Photos by Devan Ence

Some might look at this truck, as amazing as it sits in beautiful bare-metal skin, and see transport wheels and its incomplete interior only to ask, Why is it deserving of a spot in print? Why not wait for it to be completed THEN feature it?

While those are valid questions, it’s important to realize that not all project vehicles are built in vain. This 1968 F-100 isn’t exactly on the cusp of being buttoned up for good, but it’s close, and it has come a long way since Taylor Marecle first bought the truck back in 2014. A lot has happened since then—both with the truck and in Taylor’s personal life—and instead of letting things get the better of him, he has instead put things into perspective and has continued in the only direction that truly matters: forward.

Taylor is a custom truck guy through and through. This truck would have been customized and fully built one way or another, but he was faced with circumstances that gave him a unique incentive to press on and raise the bar for the bumpside project he has always wanted. Taylor’s brother Griffin, who was also a big F-100 guy, passed away in a motorcycle accident in 2019. While the two brothers struggled to get along as kids, they fused together as adults through their shared passion for Ford pickups and everything else that goes along with sharing brotherhood and family life.

“I have dedicated my ‘63 build to the memory of my brother and have even named it after him,” Taylor says. “Griffin was the original Fly’n Lion. He never had less than five project trucks going on at once—not to count the 20 friend projects that he was helping with, which he put more time into than his own projects. He was never short on close friends, and I was honored to be included in that group.”

While both Taylor and Griffin enjoyed looking at a clean, classic Ford truck, they were both heavy into performance as well.

While both Taylor and Griffin enjoyed looking at a clean, classic Ford truck, they were both heavy into performance as well. This is what inspired Taylor to secure a 2019 Coyote engine for his ’63, along with a VMP supercharger to add even more power gains to the mix. Oh, and the Tremec Magnum 6-speed transmission he also got would soon make driving the F-100 an absolute blast. Ordering the major parts and supporting components is one thing, but for the much larger scope of customization as far as fabrication and metalwork goes, Taylor made a great decision in asking Sonny Warner of Sonny’s Speed and Kustoms in Twin Falls, Idaho, to assist in these very important categories and then some. Not only did Sonny help in planting the Coyote engine into place, but he has also constructed sheetmetal paneling within the engine bay to fully preface the compartment with more of his excellent craftsmanship to come.

Getting the right stance for the truck was of utmost importance for Taylor, and after bouncing ideas off Sonny on how to get an ideally aggressive ride height, the two settled on a list of modifications to make it happen. To start, Sonny boxed the factory ’63’s frame for rigidity and created exhaust pass throughs that would soon house the custom piping he would later create. A Crown Vic crossmember and Fat Man Fabrications took up residence at the F100’s front end, and a custom 4-link setup was fabbed up along with a through-frame sway bar for the rear. To further promote overall excellent ride quality, Ridetech coilovers were added to each corner to seal the deal on the truck’s modernized chassis system. Upgraded Wilwood braking components for each end were also assembled to ensure the truck’s stopping power would be just as powerful as its momentum.

With the engine and suspension departments shown some attention, Sonny soon moved onto working on the Ford’s 60-year-old body. While the truck didn’t come to Taylor in horrible condition, there was some specialty metalworking that just had to be done to give it that look he knew Griffin would wholeheartedly approve of. Sonny was given free rein of the rest of the upcoming modifications such as the customized factory grille, fresh Holley headlights and the addition of one-off ’73 E-100 Econoline bumpers on each end. A one-off double skinned tailgate with billet emblem was fabricated with the addition of a double walled inner bed, fresh rocker panels under the door, and for kicks, a stealthy gas filler placed behind the left taillight. Taylor and Sonny do have a plan in place for paint to come, but you can’t blame the guys for enjoying the truck as it sits in full bare metal—it is a wonderful sight to behold.

While the interior is in current ongoing progress, big strides have been made such as custom dash and metalwork, along with some awesome touches that will evolve into much more noteworthy condition soon enough. For now, it’s interesting to pay attention to the things that have been done and notice later just how much they have been improved on once the cab space is complete.

“As we make more and more progress on this truck, I can’t help but hope that Griffin is watching in agreement from above,” Taylor comments. “I didn’t realize it at the time, but a lot of the decisions I made in life were in an effort to be just like him.”

As the Fly’n Lion steadily takes its final form, we’re sure that it will go down not only as one of the coolest custom F100s to be unleashed onto the show scene, but it will also carry with it a certain sentimental value due largely in part to its very special namesake. We wish Taylor and all of those involved with the project well with the build phases that are remaining, and we are highly anticipating seeing the finished state of this impressive rolling memorial for the beloved Griffin Marecle.

Owner

Engine & Drivetrain

Chassis & Suspension

Body & Paint

Words and PHOTOS by Devan Ence

I want to introduce our 1976 F-250 Highboy, a.k.a. “Project Green Giant.” There is a lot of history with this truck for me, starting with a ride home from the hospital as a newborn. That’s right, this truck has been a part of my family since before I was born.

The truck was purchased by my parents brand new off a lot in Knoxville, Tennessee, in 1976. From there, it made the trip out to Colorado where it spent winters pulling a hay trailer through snow-filled pastures feeding horses and summers exploring the mountains around Gunnison. From there, it went to southern Utah and this is where the truck enters my earliest memories.

I can remember standing on the seat, steering the truck while it putted along in the granny gear, as my parents loaded hay on a trailer in the alfalfa field. The summer was spent riding around in the bed of the truck casting a Snoopy pole out the back with a rubber practice casting lure and reeling it back in. In the fall, it was riding around in the hills pulling a gooseneck horse trailer either headed to round up cows or going to deer camp.

At this point, I bet you are wondering why the project is called the Green Giant when it was never lifted or modified from its original state. I don’t know how many of you remember getting up and watching Saturday morning cartoons as a kid but there were always the “Jolly Green Giant” commercials that popped up during my favorite cartoons, and from that moment on that became the truck’s name.

After my folks split up, the truck made its way back to Colorado. When I was old enough to get my license, I had the choice between this truck or a crotch rocket, and of course I picked the truck. From that moment on, I drove the wheels off it, getting in trouble and making memories. After high school I left the truck with my mom where it saw its fair share of hard use and abuse around the farm. A few years ago, I was able to pick up the truck and bring it to Idaho. It was in rougher shape then I remembered, so I parked it in the pasture until now.

The plan for the build is to clean up any of the rust issues it has, add fresh paint, a lift kit, fresh wheels and tires, and a complete interior overhaul. Having the opportunity to make these changes will really help bring the truck that I always dreamed of to life. With the help of great companies like LMC Truck, Detroit Steel Wheels, Toyo Tires, Skyjacker Suspension, Auto Metal Direct, and TMI Products, we will transform this pasture ornament to a head-turning daily cruiser.

This project isn’t a complete frame-off restoration. The whole point is to clean up the truck and make it nice to drive, so I can start making memories in it with my son Emmett (currently 10 years old). Once he gets to driving age we will dive into the engine and build it together, so he has some personal investment in the truck before he starts driving it to high school. As you can see, the truck was in rough shape and a little ugly to start with and it will have to get uglier before it starts to get prettier, but that’s all part of the process. Right now, the truck is in the rust repair and bodywork stage of the build. I can’t wait to share each part of the process with all of you as we bring this truck back to its former glory.

Photos by brAndon burRell

The Ford F-150 Lightning was and still is a very exciting performance-based pickup model. The inaugural 1993 first-gen model was introduced as a direct response to take on two hopped-up rivals in the OEM performance truck segment—the GMC Syclone and the Chevrolet 454SS. This was a grand time when consumers were introduced to a factory-direct combination of muscle car action in the shape of a pickup truck. Mix this in with the beginning stages of the custom sport truck scene in the early ’90s, and we had the makings of a perfect storm within the custom auto industry. The days of trucks serving as mere oafish utility vehicles were officially over from this era forward.

There’s so much to love about this first-gen F-150 Lightning, and that sentiment has been evident across the board—including from GM purists.

While many customized first-gen Ford Lightnings have surfaced since their initial release, we have yet to see an example of one built like the truck David Shulman and his daughter Madison have put together. Their ’93 is the epitome of throwback retro vibes fused with modern street aesthetics. Those familiar with David’s name know that he does not play around when it comes to the vehicles he chooses to buy and build. He’s a man who enjoys the finer things in life, and when the time comes to get down to work on a new ride, half measures are never taken.

