the cab to the frame even though there was no wiring or glass yet. Robert’s brother Joshua has a background in bodywork, so he handled all the body smoothing and shaved the doors, gas tank lid, drip rails, third brake light, tailgate handle and antenna.

The interior was half done, with Kyle trying to use a ’59 Impala dashboard inside. It wasn’t fitting properly, so Wesley and Joshua stretched it 2 inches on each side, making it fit into place. The body was a light gray primer and the frame was bright red, so Joshua coated the entire 1994 Chevrolet truck in a bright red mix that matched the frame. The next step was making sure the Chevy would be a solid driver, so an LS6 was pulled from a ’04 Silverado and fit into the engine bay. The new intake wouldn’t clear the hood, so he had to use ZO6 injectors and the hood finally closed. Wesley had to install a custom-built wiring harness from Hotwire to match the right length. After that was wired up, Oilmasters in Tifton, Georgia, built a 3-inch exhaust with true dual Black Widow Venom 250 mufflers. Derek Browing tuned the motor and dialed in the horsepower to put out 410 hp.

The interior was half done, with Kyle trying to use a ’59 Impala dashboard inside. It wasn’t fitting properly, so Wesley and Joshua stretched it 2 inches on each side, making it fit into place. The body was a light gray primer and the frame was bright red, so Joshua coated the entire 1994 Chevrolet truck in a bright red mix that matched the frame. The next step was making sure the Chevy would be a solid driver, so an LS6 was pulled from a ’04 Silverado and fit into the engine bay. The new intake wouldn’t clear the hood, so he had to use ZO6 injectors and the hood finally closed. Wesley had to install a custom-built wiring harness from Hotwire to match the right length. After that was wired up, Oilmasters in Tifton, Georgia, built a 3-inch exhaust with true dual Black Widow Venom 250 mufflers. Derek Browing tuned the motor and dialed in the horsepower to put out 410 hp.

Inside the Chevy, Wesley removed seats from a ’90 Chevy Suburban and cut them down. The foam was reshaped and the factory seat slides remained. The seats were stitched up using black and red houndstooth centers. Joshua assisted Robert with getting the black carpet mounted along with the door panels and new poppers for the doors. Robert called in about five friends to get the bed back on the truck and lined up. Kyle and his crew at his business, Boring’s Glass Company, got all the glass installed and road ready. Robert continued to add final touches with a new center console to fill between the seats. Robert added a box behind the seats to house the battery for the Chevy.

Since his purchase of the rolling chassis, Robert has about 3,000 miles on the Chevy C1500 traveling to shows and events all throughout the country. He owes his dedication and passion to his loyal wife Jessie, who insisted he finish the build no matter how long it took.

Since his purchase of the rolling chassis, Robert has about 3,000 miles on the Chevy C1500 traveling to shows and events all throughout the country. He owes his dedication and passion to his loyal wife Jessie, who insisted he finish the build no matter how long it took.

Robert was able to make Door Dragger a huge success with the helping hands of all his close friends and brother. His lifelong friendship with his middle school buddy Kyle led Robert to purchase and help build his very first truck.

Owner

Robert Walden

1994 Chevrolet C1500

Moultrie, Georgia

Club Affiliation: Aftermath

Chassis

Front Suspension: Michigan Metal Works control arms, Belltech drop spindles, Slam Specialties SS7 bags

Rear Suspension: Ektensive two-link with Panhard bar, box back half frame, Slam Specialties SS7 ’bags, two Viair 400c compressors, two 5-gallon air tanks, Accuair E-Level air management system

Drivetrain

Engine: 6.0 LQ9, upgraded cam, springs, rockers, LS6 intake, Z06 injectors, tuned by Derek Browning of Browning Tuning, 3-inch custom exhaust, true dual Black Widow Venom 250 mufflers

Transmission: 4l60e

Rearend: 9-inch Ford rear end, limited slip, 3:50 gears

Body/Paint

Metal work by Wesley “Stick” Copeland

Paint and bodywork by Joshua Walden

Shaved drip rails, door handles, third brake light and tailgate

Traditional 4.5-inch bodydrop

Custom-mixed red paint

10-gallon custom stainless fuel cell

New clear glass by Boring’s Glass Co. in Moultrie, Georgia

94-98 GMC grille with billet insert

LED headlights and taillights

Sir Michael’s rollpan

Tailgate handle flip kit

Interior

1959 Chevy Impala dashboard swap

Omega Kustom gauges

1990 Suburban seats cut down and reshaped by Thomas at Top Shop in Cairo, Georgia

Custom built door panels and center console

Interior work done by Wesley Copeland

Retro style billet steering wheel black half-wrap

Stereo: Pioneer head unit, Pioneer components, Pioneer shallow mount 12-inch subwoofer, two HiFonics amplifiers

Wheels & Tires

Wheels: 22×9 Intro Radicalli polished

Tires: 255/30R22 and 265/35R22 Pirelli Scorpions

Special Thanks: My wife Jessie, Wesley “Stick” Copeland, Joshua Walden and Kyle Boring

Before the pandemic, life was easier in so many ways for so many people. One problem we constantly heard was builders had increased customer orders but couldn’t procure the materials needed for manufacturing, which is what we went through while trying to create content for our tech section.

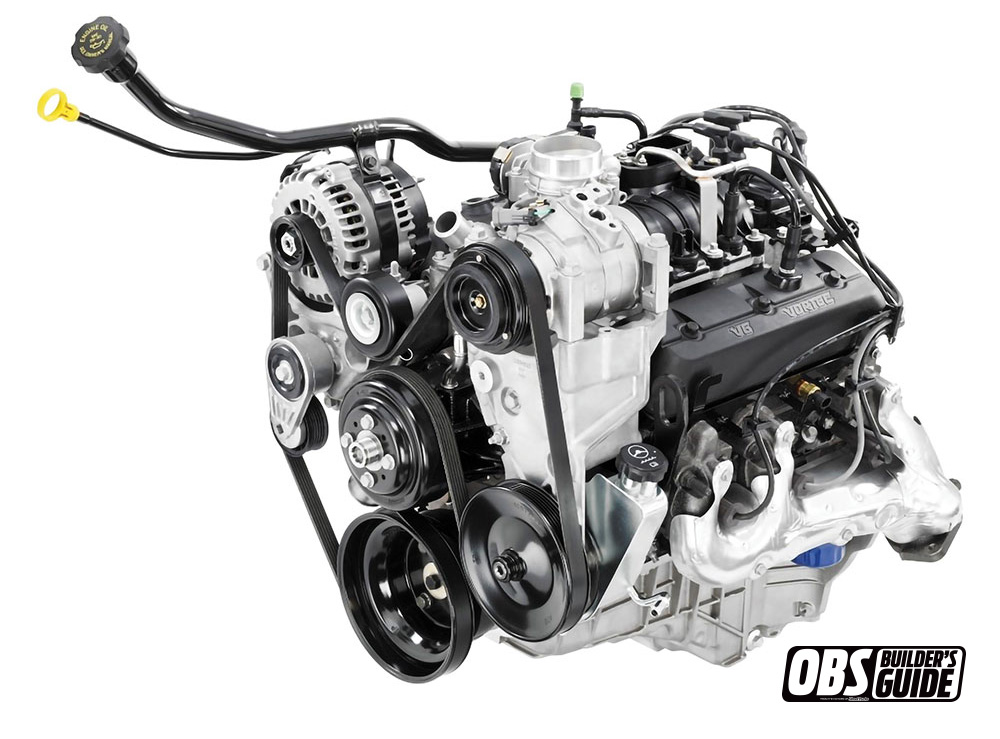

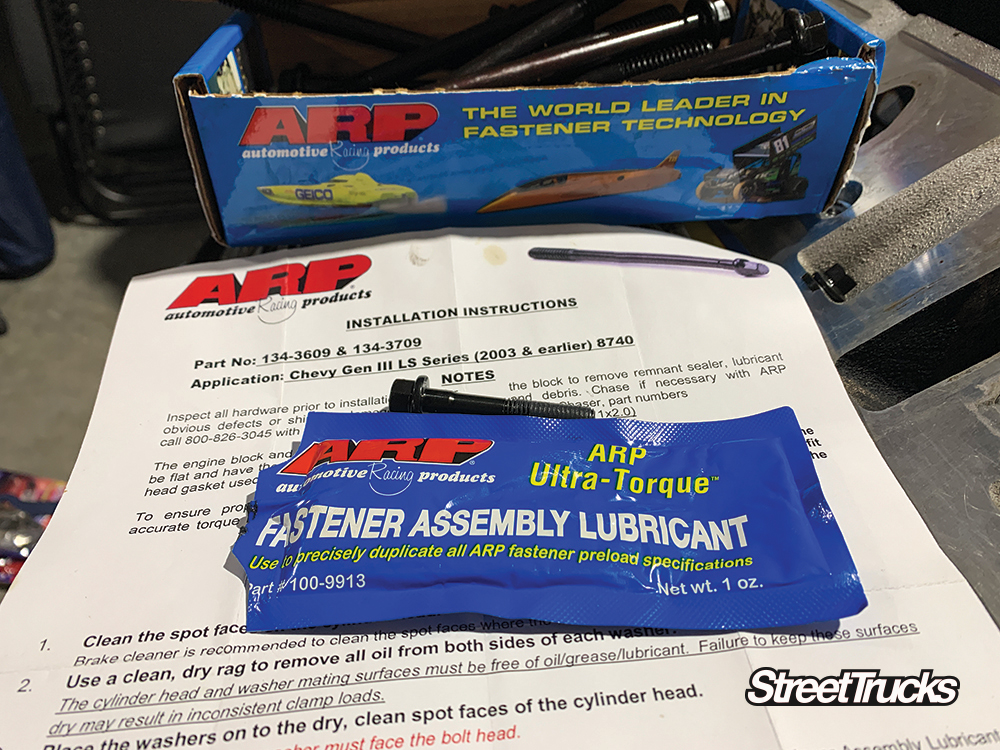

The last time we visited this particular project was over six months ago with the installation of a QA1 coilover suspension. This 1997 Chevy C1500 now handles like a rail car but lacks the power to really test out the engineering. Yes, we could upgrade the factory 305ci engine to gain a few hundred horsepower, but the time, dollars and effort spent doing that would be on par with a complete LS engine swap. So that’s the route we are going on this build, and we really hope you follow along.

