Sam Logan August 23, 2022 All Feature Vehicles

Since race pistons in domestic V-8 engines move up and down in excess of 100 times per second, replacing them is a normal part of a racer’s routine. NHRA Top Fuel and Funny Car teams replace them after every race pass and every second qualifying pass. Pro Stock teams replace them after every 40 passes approximately, and weekend warriors replace them every 12 to 18 months, sooner if their engines are nitrous-assisted. At piston replacement time, questions of spec changes usually arise, especially the topic of compression ratios.

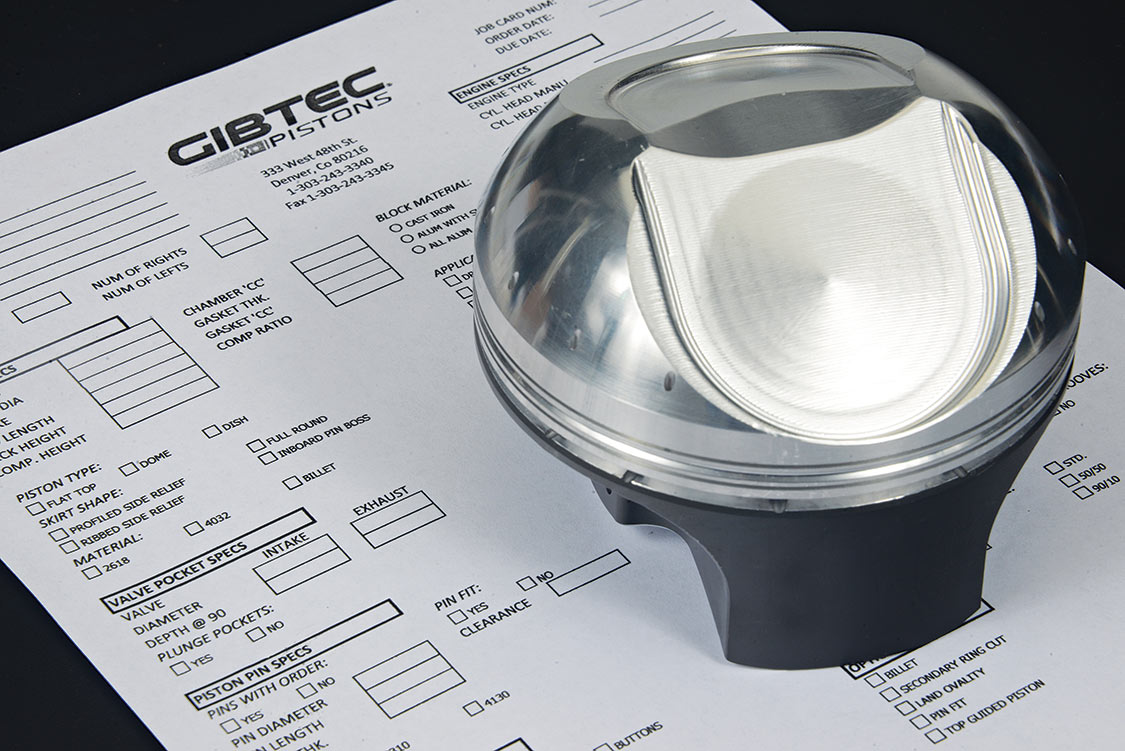

Gibtec Piston’s Rob Giebas explains, “An engine’s compression ratio is calculated by comparing two volumes in the cylinder. One is the swept volume plus the clearance volume. The other is the clearance volume only. The larger the first volume and the smaller the second, the higher the engine’s compression ratio”

Swept volume, also called displacement, is the volume a piston displaces in a cylinder as it moves from its lowest point (bottom dead center) to its highest point (top dead center). Displacement does not include the clearance volume, which is the volume above top dead center. By dividing the combined swept and clearance volume by the clearance volume only, the compression ratio can be calculated.

For example, if the swept and clearance volume of a 632-ci, big-block Chevrolet is 1,380.34cc and the clearance volume only is 86.69cc, the compression ratio would be stated as 15.92:1.