When David tracked down a Lightning he was interested in purchasing, he was relieved to find that it was parked somewhere in Florida that wasn’t too far from his front door. He would’ve had an issue venturing much farther out of his way to retrieve the truck if need be, but luck was on his side this time around. This afforded him the luxury of giving the truck a look in person without making much of an effort. What David found was a very clean, solid, and original 1993 Ford Lightning that had only see two previous owners. There really wasn’t a reason to not buy it, especially after negotiating a good starting price point that would work great for the full frame-off project he had envisioned.

While the Lightning models come lowered about 2 inches from the factory, this ride height just wasn’t going to be low enough for David and Madison. With that in mind, they instead checked the Ford in with Jake McKiddie and the team at Phat Phabz in Choctaw, Oklahoma, for their full custom treatment, which would start with the fabrication of a full custom chassis. This front-to-back frame package features a lock-to-lock turning radius with adjustability of up to 14.5 inches of lift to free up large diameter wheels for unobstructed drivability. Front 2600 Air Lift Dominator air bags along with a parallel rear four-link setup topped with Firestone sleeve ‘bags make for comfortable cruising at just about any speed. This all comes with the highly desirable ability to lay the Lightning down on the ground, tucking the 22-inch front and 24-inch rear Hot Rods By Boyd wheels up into the body with ease.