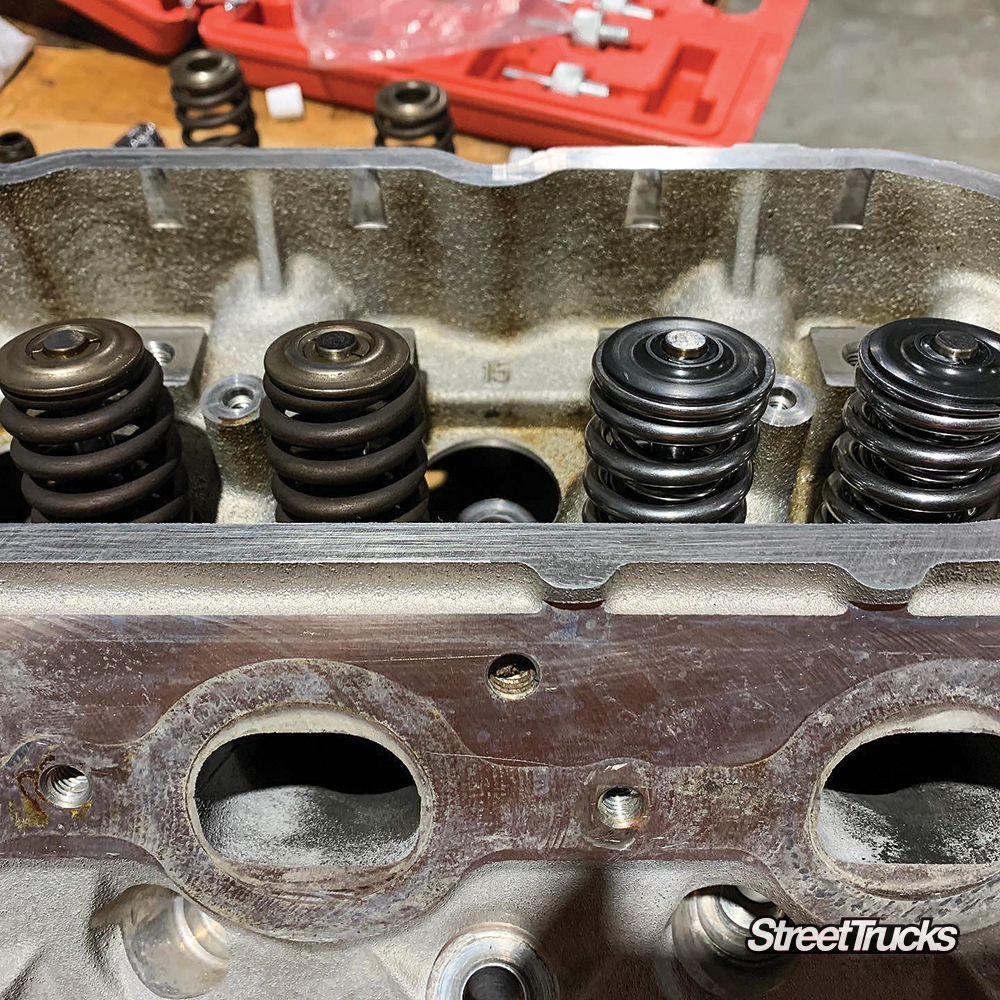

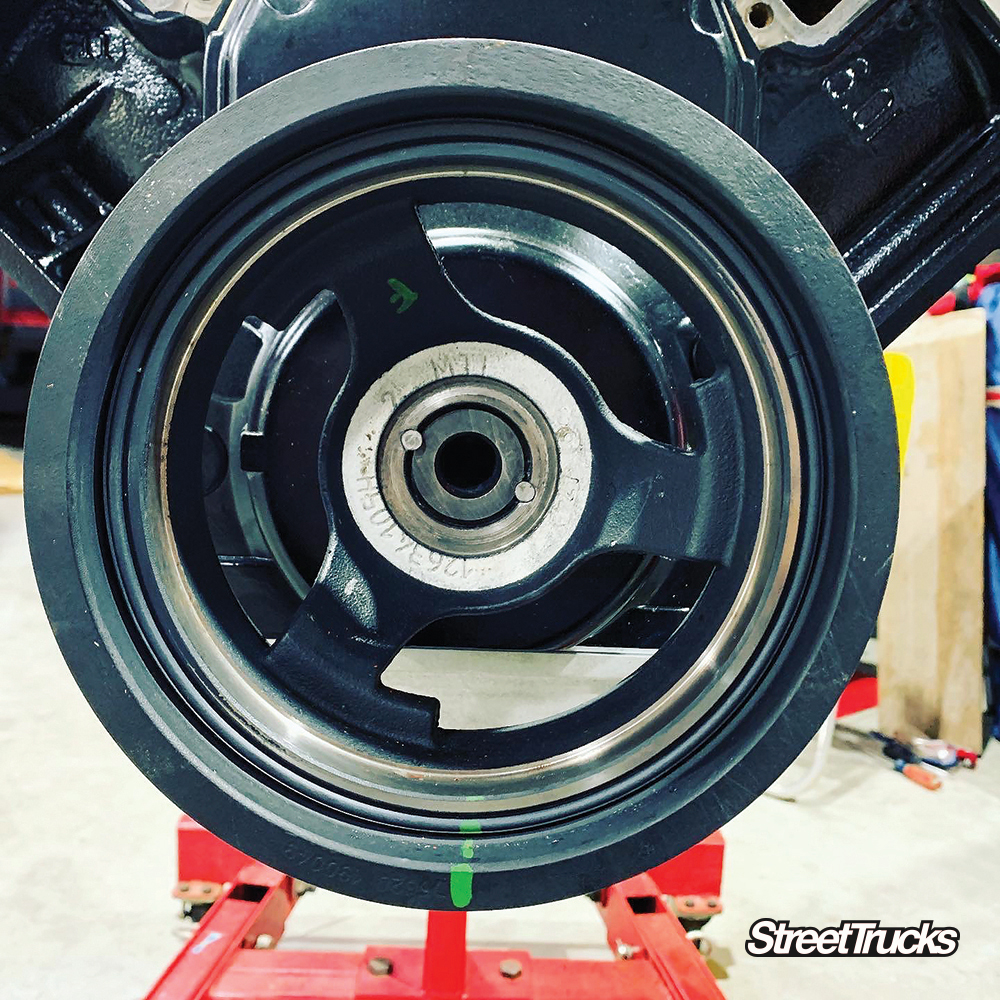

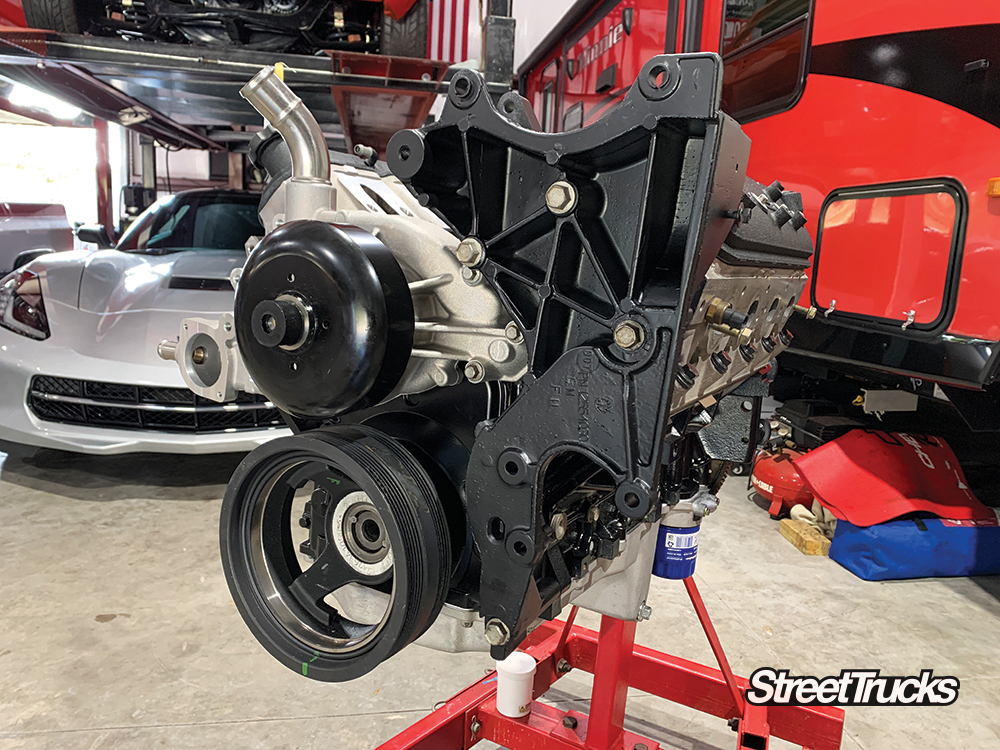

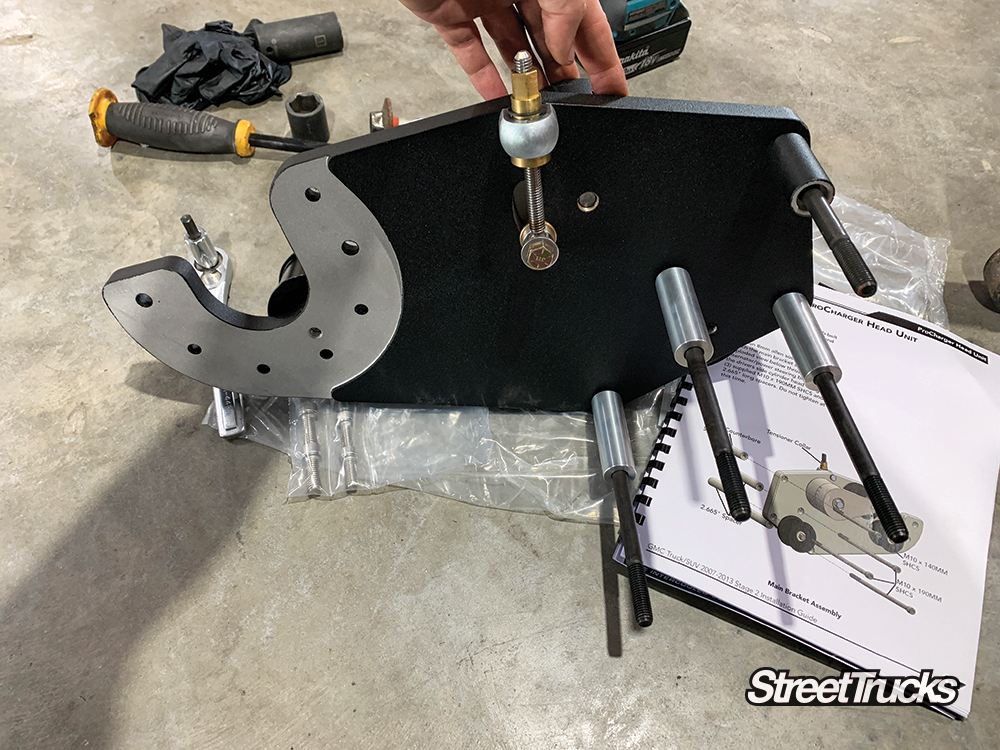

Our block of choice is a 6.0-liter LS engine out of a 2003 Silverado 2500 HD. We are going to completely strip it down and prep it properly for the big power we expect to get with this ProCharger supercharger system. Along the way, we will strengthen the structure with ARP bolts and paint it nicely to match the rest of the truck. This P-1SC-1 supercharger system from ProCharger is self-contained (SC) and the only gear-driven centrifugal superchargers to feature self-lubrication. SC ProChargers also feature the highest step-up ratio, exclusive billet impellers and the industry’s only billet gearcases for superior rigidity, sealing and appearance.

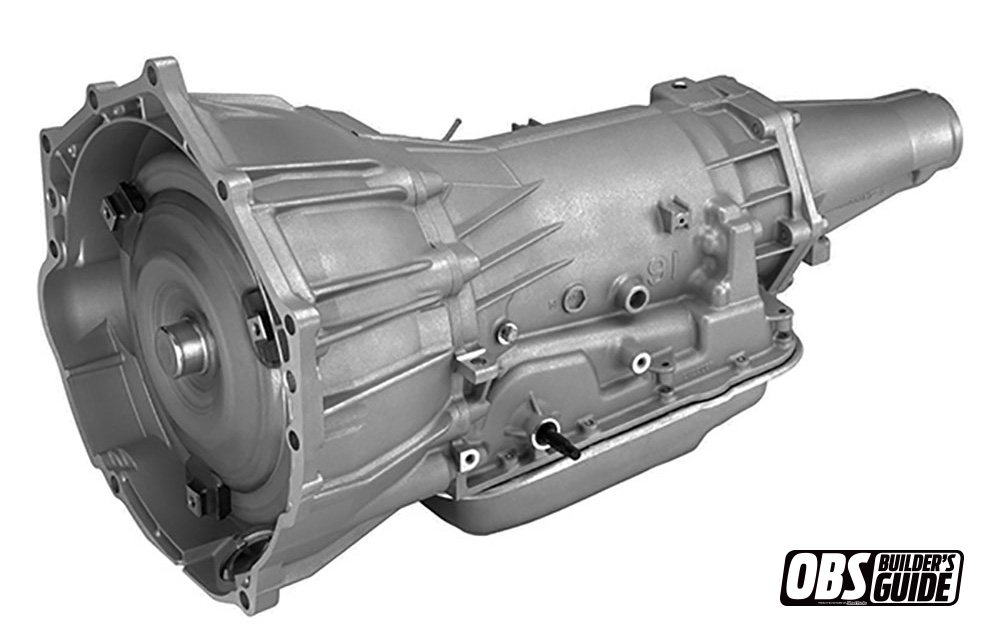

We are sending the harness to Current Performance Wiring for a complete overhaul. Which will make it plug and play with our 6.0-liter LS. The follow OEM wire colors and use OEM connectors to produce the best quality products. They go through a multi-step quality inspection process that’s guaranteed to meet or exceed even the most demanding show car owner’s expectations. We are replacing this original OEM transmission with a Chevrolet 4L80 transmission to handle the additional power and finishing it all off with some Red Line fluids. Keep in tune with this one because the end result will be something you want to see, we promise!

Current Performance Wiring manufactures custom engine & transmission harnesses for:

Check Out A Video: https://youtu.be/EPQQWeW8xFI

SourceS

ARP Bolts

800-826-3045

arp-bolts.com

Current Performance Wiring

727-844-7570

www.currentperformance.com

ProCharger Superchargers

913-338-2886

www.procharger.com

Red Line Oil

800-624-7958

www.redlineoil.com

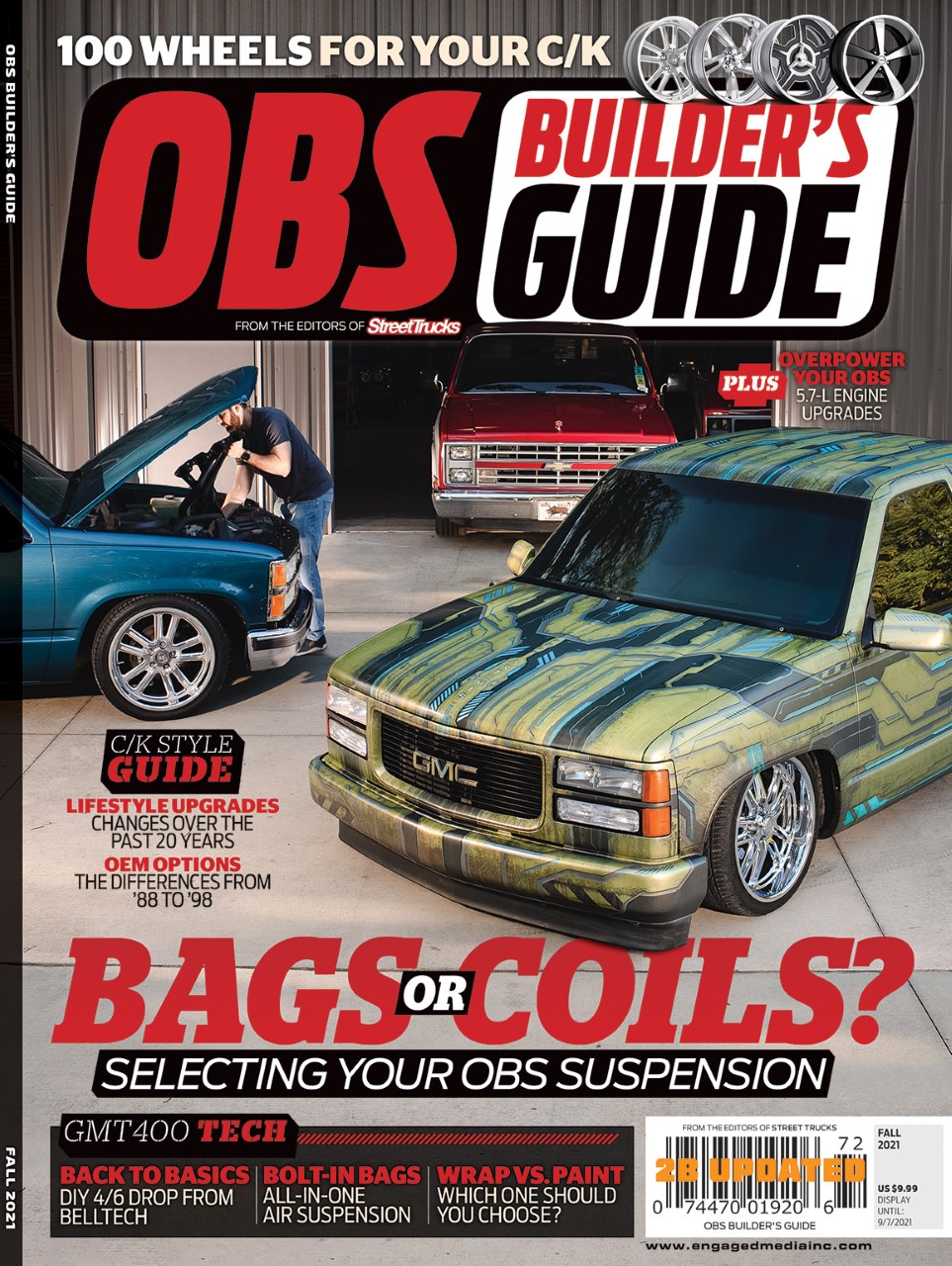

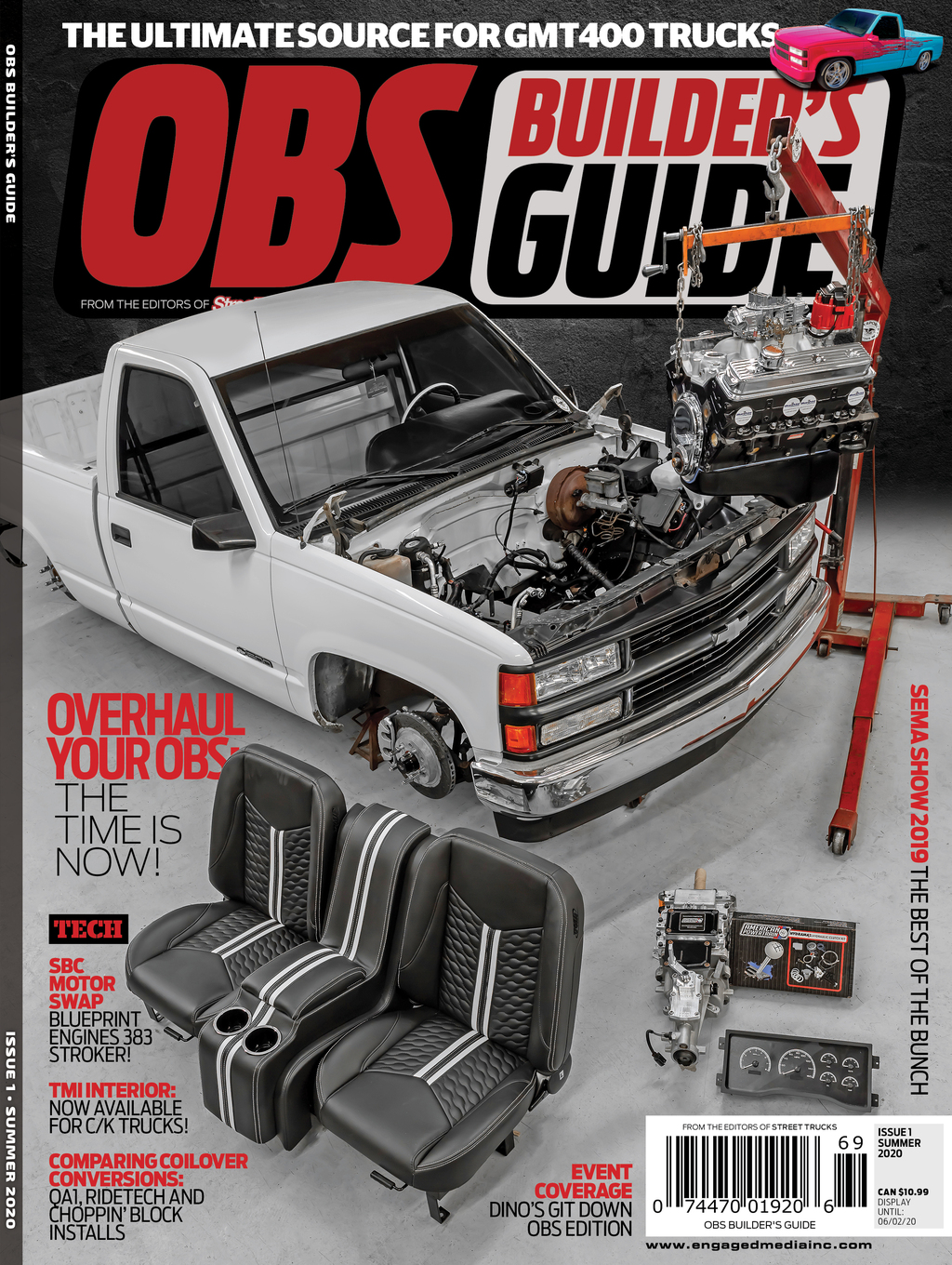

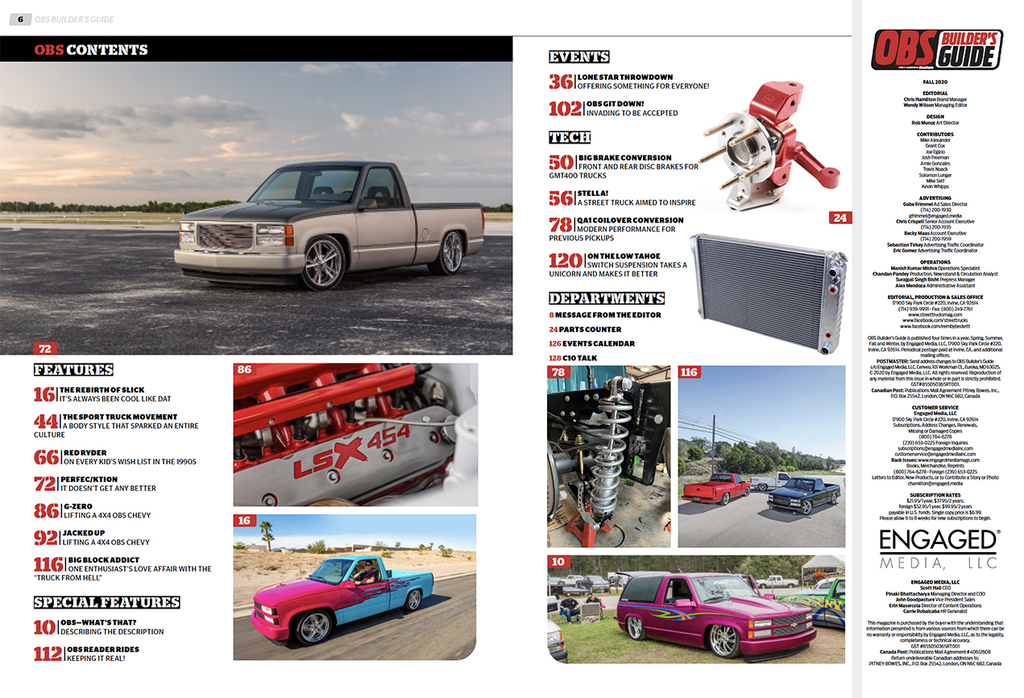

Premier issue number one of OBS Builder’s Guide was so successful, we’re going to do it again! From the editors of Street Trucks Magazine comes the all-composing guide to restoring and customizing one of the most popular body style trucks ever released. Chevrolet’s 88-98 Fullsize trucks and SUVs spawned a massive sub-culture of passionate enthusiasts, artists, and gearheads worldwide. With over 800,000 OBS (Old Body Style) trucks built and sold within the first year of production, it’s easy to see why this is one of America’s most beloved bodies. The OBS Builders Guide is here to document this trend-setting truck and bring you the best how-to tech, feature stories, manufacture spotlights, event coverage, and new product reveals that relate. In this book you will see things like:

Now that our 1998 GMC sierra is completely covered in an all new custom wrap from GLARB and Tate Designs, we have to take a trip down to Overpower Customs to pick her up. Next stop is Florida Boy Customs for a full custom interior.

We can’t wait to show you guys the strong, stay tuned or be there at Daytona truck meet 2021 for the official reveal! Huge shout out to Josh from C10 Club of Florida for not only towing our project back for us, but also shooting and editing this great video.

We hope to bring you quite a few more of these videos, so you can stay up-to-date with this amazing build.

Project Artemis Debut Article – https://www.streettrucksmag.com/project-artemis-debut-our-1997-gmc-sierra/

Project Artemis Goals and Parts Used – https://www.streettrucksmag.com/88-98-obs-project-artemis/

Project Artemis Front Suspension Install – https://www.streettrucksmag.com/ridetech-air-suspension-project-artemis/

Most everyone reading this magazine understands what a battle building a full custom truck can truly be. The constant snowball effect, the nickel and diming of every little part, the late nights and early mornings, the missed birthday parties and family events, and on and on. But none of this comes close to comparing with the real-life battle that the Neeld family was hit with mid-build.

Jimmy Neeld was handed down a passion for custom trucks from his hero: his pops, Jim Neeld. Father and son, Jim and Jimmy, have worked in the garage together ever since Jimmy was old enough to hand his dad a wrench, and that passion blossomed through the years. They have built a couple rides together and hit the road across the country, enjoying shows and family time and sharing this passion.

But one thing Jimmy was not prepared for during their latest build together was the news of prostate cancer. Mid-build, Jim was diagnosed, and this put things on hold as the family pulled together for Jim. For those who haven’t had the pleasure of meeting Jim or Jimmy, the Neeld family is a strong, tight-knit family, and when one battles, they all battle. The family rallied around Jim. Through surgery, treatment and all, Jim fought the hard road and did so with his family by his side.

But one thing Jimmy was not prepared for during their latest build together was the news of prostate cancer. Mid-build, Jim was diagnosed, and this put things on hold as the family pulled together for Jim. For those who haven’t had the pleasure of meeting Jim or Jimmy, the Neeld family is a strong, tight-knit family, and when one battles, they all battle. The family rallied around Jim. Through surgery, treatment and all, Jim fought the hard road and did so with his family by his side.

Battling cancer is probably one of the hardest things a person could ever endure, but ringing that bell and beating this silent killer definitely sheds a different light on things. The little things become that much more important, and spending time with his son Jimmy, building their dreams out of their garage, is something Jim had missed dearly. As soon as he was able, father and son jumped right back into the dually build to see it through. As you’ve seen, the Neelds just don’t quit! So, they tackled the hardest parts of the rebuild first to get them out of the way.

Starting on this beast of a dually bed, they redid the sheetmetal bed floor, cut off the old bent-up roll pan and replaced it with a new smooth one. They also added some old school 1989 Cadillac taillights and welded and smoothed the tailgate. Next, the rear fenders were molded to the bed sides and the rear marker lights were also shaved.

Starting on this beast of a dually bed, they redid the sheetmetal bed floor, cut off the old bent-up roll pan and replaced it with a new smooth one. They also added some old school 1989 Cadillac taillights and welded and smoothed the tailgate. Next, the rear fenders were molded to the bed sides and the rear marker lights were also shaved.

Moving on to the cab, they added a bodyline behind the rear doors, shaved the third brake light, shaved the rain gutters, fixed minor body work, and added a smooth cowl and a cowl induction hood to the mix. Because paint and body are what Jim and Jimmy do, they knew this one had to be extra special. A month-long process to the exterior with a little over 3 pounds of Tropical Glitz Frostbite Flake, laced roof and House of Kolor Tangerine Kandy (roof/side stripe), and she was starting to come together. Interior pieces were color matched with PPG beige, and in the bed Jason Feltham from Feltham Fabrications worked his magic on the custom billet FLO airride tanks. Then Brandon Shirley from Mad House Designs pinstriped everything bringing it all together quite nicely.

After the paint and interior work, the new custom cut 24-inch Alcoas were added to make things that much sweeter. And the custom-built spare tire mount for an additional Alcoa in the bed really finishes things off.

After the paint and interior work, the new custom cut 24-inch Alcoas were added to make things that much sweeter. And the custom-built spare tire mount for an additional Alcoa in the bed really finishes things off.

With all of the builds the Neeld family has under their belts, this dually definitely hits home and holds a special place in their hearts. Proof that truly anything is possible, with hard work and a positive outlook on life, miracles can and DO happen! Jimmy and Jim are the type of people the truck industry and scene need more of—good people coming together to spread love and share their passion with others, all the while enjoying and putting their family first. Very proud to call you friends, and can’t wait to see what comes out of the Neeld garage next!