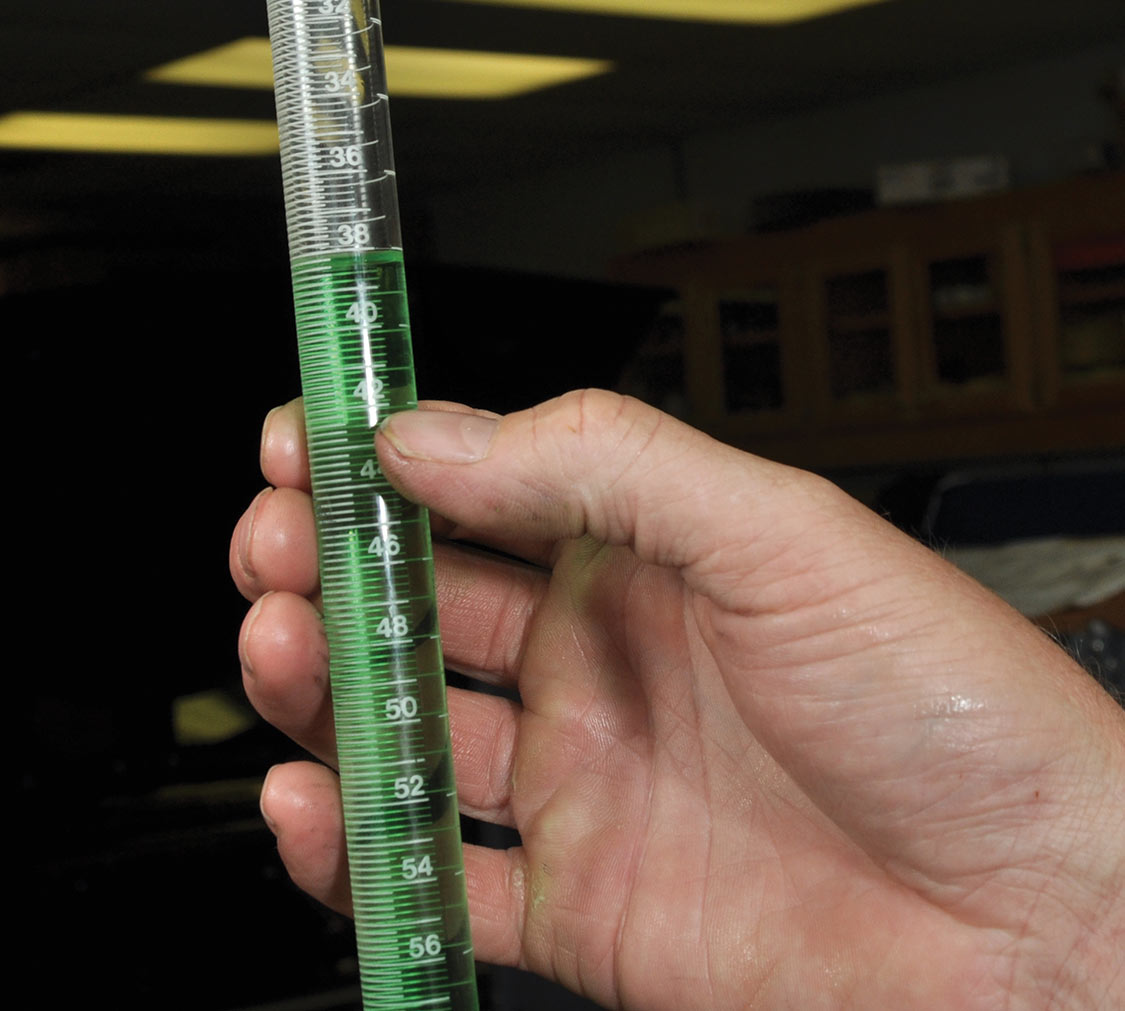

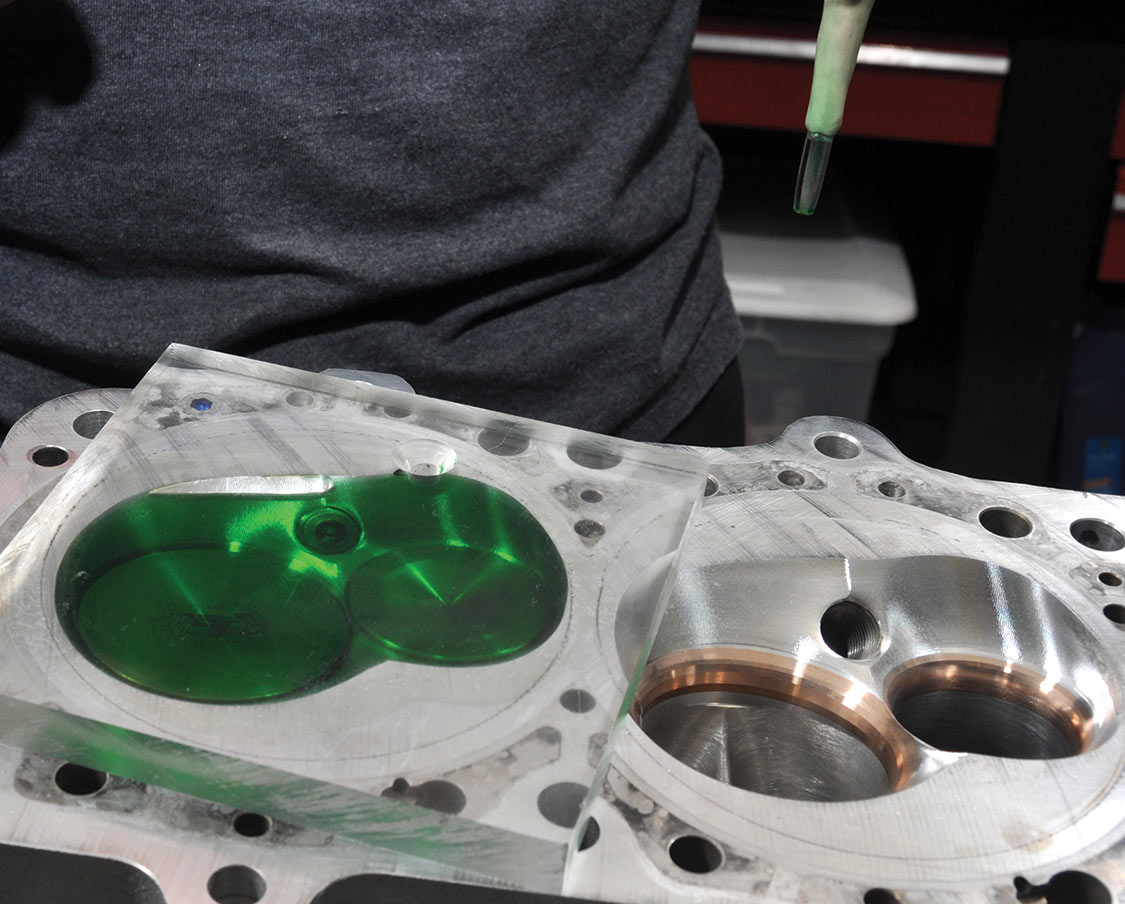

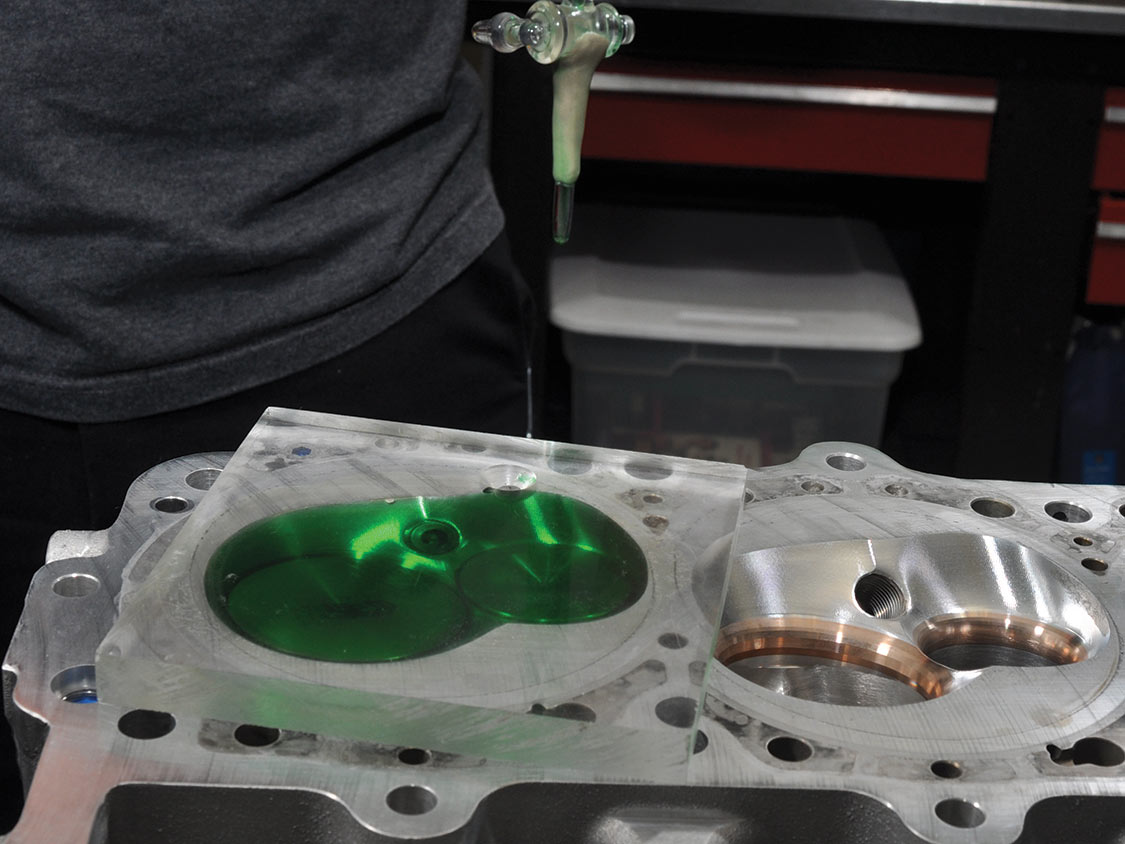

To find the engine’s displacement in cubic inches the following formula can be applied: 0.7854 x bore diameter x bore diameter x stroke length x the number of cylinders. To convert cubic inches to cubic centimeters, multiply by 16.39. Using a burette is the best method for measuring the clearance volume (chamber volume plus piston volume above top dead center).

Compression ratios are often influenced by competition rule books. Also, engine efficiency is a deciding element in their composition. Higher compression ratios aren’t always those best calculated to succeed. When you over-compress the cylinder, you induce a pumping loss since it takes horsepower to squeeze the cylinder’s contents.

In addition, overly advanced ignition timing isn’t always recommended either. As Chuck Lawrence of Jon Kaase Racing Engines contends, “Earlier firing of the ignition causes the engine to work harder, as the piston is rising on its compression stroke it has to overcome the premature downward forces of the expanding gases.”

Calculating compression ratios accurately is important for at least three reasons. “First,” says Giebas, “pistons are often requested with compression ratios higher than are physically possible to provide. Second, some sanctioning bodies stipulate strict limitations on compression ratios, and if they are not calculated precisely, the racer could either squander power or unwittingly get caught cheating. Third, if the race engine is designed to meet strict specifications, including operating on a specific race fuel, having the compression ratio calculated properly is worth doing.”