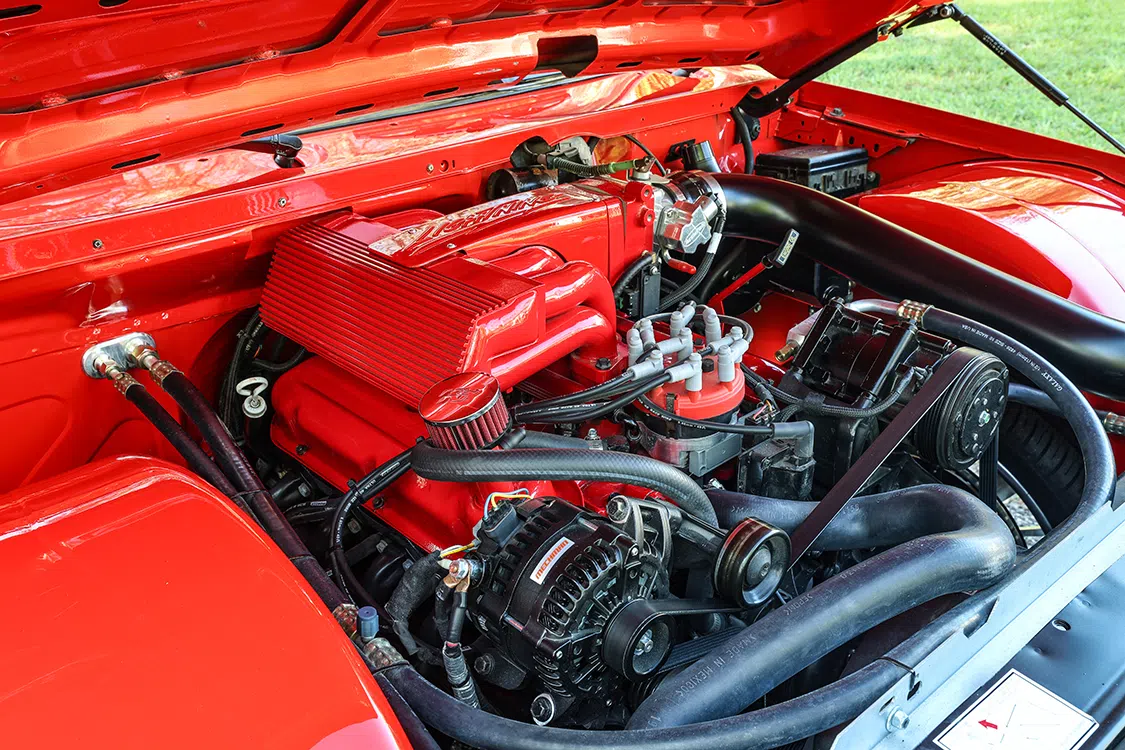

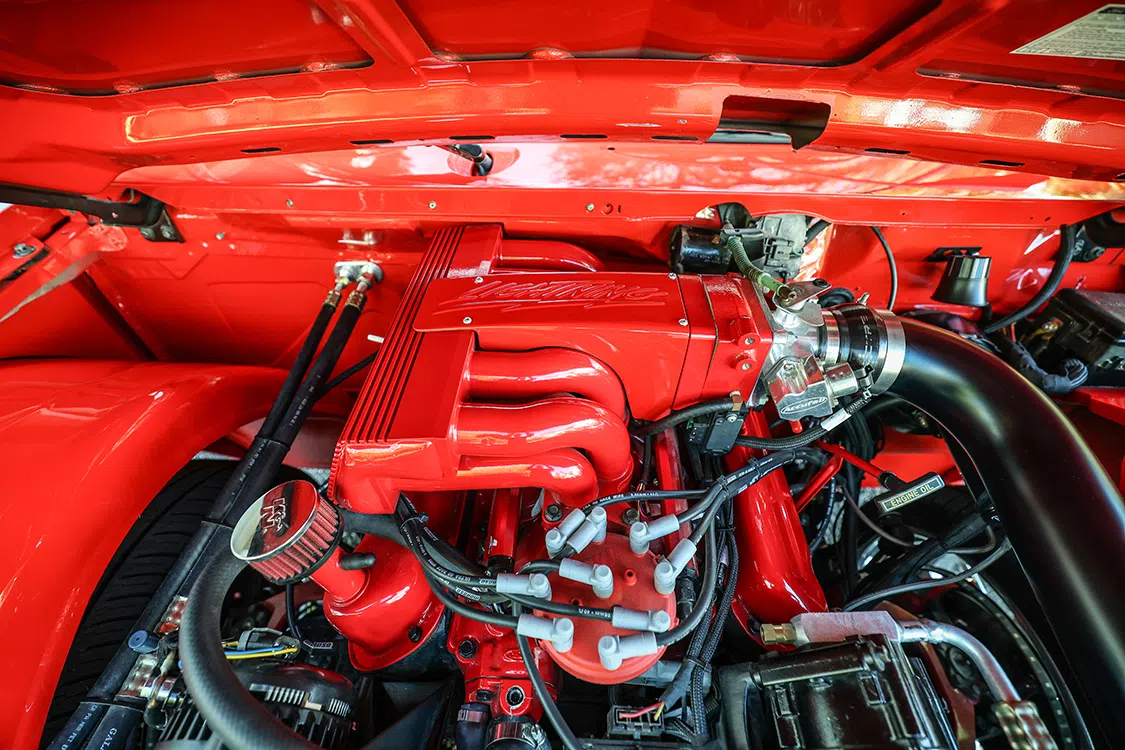

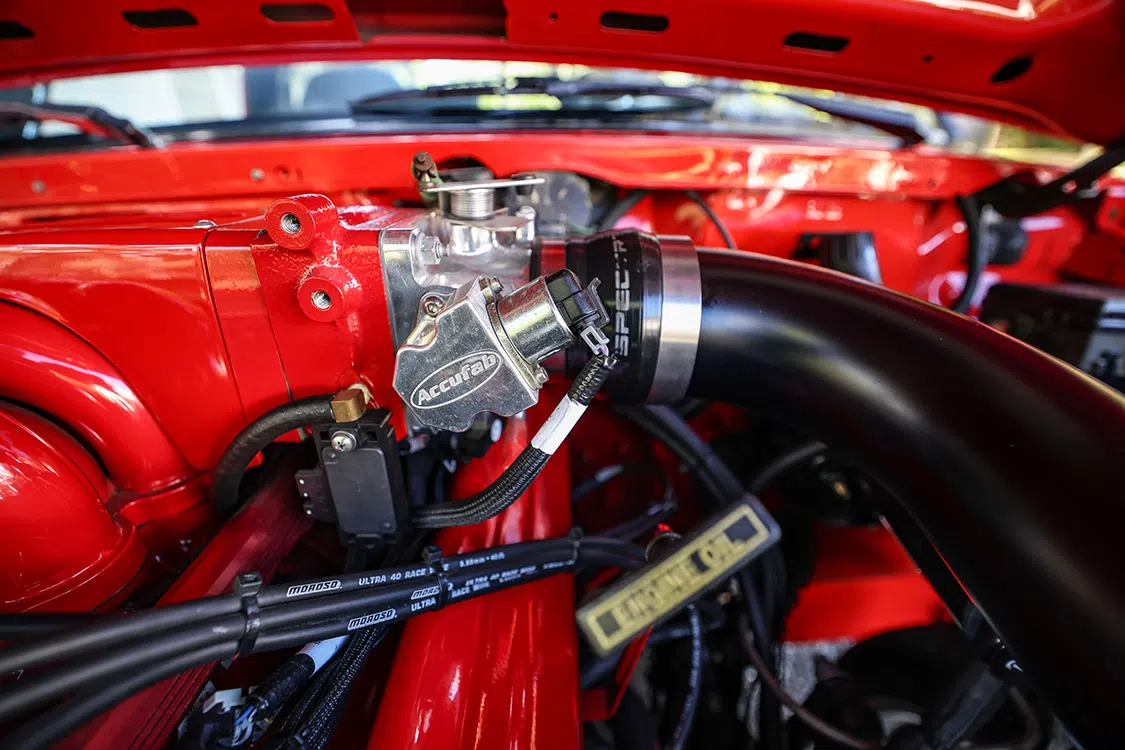

Building the frame from scratch bought David some time to arrange for the factory 5.8L engine to be plucked and rebuilt. To assist with this, he turned to Gerald Brand of Brand Racing Engines in Oklahoma City to tear the Lightning’s factory-equipped powerplant down and beef it up from the inside out. Along with the general gutting and cleaning process, Gerald outfitted the V-8 with Diamond pistons, Crower camshafts, Scorpion roller rocker arms and lifters, as well as created full custom air intake and exhaust systems. The result of the engine rebuild process netted a better-than-stock, still-numbers-matching engine that has the capability to rumble meaner than ever before.

When it came time to finish off the inside of the bed, the custom bead rolled panels that make up the walls and floor portions were coated in Line-X to give the Ford a contrasting pop of color while creating a useable cargo space to comfortably haul around valuable supplies or a stack of Christmas gifts from Santa.

Before the engine was replanted underneath the hood, the bay was treated to a set of tubs and bodywork to get it prepped for its final stage of paint. The same process was also rolled out to the rest of the Ford’s exterior landscape, as the body was shaved clean of the drip rails, cab seams, and wiper cowl. These alterations, as labor intensive and necessary of a skilled hand as they are, cleaned up the Lightning’s façade enough without performing too many modifications. To further change up the frontend a few degrees, a custom front air dam/bumper was created, and a GrantFab roll pan was utilized to better round off the rear. These mods to the Ford gave David and Madison’s truck a one-of-a-kind appearance without calling attention to every single tweak that has gone into streamlining its appearance. Only those who are very familiarized with these first-gen Lightning models will pick up on everything included in the truck’s exterior restyling.

Since the F-150 Lightning was originally made available in red from the factory back in 1993, David felt that recovering the truck with a fresh coat of red paint would go a long way to staying true to the truck’s roots. Ryan Kidd at S&R Designs in Fort Smith, Arkansas, was approached to handle this portion of the project, and the color he suggested was Infra-Red from Orion Automotive Finishes—an excellent shade to run with. The color was also been applied inside of the engine bay, as well as on the large spokes on the wheels. When it came time to finish off the inside of the bed, the custom bead rolled panels that make up the walls and floor portions were coated in Line-X to give the Ford a contrasting pop of color while creating a useable cargo space to comfortably haul around valuable supplies or a stack of Christmas gifts from Santa.

Instead of doubling down on the inclusion of red paint inside of the cab, the restyling of the interior takes a cue from the bed as far as the hues used. Aside from the wrapped Hot Rods by Boyd steering wheel, the majority of the cabin was done in black to promote a chill and subdued environment for cruising. Innerworx in Sarasota, Florida, joined the project to handle all the truck’s upholstery needs, and Eric Ryan at Advance Audio Concepts in Pompano Beach, Florida, lent a hand by customizing the dash as well as wiring up the full stereo system featuring a Stinger Heigh10 infotainment head unit. Since the weather can get a bit hot and humid for the Shulman family in Florida, working in a Restomod Air A/C system was an absolute must before the project was considered complete.

In right around nine months after the Lightning project kicked off, it was finished just in time to debut at SEMA 2022. The response from show attendees was extremely positive, which wasn’t a surprise to anyone involved in the build process. There’s so much to love about this first-gen F-150 Lightning, and that sentiment has been evident across the board—including from GM purists.

Madison wasn’t old enough to drive the truck back when it was first unveiled, but by the time you read this, she will have her license in hand. While we’re sure David has taught her to practice safe, responsible driving habits, we’d like to give others sharing the road with her a little slice of advice—don’t give her a reason to flex on you. Surely, she has gotten the hang of harnessing and unleashing the true power of her truck by now. Consider that your one and only warning.

David and Madison Shulman

ENGINE & DRIVETRAIN

SUSPENSION

Wheels & Tires

Body & Paint

Interior & Stereo

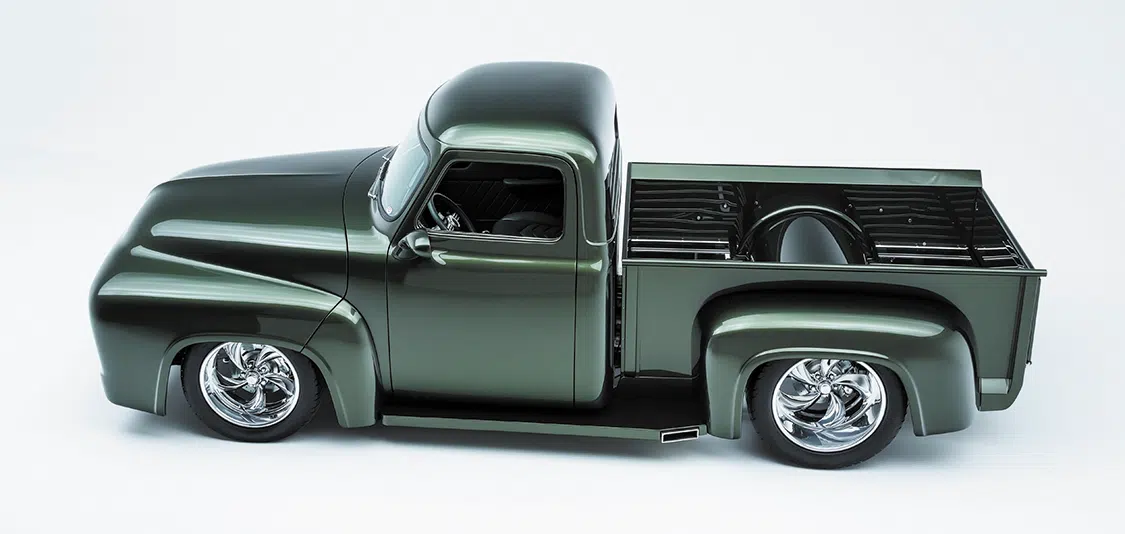

It doesn’t get more American than a classic blue oval F-Series truck except – well, this truck is Canadian! Actually, it’s a ‘54 Ford F-100 that was exported to Canada and not actually a Canadian Mercury M-Series, so maybe it’s still American after all? Yes? No? Either way, it’s a bitchin’ truck that sports tons of unique, custom modifications thanks to the folks at Heighton Restorations and Vern Heidt, among other key players in the transformation of this once stock truck.

Gilbert Desrosiers had always wanted to build another custom classic truck like the ‘55 F-100 he has owned for decades but just couldn’t find the time to plan things out the way he wanted. Upon retiring a few years ago, he finally found himself with oodles of time and nothing to do. So, with his wife’s blessing (and possibly encouragement, but that’s just unsubstantiated rumor), Gilbert got busy on turning his dream into some real deal steel. The truck would be another ‘55 F-100, but there were a lot of things he wanted to do differently this time. It would take half a decade to complete, but as you can see, the results were well worth the effort expended.