Truck specs

Truck specsJimmy Neeld

1997 GMC C3500

Smith’s Grove, KY

Sunset

24-inch Custom Cut Alcoa’s with 275/25R24 Lexani LX-Thirty tires

Air Lift Performance D2600 ‘bags

Ridetech Strong Arm Uppers & Lowers

FLO Air-ride comps and custom tanks painted by Feltham Fab

Z’d and notched frame for clearance, bed lined frame black

Performed by Jim & Jimmy Neeld

Shaved door handles, antenna, third brake light, roll pan and tailgate

Body Mods: Added bodyline behind rear doors, molded rear fenders, flush mount chopper style fuel cap in the bed rail, 1989 Cadillac taillights, custom spare tire bed mount for an additional 24-inch custom cut Alcoa spare wheel

Bolt-ons: Street Scene smooth wiper cowl panel, front fender flares, billet grille with custom billet grille bumper inserts

Misc.: All clear headlights, turn signals and roof lights, tinted windshield/side/rear glass

Brand and Colors: PPG ambulance white base with 3 pounds of Tropical Glitz Frostbite Flake, PPG black base (lace roof), House of Kolor Tangerine Kandy

Extras: FLO air tanks custom painted by Jason Feltham (Feltham Fabrication), pinstriping by Brandon Shirley of Mad House Designs

Interior color matched PPG beige

Performed by Upholstery by Mike’s Upholstery in Seaman, OH

Seats: Stock seats (front and rear) sectioned and covered in faux alligator and beige vinyl

Dash: Painted PPG tan

We walk you through the 5.3 LS install into Travis’ ’99 Tahoe. This video will explain what parts we used, the main steps we took and the outcome. It is almost like these trucks were made specifically to LS swap as it is fairly easy to do and fit well.

The decade in which you grew up affects your relationship with CHEVY TRUCKS. Maybe your dad, grandpa or uncle had an older C10 model that was kept somewhat stock or had very minimal modifications made to it. More than likely, the odds of gramp’s truck being in stock condition would be more plausible than your pops keeping his ride free of accessories. Having an old pickup around really influences you as a kid and creates memories that stick around into adulthood.

However, if you were reaching driving age when the fourth generation of full-size Chevy pickups was being unleashed onto the public, right around the very late ’80s, you just might have a naturally stronger attraction to this new wave of truck style. The ’90s were on the horizon, and so was a new style of, well, everything. Aside from the “hip” new fashion and music trends, there was a new type of truck on the streets for cruising around with your friends. The evolution of the modern American truck had arrived.

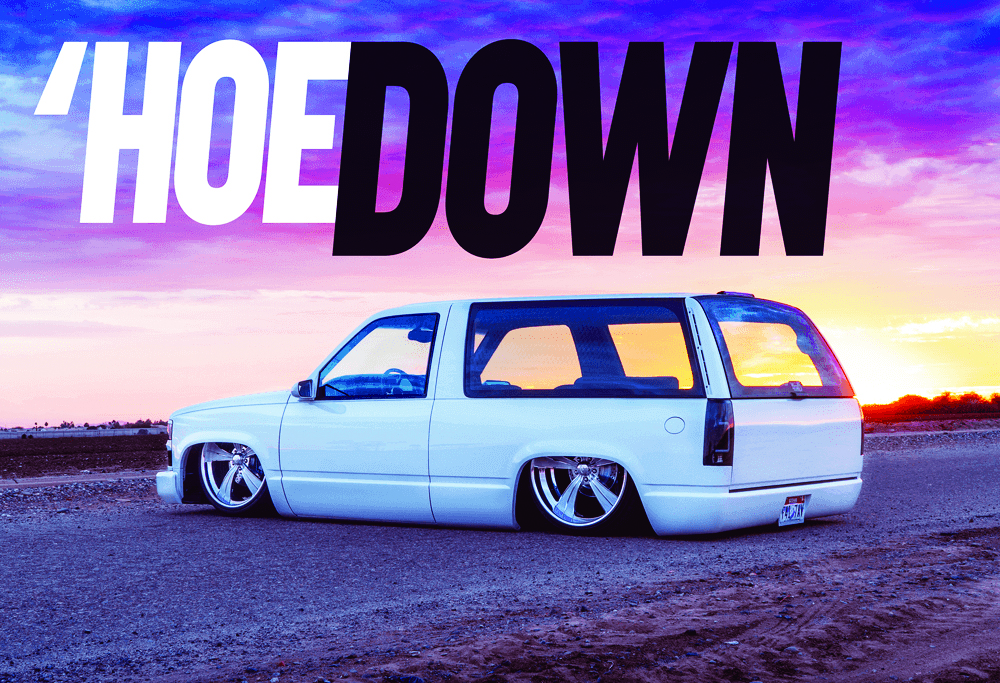

Held in Glendale, Arizona, the world-famous Dino’s Git Down brings together more than 1,600 Chevrolet/GMC trucks from all over the U.S. Originally, this event only accepted Chevy trucks between the years of 1947-1987. After enough requests from the GMT400 crowd, however, Dino and crew decided to open the field this year to include Chevy OBS trucks and SUVs. This gathering is the elite of elite when it comes to quality and craftsmanship, and it’s strictly Chevy/GMC trucks only. That’s right—no Fords allowed!

Dino Battilana is a hardworking business owner during the day and one of the most hardcore Bow Tie believers in the country. Building badass trucks and having friends over to your house for a cookout is satisfying enough for most men, but not for Dino. A once-per-year gathering of gearheads with limits on the line-up and no money needed is more his style. No registration and no admission are necessary—just show up hungry and be ready to talk trucks! For the last 10 years, he has been doing that exact concept, and the whole country is taking notice.

Even though the event was promoted as a single-day event, there were plenty of other cool things to do before and after the show, including a pre-show mixer on Thursday and a Saturday morning cruise to Switch Suspension for tacos! Saturday night is the official 21-and-over after party where things get a little crazy, but more fun can’t be had anywhere else. Try and describe a better weekend than that! Be sure to follow them online so you don’t miss out on your chance to be a part of the biggest free C10 event nationwide. Now let’s check out the OBS pics!

Add modern performance to a pickup that was designed for utility. With QA1’s bolt-on front and rear systems, not only can you lower your C1500, but you’ll also have ride height adjustability on all four corners, giving you that perfect, level stance. The front systems offer up to 5-inch of drop with drop spindles, and control arms provide more room for wider wheels and tires. The rear system offers up to 7 inches of drop, and the torque arm design reduces binding found in other four-link systems.

MSRP:

Front: $2,298.66 Rear: $2,482.87

QA1

952-985-5675

www.qa1.net

Bolt-on coilover suspension systems dramatically improve handling and ride quality when lowering a truck to the 4/6 level or lower. The wishbone multi-link rear suspension, heavy-duty C-notches, tubular A-arms, drop spindles, HQ adjustable coilovers, Musclebar front sway bar, Delrin bushings and R-joints all work together to create the best ride imaginable. And best yet, this kit is also available in an air-ride configuration.

MSRP: $5,900

Ridetech

812-482-2932

www.ridetech.com

This deluxe lowering kit for ’88-’91 Chevy/GMC C1500 includes light duty spindles. Easy to install in your driveway!

MSRP: $668.88

Western Chassis

866-288-5467

westernchassisinc.com

Lower your sport truck or SUV right the first time. Belltech’s complete lowering kits include all the parts and pieces you need to achieve not only the look you want, but the alignment, performance and safety you need.

MSRP: $957.91

Belltech

800-445-3767

www.belltech.com

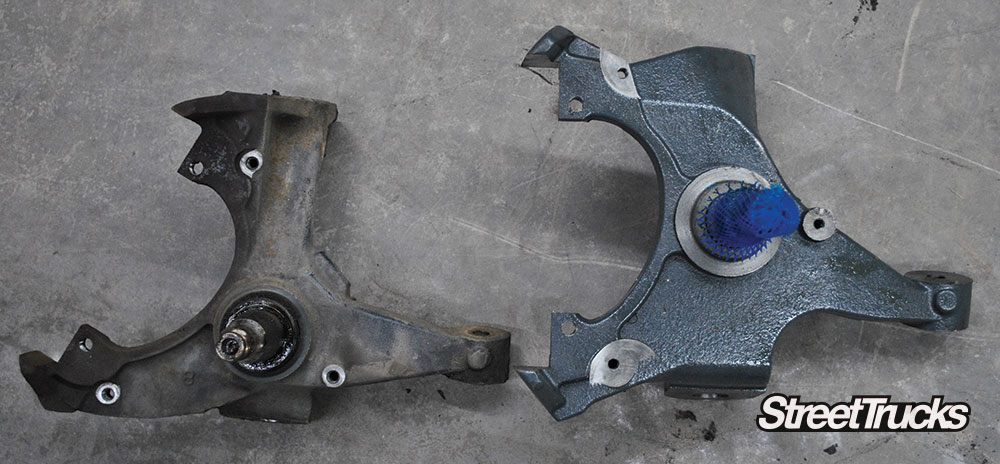

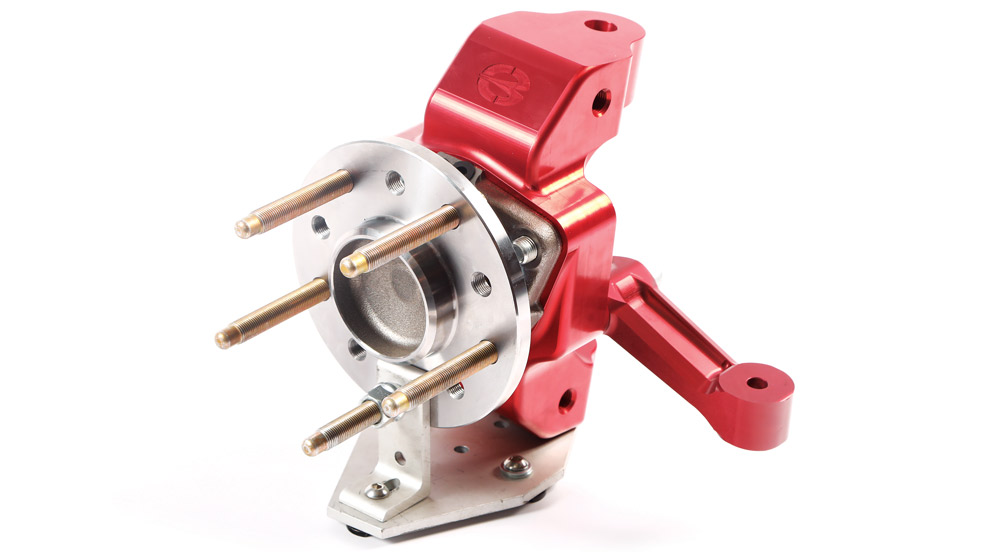

This aluminum 2.5-inch drop spindle for GMT400 GM C/K 1500 2WD truck and SUV models features an OEM style GMT800 sealed hub conversion in dual 5×5, 5×4.75 or OEM 6×5.5 lug patterns. The Modular Truck spindles are also ABS-ready for ’95-’98 factory equipped trucks. The anodized finish will keep these beauties looking and performing great over the long haul.

CB Chassis Products

559-275-2901

ww.cbcpro.com

Aldan C1500 suspension packages are designed to convert your stock, front suspension to fully ride-height adjustable coilovers with adjustable shock absorbers in the rear. They’re designed for the GMT400 and C1500 2WD truck chassis.

MSRP: $915.95

Aldan American

310-834-7478

www.aldanamerican.com

This Air Suspension System is specifically designed for the ’88-’98 Chevrolet and GMC C1500 truck and includes everything needed to create modern drivability with an ultra-low show stance. The package contains front upper and lower control arms, front CoolRide with HQ Series shocks, front sway bar, drop spindles, rear wishbone with C-notches and Shockwaves.

MSRP: $5,900

Ridetech

812-482-2932

ridetech.com

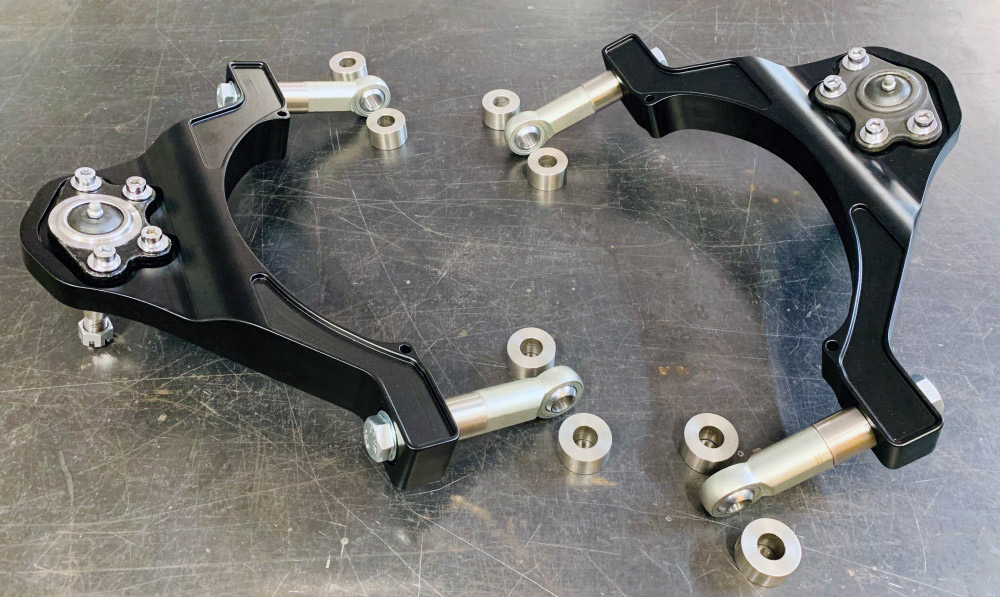

OBS Chevy Racing billet control arms are made out of T-6 6061 billet aluminum and designed to have the utmost in adjustability, strength, ease of use and cool style. Imagine being able to change your alignment in a few minutes depending on the activity. Simply jack up the truck a little to relieve pressure, loosen the top rod end bolts, change out your desired spacer, and you’re ready to go. These arms are great for autocross, road course racing and lowered trucks wanting to get that perfect alignment with style. Correct ball joint angle for lowered trucks, solid billet construction, solid connection through high-end rod ends.