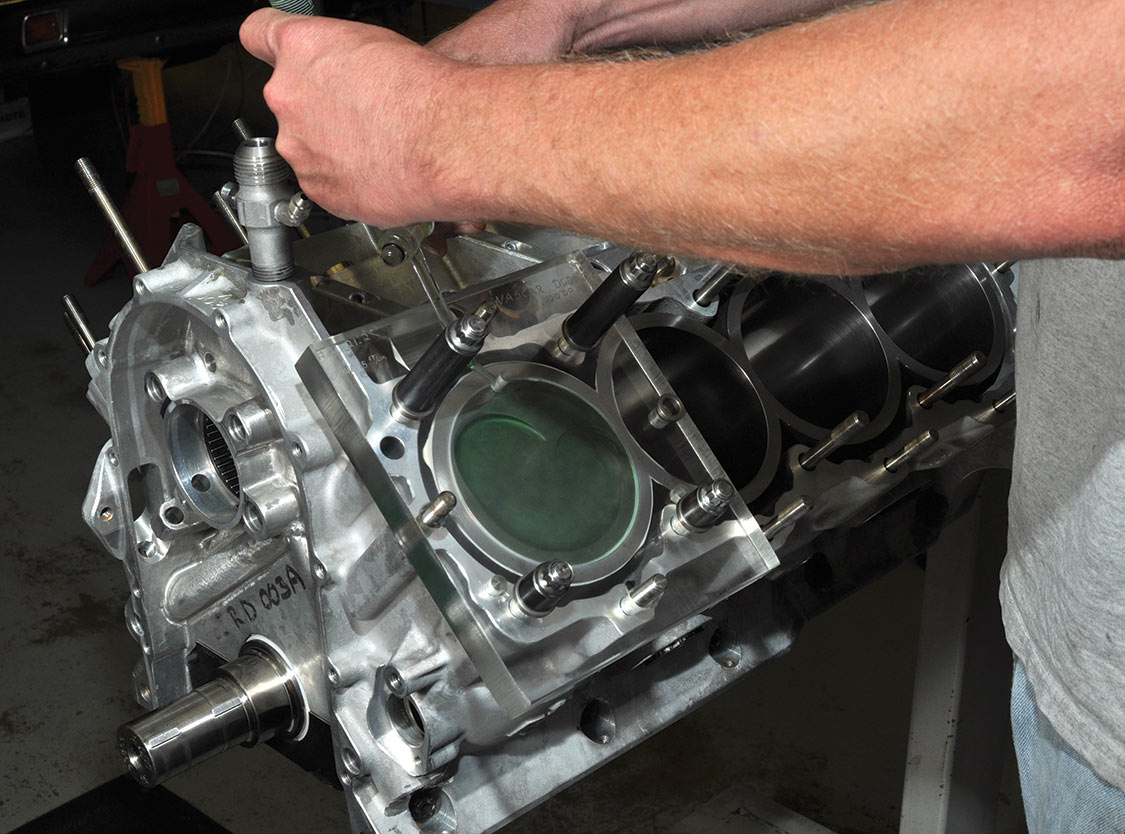

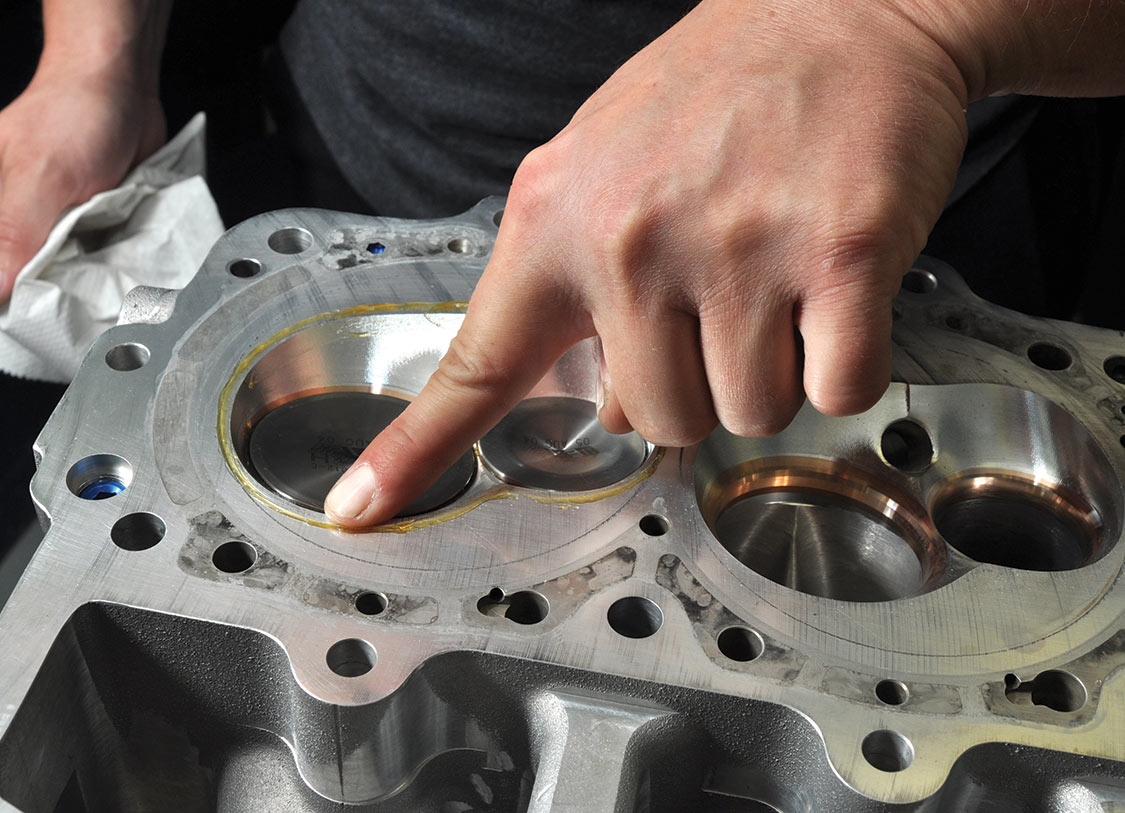

Yet crucial data is often omitted from custom piston information forms. The two most common difficulties are block deck height and chamber volume. Chamber volume is measured by inverting the cylinder head on the workbench (complete with two valves and a spark plug installed), placing a piece of thick acrylic plastic (with a ¼-inch or 3⁄8-inch-diameter hole in it) over the combustion chamber, filling a 100mm burette graduated in cc’s with a colored liquid and transferring the liquid to the combustion chamber. This measuring process is duplicated to establish the piston volume.