Once he had an idea of what he wanted, Gilbert called on Vern Heidt to assist. A TCI chassis was equipped with RideTech Shockwave airbag-over-shock units on all corners of the suspension, providing a compact solution to fitting the air ride. The wheels are wild and wide American Racing VF489 rollers, measuring 18×8 at the front and 20×15 at the rear, with equally impressive 28×10.00R18LT and 31×18.00R20LT Mickey Thompson Sportsman S/R rubber.

It’s just about impossible, even for the seasoned F-100 enthusiast, to spot all of the changes that were made to the truck’s body while at Heighton Restorations. Sure, you can spot the chopped top easily enough, and maybe even the shaved drip rails, but did you notice that the roof was also decrowned an inch? The shaved door handles and custom mirrors are obvious, but did you see the rounded door corners? And those diagonal lines on the front fenders are a definite giveaway that the truck sports a one-piece tilt front end, but did you pick up on the widened rear fenders? What we’re trying to say is that there’s a whole lot going on, there isn’t enough room here to list it all, and we’re here for it!

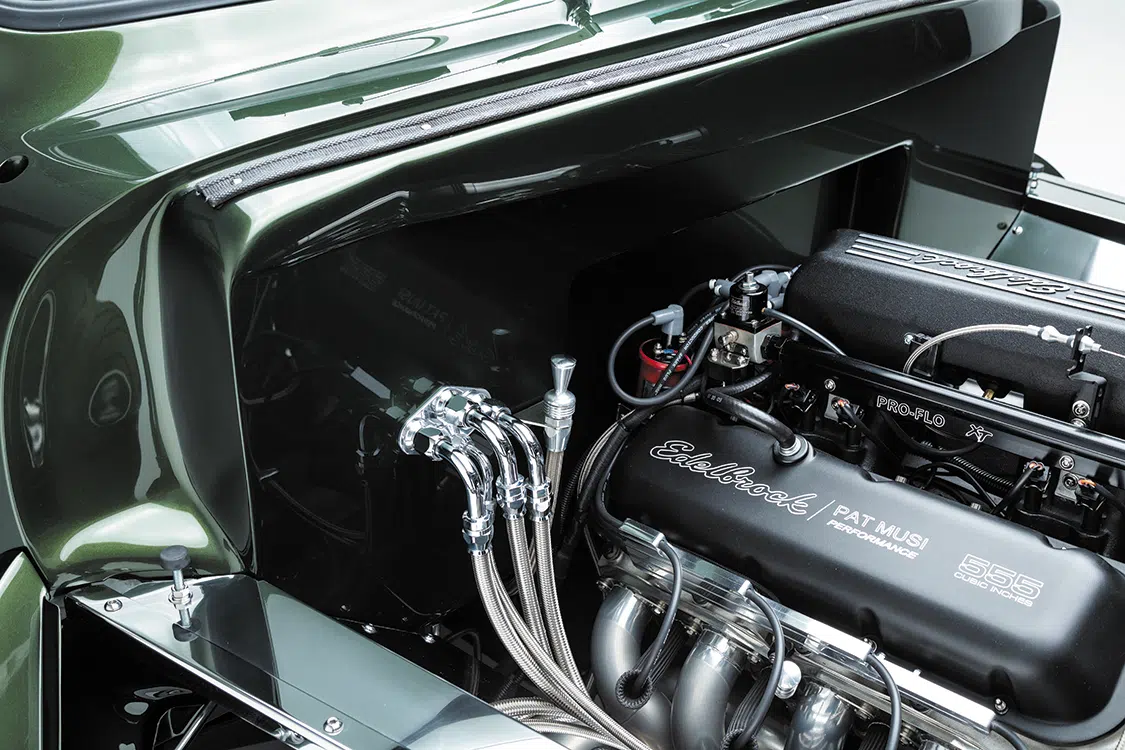

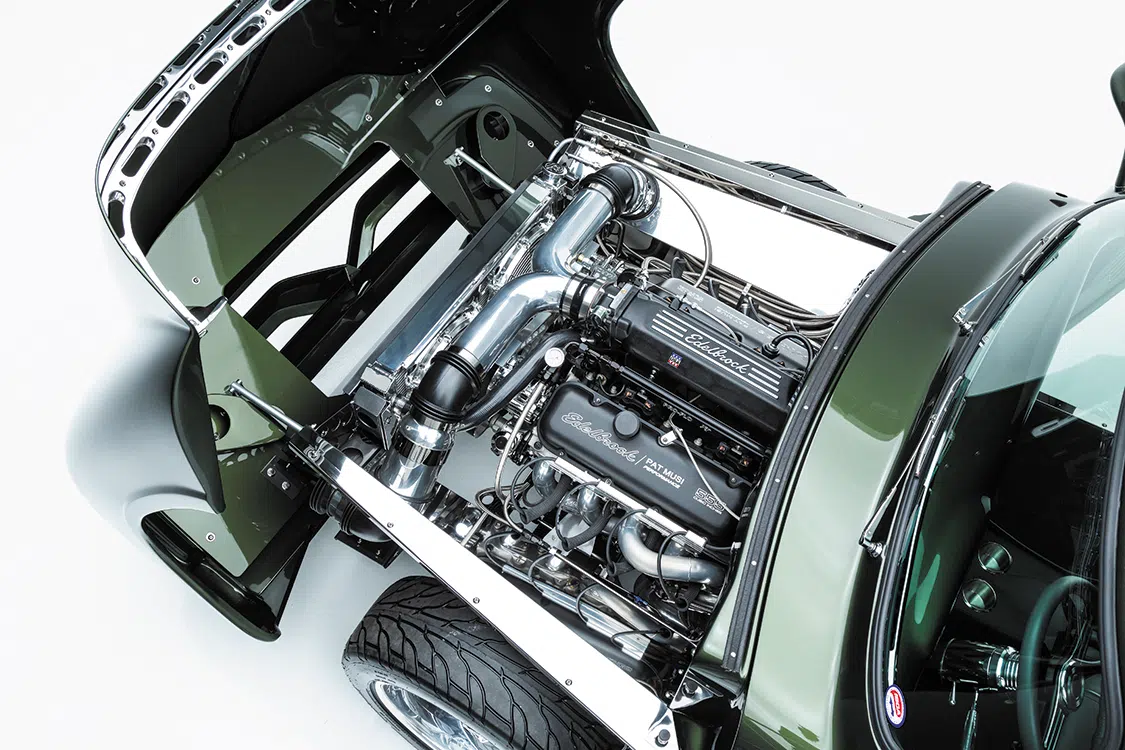

As you can imagine, a ton of work went into all of the body modifications and getting the body absolutely perfect, which the PPG Envy Green paint shows off beautifully. You’d almost forget that there’s more to see of Gilbert’s F-100 – a lot more! For example, there’s the brilliantly finished Edelbrock/Musi 555ci Chevy crate engine that has been topped with an Edelbrock Pro Flo EFI setup. Sure, we’ve all seen Chevy small blocks under the hoods of Fords over the decades, but you have to admit that a big block of this pedigree is an unusual yet awesome choice – especially with the 4L80E-based TCI Automotive 6x automatic transmission!

And with all of this going on, you know the interior just has to be on point – and it is. Jeff Wingrove fabricated and upholstered the custom door panels, headliner, under-dash panel, and center console then matched the Chrysler 300 bucket seats to complete the textile transformation. Topping things off are the Dakota Digital VHX gauges and an Alpine sound system. Again, there are so many subtle (and not-so-subtle) changes that it’s tough to spot them all without staring at these photos for a good while.

Gilbert’s F-100 has been finished for a few years now, but because of Covid it hadn’t seen many shows until recently. Still, top finishes at World of Wheels in both Calgary and Boise in 2020, Spokane Speed and Custom in 2022, and World of Wheels Calgary this past year have proven that the truck is a crowd (and judge) favorite!

Chassis & Suspension

Wheels & Tires

Body & Paint

Interior & Stereo

Ford’s popular 6.7L PowerStroke diesel engine, employed in 2011-present F-series pickup trucks, can now be fortified with special high-strength connecting rod bolts from ARP.

ARP

805-339-2200

www.arp-bolts.com

Diesel Auto Power’s 47RE transmission line kit fixes the common issue of leaking, broken, or pinched factory transmission cooler lines. This kit includes all the necessary fittings and hose to run new cooler lines from the transmission to the factory-location heat exchanger on the passenger side of the Cummins engine block, and then forward to the factory air to oil cooler in front of the radiator, and back to the rear cooler return fitting on the transmission. Also included are premium rubber coated line clamps that enable a clean and secure installation. The supplied blue hose is rated for high temperature and 300 psi pressure, the perfect hose for replacement transmission cooler lines.

