I go to a lot of car shows. It’s not just my pastime… as the founder of CarShowSafari.com, a nationwide car show, and motorsport listing website, it’s my passion. From local Cars & Coffees in New Jersey to mega hot rod shows in California, to the Concours d’ Elegance in Greenwich, Connecticut, I go to as many auto events as possible.

But there are a few that really stand out, and Woodies on the Wharf is one of them.

Organized by the Santa Cruz Woodies Club, Woodies on the Wharf is an incredible annual car show attracting nearly 200 classic Woodies from all over the United States.

Held each June in Santa Cruz, CA, the event features gorgeous cars in an equally gorgeous setting on the largest wharf on the west coast. With a wide array of styles, models, and colors, from spectacular 100-point restorations to well-weathered, barn-find survivors, this show provides a living history lesson on the wood-bodied automobile. Fords, Chevys, Buicks, Dodges, Plymouths, Chryslers, Mercurys, and Pontiacs are in abundance, but the event also attracts Packards, Studebakers, Volkswagens, and even a few Morris Minors. Yep, all Woodies.

And in the Woodie world, the owners can be just as colorful as their cars, putting their own whimsical spin on displaying their wooden wonders. With classic surfboards, beautifully-crafted canoes, vintage luggage sets on top, and old-school surfing and national park stickers on the windows, it would not be unusual to see a full set of vintage camping gear in the back, complete with antique coolers with period-correct beer cans on ice. If there’s one thing Woodie owners have, it’s a sense of humor! Even the license plates can be fun, with “IGTAWDY”, “PLYWUD”, and “WUZATRE”, among others.

With perfect weather, great restaurants, fun shops, wonderful people, and nearly 200 Woodies out on a wharf overlooking the ocean, this event could not have been more magical.

This year the National Woodie Club joined in the festivities, combining their national event with the Santa Cruz event, helping to bring in Woodie board members, dignitaries, and aficionados from all across the country.

With perfect weather, great restaurants, fun shops, wonderful people, and nearly 200 Woodies out on a wharf overlooking the ocean, this event could not have been more magical. With such a diverse group of unique cars, there is plenty to see, plenty to do, and plenty to chat about. And in the afternoon, after the announcements, dedications, raffle drawings, and awards ceremony, the event commenced with a parade of Woodies driving in single file down the wharf led by a police escort, past a cheering crowd, providing the perfect photo ops.

Our adventure continued the next morning, with my wife and I riding with Santa Barbara Woodie Club members Rick and Eliane White in their red 1950 Ford Woodie, followed by 60 other Woodies. We traveled along Santa Cruz’s beautiful Westcliff Drive past the lighthouse and along the bluffs overlooking the Pacific, and back to the Santa Cruz Beach Boardwalk, all with waving and cheering fans along the route.

Woodies on the Wharf is an event not to be missed by Woodie enthusiasts and anyone who appreciates these unique and beautiful pieces of rolling art. And you can be sure we’ll be back on the wharf in Santa Cruz again next year.

Casual fans may not realize how rare Woodies are. For instance, Ford produced less than 1700 total. And the last production Woodie was the ’53 Buick. By the late 50s surfers found these poorly maintained used cars were a cheap way to haul their boards to the beach. Plus wood boards on Woodies was a natural fit and made for a good look. The Woodie surf wagons gave the old vehicle a new life. And enthusiasts have kept it going ever since.

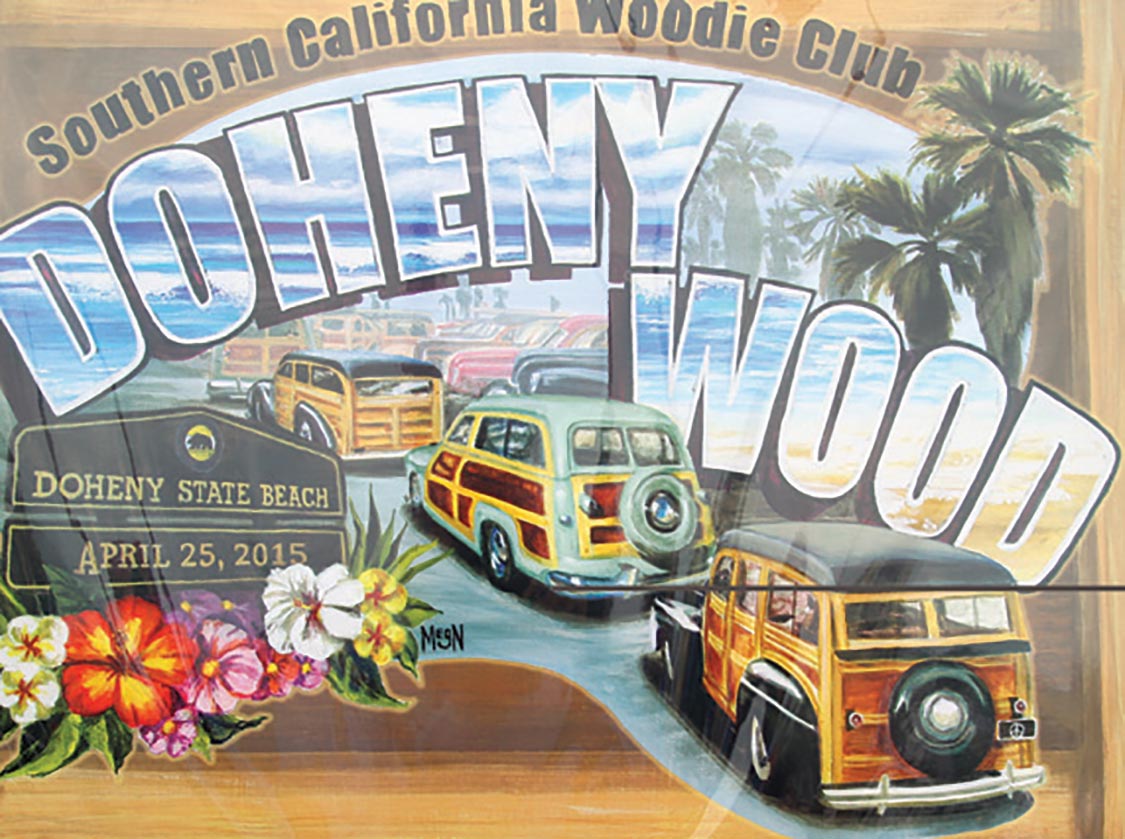

Given its history you can well understand why there’s something special about Woodies at the beach. And in Southern California near Dana Point lies California’s first State beach, Doheny Beach, which is the perfect place to celebrate these rare rides. This event gathered more than 150 of these rare vehicles in one place for spectators to enjoy. The weather for the SoCal Woodie Club event was a little cool, but otherwise a very comfortable beach day. However, during the awards ceremony we did get a rain shower. With the drought in California, no one could rightly complain about a little precipitation. The weather couldn’t put a damper on the show. The Woodies still captured everyone’s imagination, and reminded us all of a bygone, more blissful era.