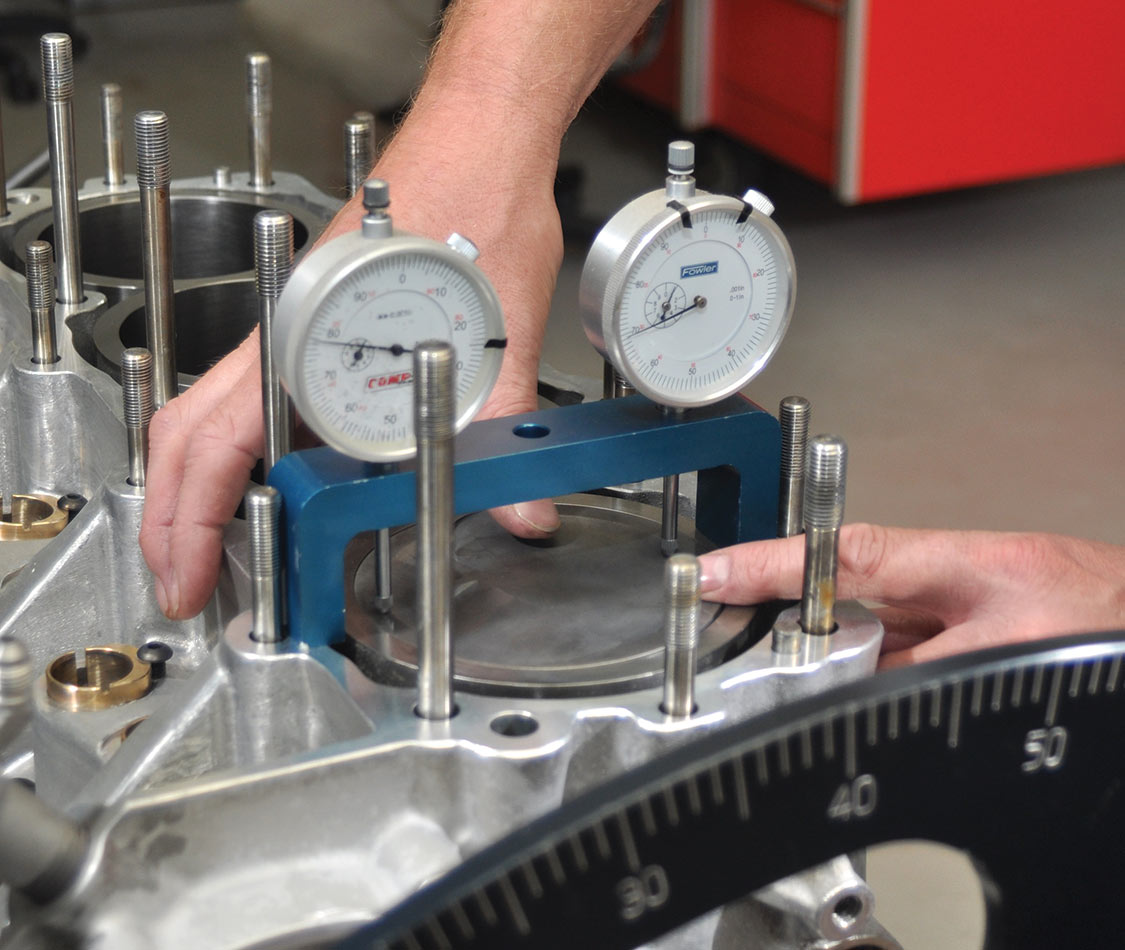

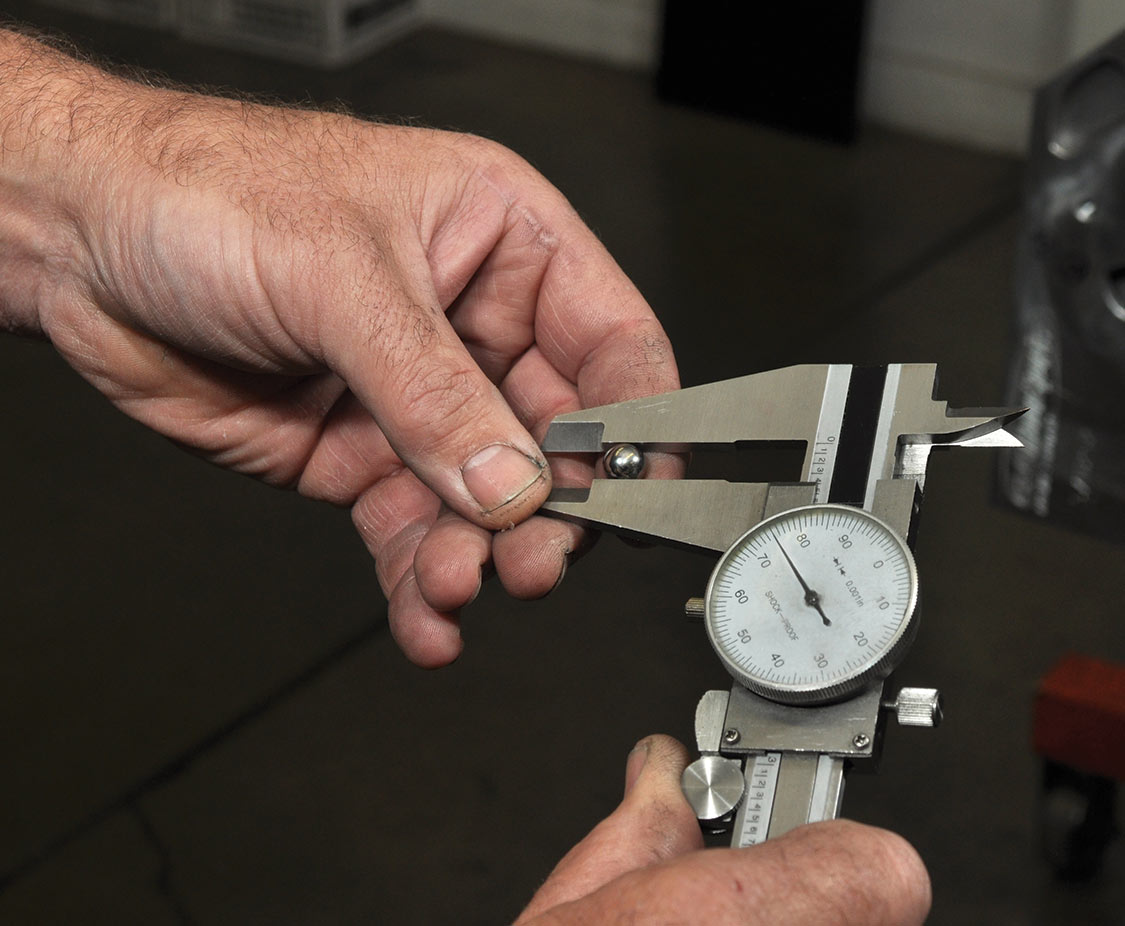

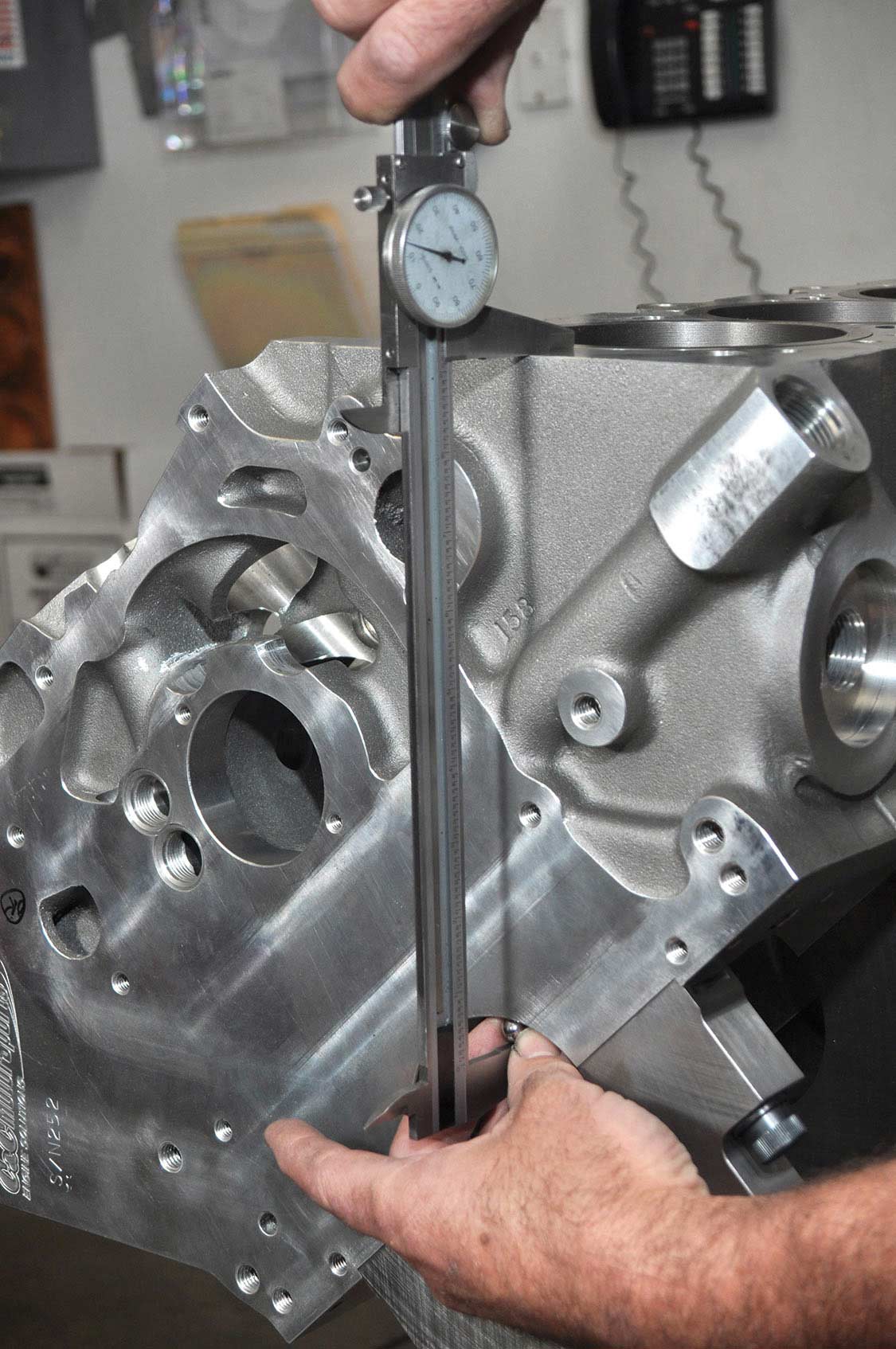

Block deck height is measured from the crankshaft centerline to the block deck, usually with some form of caliper. Knowing the exact block deck height is crucial because it is used to verify four vital measurements: half of the stroke dimension, rod length, compression height and the piston-to-deck dimension.

The piston-to-deck dimension is the measurement from the flat area around the piston perimeter to the deck surface. A decision must be made whether to place the piston at zero (flush with the block deck surface) or place it down the bore by a small amount. Most engine builders request the piston-to-deck dimension to be .005 inch or .010 inch down the bore. This small fudge factor gives them the ability to take a skim cut off the decks at a later date if needed.