Diesel Auto Power

www.dieselautopower.com

Whether you need a better-than-stock replacement torque converter or a full-blown sled pulling converter, RevMax has you covered! Each RevMax diesel performance converter is custom-made to your exact specifications. Stall speeds and efficiencies are precisely matched to your truck. This is not a one-size-fits-all converter; this is a tailor-made unit for your truck and only your truck.

RevMax

877-780-4334

www.revmaxconverters.com

Power Driven Diesel offers a new in-cab fueling control for mechanical diesel trucks: the AFC LIVE In-Cab Fuel Tuner (patent pending). It allows you to adjust the fuel rate to advance slowly for better smoke control and fuel economy or let the rack travel fast for ultimate power. All of this live tuning is possible in-cab while driving with the twist of a knob.

Power Driven Diesel

435-962-9555

powerdrivendiesel.com

Remove your crushed oval-shaped stock downpipe and replace it with a smooth, round, long-lasting full 304 stainless steel downpipe from PPE. Includes a woven titanium sleeve to reduce engine bay temperatures.

PPE Diesel

725-238-2002

ppepower.com

This all new Garrett turbo comes with a install kit and will support up to 500RWHP. It pairs great with stock injectors all the way up to our 175/30 performance units. It provides great spool up and performance without sacrificing driveability. This turbo has the same 10-blade turbine used in the PowerMax turbo line and will have a loud exhaust whistle. This turbo can be used on all years of 6.0L Fords. To utilize on later 2004.5+ model years you will have to leave out one mounting bolt.

RCD Performance

309-822-0600

rcdperf.com

You need the biggest brake that’s built as tough as your Ford F-450. The 8-piston, heavy-duty B8-Beast Brake Caliper Upgrade Kit from SSBC-USA gives your Ford Super Duty F-450 truck the stopping power and performance it needs to get any job done.

This front brake caliper kit is made in the USA from high-quality aircraft-grade T6061 aluminum billet and is designed to bolt onto your 4WD 2017-2022 Ford F-450. Designed and engineered to provide massively more stopping power, the B8-Beast overpowers the empty space behind your wheels improving the overall look and style of either your everyday ride or prized, custom build.

SSBC USA

716-775-6700

ssbc-usa.com

The Titanium Signature Series diesel fuel system was engineered by FASS Diesel Fuel Systems to be the top performing, longest lasting, and most reliable aftermarket filtration system in the diesel industry. Rated at 110 gallons per hour and backed by the company’s limited lifetime warranty, the Titanium Signature Series fuel system can support your Nissan Titan diesel engine with enough fuel for up to 700 hp. A Titanium Signature Series fuel system also offers advanced filtration benefits that will help protect your injection system, effectively extending the life of both your injection system and injectors. Benefits include FASS Diesel Fuel Systems’ patented air/vapor removal process.

Fass Fuel Systems

866-769-3747

fassride.com

In the lush vineyards of Temecula, California, a different kind of craftsmanship is brewing. This is the home of the Scorpion EV, where the roar of the classic Cobra V8 is being transformed into a hiss, thanks to a new conversion solution. Under the leadership of Dr. Bill Cardoso, this innovative company is pioneering its Venom kit – with incredible feedback from the trade.

The Scorpion Legacy: From Dreams to Driveways

The origins of Scorpion EV are rooted in passion and ingenuity. It all started with the Silver Scorpion (featured in EVBG 04), a ground-breaking project that merged the classic style of a Cobra with the incredible performance the Tesla Model S Drive Unit. This creation wasn’t just a display of engineering prowess; it was a personal quest for Bill, fueled by his love for classic cars and his desire to share this passion with his daughter, who found the loud engines of traditional sports cars unsettling. The result was a car that not only turned heads but also opened minds in the traditionalist Cobra world. The Silver Scorpion, a 2022 Scorpion EV Scorpion 600, became a symbol of what’s possible at the intersection of heritage and innovation and set new standards in the classic car world.

Venom: A New Chapter in E-Conversions

Buoyed by the success and the lessons learned from the Scorpion 600, Scorpion EV set its sights on a new venture: the Venom Kit. “We listened to our customers and created Venom, a sleek and sophisticated EV conversion kit that meets their desires,” explains Dr. Cardoso. Priced at $39,999, with a $1,000 deposit to secure a spot in the production line, the Venom Kit is more than a set of parts. It’s a comprehensive solution, meticulously crafted to ensure that converting a Cobra to electric propulsion is not just possible but also enjoyable and relatively quick. The team even converted a cobra at SEMA in less than 20 minutes, live at the show!

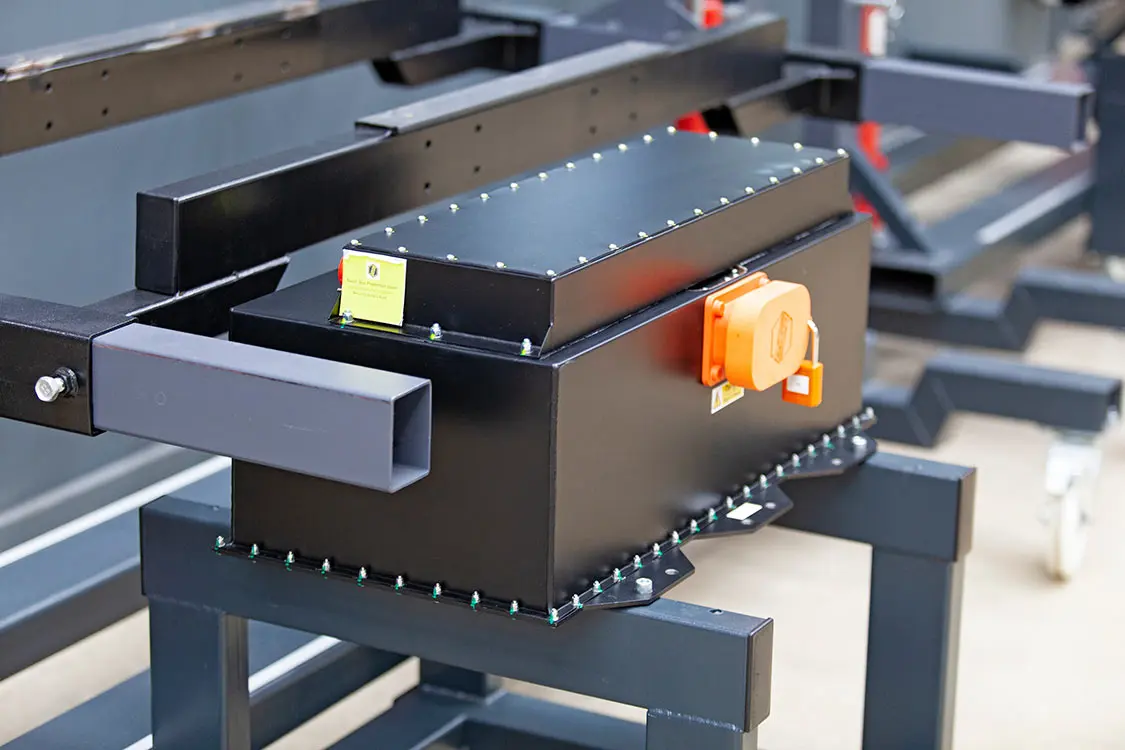

At the heart of the Venom Kit lies the Hyper 9HV motor, known for its robust performance and reliability. This motor, paired with the advanced Hyper-Drive X144 controller/inverter, forms the backbone of the conversion system. Power storage is a key aspect of any EV system, and the Venom Kit addresses this with seven Tesla S modules, offering 40kWh capacity. These modules, from the 2020-onwards line-up, are recognized for their energy density and longevity. Management is covered by an industry-standard Orion BMS 2 O2BMS48 to ensure optimal performance and battery health. Charging the Venom system is done by the Elcon 6.6kW charger. The kit also includes an Elcon 1.5kW DC/DC converter, ensuring the vehicle’s 12V systems are reliably powered.

Plug and Play (Hard!)

