Kevin Aguilar October 21, 2022 All Feature Vehicles

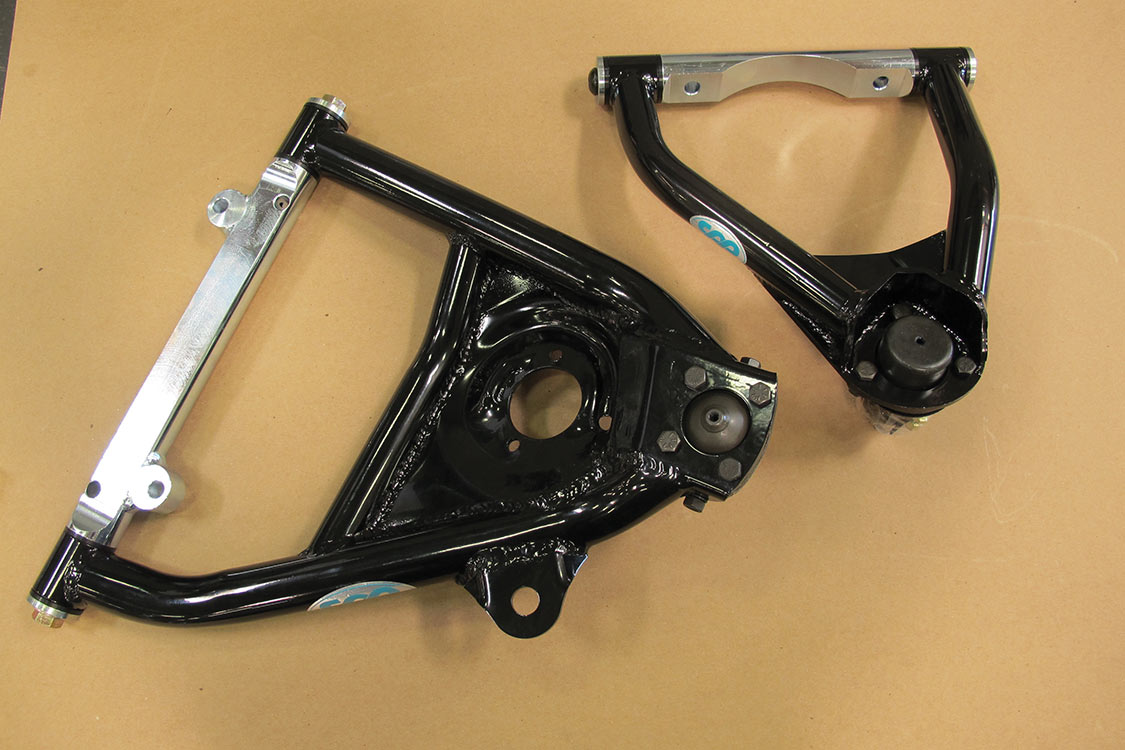