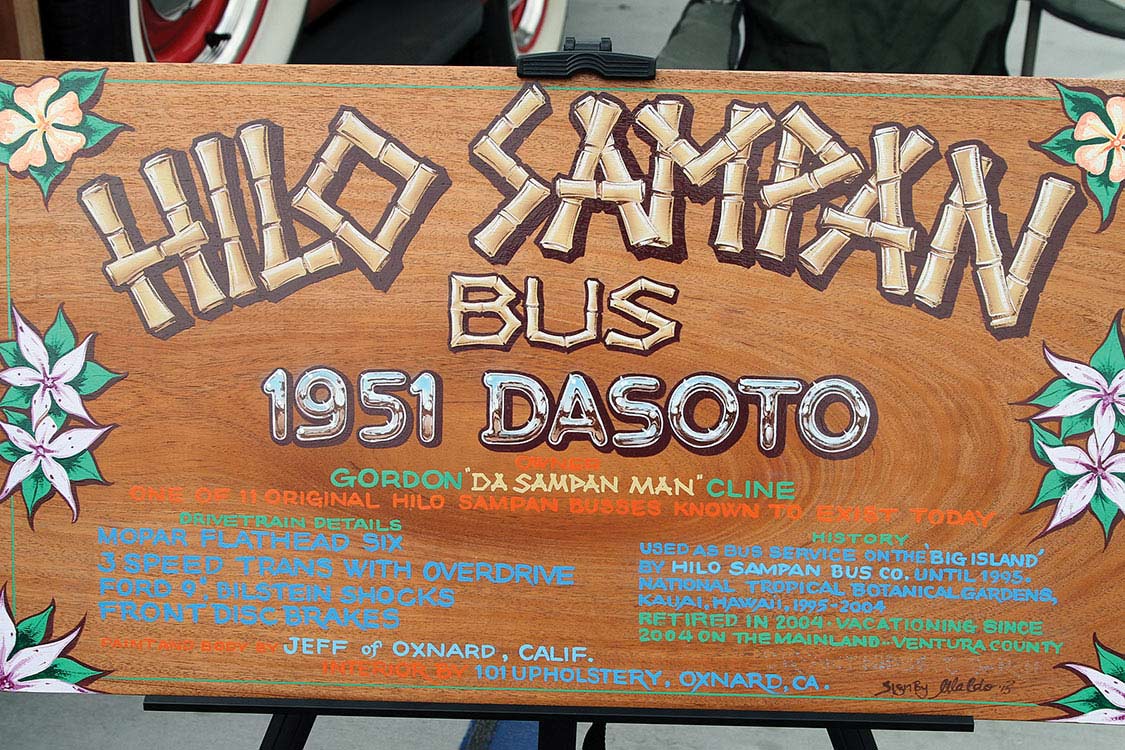

Longtime friends Ben McCloy and Scott Satterla didn’t intend to open a hot-rod shop, it just sort of happened after they built their 1928 Hudson Woodie. Their work on this car drew so many requests for similar work, they quit their day jobs and opened Jack Dick Customs in Martinez, California, one year ago and have been busy ever since.

McCloy had always admired the looks of the 1928–1929 Ford Tudor sedans, so when a rusted hulk of a Hudson sedan body showed up on Craigslist for $500, McCloy jumped on the project. Neither McCloy nor Satterla had shop space at the time so the freshly purchased bare body sat in Satterla’s driveway while McCloy sought to purchase a frame, doors, roof and any hardware for the orphan Hudson. The parts they needed turned out to be more than a little elusive so they set about building their own.

They laid the frame on the driveway using 2 x 3 box steel and measured other hot rods and customs to get the proportions right. A small-block Chevy motor and 400 trans were mocked up and the body fitted after being shortened 9 in. McCloy had always liked the looks of Satterla’s 1948 Chevy Woodie, so when it came time to make the missing doors, McCloy made them from wood and the Woodie project took off. Wooden quarter panels followed and with no overall theme for the Hudson in mind, McCloy and Satterla started adding whatever was lying around Satterla’s garage, what they could find at swap meets and what looked cool at the local home improvement stores.

The woodwork fell mostly to Satterla while McCloy scrounged for hardware. Flat pieces of mahogany, oak and zebrawood were cut to size and screwed onto the Hudson body.

Soaking planks in Satterla’s hot tub over night, bending them into place and screwing them down made the curved pieces. McCloy and Satterla had planned to cover the factory opening in the sedan’s roof with the traditional fabric, however, once the wood spars were in place they looked so good it would have been a shame to cover them up. So the Hudson Woodie became an open car. With no roof rack to hold an old surf board McCloy had in his closet since high school, McCloy used the skeg off a Maharaja water ski to give the Woodie’s roof a “surfboard” look. Later McCloy covered his 1980’s vintage pink surfboard with some wood-grain contact paper and fashioned a roof rack out of banister railing holders and shovel handles from the home improvement store.

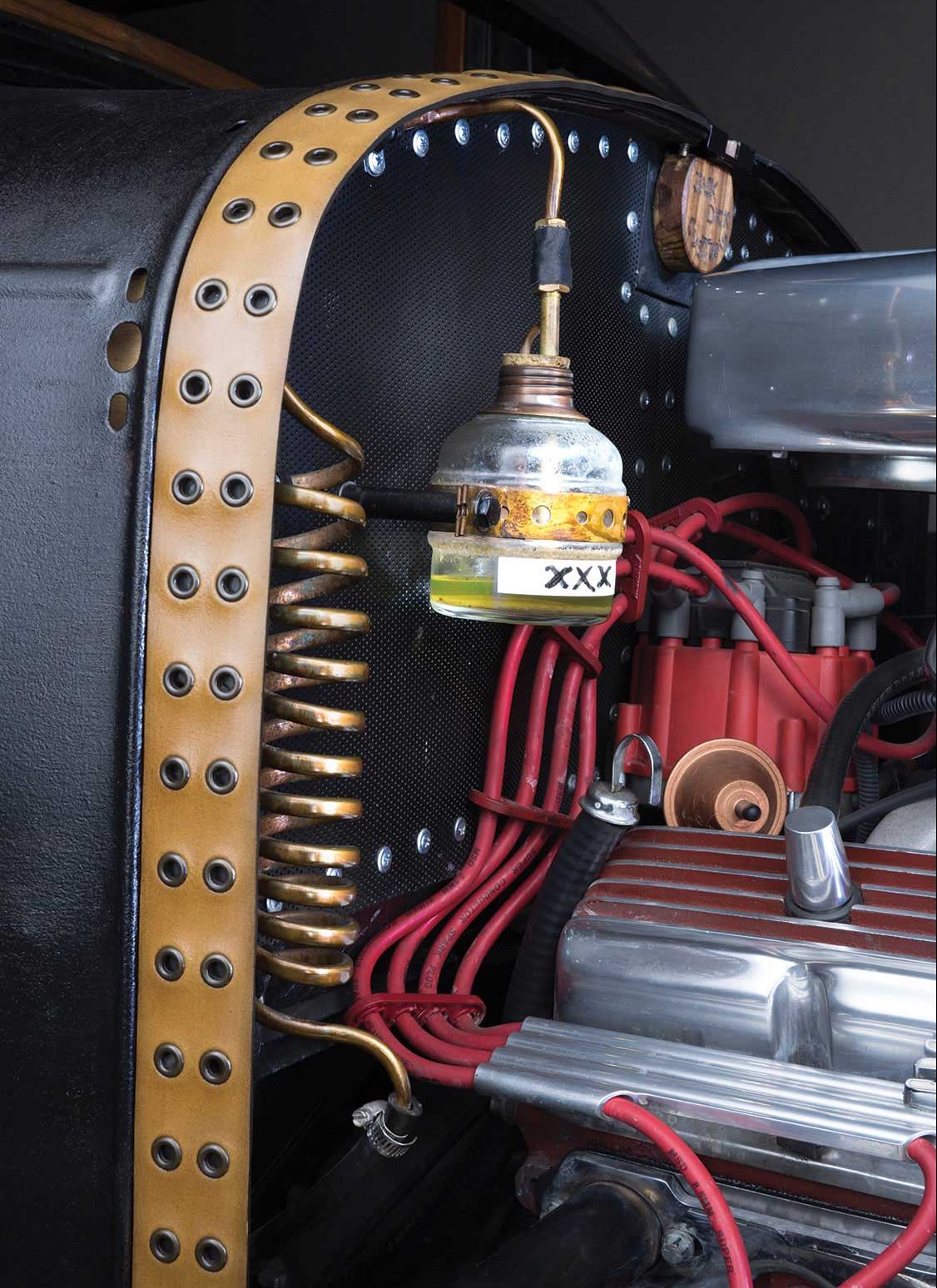

Once the wood was placed, the Hudson started to look like a rumrunner boat and a moonshiner hot rod combined so a Mason jar dome light, whiskey-still coiled copper tubing and the “XXX” radiator overflow bottle were all added. Still using whatever they had on hand, mid-1920’s Ford door latches were used on the outside. The local home improvement store sourced the drawer pulls for inside door handles and the gate latches that ensure the suicide hinged doors stay shut at freeway speeds. A gauge panel from a 1957–1960 Ford truck from Pick-n-Pull found its home in the dash while a working altimeter donated by Satterla’s father was fitted to the floor to round out the instrumentation.

Lots of people are interested in it. People feel it’s okay to touch it. Climb on it, touch it, smell it. I like that people get a more visceral connection to the car. Makes it more real.

In keeping with the newfound aviation influence, the switch panel was located over the windshield and given a vintage airplane look. With this aesthetic twist in mind, four bomber seats were sourced and placed on top of the home improvement store hall runner carpeting. The license plate in the floor is a cover for the brake master cylinder bolted to the frame below the body. The drilled out steering wheel resembles vintage aircraft controls and is fitted with a swap meet horn button. The glovebox is a little chest from a craft store with a boat tie-off cleat as a handle. A skeleton key found at a swap meet was ground down to fit a battery disconnect switch and serves as the ignition key. With little room left, fitting the spun aluminum gas tank was a chore. “I tried about seven different ways to fit it in there,” says McCloy, “before it found its home in the center of the two rows of seats.” The ammo box under the dash is a tool chest that holds all the tools needed for roadside repairs. “We built the car using as few sizes and types of nuts, bolts and screws as possible so our emergency tool kit would be small,” McCloy says.