MSRP: $799

OBS Chevy Racing

866-922-3533

obschevyracing.com

Looking to lay out your ’88-’98 full size truck on some 24s? Then you’ll be needing these! Includes one pair of upper and lower control arms, built-in lower bag brackets, built-in lower shock brackets and ball joints.

MSRP: $830

CB Chassis Products

559-275-2901

cbcpro.com

These 3-inch drop springs from CPP are available for a simple factory swap. Pair it with the company’s rear flip kit and shackles for a full 4/6 drop.

Classic Performance Products

714-522-2000

classicperform.com

The combination of Calmax arms and coils springs up front net you out 4 inches of drop without wheel clearance or alignment issues. and we put this together with our DJM 6-inch axle flip kit.

MSRP: $746.62

DJM Suspension

310-538-1583

djmsuspension.com

StreetGRIP is a high-performance 4/6 drop lowering suspension system for ’88-’98 C1500 pickups. Like all StreetGRIP systems, Ridetech focuses on the areas of the OE suspension that need improvement rather than upgrading everything. In the case of ’88-’98 C1500s, that means keeping the factory control arms and leaf springs.

MSRP: $1,800

Ridetech

812-482-2932

ridetech.com

Looking to bag your OBS for an affordable price? AVS makes it easy with this complete all-in-one kit.

MSRP: $2,950

AVS on the Web

559-486-5444

avsontheweb.com

Kit Includes:

MaxTrac Suspension K330546 has an all-in-one solution for your 2WD ’88-’98 Chevy Silverado 1500. MaxTrac drop kits use 2-inch front spindles, 2-inch lowering springs as well as MaxTrac shocks for the front. The rear lowering uses a 6-inch rear flip kit with shock extenders, a rear C-frame support and MaxTrac shocks.

MSRP: $875.38

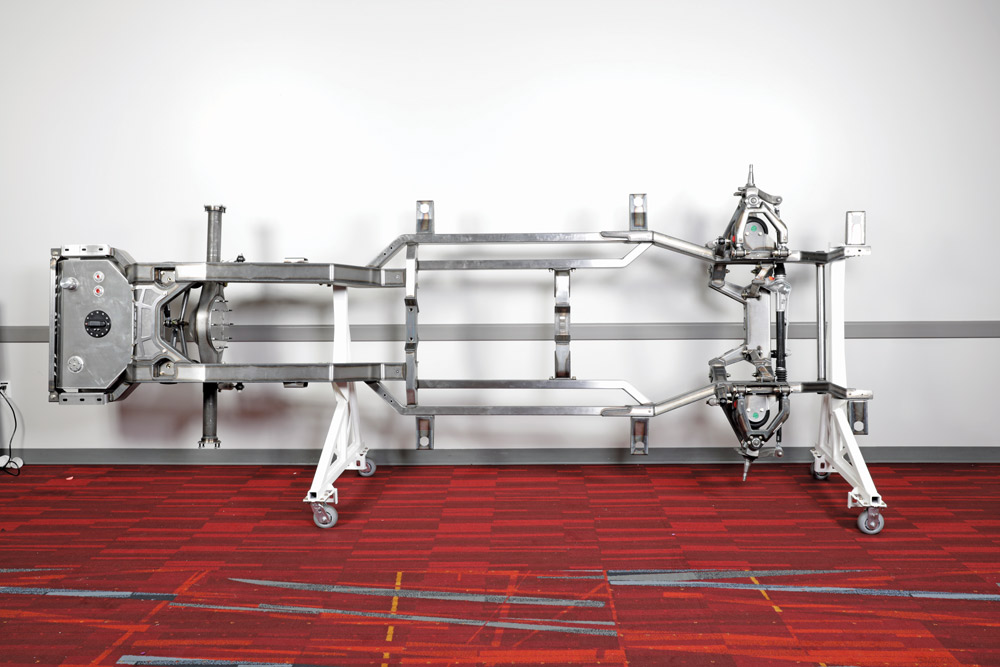

This complete air-ride chassis for “Old Body Style” single cab 2WD GM pickups is engineered to provide the best ride quality and performance for a full-sized ‘bagged truck. Designed from the ground up with all new suspension geometry and modern drivetrain adaptability, this system also allows for large diameter wheels and most aftermarket engine accessories without worrying about any weird fitment surprises.

GSI Machine & Fabrication

480-940-1806

www.gsimfab.com

In this kit, the control arms are narrowed 1-inch on each side for proper alignment; the ball joints are pushed forward ⅞-inch to re-center wheel; bushings are polyurethane, utilizing Moog ball joints; and sway bar heim attachments are included, along with Aldan American Direct bolt-in coils with your choice of spring rate.

MSRP: $1,750

Elevated Concepts

www.elevatedconceptsinc.com

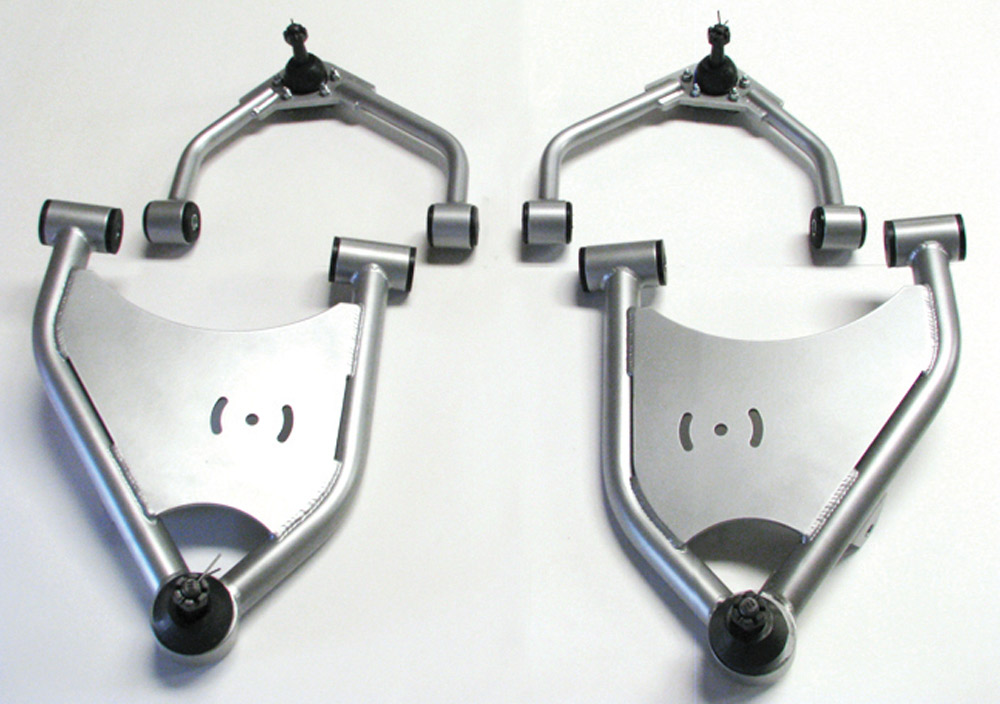

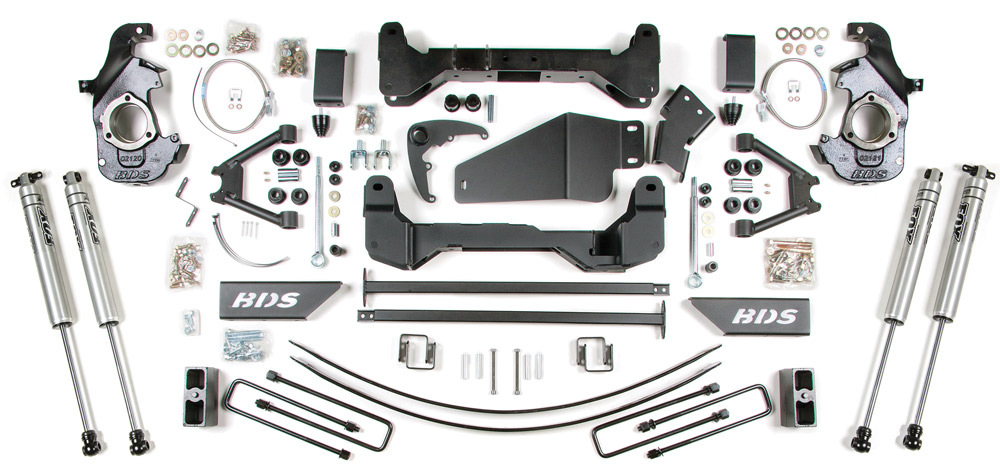

This tightly engineered 6-inch suspension lift kit is designed around two heavy duty upper A-arms, one-piece ¼-inch laser cut high clearance crossmembers and replacement steering knuckles. This combination offers zero track width change, unlike many knuckle kits on the market. Clears a 35×12.5-inch with 20×9 wheels and 5 ¼-inch backspacing.

MSRP: $2,173.59

BDS Suspension

517-279-2135

bds-suspension.com

This complete rear system incorporates both of the bolt-on four-link and cantilever kits together. Fabricated with the quality you’ve come to expect from KP Components, it is able to lay out most 24-inch wheel and tire combinations and offers you about 12 inches of travel right out of the box

MSRP: $1,699

KP Components

888-388-0299

www.kpcomponents.com

MaxTrac offers a 3-inch lifting front coil spring to easily raise your 2WD Chevy Silverado 1500 from the factory stance. MaxTrac also offers a 4-inch lifting block kit for your 2WD ’88-’98 Chevy Silverado 1500. An alternative is the company’s 2-inch rear lifting shackles. Not only are these easier to install than blocks, but they can be combined with a rear block to get additional lift or be used to simply fine tune the ride height of the rear.

MaxTrac

866-409-8673

maxtracstore.com

This rear-only suspension kit from React converts the factory suspension in your 88-98 Chevy truck to a parallel 4-link setup with a panhard bar, c-notch, u-bolts and a rear frame crossmember. This kit is adjustable down to a 7-inch drop in the rear. All made in the USA, so you know it’s solid quality.

Features:

QA1 Rod Ends for Panhard Bar

Satin Black Powdercoated

Run up to 10-inch wide wheels

MSRP: $2,200

React Suspension

480-420-8175

reactsuspension.com

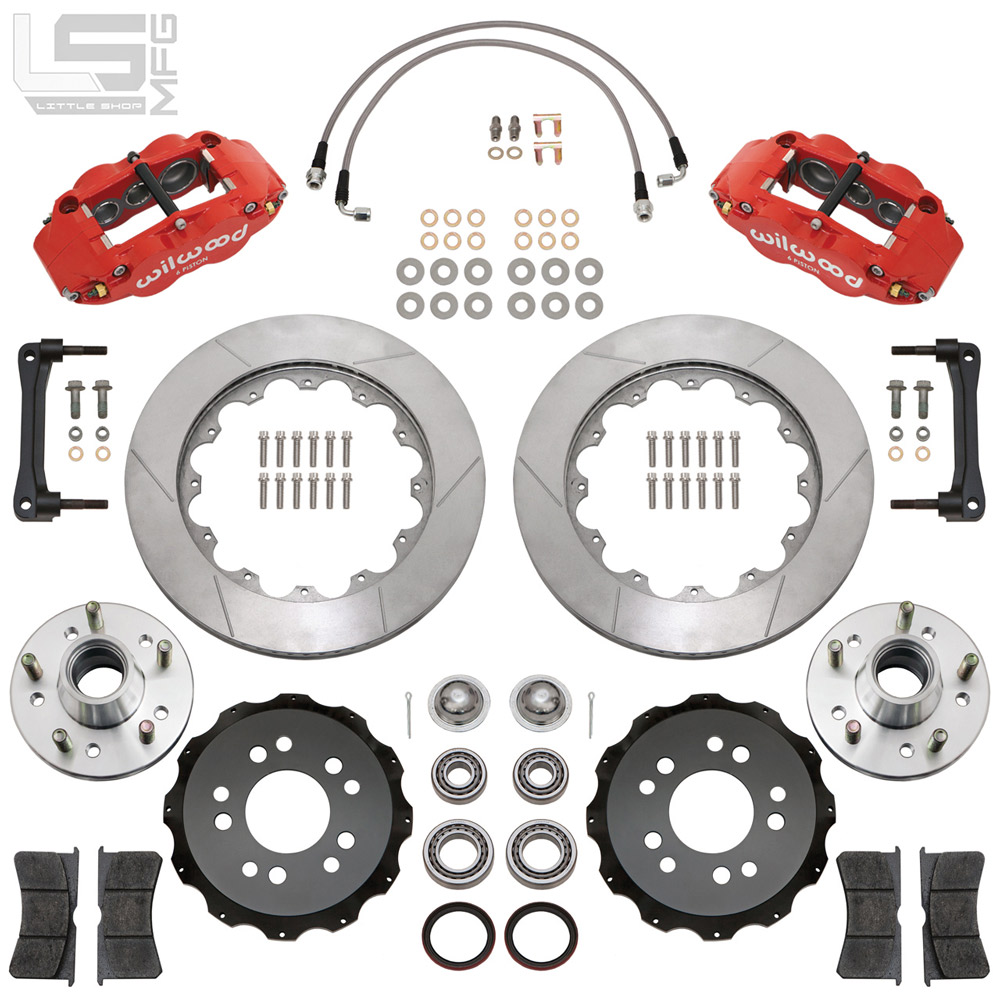

Classic Parts of America price: $199.95

LMC Truck price: $119.95 – $179.95

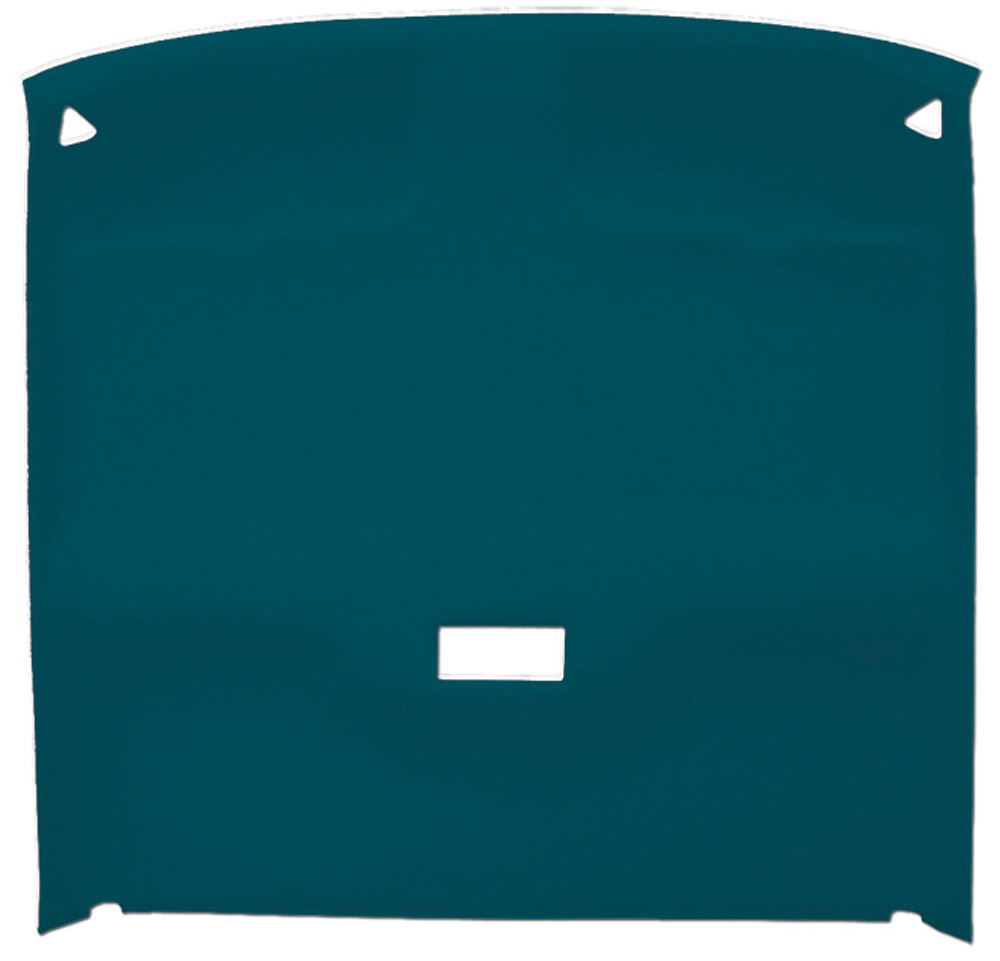

TMI now offers high-value interior automotive components including complete seats with brackets, interior center consoles, carpet kits, all new door panels, even a new headliner. Currently in production for ’88-’94 Chevy C1500 standard cab trucks.

TMI Products

951-272-1996

www.tmiproducts.com

Classic Parts of America price: $244.95

Classic Parts of America price: $299.95

Classic Parts of America price: $399.95

Classic Parts of America price: $94.95

Classic Parts of America price: $24.95

Classic Dash price: $129

Dakota Digital price: $795

Corbeau Racing price: $349

TMI Products

888-460-0640

www.tmiproducts.com

BluePrint Engines offers a direct replacement 383ci Stroker crate engine for ’88-’98 Chevy trucks. This is a small block GM style, fully dressed long block with carburetor. Aluminum heads and a roller cam are preinstalled and drop-in ready.

MSRP: $5,399

BluePrint Engines

800-483-4263

blueprintengines.com

Borgeson steering shaft for full size Chevy and GMC trucks connects to the factory column and OEM steering box. It includes a complete rag joint and billet steel universal joint and weights 5.3 pounds.

MSRP: $248

Borgeson Universal Company

860-482-8283

www.borgeson.com

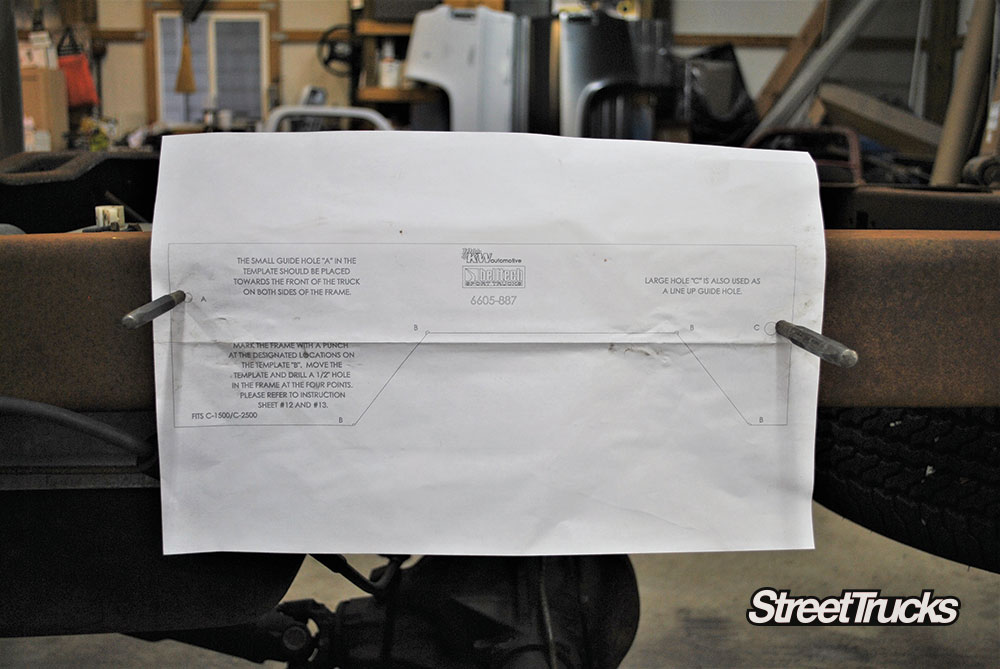

This brake kit will work with any HD brake spindle, such as McGaughy’s, Street Edge, Belltech and even stock. You will receive a template and instructions for modifying your spindle, which requires cutting of the caliper ears and drilling and tapping for the caliper mounting bracket.

MSRP: $1,095

Pro Performance

480-420-8175

azproperformance.com

Pro Performance offers this new brake kit for ’88-’98 Chevy trucks with factory rear ends and does not require machining to the axle or rotors. It uses new calipers, not rebuilt ones. It features laser-cut zinc plated caliper brackets and is designed to fit most 18-inch wheels and larger.

MSRP: $875

Pro Performance

480-420-8175

azproperformance.com

These kits are designed to provide a 30-50% increase in fuel economy, a low RPM cruising for greatly reduced driver fatigue, an improved highway driving experience and reduced engine wear leading to longer engine life with cooler engine operating temperatures.

American Powertrain

931-646-4836

americanpowertrain.com

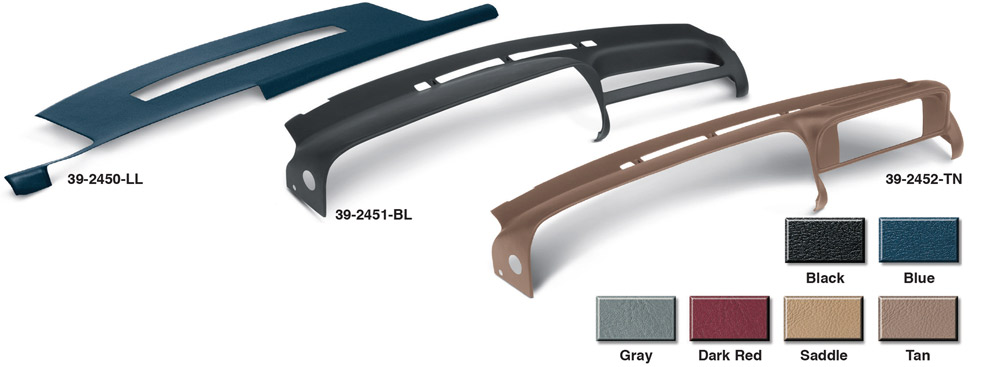

This 14-inch C1500 kit utilizes Wilwood 6-piston FNSL calipers, aluminum hubs, hats and machined 6061 AL brackets that bolt directly to the factory spindles or drop spindles without drilling. Designed to fit ’88-’00 full-size 2WD GM trucks and SUVs.

MSRP: $2,424

Little Shop Mfg.

www.littleshopmfg.com

Works with both ½- and ¾-ton models. Includes motor mounts, frame brackets, transmission crossmember, transmission mount and hardware.

MSRP: $479

This 4WD mount kit locates the engine at the factory bell housing location so you can use your original transmission, transfer case and crossmember.

MSRP: $299

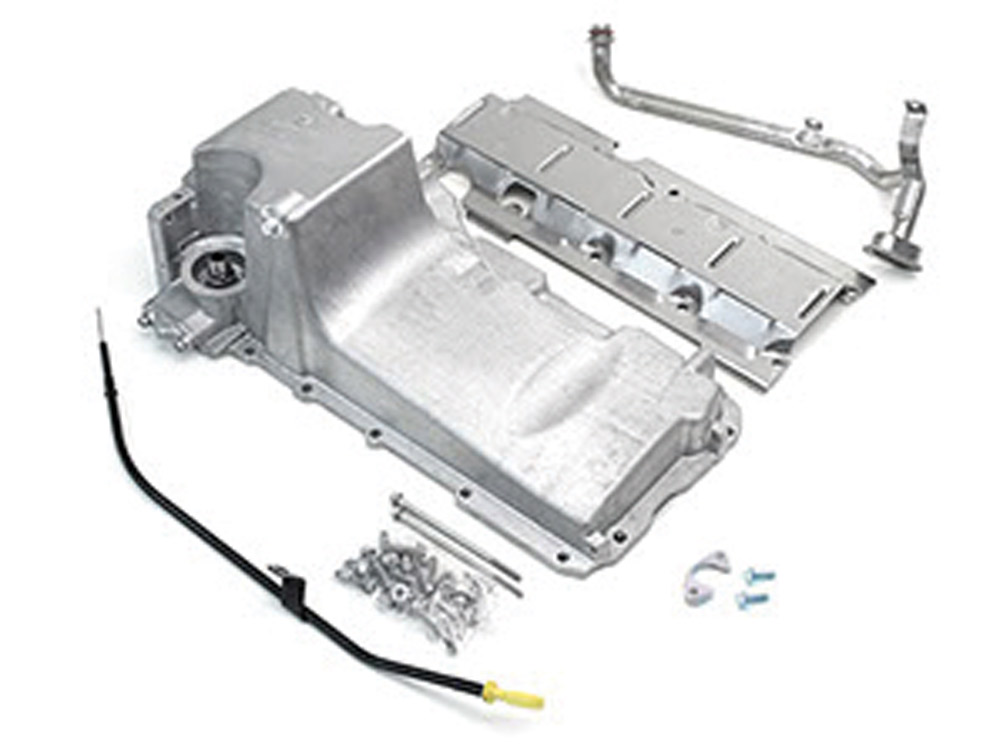

These kits come standard or machined for the oil bypass valve to use with displacement on demand or variable valve timing. They include a new full-length windage tray, pickup tube, hardware, gasket, dipstick and a pickup tube girdle.

MSRP: $249

These headers feature 3/8-inch laser cut flanges with the tubes welded inside and out and then machined. They include gaskets, bolts, reducers and O2 sensor bungs. Standard ceramic finish is polished silver; contact the company for bare steel and black ceramic coated pricing.

MSRP: $249

These radiators feature all-aluminum construction, stamped tanks with strengthening indentations, and a double pass design that put the inlet and outlet on the same side. The all-important steam port bung is welded into the upper part of the tank, which lets your new LS engine vent properly. They also include a sensor port that can be used for a coolant temp fan switch.

MSRP: Starting at $619

BRP HotRods

770-751-0687

www.brphotrods.com

BRP HotRods offers stand-alone harnesses as well as harness and re-flashed computer packages.

BRP HotRods

770-751-0687

www.brphotrods.com

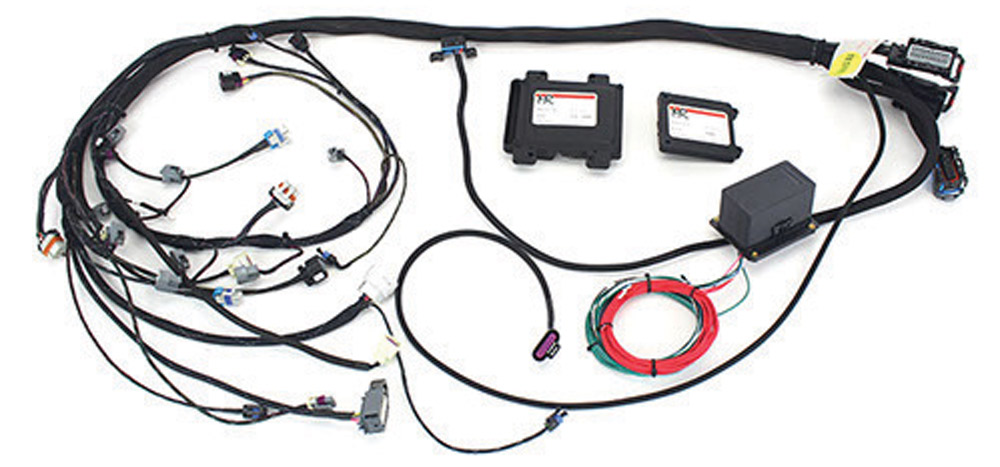

Available for ’91-’07 Chevy/GMC Silverado/Sierra, Suburban and Tahoe, these true plug-and-play custom built harnesses are designed specifically for your project utilizing a ’94-’97 LT1/4 or ’97-up LSx or Vortec small block.