The compression height of the piston, also known as compression distance, is measured from the centerline of the piston pin to the flat area on the top of the piston. Once these dimensions are established accurately, the piston will be positioned at the precise height in the cylinder, and the compression ratio will be exactly as desired.

However, when some of these vital dimensions are omitted—perhaps the spaces are left blank or they contain the word “stock”—grief usually follows.

Let’s assume the racer has a desired compression ratio of 11.9:1 and believes the block deck height to be stock. Let’s further assume 10.720 inches represents stock. But at sometime in the past, and unknown to the present owner, the block visited a machine shop where the decks were “cleaned up” and the height is, in fact, 10.700 inches and not 10.720 inches. As a result, the .020-inch difference in compression distance will cause the piston to sit higher in the bore, resulting in a much higher and unwanted compression ratio of around 12.5:1.

Savvy piston makers with experience in different race engine categories will tell you that compression is a most intriguing topic, and that having more is not always to your advantage. “When better cylinder head and induction manifold designs prevail,” says Giebas, “less compression is needed because they accomplish better cylinder filling. Therefore, it compresses more air in a given area, but if the cylinder head and the induction system are less efficient, more compression is needed because there is less air in the cylinder.”

Gibtec Pistons

333 West 48th Street

Denver, CO 80216

303.243.3340

Gibtecpistons.com

Jon Kaase Racing Engines, Inc.

735 West Winder Ind. Parkway

Winder, GA 30680

770.307.0241

Jonkaaseracingengines.com