With the interior outfitted, McCloy and Satterla turned their attention to the mechanical aspects of the Hudson. Summit Racing supplied the 380-hp 4-bolt main 350 engine and TH400 automatic transmission. Dressing up the Chevy small-block are an Edelbrock intake, Demon 650 carb, Mr. Gasket air cleaner/scoop and Cal Custom valve covers. A 1968 Bronco donated its 9-in. posi 3.73 rear end, which sits on a custom coil spring/trailing arm set up similar to a 1960s Chevy truck. Mickey Thompson Sportsman 33 x 19½ tires with vulcanized porta-walls ride on painted Weld wheels out back while reversed Weld drag wheels with 235 x 75-15 tires ride on the Ford Model A 6-in.-drop-tube axle front end.

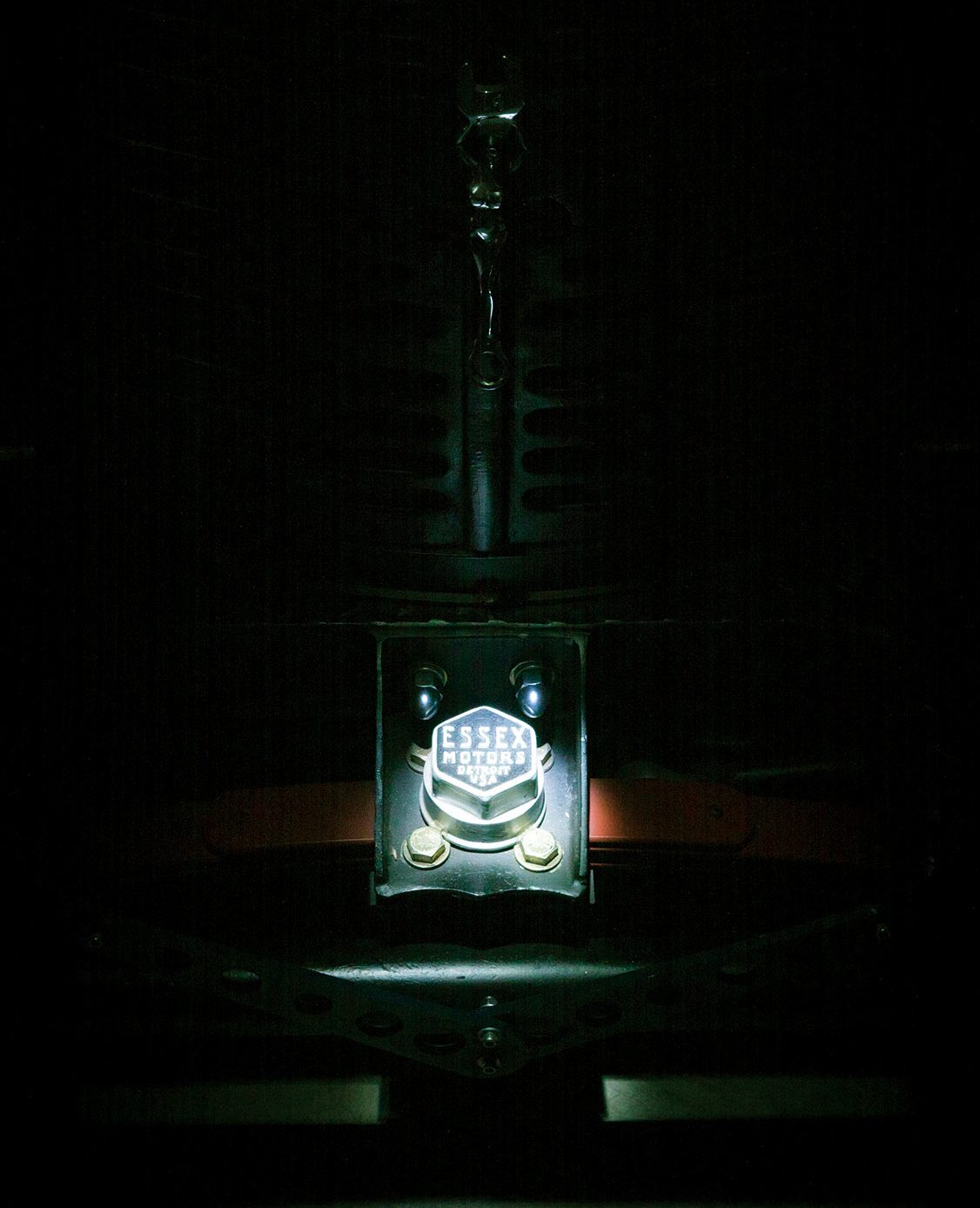

With the powerplant and suspension handled, McCloy and Satterla turned their attention to the exterior look of the Woodie. A Hudson Essex wheel cap bought for $3 at a swap meet tops the front-end spring perch. “I think it needed this, as nothing else on the car said Essex or Hudson,” McCloy says. Capping the front end is an International Harvester tractor radiator shell that was cut down 3 in. to fit. While it was a cheap eBay find, McCloy said it needed lots of attention with a ball-peen hammer and dolly. A “lady wrench” adorns the front of the grille while the hood ornament from McCloy’s 1948 Chevy rests on top. Packard headlight shells sport 1940s Chevy chrome trim and 1932 Ford lenses. Keeping with the what-you-can’t-hide-enhance theory, an over abundance of machine screws highlight the perforated sheet metal covering the many holes in the factory firewall. After a shopping trip to the local clothing store McCloy discovered his new belt would make the perfect accent to frame the engine compartment, so he went back and bought two more and fashioned them into cowl and grille shell welting. A gap between the body and frame at the rear of the sedan is filled with a pair of drilled copper plates. Slightly above, the gas cap was fashioned from a Tri-Five Chevy bumper bullet. Finishing off the rear end are mid-1930s Ford taillights. Rust Reformer applied with a dirty, crusty paintbrush give the metal body parts a slightly wood-grain finish.

He wouldn’t say exactly how much he has invested in the Woodie, but has said he’s been offered many times that amount to sell it, but he won’t because it is such good advertising for the shop.

The entire built took three months of labor in Satterla’s driveway. The inaugural run transformed what should have been a 15-minute ride to the local car show into a two- hour ordeal of roadside alignment sessions and adjustments. But once they sorted out the Hudson, it has proved reliable, comfortable and fun to drive even on long road trips. Both McCloy and Satterla enjoy taking their creation to shows such as Woodies on the Wharf in Santa Cruz, California. “Lots of people are interested in it. People feel it’s okay to touch it. Climb on it, touch it, smell it. I like that people get a more visceral connection to the car. Makes it more real,” McCloy says. He wouldn’t say exactly how much he has invested in the Woodie, but has said he’s been offered many times that amount to sell it, but he won’t because it is such good advertising for the shop. So much so that after just one year in business, Jack Dick Customs (https://www.facebook.com/jackdickcustoms) has had to move to a larger shop. Finding this orphan Hudson not was not only the start of a fun project for two longtime friends, but it was also the start of a new and growing business for them both.

MENTOR, Ohio (August 9, 2023) – Wiseco Performance Products, a prominent name in the Race Winning Brands (RWB) family and renowned icon in automotive and powersports forged pistons and performance products, is thrilled to announce the launch of its all-new website. This dynamic digital platform aims to provide enhanced support to customers and fellow racers while delivering a seamless shopping experience for high-quality performance components.

With the unveiling of the new website, customers can now conveniently purchase automotive forged pistons and piston components, as well as a comprehensive range of proven powersports performance components, directly from Wiseco. The intuitive interface incorporates model and engine specific filtering capabilities, enabling users to effortlessly search and locate the components they need.

In addition to facilitating easy access to premium products, the Wiseco website also serves as a valuable resource for automotive and powersports performance enthusiasts. The platform features a wealth of technical content, including engine building tips, how-to guides, frequently asked questions (FAQs), and much more. Customers can tap into this knowledge base to gain insights and make informed decisions for their projects.

Moreover, the new website offers a plethora of supplementary resources, further demonstrating Wiseco’s commitment to customer satisfaction. Visitors can access Wiseco’s custom piston order form, installation and operation manuals, racer support information, and various other helpful materials. This comprehensive platform ensures that customers have all the tools they need to achieve their performance goals.