MSRP: $975

Current Performance Wiring

727-844-7570

www.currentperformance.com

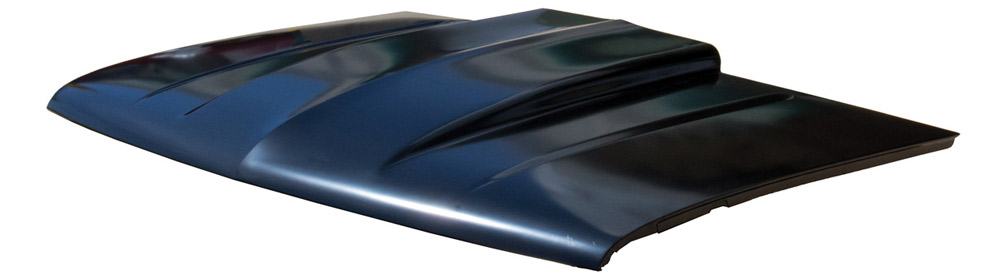

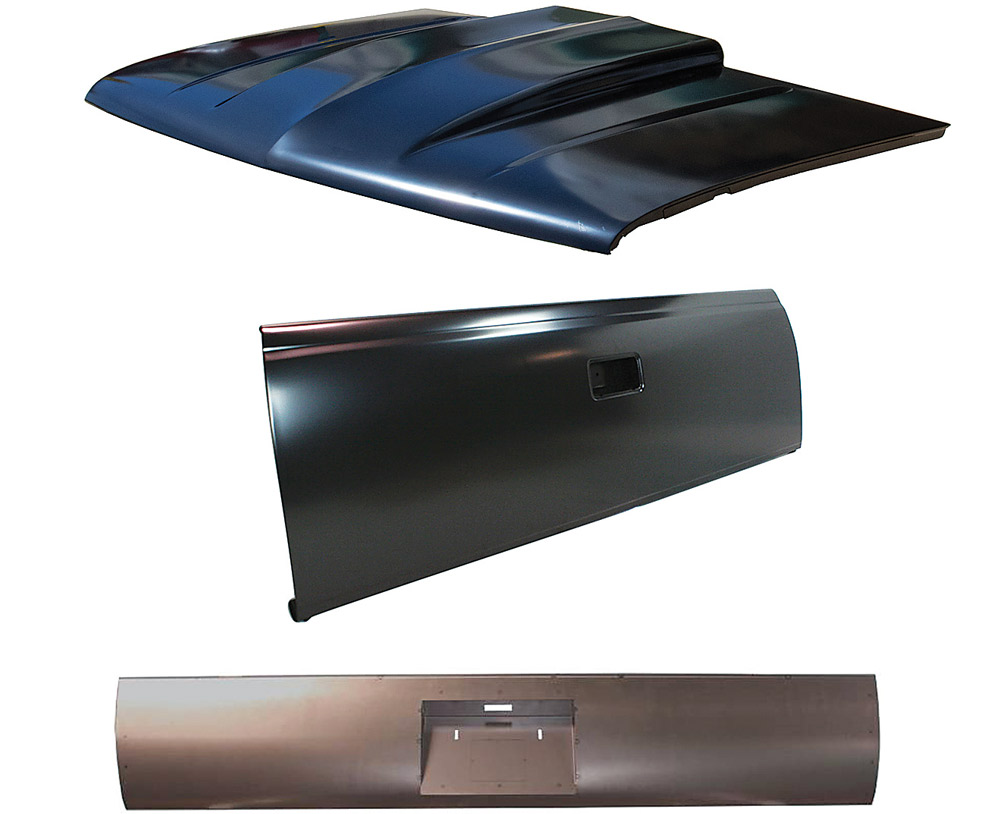

Auto Metal Direct offers hoods for ’88-’98 Chevy GMC C/K pickup, ’92-’94 Blazer and Jimmy, ’95-’99 Tahoe and Yukon along with ’92-’99 Suburban. They’re all stamped from heavy gauge steel with factory style underside.

MSRP: $279

Auto Metal Direct

833-404-4777

www.autometaldirect.com

This six-piece door window channel beltline kit includes the beltline moldings and glass run channels for each front door of the vehicle.

MSRP: $250.99

Steele Rubber Products

800-447-0849

www.steelerubber.com

NPD reproduction tailgates offer a ready-to-paint finish at an affordable price.

National Parts Depot price: $89.95

National Parts Depot

800-874-7595

www.npdlink.com

Lose the bumper and gain the sporty look we all love. AVS on the Web offers roll pans for OBS trucks with and without a tag box.

AVS on the Web price: $190

AVS on the Web

559-486-5444

www.avsontheweb.com

You know those trucks that are awesome at first glance, and then just keep getting more awesome once you really start staring for a while? This is one of those trucks. In fact, a lot of Scott Waksmacki’s ’93 Chevy C1500 is downright understated and takes a trained eye to truly appreciate. As a woodworker, Scott is accustomed to having to get things just right.

Wanting, according to Scott, “…a simple truck to drive…” turned into much more when he decided to drop off his Chevy at Jeremy Miranda’s Miranda Built in Delray Beach, Florida, for a little bit of customization. The zero-rust, low-mileage ’93 Chevy C1500 had always been kept in a garage and was the perfect candidate for a clean street cruiser.

Jeremy started off by lowering the truck with a 5/7 drop from Belltech (with upgraded Bilstein shocks) before eventually bolting on the Cerakote-covered 19×8 and 20×10-inch Hot Rods by Boyd Amarillo billet aluminum wheels and Michelin Pilot Super Sport XL tires in 245/40 and 275/35 sizing. But that’s just what you can see from the outside. What you can’t readily see is that Jeremy fully restored the chassis and narrowed the rearend 3 inches per side to fit the low-offset rear wheels.

Then there’s the other subtle stuff like, well… everything. You’d think that with mods like shaved handles, a shaved cargo light and shaved everything else (also done by Miranda Built), that all of these things would stand out, but that’s the beauty of Scott’s truck—they all blend in seamlessly, as they should, underneath the flawless paint, which was applied skillfully by Keenan Hailey.

Using Jade Green Metallic, Champagne Silver Metallic and Samoa Orange striping, the Chevy’s perfect color combination definitely gives us the same kind of goose bumps we got when we first laid our eyes on the Troy Trepanier-built Chicayne back in the day. And, as you’ll notice, the paintwork itself is amazing, wrapping in and out throughout the cab and bed. Scott shared with us that the green is a Lincoln color, the champagne is from a Cadillac, and the orange stripe is out of Audi’s swatchbook.

Before putting the truck back together, Scott collected all new original GM glass, rubber and door seals to ensure that the truck was as good as, if not better than, brand new. It would also help preserve the spotless, original interior. The only change to the inside was to install a simple audio system, which uses Alpine and JL Audio components for a clean sound.

The finishing touch on the truck was the custom flush-mount aluminum tonneau cover built by Jeremy, which closely resembles the highly coveted Checkmate FX tonneau covers of long ago. Certainly one of our favorite, long-gone products for these trucks!

It’s interesting to note that the truck didn’t leave Miranda Built until every last piece had been restored or replaced, making this essentially a new truck except for the original interior. And yes, the Chevy grille was swapped out for an NOS GMC Sierra unit, with a T-Rex billet grille added for more classic style points. Scott told us that there’s not really anything he’d want to change on his truck, but then he paused and added, “Maybe an LS swap?” And so the endless cycle continues!

The classic movie, “A Streetcar Named Desire,” was recently selected for preservation in the United States National Film Registry for being “culturally, historically or aesthetically significant.” Lately, it seems that ’88-’98 Chevy trucks are quickly being known to have the same qualities in the truck enthusiast world. GMT400 trucks were on every street corner and car show in the ’90s. With massive production numbers and excellent engineering, these Chevy trucks are still pretty easy to come by and available in many different forms, including shortbed, longbed, quad cab and even two different SUV platforms. Oftentimes, the guy who’s buying and restoring these trucks wanted one in his teen years, and now he’s older, generally successful and more financially stable than when he was 16 years old. These factors also drive custom parts manufacturers to focus on making products for the industry icons and get ahead of the popularity curve.

It’s easy to talk the talk and say you’re a fan of this body style, but it’s far more impactful to walk the walk and own one yourself. So, we took the challenge and jumped into the deep end of desire by picking up a running, driving ’95 Chevy C/K truck from the original owner for a smooth $2,000. Cold A/C and a solid cranking 4.3-liter V-6 gave this truck the appeal, but the full gas tank and a fresh oil change showed us that the previous owner still had love for this 20-plus-year-old family member.

To quickly explain the project’s name: “Stella” is a Latin term meaning “star.” The name popped in our heads after we ordered our 22-inch American Racing Nova wheels. The word “Nova” is a female name of Latin origin that has a definition of both “newness” and “of great energy.” It’s also an astronomical term for a star that suddenly increases in brightness, just like this truck’s future. (Plus, Stella was a pretty stellar character in “A Streetcar Named Desire.”) So, with all that in mind, the name Stella just fits, don’t you think?

Over the next few pages, we’re going to take you through the process of giving this truck new life on the same old roads it’s been cruising down since its inception, first starting with a new suspension, upgraded disc brakes and a new set of wheels and tires. That’s only the beginning, but you have to follow along to see the rest. If this truck doesn’t motivate you to go out and start wrenching on your own OBS project, I’m not sure you picked up the right publication. Now let’s get to the good stuff!

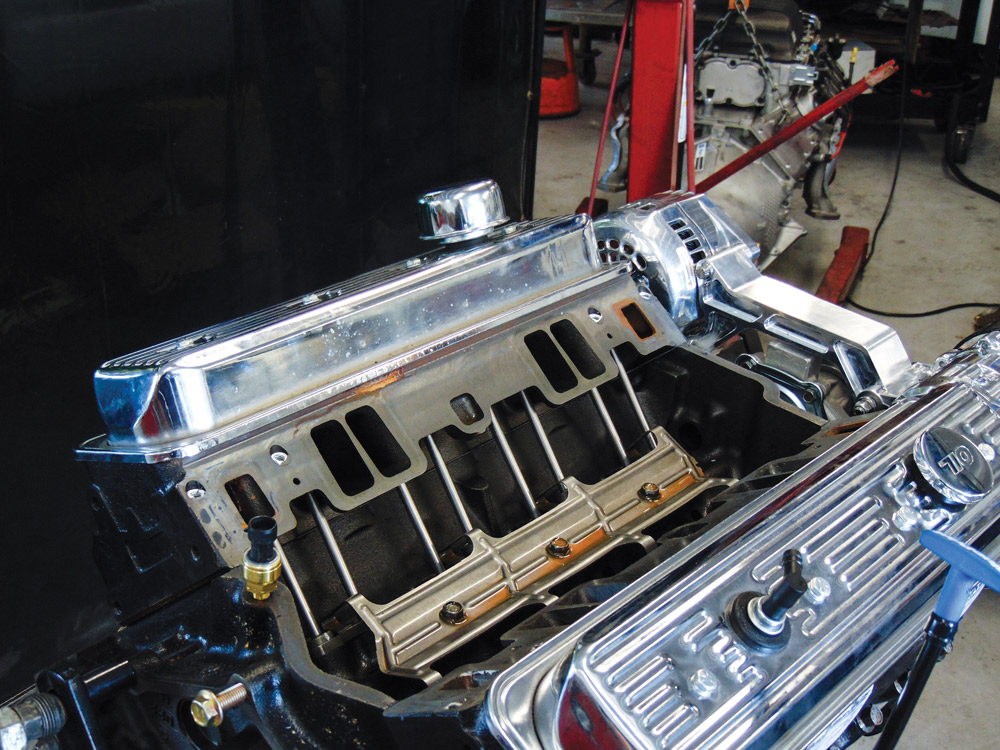

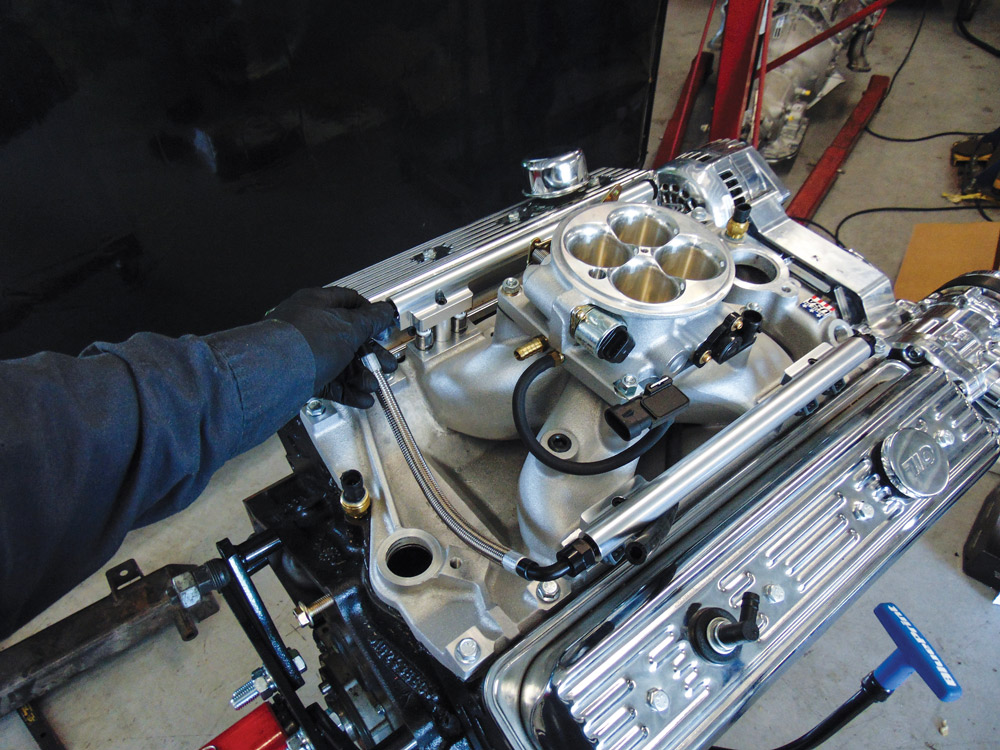

To control our fuel delivery system, we chose to go with Edelbrock’s new Pro-Flo 4 electronic fuel injection. The Pro-Flo 4 is not just a replacement for your carburetor. It’s a complete engineered system that provides the ultimate in performance, drivability and quality. This will result in a smoother idle, faster acceleration, better peak power, improved fuel economy and the ability to control detonation, all in the E-Tuner 4 app.