One of the Venom Kit’s most appealing features is its user-friendly design. The system is engineered for a plug-and-play experience, significantly simplifying the conversion process. This approach is a boon for both seasoned mechanics and DIY enthusiasts, allowing for a complete conversion in less than a day – particularly once you have done it once.

The Venom Kit is complemented with the proven Tremec T-5 manual transmission. This setup allows for the retention of the car’s original driving feel, with the reliability of a modern gearbox. Additionally, the kit includes a Tesla Model S water pump and cooling system fittings. Control and monitoring of the system are made possible through the Orion BMS 2 Software Utility and the SmartView TAU Software. These interfaces provide real-time data and diagnostic capabilities, crucial for maintaining the system’s performance and longevity.

Karen Salvaggio: Racing Legend, Electric Visionary

The capabilities of the Venom kit have been put to the test by none other than Karen Salvaggio, a legend in the world of Cobra racing. Her expertise and background add a layer of credibility to Venom’s prowess. Showing us the Venom system’s capabilities in a striking red Cobra, Karen’s adds ‘‘Venom transforms the classic driving experience, marrying tradition with innovation”. And it is not just here claims that support the kit’s design and performance: Scorpion EV’s innovative engineering was recently recognized on one of the industry’s biggest stages – the 2023 SEMA Show. There, their EV-powered Factory Five Mk4, equipped with the Venom kit, was honored as the “Best Engineered Vehicle of the Year.”, validating the team’s hard work, ingenuity, and vision.

A Blend of Aesthetics and Technology

What makes the Venom Kit particularly appealing is its attention to detail, not just in terms of performance but also in aesthetics. Housed in a stylish, sturdy aluminum box, the kit is designed to integrate seamlessly into the Cobra’s engine bay without any alteration to the body or structure, ensuring that the car’s iconic look is preserved – and the operation is 100% reversible. If this doesn’t seal the deal, nothing will!

EV Builder’s Guide Vehicle Specs

Owner Name: Dr. Bill Cardoso

Location: Temecula, CA

Model: 2022 Factory 5 Cobra with Venom conversion system

Overall Vehicle Weight: 2,460lb

System price: $39,999.00

Occupation: CEO of Creative Electron and CEO of Scorpion EV

Technical Specifications:

Kit Interfaces:

Additional Information:

Accolades:

Contact:

Scorpion EV

scorpion-ev.com

Photos by Mach1Media

When it comes to any automotive-minded person’s bucket list, attending the annual SEMA show in Las Vegas is among the top goals. But to have a vehicle you built yourself on display at the biggest after-market convention? Now that’s an accomplishment many of us can only dream of, and only a select few can say they did.

Among those on the list is Thomas Szabo, owner of Superior Diesel Performance in Saskatoon, Saskatchewan, Canada. But he didn’t just build a SEMA show vehicle—he took the saying “Go Big or Go Home” to a whole other level.

Specializing in Super Duty trucks, Thomas wanted to do something a little different for his SEMA debut and build a custom Ford Excursion. But we’re not talking about just any old custom Excursion—we’re talking going well beyond the norm, even by SEMA show standards. Knowing the project would be a big undertaking anyway, as Thomas told us, “We decided to go all out and make it a six-door.”

Stretching the Excursion took many tricks, starting with modifying the Ford from the frame up. Responsible for the bodywork on this unique build, Western Millennium Collision literally took two vehicle bodies and grafted them together to give the Excursion its limousine status. Among one of the coolest tricks implemented in the project was incorporating Super Duty bedsides into the rear quarters. Doing so gave the Excursion larger fender flares in the rear that could almost pass as “factory” with how well they continue into the body lines all the way around the truck.

Less obvious aesthetic choices for the Excursion include shaved badges and keyholes, textured trim panels and door handles, an RK Sport hood, Fusion bumpers, and a custom Overkill Fab front grille. Nine Rigid lights adorn the grille, wheelwells, and bumpers, while a custom Gen-Y Mega-Duty hitch and rear bumper hooks flex out back just waiting for a job to do.

As for the paint, it’s probably not what you’d expect. Shifting from black to dark brown, the exterior of the Excursion was painted by Andrey Kolesnik of Western Millennium Collision in factory Ford gloss black with three coats of copper clearcoat on top.

Inside, the Excursion is just as gorgeous, featuring black leather and suede Roadwire front and second-row bucket seats with two matching rear benches. These seats set the tone for the matching custom headliner and door panels, complements of the talented Tory Wilcox of Ripstitch Interiors. In the dash, Edge CTS3 gauges keep temperatures, speed, and other need-to-know measurements front and center, while a full Kicker stereo system pumps tunes throughout all four seating rows thanks to a combination of speakers, amps, and eight and 10-inch subs, the aforementioned fitted into a custom center console box and spare tire box.

“Incorporating Super Duty bedsides into the rear quarters … gave the Excursion larger fender flares in the rear that could almost pass as ‘factory’ with how well they continue into the body lines all the way around the truck.”

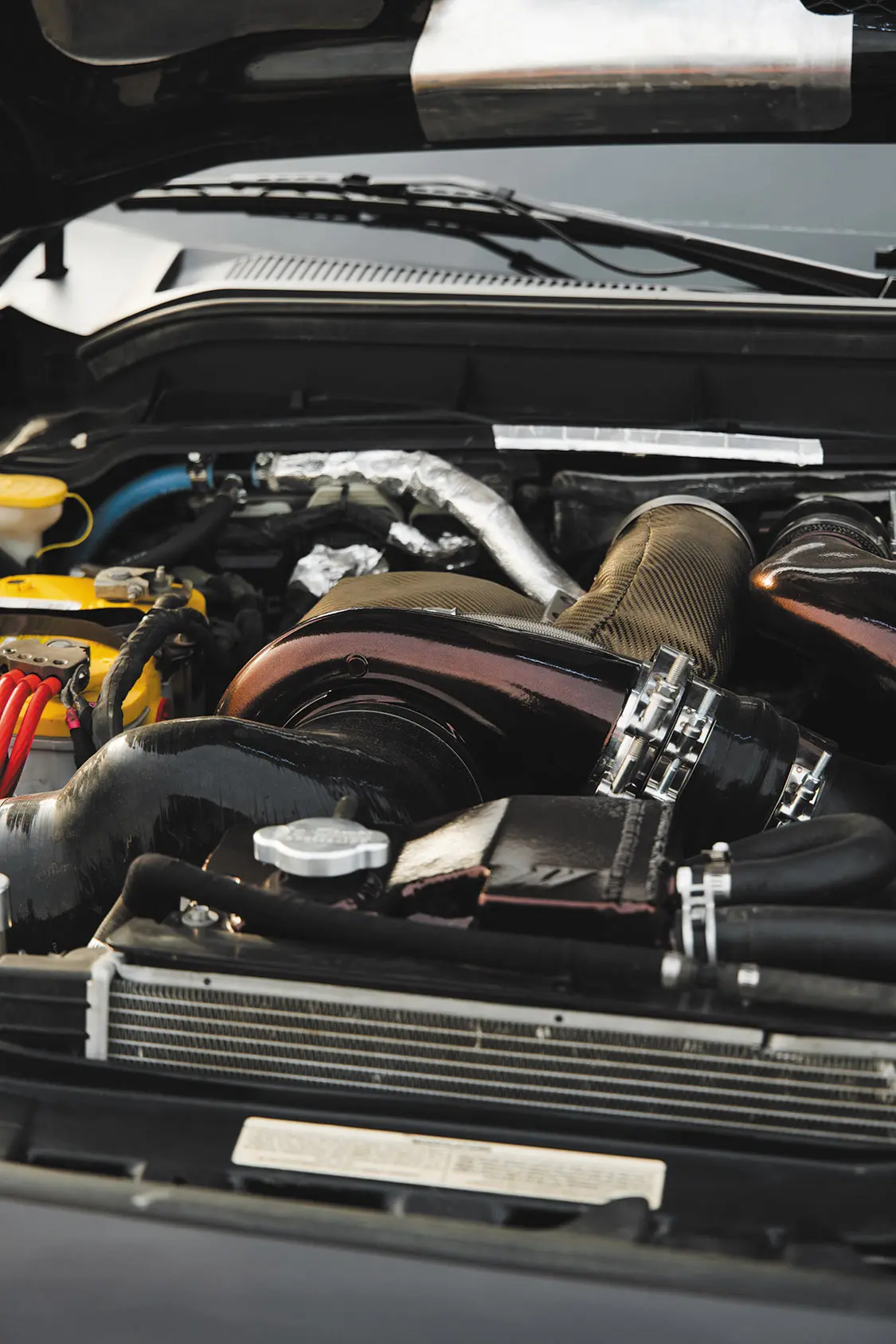

Certainly a looker, the Excursion couldn’t be left with stock mechanics. While this bad boy retains a 2013 6.7 Power Stroke diesel, Thomas gave it a full revamp fitting of the truck’s custom status. Right off the bat, you’ll notice a Compound S480 Turbo setup over a BD Diesel Scorpion 64.5mm turbo kit. A BD intake manifold, headers, and a custom 4-inch downpipe with a 4-inch BD exhaust brake were also added to the truck, dumping the diesel’s exhaust just in front of the rear axle via 5-inch duals.