“Wiseco Performance Products is excited to unveil our all-new website, designed to cater to the needs of our valued customers and racing community,” said Scott Highland, Director of Marketing at Race Winning Brands. “We invite everyone to visit Wiseco.com today to experience our revamped digital platform, explore our extensive range of performance components, and take advantage of the wealth of technical resources available.”

Wiseco Performance Products’ dedication to innovation and customer service is exemplified through the launch of its new website. By combining a user-friendly shopping experience with a wealth of technical expertise, Wiseco solidifies its position as a trusted partner for automotive and powersports enthusiasts seeking top-tier performance products.

About Wiseco Performance Products

Born over 80 years ago from the passion for racing, Wiseco is a world leader in manufacturing high-performance, forged pistons for the motorcycle, automotive, ATV, snowmobile, personal watercraft, and outboard marine markets. The Wiseco crew shares the same level of dedication to motorsports as their customers and are focused on continually refining the quality and practices it takes to exceed expectations. Engineered, forged, and machined on cutting-edge equipment in the U.S. at Wiseco’s Mentor, Ohio manufacturing facility, Wiseco pistons are the undisputed leader in quality and performance. Wiseco Performance Products, built for racers, by racers.

About Race Winning Brands

Race Winning Brands (RWB) is the leading manufacturer of racing and high-performance parts sold to automotive and powersports markets. RWB is the preferred source for high-end pistons, engine blocks, cylinder heads, intake manifolds, connecting rods, crankshafts, clutches and other engine and driveline-related performance components. RWB markets its products through multiple prominent brands including BoostLine Products, Corsa Performance, CV4, Dart Machinery, Diamond Pistons, Haltech, JE Pistons, K1 Technologies, Manley Performance, MGP Connecting Rods, PAC Racing Springs, ProX Racing Parts, Rekluse Motor Sports, RevMax, TransGo, Transmission Specialties, Trend Performance, Victory1, Volant Performance and Wiseco Performance Products. RWB sells to a diverse and unmatched customer base of professional and sportsman racers, engine builders, enthusiasts, OEMs, automotive and powersports dealers and wholesale distributors. RWB is headquartered in Mentor, Ohio with sales offices and manufacturing operations in strategic locations throughout the United States, Canada, and Europe. For more information, please visit racewinningbrands.com

Need to step up your wire and tube management game? Made-4-You Products (M4YP), a leader in the automotive aftermarket industry since 1985 with worldwide sales and distribution, has the perfect solution. M4YP’s product line consists of injection molded line clamps, plug wire separators, and related wire and tube management products. Molded from nylon, these clamps and related parts will not fade, stain, or discolor and are impervious to automotive fluids.

Lokar Performance Products

2545 Quality Lane

Knoxville, TN 37931

865-824-9767

My pal Gene Winfield generally holds his annual open house in October, which is a good thing. The reason it’s a good thing, other than it’s a very cool event, is Gene’s shop is two hours north of L.A. in the Mojave Desert. So October is a whole lot more comfortable than mid-summer. SO-CAL Speed Shop founder Alex Xydias and I made the trek and we had a spectacular time.

Let me back up a bit for those of you who may not know the Winfield story. Gene was born 1927 and grew up in Modesto, California, where he was exposed to auto body shops and auto racing. At a young age, Gene opened his own business in Modesto, Winfield’s Custom Shop, and the rest, as they say, is history. In the mid-’60s, his custom designs caught the attention of the film industry, resulting in a large body of his work being seen onscreen, including in the iconic 1982 film Blade Runner. One of Gene’s early innovations was blended custom paint, where two colors are meticulously faded together.

Gene did a stint working for the model car company AMT from 1962-71, managing the Phoenix-based Speed and Custom Division Shop where they built full-scale cars as promotional vehicles. After the division was closed, Winfield continued to work in the custom car field and appears as an honored guest at auto-related events worldwide. Yes, worldwide! In fact, Gene has chopped 17 tops this year alone while on the road, not bad for an 86-year-old teenager!

I’ve known of Winfield all of my life since my dad was a big fan. Here’s another one of those impossible turn of events where I’ve become friends with one of my heroes, as is the case with Chrisman, Xydias, Parks, Isky, etc.

Okay, back to the subject at hand: Winfield’s shop is amazing, it’s a must-see kind of place. The open house crowd was huge and 300 modified cars of every description jammed the property. Gene opened up his shop to display a few of his creations, and the car parts on the back property defy description! Gene has been after Alex and me for years to come and celebrate his open house, and for some reason or another we were unable to attend. Well, let’s just say that we’re hooked and we’ll be there in 2014—what about you?

It’s not every day you meet an 88 year-old—especially one with a storied past, and who has more going on than most adults that are supposed to be at the height of their careers. How many people do you know who continue to pursue their dreams with reckless abandon well into their 80s? Well, to Gene “Windy” Winfield, age is just a number. He continues to do everything he loves with gusto, and fortunately for us car folks, his chosen profession is fast and custom cars. Through his right-hand man and personal manager, Johnny B. Good, who knows every detail of Gene’s ultra-busy life, (March had Gene home for only eight days!) from painting cars or teaching metal shaping classes worldwide, to shaking hands with folks like us, we were able to meet this car icon and tour his home.

I showed up at his dusty shop on a lonely stretch of Sierra Highway with two photographers at my side. Johnny gave us a warm hello, and within minutes, Gene came out from his workshop and welcomed us like we were old friends.

The first order of business was to tour Winfield’s Rod & Custom Shop, the place where some of the most beautiful cars in the galaxy are created. Every vehicle that passes through these portals exits as a one-of-a-kind rolling masterpiece and nothing leaves until it gets his nod of approval, and in some cases, his car stamp.

Gene walked us through the cars there and explained what was being done to make each one a Winfield Custom. It’s a bustling shop, with anywhere from four to a dozen craftsmen, all performing various tasks to custom cars using skills they learned from Gene, as well as utilizing handmade tools to do specific tasks, all developed by Gene and his brilliant crew. However, he himself takes pride in personally (and oh so perfectly) spraying every custom painted machine that leaves his shop.

From there, we moved into the back desert lot where we saw a few dusty vehicles that were purpose-built to fit specific film roles, such as the flying police car from Back to the Future Part II, and a “wind-up” life sized toy car, used in a motor oil commercial. Also, waiting to be restored was a “Mirage”, a Cadillac luxury pickup conversion. Gene explained that in the mid ‘70s, he ran a shop called Traditional Coach Works Ltd of Chatsworth, CA that built and sold 96 Cadillac station wagons and 120 pickups, all built to Cadillac’s high standards and sold through Cadillac dealerships. In fact, Evil Knievel owned two, and one shows up the movie Viva Knievel. Gene recently managed to round up one survivor, and soon plans to restore it to its former glory. Several other remnants of cars sunbathe in the Mojave desert sand as they await future customization.