The key to the improved performance is the fuel injector location, which is at the end of the runner on the intake manifold right before the airflow stream enters the combustion chamber. This location provides a more efficient mixture control that’s unaffected by varying intake manifold runner temperatures and length.

Next to be bolted to the block are our Hedman Hedders designed for the SBC 350ci engine. Hedman Hedders began as a one-man shop in 1954. Bob Hedman, founder of Hedman Hedders, sold his highly sought-after exhaust tubes to fellow racers on the salt flats of the Mojave Desert. But what started out as a way to make a few bucks to pay for Bob’s racing hobby quickly turned into the premier header manufacturer for both the racing and street header marketplaces.

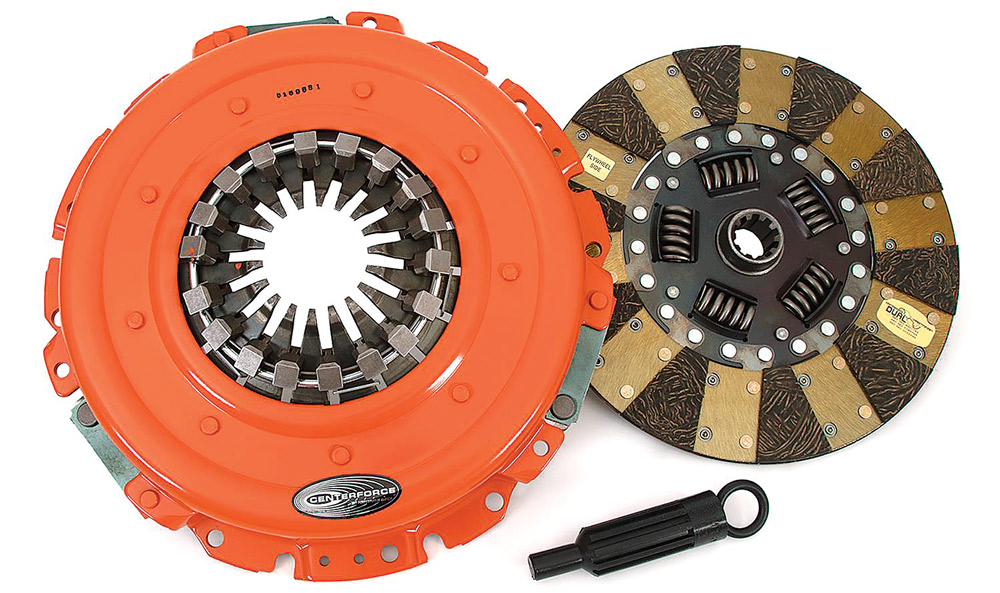

Centerforce is the clutch of choice for our project and recommended by American Powertrain. The Centerforce II Clutch Series utilizes a full facing disc with premium friction materials and a pressure plate with centrifugal weights. It offers superb holding power and maximum clutch life, making this clutch ideal for selected street/strip, off-road and towing applications.

• Patented centrifugal weight design

• Patented ball bearing pressure plate

• High quality friction material

• Light pedal effort

• Increased holding capacity

• Smooth engagement

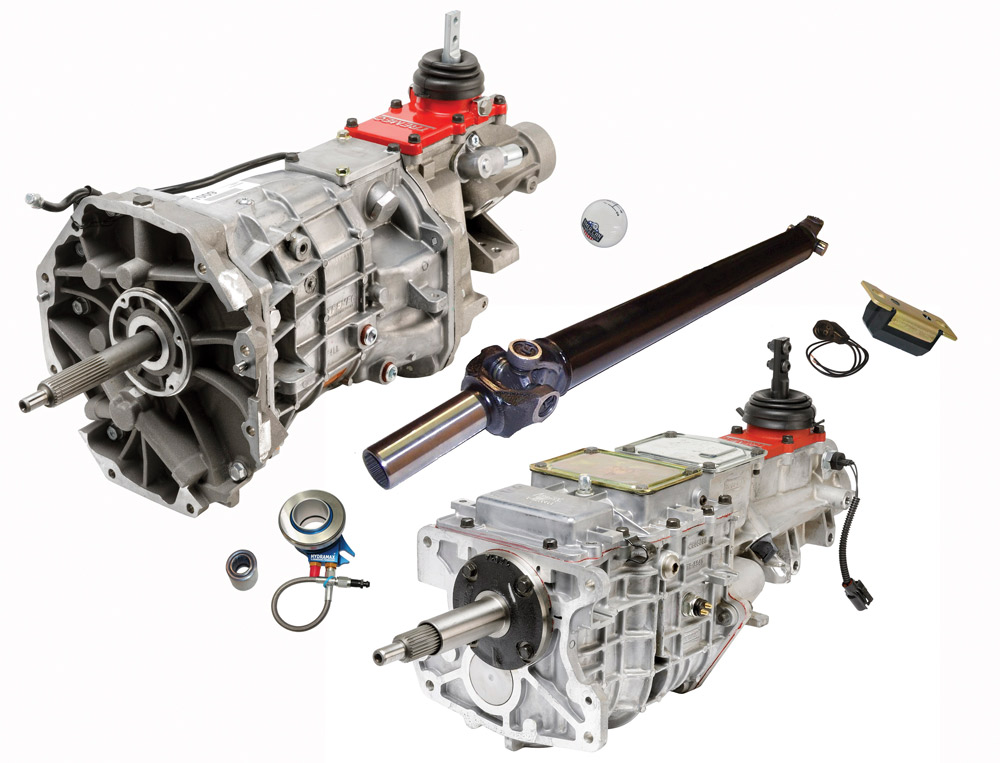

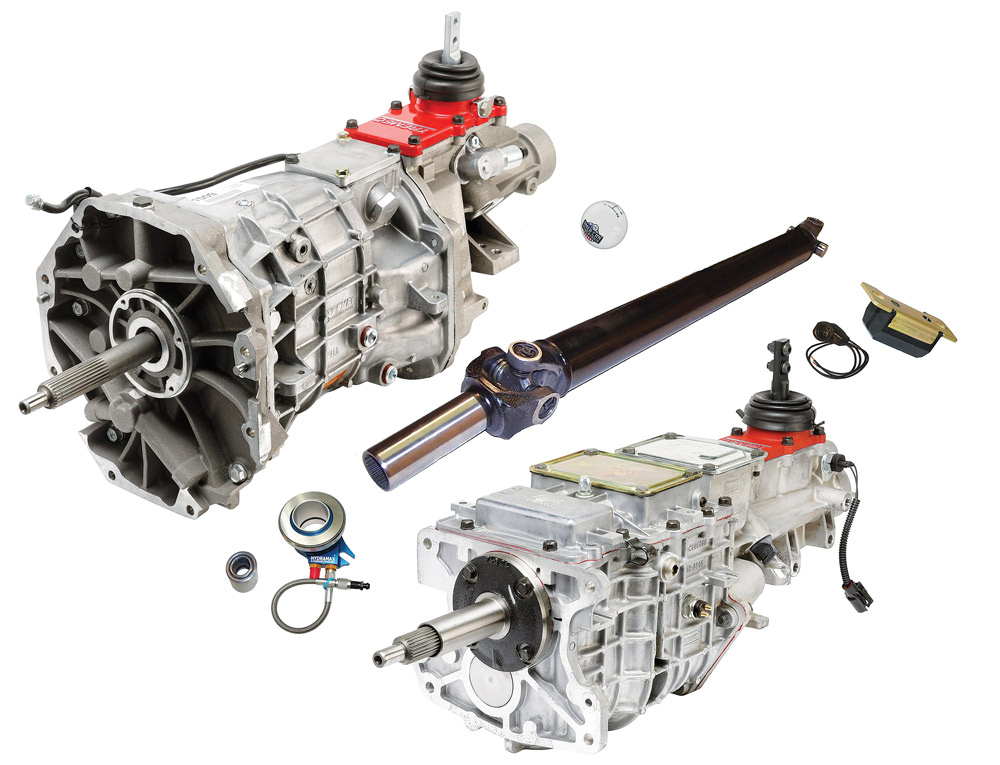

American Powertrain’s Pro-Fit kits for 88-98 Chevy/GMC C1500 OBS GMT400 trucks come in either 5 or 6-speed. There is no need to cut the floor if your truck is already manual since it fits in the factory location. This kit reuses the original cross-member. It’s actually a very easy install!

Benefits Include:

30-50% increase in fuel economy

Low RPM cruising for greatly reduced driver fatigue and an improved highway driving experience.

Reduced engine wear leading to longer engine life

Cooler engine operating temperature

The 88-98 Chevy kit includes

AP Revolution Shifter Mechanism locates shifter that will fit bench or bucket seats

Seamless DOM Driveshaft Assembly that has been race balanced

Solid U-Joints

A Driveshaft Slip Yoke made from Cryogenically hardened steel

Polyurethane Transmission Mount

Greased and pre-packed pilot bearing with stainless rollers

Reverse Light Harness

Electronic Speedometer Conversion

Shifter Knob and all the Hardware and instructions you need.

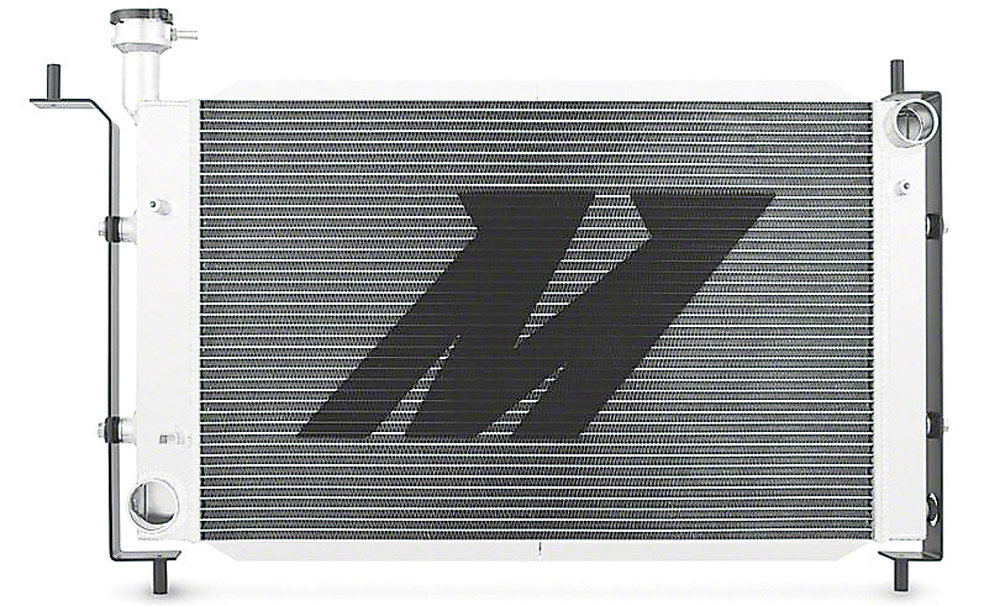

With the engine fully assembled, Trey can slide the engine into the bay and start prepping the cooling system. We used a set of factory V-8 motor mounts to bolt it to the frame and Mishimoto radiators and electric fans. This is a 6.2-liter (383ci) diesel cooling system that Trey recommended for additional cooling. To make it all work correctly, Trey installed a factory OEM diesel coolant reservoir and made a trick aluminum coolant transfer pipe.

Project Sources

American Powertrain

americanpowertrain.com

American Racing

www.americanracing.com

Autometal Direct

www.autometaldirect.com

Automotive Touchup Paint

www.automotivetouchup.com

AVS on the Web

www.avsontheweb.com

AZ Pro Performance

azproperformance.com

Blueprint Engines

blueprintengines.com

Centerforce Clutch

www.centerforce.com

Classic Industries

www.classicindustries.com

Dakota Digital

www.dakotadigital.com

Dynomax Exhaust