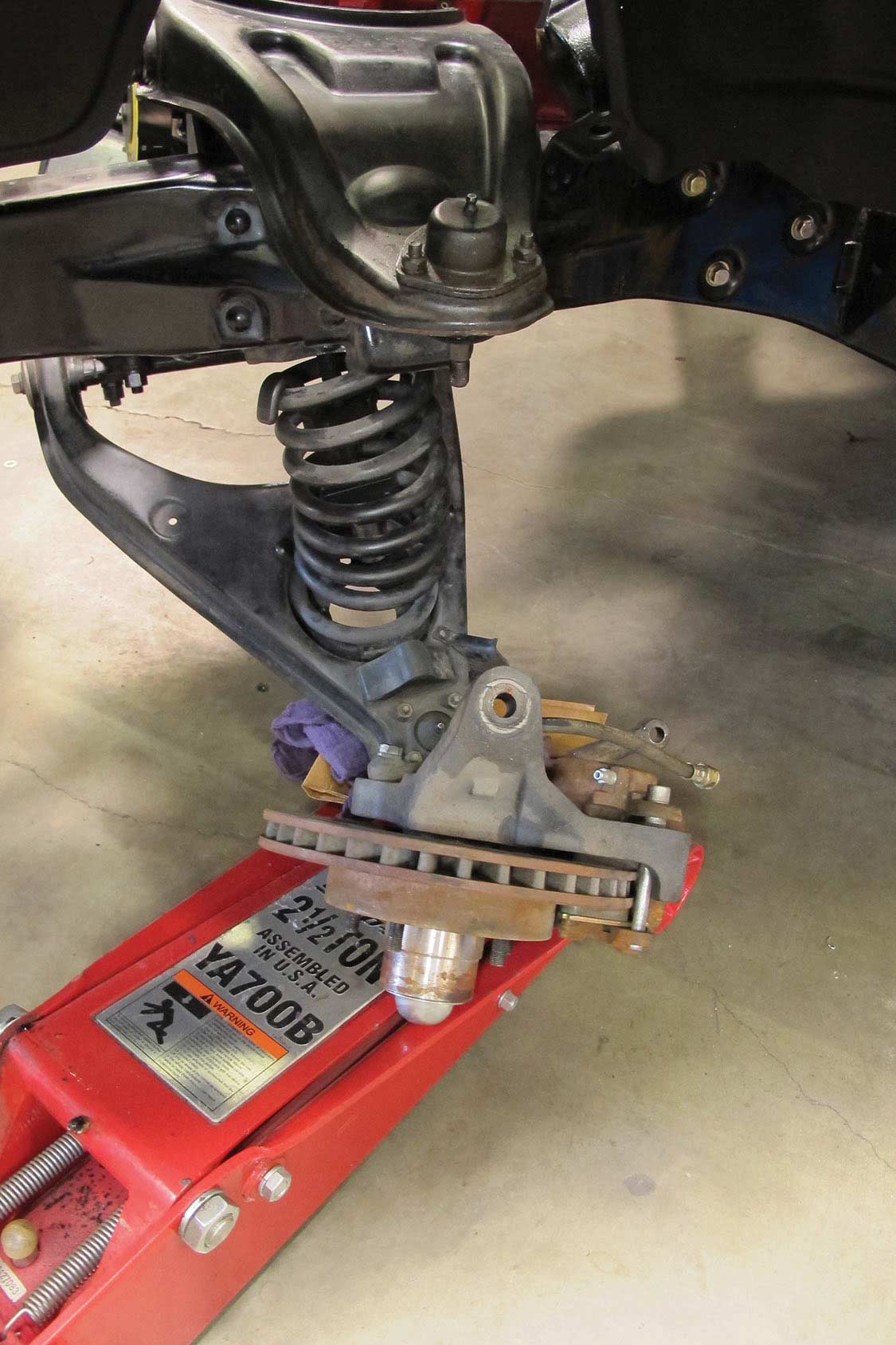

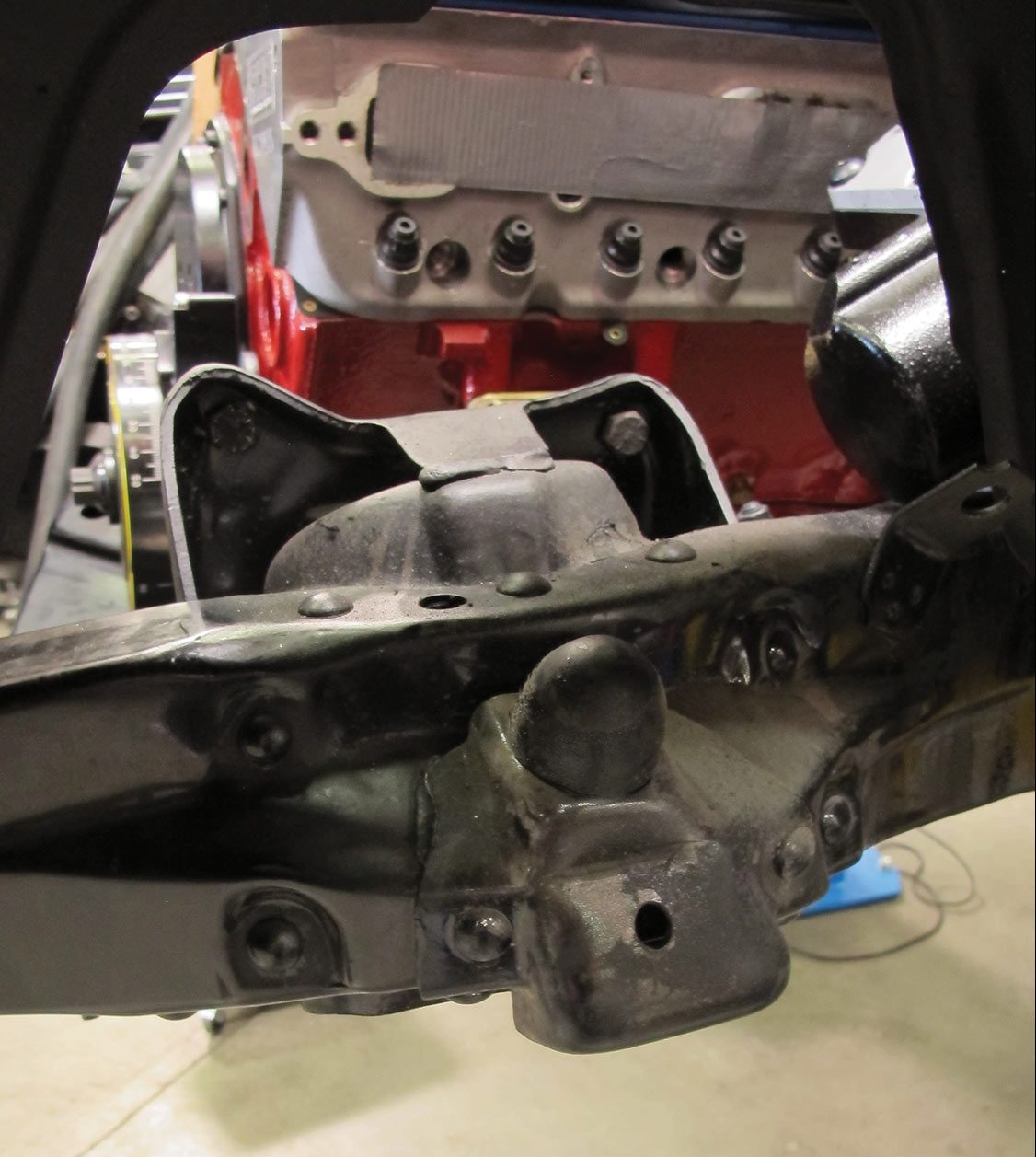

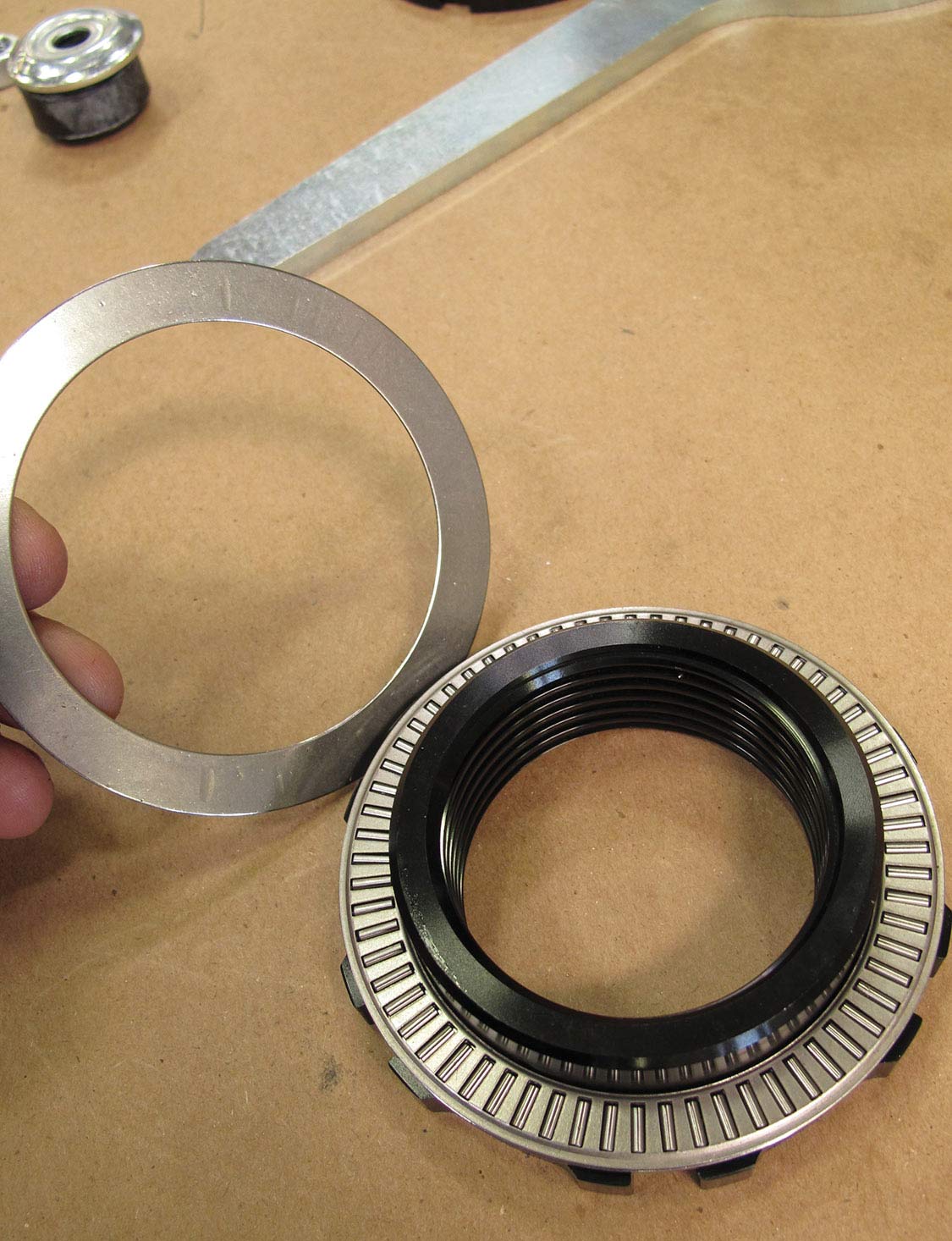