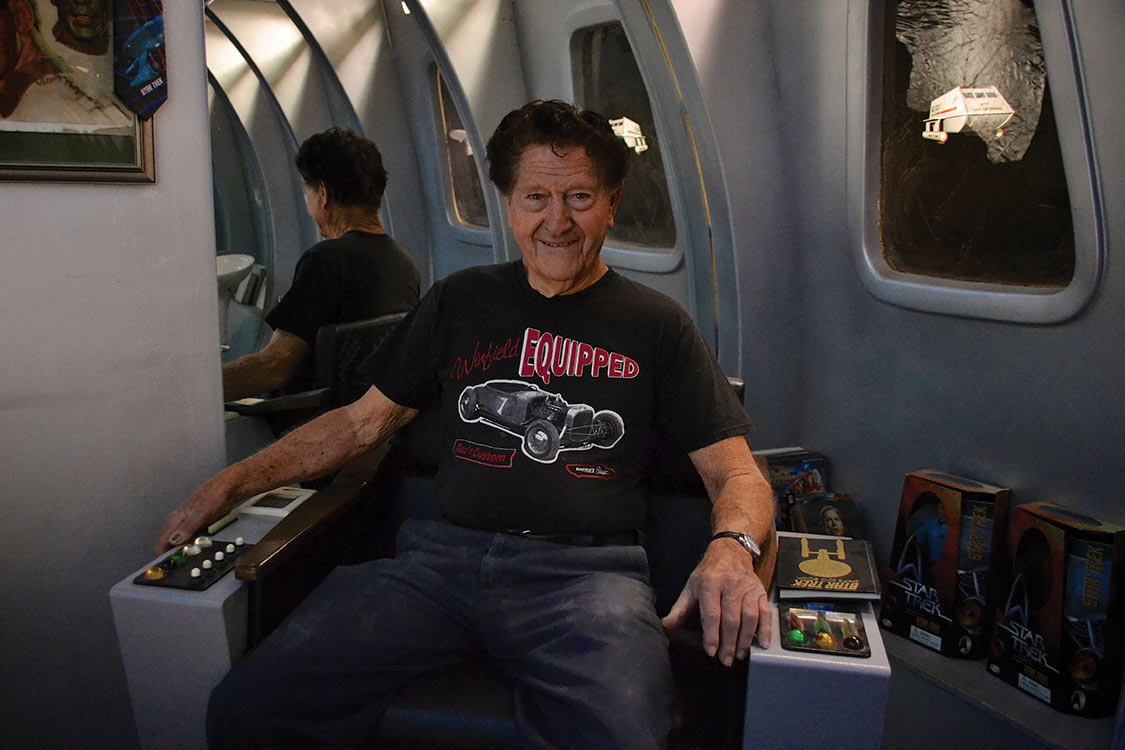

Next, was a tour through Windy’s Museum. From the outside, it’s not much more than a little old roadside service station, but inside, it’s a trip down memory lane filled with photos, trophies, movie props, model cars, and stories galore. Stepping inside, Gene was simply gushing to show us antiques from his personal collection, as well as from his family life. There is even a tribute to his favorite soda shop from the 1950s.

Further in, we passed through a room dedicated to TV and movie vehicles, and even got to stand beside his futuristic 1966 creation “Reactor”, as Gene explained how it was built and where the car appeared on-screen in multiple shows. The walls are covered with photos of film cars that he personally had a hand in creating, from Bewitched to Blade Runner to Back to the Future. Also, we were sure not to miss the room filled with all of the scale model kits and Hot Wheels he helped create. Got Tail Dragger? (See the sidebar below.)

Not to give it all away, but upon learning of Mr. Winfield’s early affiliation with Star Trek’s design department, we were “beamed” into his Star Trek-themed room featuring props and other special surprises. The hot rodding and land speed room was filled with hi-octane racing history, and there is even an area that is dedicated to all of Gene’s personal friends and heroes, both past and present, who have made their mark in the custom car industry.

In a nut shell, Windy’s Museum is a journey though Gene’s life. If you find the time, we highly recommend stopping in for a tour. Calling ahead is suggested, but even if Gene himself is away from the shop, one of his knowledgeable and friendly staff members will happily give you the guided tour. Meeting Mr. Winfield was truly inspirational, exhilarating and educational, and as Gene often says, “Every day is a school day!” We at Drive! thank Mr. Winfield for his hospitality, kindness and generosity.