Other features include a rebuilt bottom end with O-ringed heads and ARP head studs, a PPE oil pan, and an S&S Diesel Disaster Prevention Kit, protecting the fuel system from any possible malfunctions of the fuel pump. Prismatic powdercoated valve covers, upper oil pan, and accessory brackets carry the Excursion’s color scheme throughout the engine bay.

“Thomas hit it out of the park with this build, not only aesthetically, but also in form and function—right down to the custom suspension system that sends this truck soaring about the rest.”

Backing the 6.7L V-8 is a rebuilt Ford 6R140 automatic transmission, which was fitted with an Alto HD clutch pack, Suncoast shafts, and a custom valve body by Mister Transmission. A Suncoast 1700 stall converter feeds the truck’s ponies to the trans while a PPE deep sump pan helps keep extra fluid flowing for optimal performance. Continuing with the truck’s aesthetic cues, both the transmission and the transfer case were powdercoated using Prismatic powder to match the Excursion’s exterior paint.

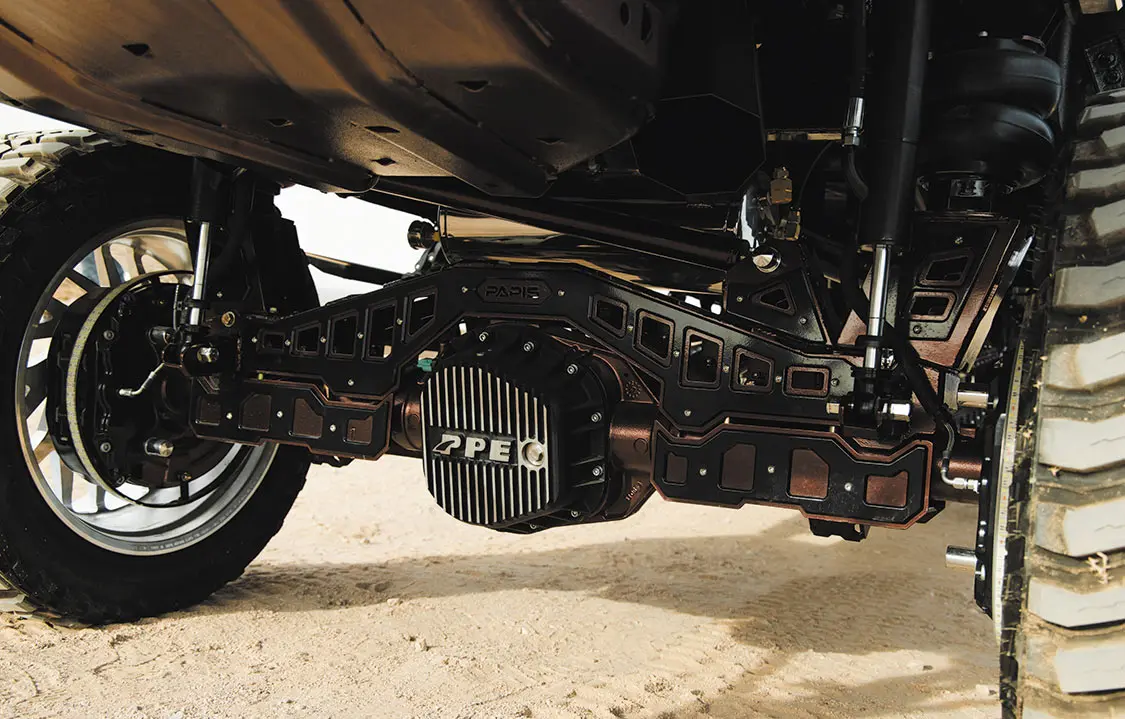

Down below, the Ford’s factory driveline spins a Super Duty Dana 60 in the front and a Dana 70 in the rear, both featuring Nitro 4.30 gears and install kits inside powdercoated axle housings with PPE diff covers. Six-inch backspaced Mickey Thompson 38/15.5/r24 Baja Boss shoes, wrapped around 24×14-inch Gear Off Road wheels, plant the six-door beast to the pavement, while stopping power is provided by 15.5-inch front and 15-inch rear 6-piston Wilwood brakes fitted with braided stainless steel lines.

No SEMA show vehicle is complete without customizations from top to bottom, and Thomas hit it out of the park with this build, not only aesthetically, but also in form and function—right down to the custom suspension system that sends this truck soaring about the rest.