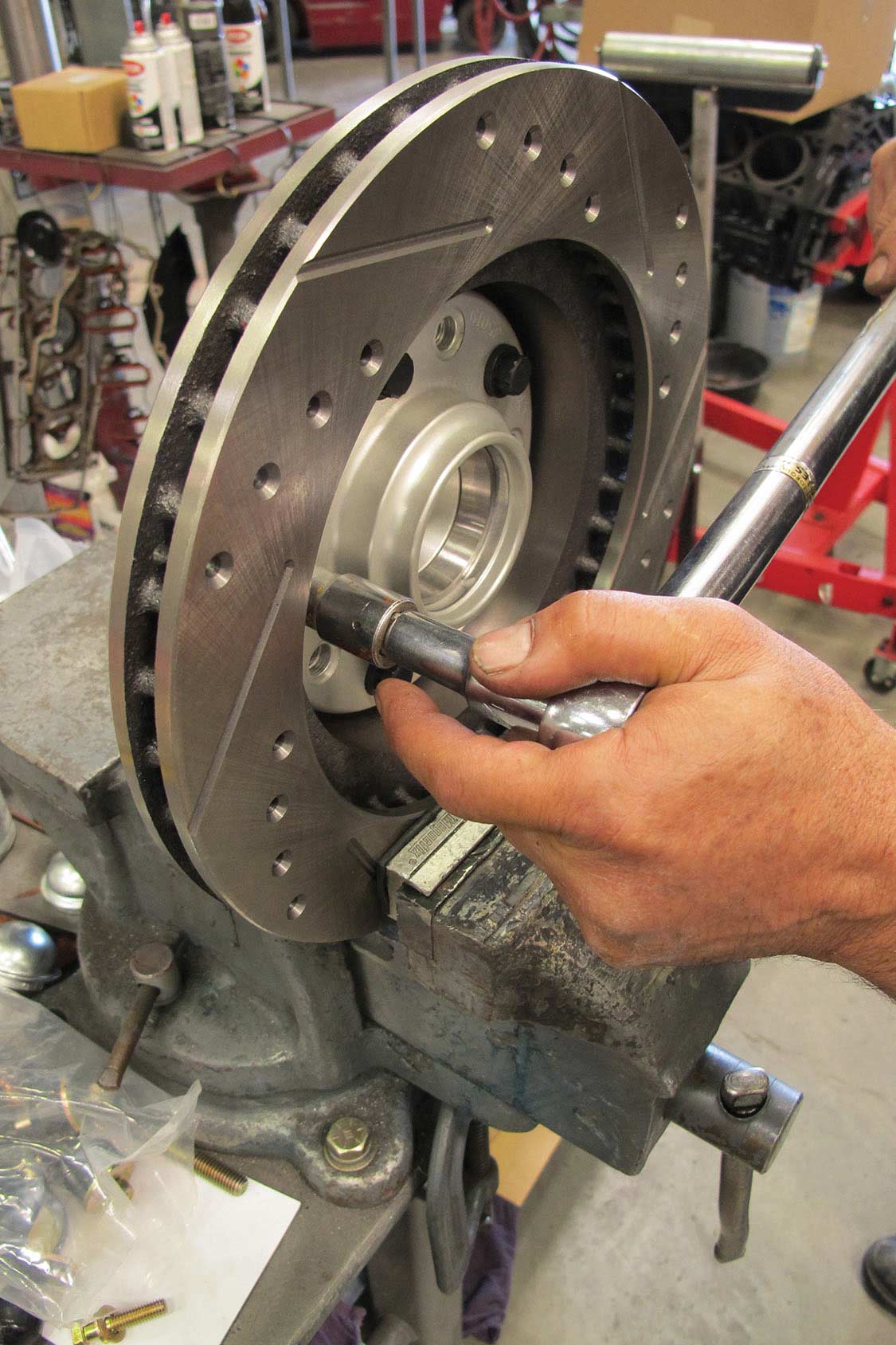

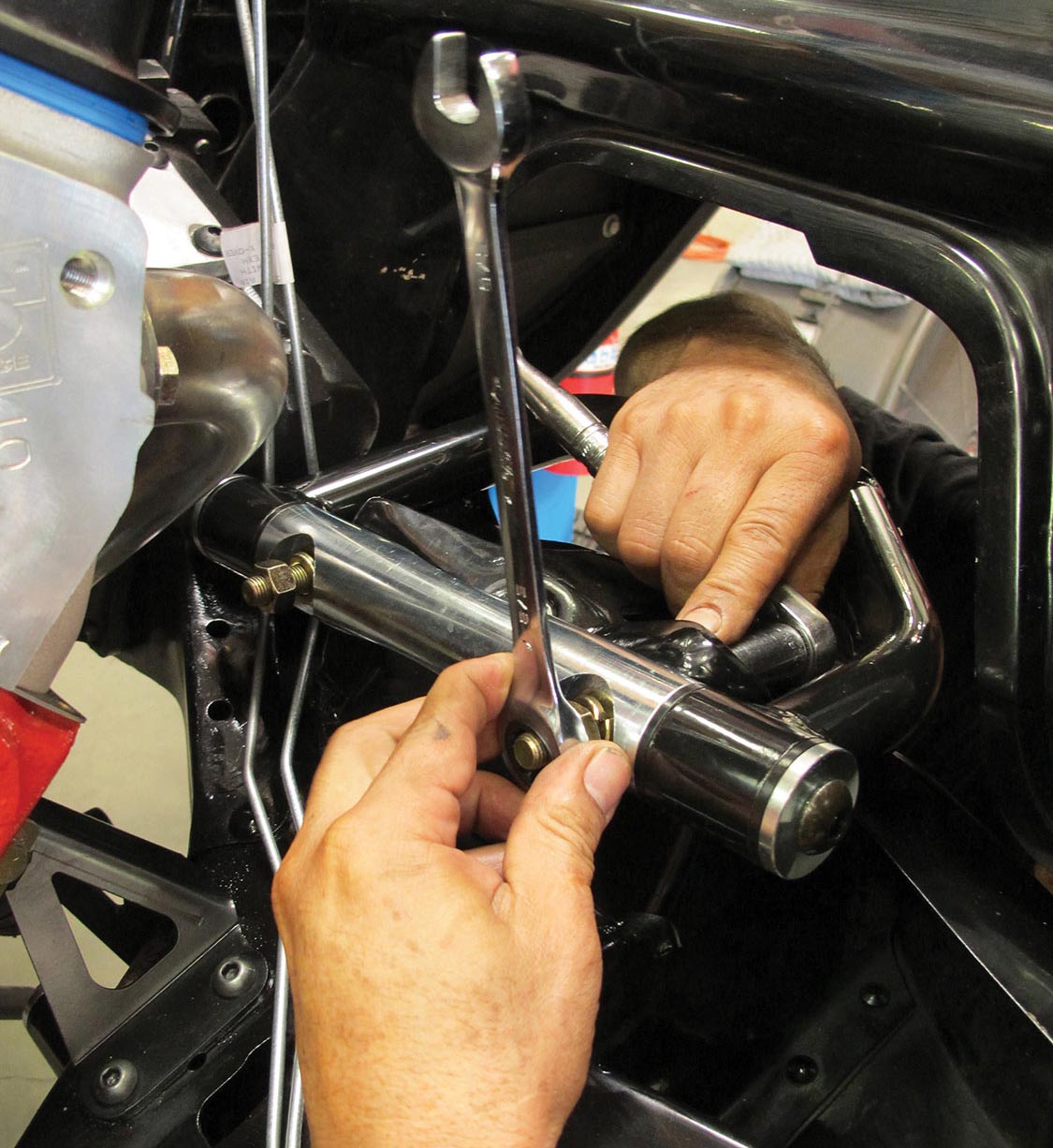

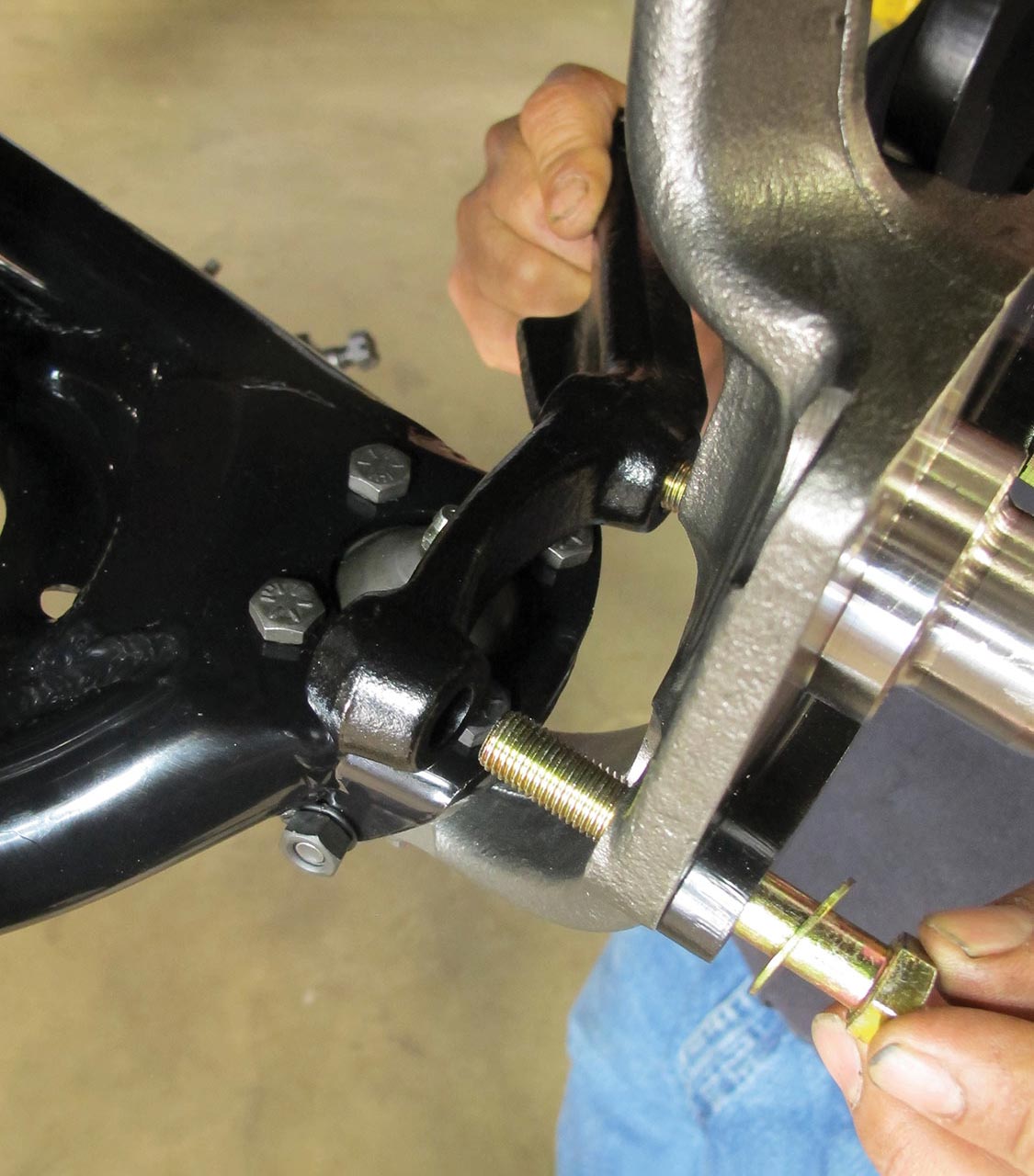