Winfield’s Rod & Custom

8201 Sierra Hwy

Mojave, CA 93560

(661)824-4728

Museum entrance is FREE Donations are accepted

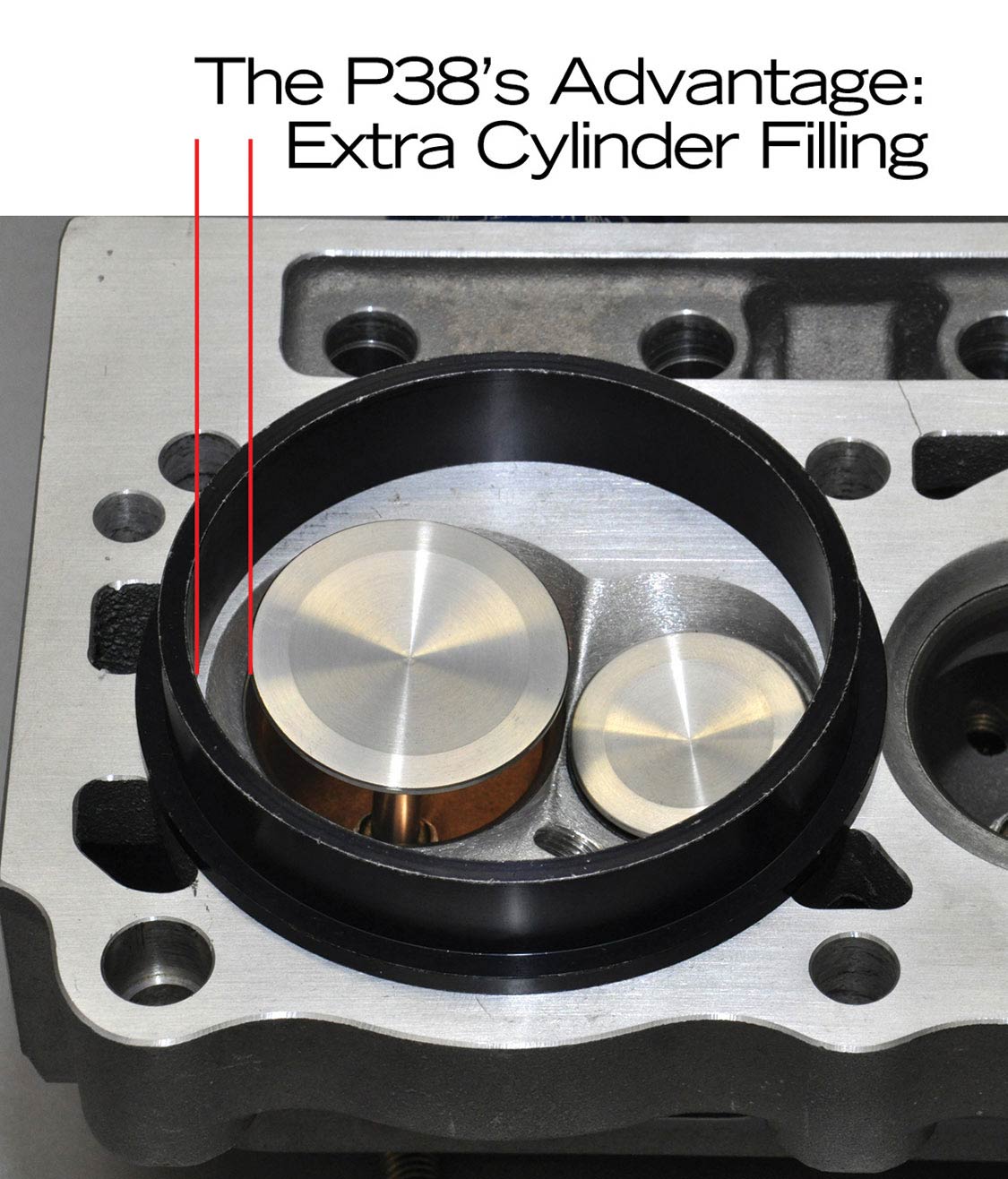

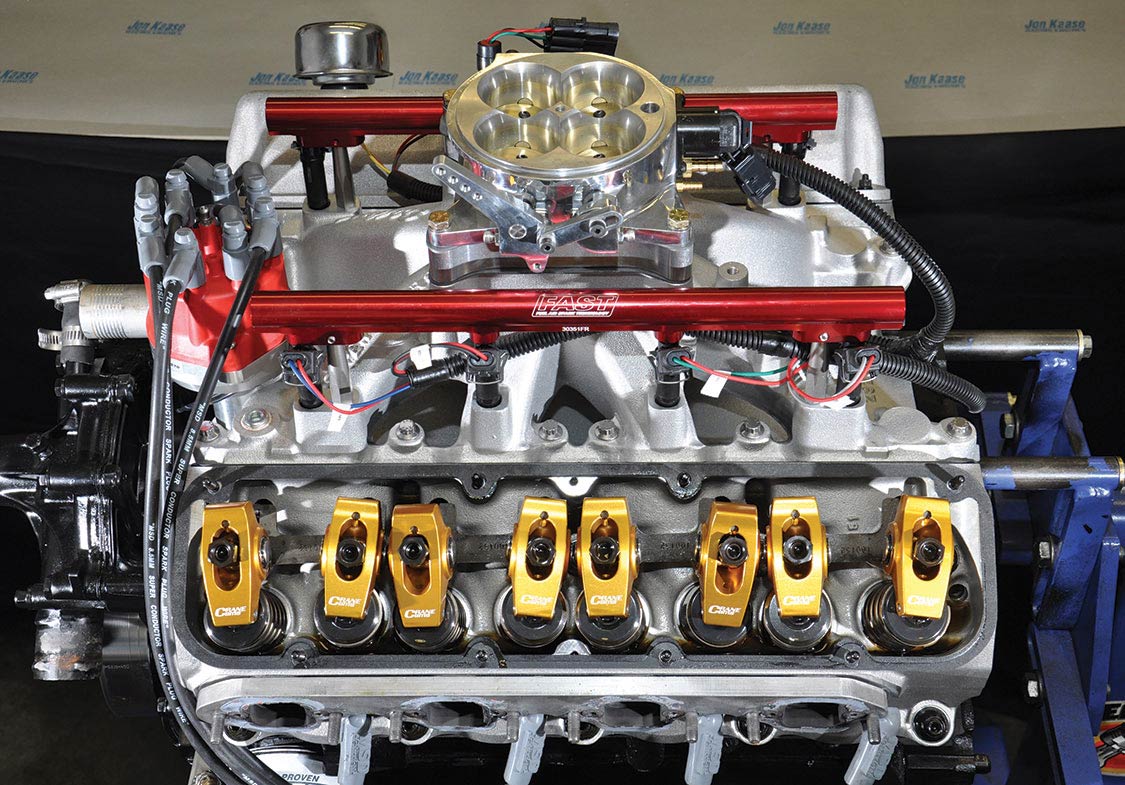

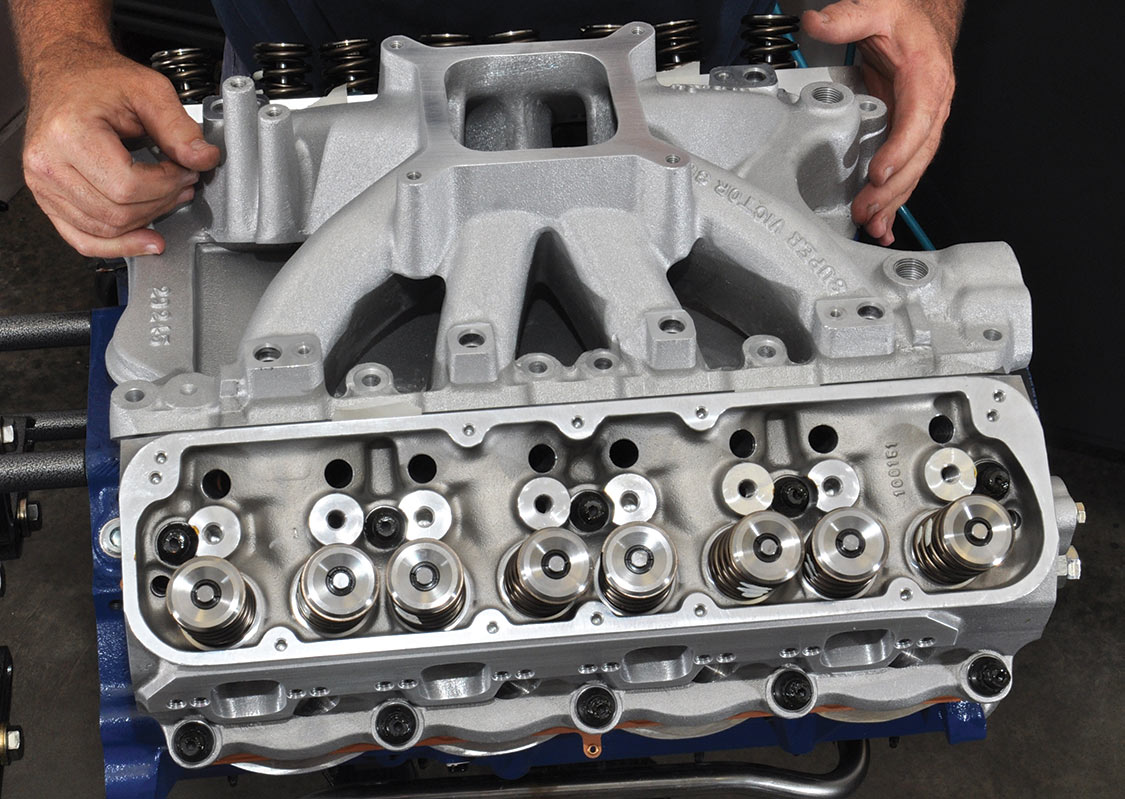

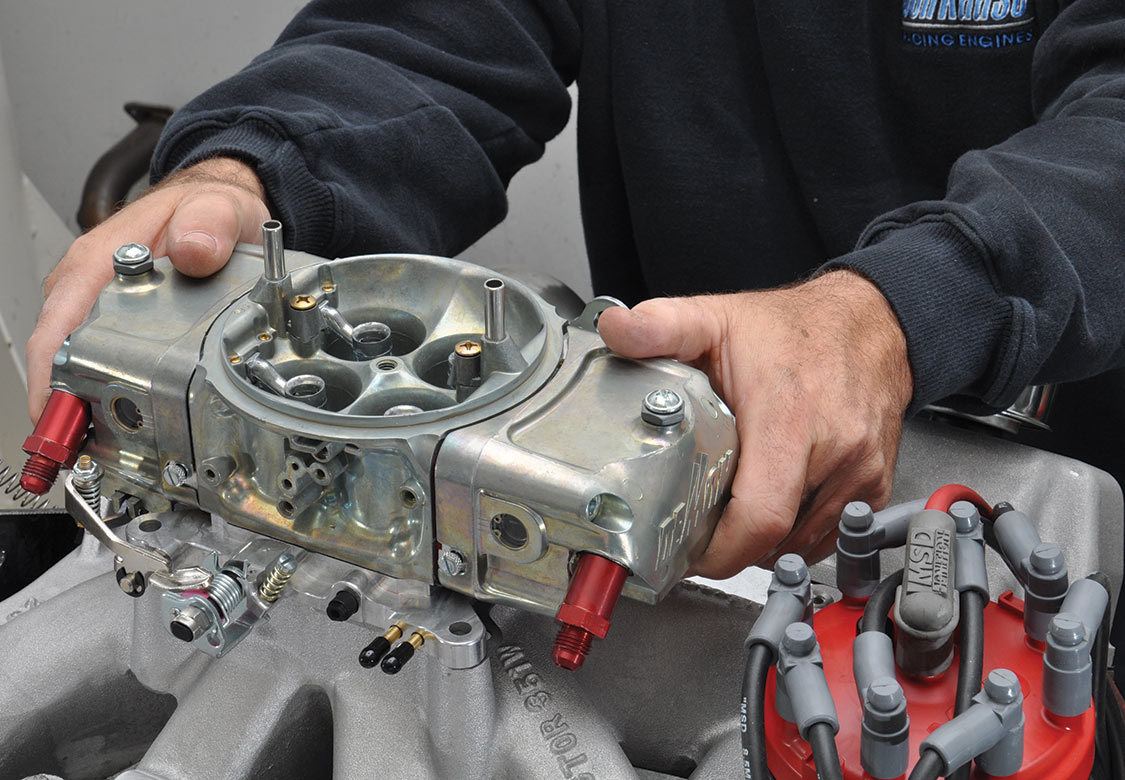

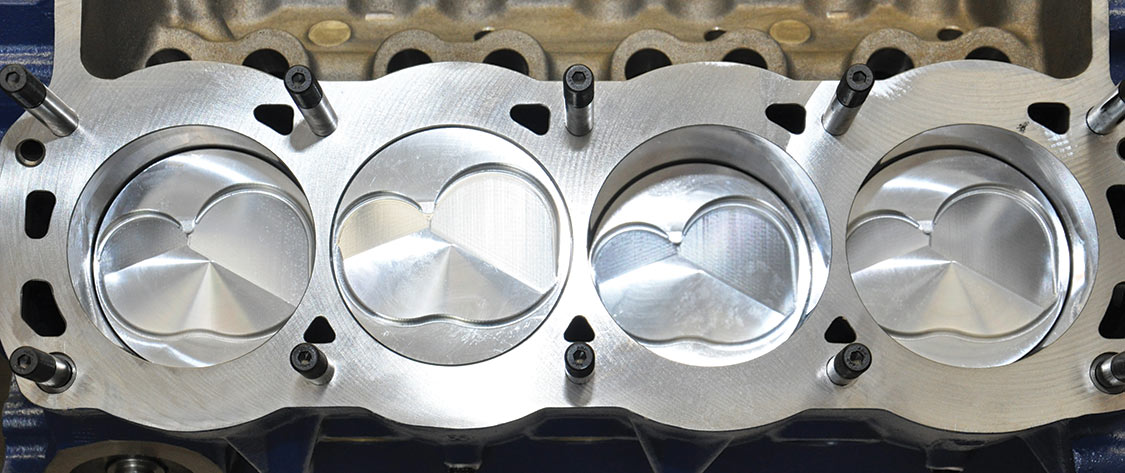

Engine philosopher Jon Kaase of Jon Kaase Racing Engines in Winder, Georgia had one of those nagging ideas. You know the type; the ones that make you look at something and say “why not?” For years he watched the ubiquitous Ford 302 market amass part upon improved part, but observed nary a deviation from the original cylinder head configuration. He thought he could produce cylinder head castings that looked like an ordinary Windsor 302/351 on the outside but inside would perform entirely different from the original blueprint. Being a racer, he knew the value of stealth. But more importantly, as an engine builder he knew the prime advantage of canting the valves to open towards the center of the cylinder, thus mitigating the natural shrouding effect of the cylinder wall.

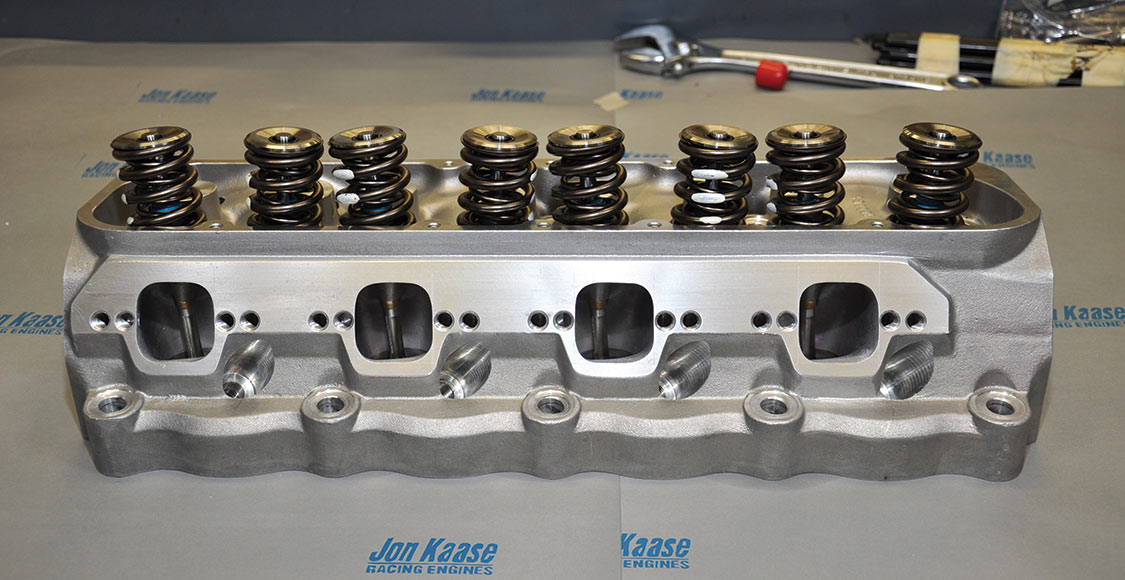

The Ford P38 cylinder head was designed primarily for the 302W (8.2-inch deck height, 4×3 bore/stroke, 5.095-inch rods). It’s derivative of the popular 347-ci (over bored by .030-inch and stroke increased to 3.400-inch), the 351W (9.5-inch deck height, 4×3.5 bore/stroke, 5.960-inch rods) and the 427-454W Sportsman-type Dart block (9.5-inch deck height with 2.750-inch Cleveland main journals). Combustion chamber volume is typically 60-62cc.

For better cylinder filling, Kaase envisioned valves canted at 8×4.5 degrees on the intake and 10×4 degrees for the exhaust. The new territory produced by this modification would allow him to increase the diameter of the valve heads to 2.100 inches and 1.60 inches and by astute CNC porting he would induce far superior airflow and cylinder filling compared with any conventional layout. The revised angles advantageously place the intake valve in the cylinder bore and the CNC porting is much more efficient than the original. It also has the qualities of a sweeping short-turn radius (on the floor of the port) and deeper valve bowls, giving the atomized fuel improved entry to the combustion chamber.

Assume a 2.100-inch intake valve yields 350 cfm in a port with a given cross-sectional area. Then assume that you increase valve size to 2.200 and the engine yields 360 cfm; the result could actually indicate a loss in performance. Such is the consequence of increasing the intake port and losing the air velocity because the opening is now larger. Sophisticated petrol heads know it doesn’t pay to increase cfm unless there is a simultaneous gain in airspeed.

Then, because the P38s flow so well at 0.400-0.500 inch of valve lift, the camshaft could be tailored with 5 to 10 degrees less duration. This usually results in smoother idle and better low-end manners. These Kaase heads favor camshafts with close lobe centers that tend to produce more power.

The revised angles advantageously place the Intake valve in the cylinder bore and the cnc porting is much more efficient than the original.

Though the 351 Cleveland could be coerced, its coolant flows through the front of the block and into the cylinder heads. With the Windsor, coolant flows through the intake manifold. Certainly the Cleveland’s redundant passages could be blocked off, but Kaase’s wisdom is to use the Windsor block that is stronger, readily available and requires no modification.

On pump gas and with barely 9.0:1 compression ratio, a modest mechanical roller camshaft and an Edelbrock Victor Jr. intake manifold, the Kaase 302 easily produces 500 hp at around 7,500 rpm. At the other end of the power spectrum, a Kaase-equipped 392-ci OE cylinder block belts out 650 hp all day long but is fully capable of producing 700 hp and beyond if desired.

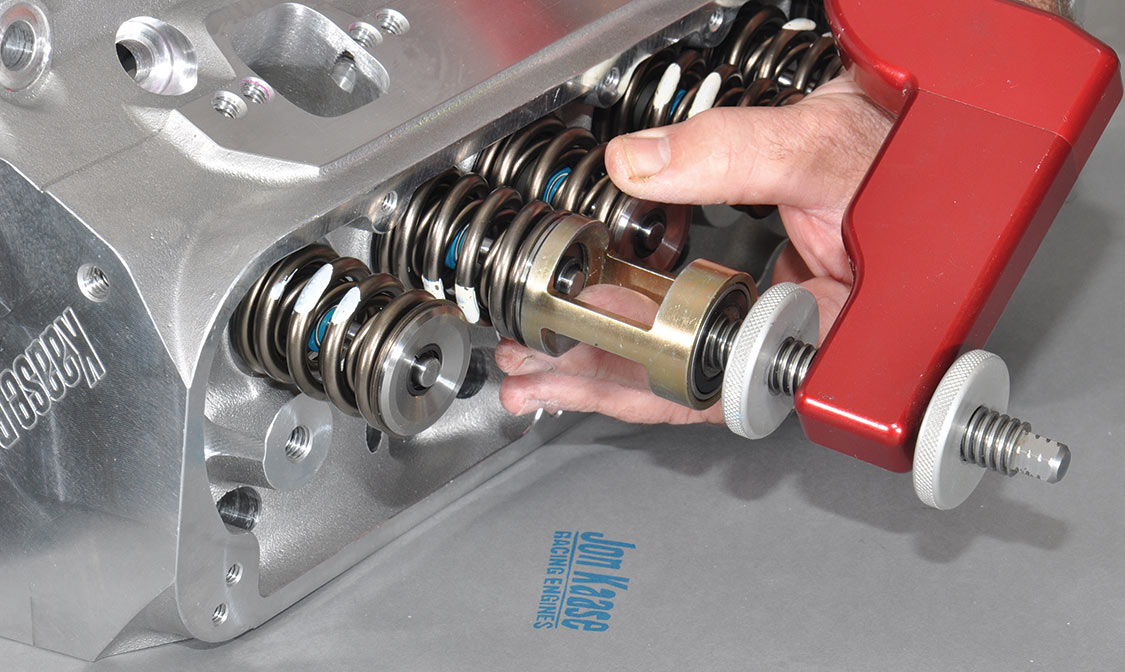

Including valve covers and valve cover gaskets, the P38 heads are supplied with larger valves, springs, seals, retainers, rocker studs and guide plates installed. Complete P38 engines are also prepared at Kaase’s facility. These are accompanied with dynamometer test results and often a video. Dyno tests ensure the engine is producing the expected power output and is free of oil and water leaks.