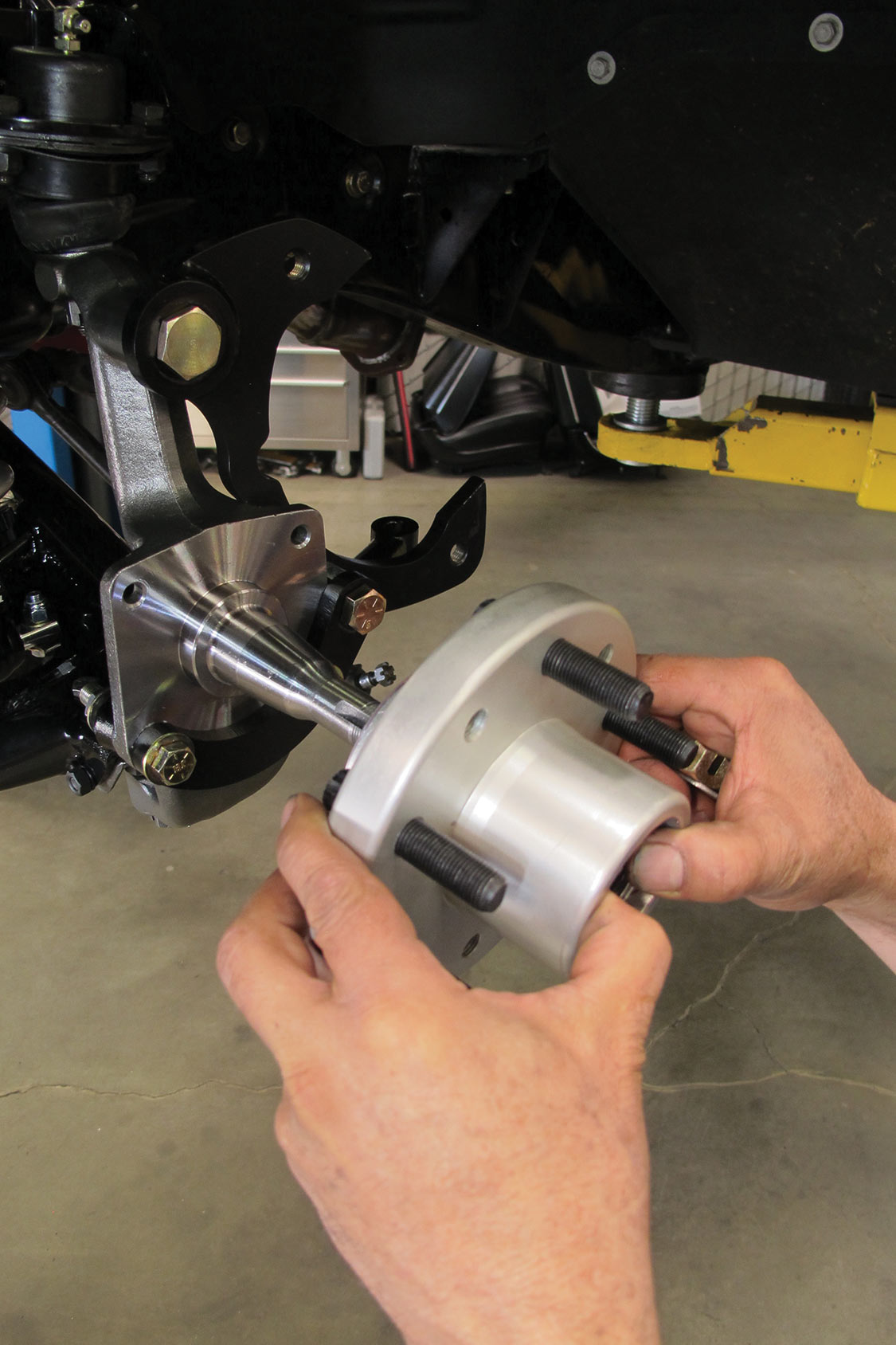

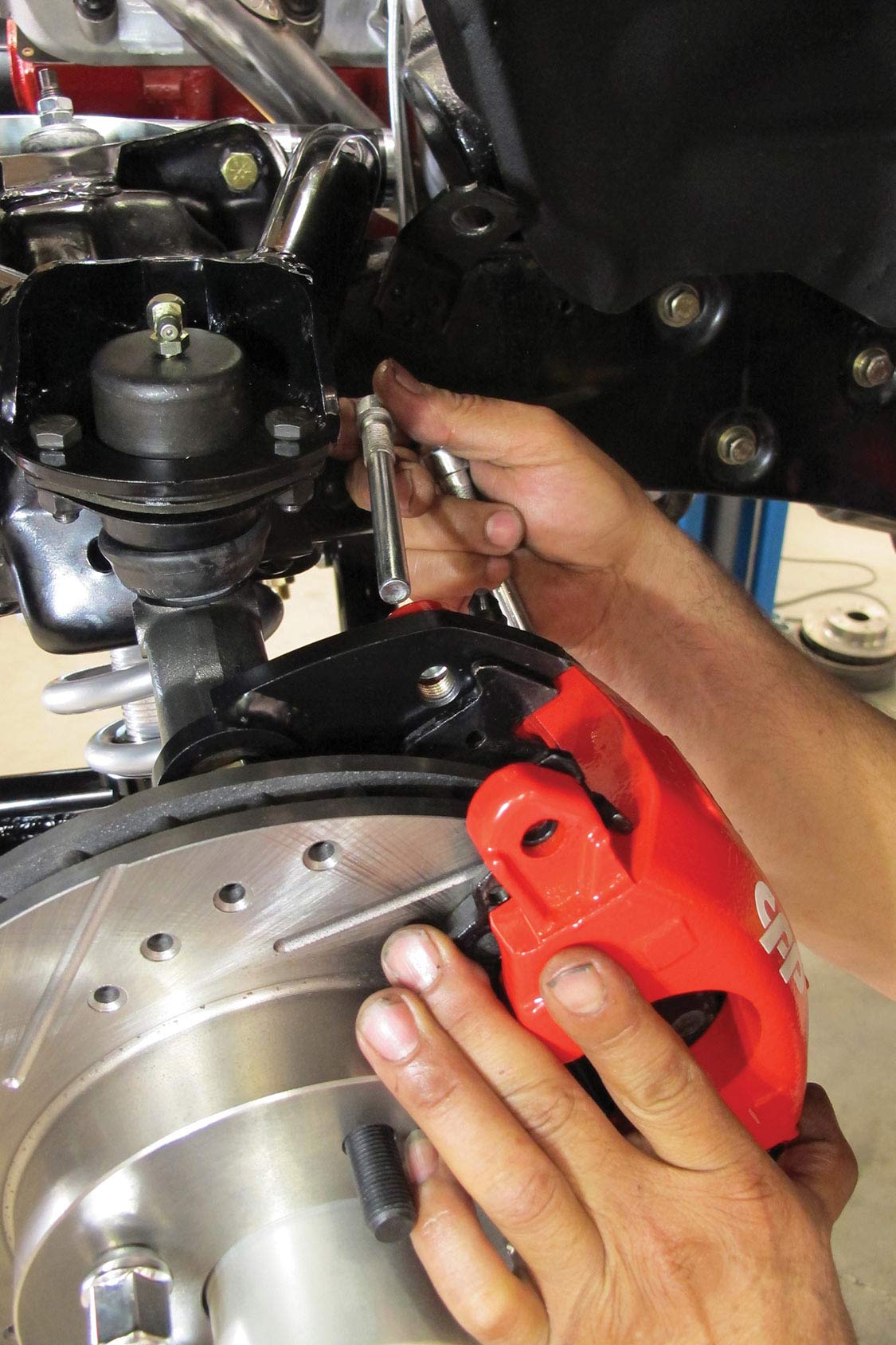