The bottom line is a Ford 302 or 351 Windsor with much improved throttle response and more usable power. It also allows the Windsor to be competitive with far more expensive modified Cleveland engines. One more thing, Kaase’s annoying, nagging feeling is a thing of the past.

Jon Kaase Racing Engines

770.307.0241

Jonkaaseracingengines.com

I’ve ridden an adventure motorcycle for tens of thousands of miles, with over a third of that off pavement, and a good portion of that on terrain above my skill level and not necessarily suited for a heavy adv bike loaded with gear. I enjoy challenges and choose to put myself in those situations. Somehow on a guided trip, on a middle-weight adv moto, and on a long, completely paved day of riding, I experienced one of the single toughest days I’ve had on two wheels.

The day started early in Ushuaia, Argentina, — the town at the end of the road — with chilly temps, fog, and torrential downpours. That transitioned into a big, steep mountain pass (Garibaldi Pass) that had snow on the shoulders and sleet falling from the sky. A few hours into the ride, on the other side of the mountain, we found refuge in a COPEC gas station coffee shop to warm up and shake out the tense muscles.

Back on the road, we found more hard rain and wind for hours. We laid on the throttle heavily during a break in the weather, enjoying about 45 minutes of glorious sunshine and light winds. Dark angry skies on the horizon foretold what we were about to face, however.

Sun turned to darkness. Dry roads turned to standing waterways. To make matters worse, for a good 15 miles, there was lots of oil on the roadway. The rainbow streaks on the dark black asphalt were hypnotizing, but bends in the road and sideways gusts of wind were terrifying.

All six bikes in our small group made it to the border stations unscathed. We waddled through the building in soaking-wet gear, laughing at each other and the conditions we had just endured. We checked out of Argentina for the last time and then checked back into Chile a few miles down the road. Little did we know that the really challenging riding was still to come.

As we rolled into Chile we were confronted with more torrential rains and strong consistent side winds. Then, the rain backed off, turning to a constant drizzle that allowed none of our gear to dry, even with the intense winds and highway riding speeds.

“Massive wind gusts seemed to punch us from all angles, pushing the loaded motorcycles all over the road for hours.”

Massive wind gusts seemed to punch us from all angles, pushing the loaded motorcycles all over the road for hours. Big trucks heading south would throw out a bow wave of water that hit us in the face and blinded us, then we’d have a fleeting moment of calm in the wind shadow before being smacked by the turbulent wind off the back of the trailer, sending the bike sideways as we leaned in and grabbed a handful of throttle to counter.

Then, the skies started to clear and sunshine poked through. The rain turned to an intermittent drizzle, but the winds intensified, blowing consistently over 32 mph, with gusts well over 55. This lasted for hours.

Our group soldiered on through this chaos, but at a fork in the road we had to make a decision. We rolled up to a small roadside wooden shelter/tiny house that is primarily used by cyclists. It had a horribly smelly pit toilet, but was an oasis from the unrelenting gusty winds. While we took refuge in the shelter as it shuddered in the wind our bikes swayed outside. One bike got pushed all the way over its kickstand and crashed to the ground. Even standing was difficult, so picking the bike up took three people. The group decided that 30 extra miles of loose gravel roads in this wind was a bad idea, so we had to skip seeing the king penguin colony.

After another hour or so battling these winds, but with progressively clearing sunny skies, we turned one final bend in the road before our hotel for the night. A many miles long straightaway stretched out before us, but something was different. There was way less noise, speed came easy, the bike rolled effortlessly completely upright, and muscles relaxed. The wind was directly at our backs and it felt like we were floating on a cloud. Pure heaven!

We fueled up, as our bikes were very thirsty from battling all the wind, and rolled into a very busy hotel. Two other motorcycle tour groups were already there, with well over 30 bikes parked out front. It was a bit of a circus with all the people, and I was reminded how nice it was traveling in a small group and staying at small lodging facilities most of the trip.

“With 16-days of travel across Patagonia on a Tenere 700 outfitted for adventure, I would have never guessed a long day on pavement would be one of my most vivid, and cherished memories.”

This was the only lodging for hundreds of miles, so was the only choice. The other riders had all battled similar conditions as we did, and were already deep into many a cold beer and sharing stories of the day when we arrived. After some cold beers, a hot shower, and a solid hot meal, our long day traversing Tierra del Fuego from South to North came to a close.

With 16-days of travel across Patagonia on a Tenere 700 outfitted for adventure, I would have never guessed a long day on pavement would be one of my most vivid, and cherished memories. It was one of the longest riding days of the trip, both in terms of hours and distance, and was all kinds of type 2 fun, which I admit I enjoy. One of my main mottos in life is: “The adventure only truly begins when…”

This March day crossing Tierra Del Fuego was not the norm on the late season North to South tour through Patagonia our group was on. Sure there was plenty of windy and wet days, but none that were as intense, long, and trying as this one. Most days offered up mostly sunny skies, puffy white clouds, and mild temperatures. From guanaco to condors and glaciers to mountain peaks there was never a shortage of interesting sights to see.

Of the 2,900 miles covered on the trip, about 900 were off-pavement, mostly on gravel and dirt roads. Besides loose gravel and some extreme weather events there wasn’t really any technical riding, but there sure was plenty of motorcycle riding adventure to be had.

From the Chilean Lakes District in the north, along the Chilean Patagonia fjords, through the small towns in the Andes, across the Argentine Pampas, and finally to wilds of Tierra del Fuego and “the end of the world,” this epic adventure motorcycle tour did not disappoint.

There were three rest days on the trip, where we stayed in the same lodging for two nights each. Motorcycle riding wasn’t required on any of these days, but on every one I couldn’t help suiting up, throwing a leg over my bike, and exploring. There is just too much in Patagonia to experience to sit idle. The short voluntary time on the motos on these days was welcomed, however, as long days in the saddle can be exhausting on body and mind.

One of my favorite rest days was the day before the windy epic. A day spent exploring Ushuaia and riding a short distance to the very end of the Pan American Highway. Not only was the quick ride on a curvy dirt road through the Tierra del Fuego National Park a ton of fun, but the town itself was a surprise.

I envisioned a sleepy tiny port town at the end of the road surrounded by nothingness. Instead, I experienced a vibrant tourist port city of considerable size built into a hillside and shadowed by mountain peaks. The food was tasty, and every souvenir you could ever want was up for grabs, if you’re in need of such things.

Huge thanks to founder and lead guide Daniel Palazzolo and the entire professional staff at Moto Patagonia for an experience of a lifetime. The quality, new, and well maintained motorcycles made the curated route, tasty meals, and world-class lodging all that much more enjoyable. The small intimate group — five guests and two guides — allowed for a nimble, flexible trip colored with authentic flavor.

“One of my favorite rest days was … A day spent exploring Ushuaia and riding a short distance to the very end of the Pan American Highway.”

From guided day tours to 16-day epics like ours, to private custom tours, and motorcycle rentals, Moto Patagonia is your source for adventure motorcycling experiences in southern South America.

Visit MotoPatagonia.com and get in touch yourself to create your own Patagonian adv moto memories.

Editor’s Note: A version of this article appeared in TREAD July/August 2023.

Wilwood Engineering has appointed Robert Hemingway as their new Director of Engineering. He will join the R&D/Engineering team and focus on Wilwood’s ability to design and produce the premium-quality brake components and systems they are known for, utilizing the latest manufacturing and new material technologies.

Robert’s acquired skills, including a Master’s degree in Engineering and Industrial Management, will be an asset to improve product development and manufacturing processes.

“I am excited to join the iconic Wilwood Engineering team and lead the already successful research and development group into the future.”

Let’s grab another gear and push the pedal to the floor as we begin the next chapter of what the best brake systems in the world are and will always be.” With over 10 years as an Engineering hardware development professional in the automotive, aerospace, and defense industry, Robert most recently served as a Sr. Development Engineer at Garrett Motion in Torrance, CA, launching new products. His prior experience included positions at Honda Performance Development as Top End Development Lead with success from Motocross to IndyCar. In addition to his engineering background, Robert brings hands-on experience as a long-time racer/mechanic, including machining and fabrication. The Wilwood staff is thrilled to have such an experienced individual guiding the Engineering team.

About Wilwood Engineering

Founded by Bill Wood in 1977, Wilwood Engineering designs and manufactures high-performance disc brakes and components from their headquarters in Camarillo, California. Products are engineered and rigorously tested for any application, creating unsurpassed braking quality and performance with sleek, modern designs. From race cars to classic cars, Wilwood has the brakes to stop you. For more information, contact Wilwood Engineering at info@wilwood.com.