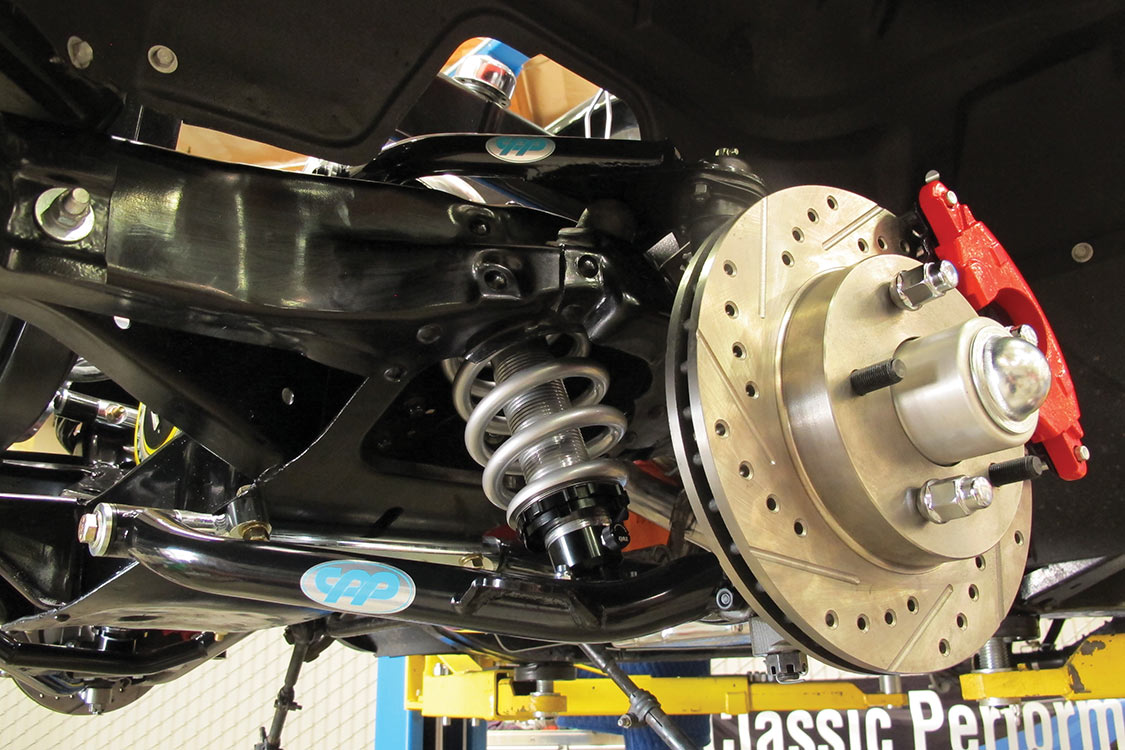

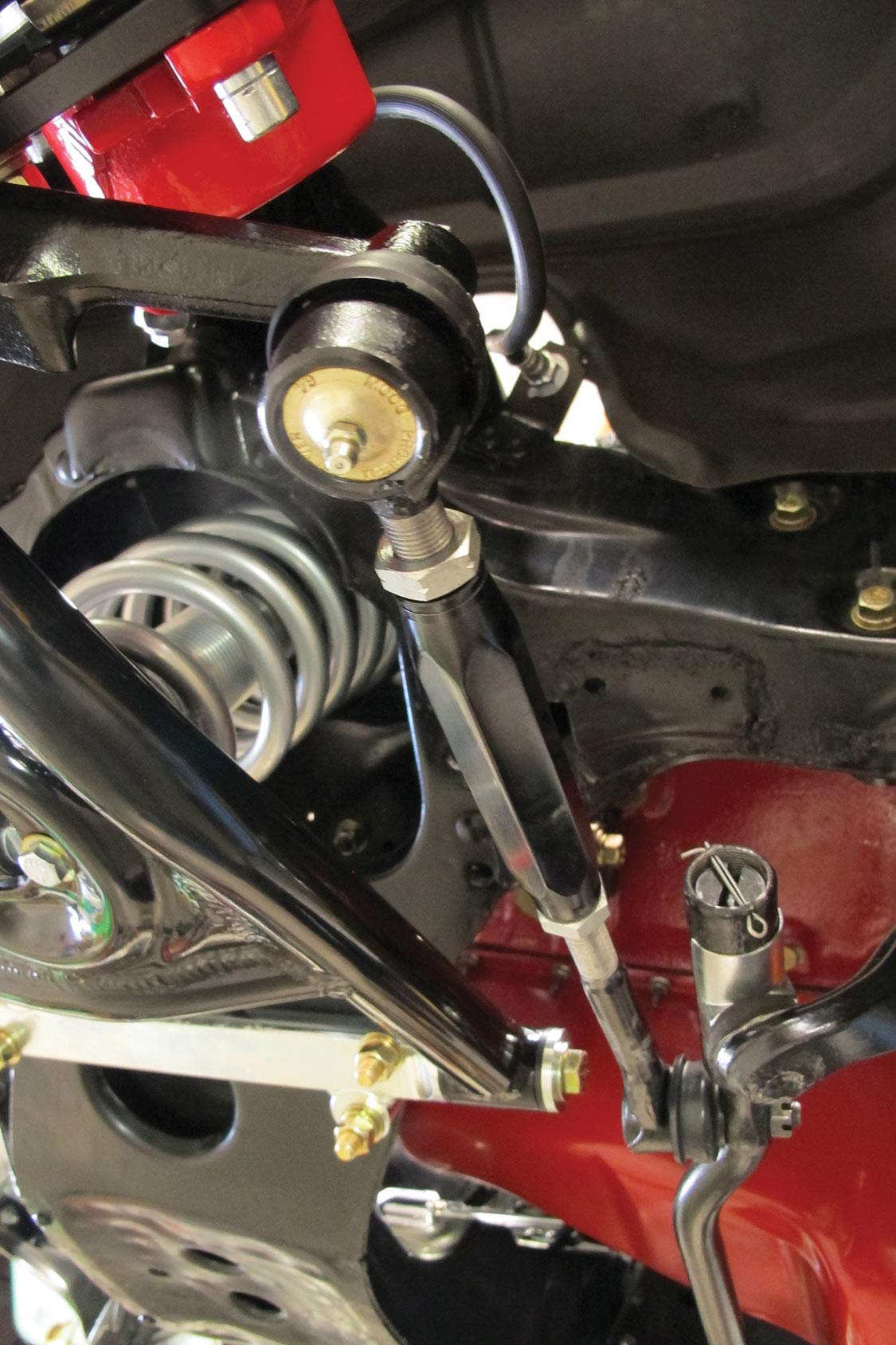

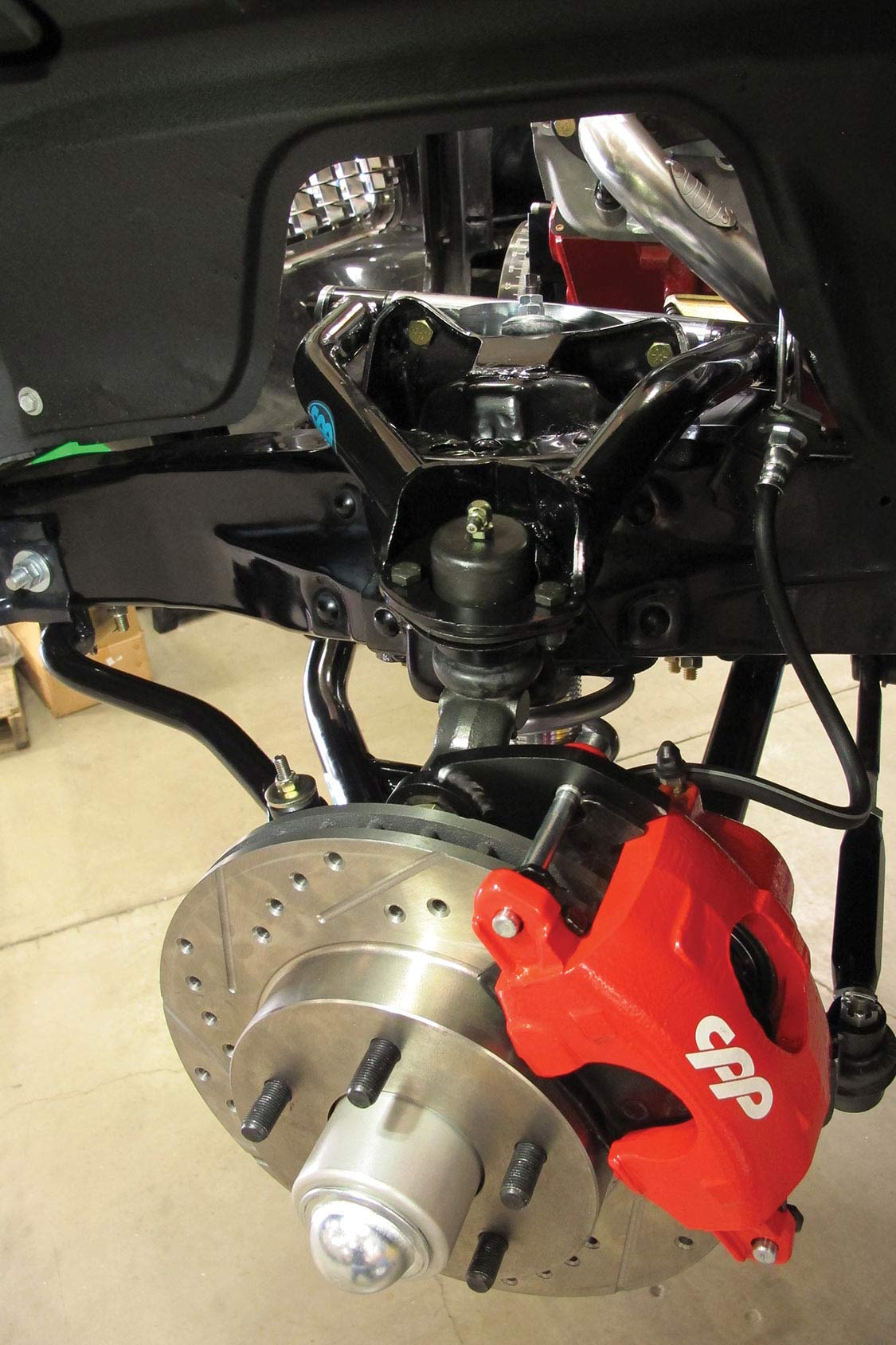

If you’re looking to make an upgrade and take your Tri-Five project to the next level, check CPP’s control arms and coil-overs plus brake kit. We provide the steps for the installation and show you how it’s done on a ‘55 Chevy Bel Air.

Classic Performance Produts

378 E. Orangethorpe Ave.,

Placentia, CA 92870

Classicperform.com