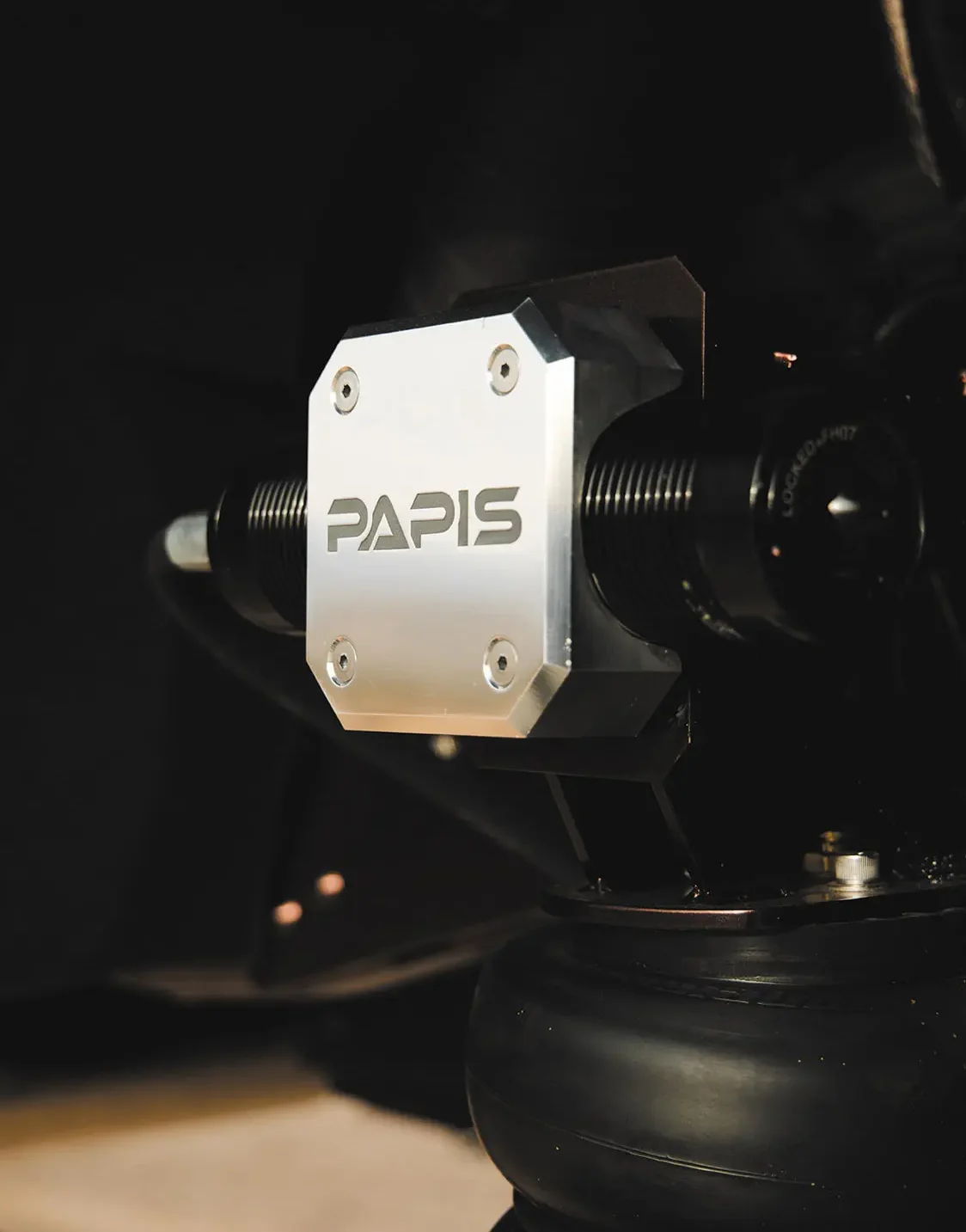

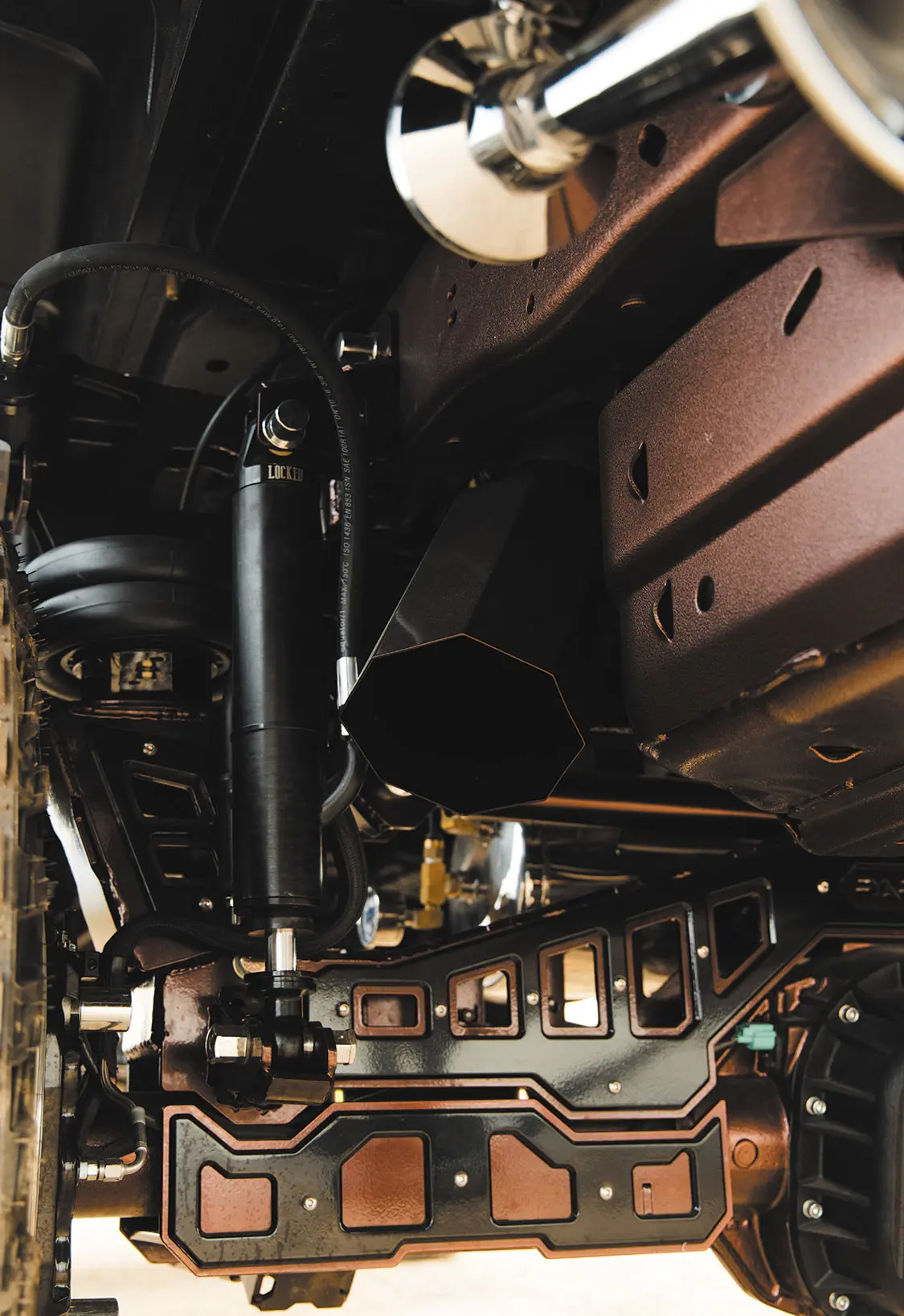

A fully custom Papis air-suspension system does numbers to set this Excursion apart, giving the truck both a unique stance and extensive capabilities with front and rear 4-links, a custom subframe and axle truss, suspension cradle, and Locked Offroad triple-bypasses with remote reservoirs capable of 10 inches of travel on all four corners. Fitted to a 2013 Super Duty front frame section that is melded to a 2002 Excursion rear, Slam Specialties SS8 airbags help actuate the Excursion’s massive lift of 8 to 14 inches above factory ride height.

Feeding the suspension system with air are polished air tanks with two compressors controlled by an AccuAir controller. This on-board air system also feeds the three horns from HornBlasters tucked up discretely under the rear bumper.

From start to finish, the project, which could have easily taken over a year to accomplish, was completed by Thomas and his team in just seven months. Along the way, aspects like shipping times and getting parts through customs challenged the team, but in the end, they pulled off a fantastic bigger-the-life SEMA build that will be admired across the States and Canada for years to come.

Owner

Chassis & Suspension

Wheels & Tires

Engine & Drivetrain

Body & Paint

Interior & Stereo

Photos by Jerome Andre

As we drive into the outskirts of Silverstone, UK, home to the iconic British racetrack, a different kind of engineering marvel unfolds at Lunaz. Founded in 2018 by David Lorenz and later joined by Jon Hilton, former Renault F1 technical director, Lunaz has embarked on a pioneering journey. Here, the past is not just preserved; it’s reinvigorated with the pulse of the future.

Our visit to Lunaz’s headquarters immediately reveals a seamless blend of tradition and innovation. The facility, absolutely buzzing with action, is where automotive history is lovingly preserved and transformed. Classic cars like Rolls Royce, Bentley, and Jaguar, each a symbol of timeless elegance, are being meticulously restored. Yet, beneath their classic exteriors, a revolution brews – these beauties are being equipped with state-of-the-art, in-house developed electric powertrains and battery packs. As Lorenz, shares, “We’re not just restoring cars; we’re ensuring they can be driven and cherished for generations to come, but in a way that’s relevant for the 21st century.”

It’s about rethinking how we approach the lifecycle of vehicles: We’re not just converting them; we’re giving them a new lease of life.

Walking through the design studio, engineering room, and workshop, we witness a symphony of craftsmanship and technology with team members from around the globe. The restoration begins with a thorough inspection, where each vehicle is assessed down to the minutest detail. This meticulous process ensures that the weight distribution, chassis integrity, and overall structure are perfectly aligned with the demands of the new torquey and powerful electric drivetrains. The transformation involves an intricate blend of traditional techniques and cutting-edge technology: Vehicles are stripped to their bare bones, with each part examined, restored, or replaced. The team uses 3D CAD models for each car to ensure flawless integration of new components, blending the original aesthetic with modern functionality.

One of the most striking aspects of Lunaz’s work is the attention to aesthetic detail. The color palette is not just a collection of shades but a thoughtful curation that respects the vehicle’s heritage while embracing modern tastes. Each color choice reflects a deep understanding of the car’s character and the owner’s personality. The customizations extend to the interiors as well.

The team, under the guidance of Jo Slater, Head of Design, works closely with clients to create interiors that are not just visually stunning but also offer contemporary comforts like advanced infotainment systems, seamless navigation, and state-of-the-art audio.

The core of Lunaz’s transformation lies in their revolutionary approach to electrification. Unlike others who might retrofit existing electric systems, Lunaz develops bespoke, modular electric powertrains. Each car’s new electric heart is carefully designed to balance its historical integrity with modern performance requirements and the owners desire. “We meticulously tailor our powertrains to enhance the driving experience while respecting the original character of these classic vehicles,” Lorenz explains.

The result is a harmonious blend of past and present – iconic cars that retain their soul while embracing the efficiency and sustainability of electric power. Understandably, the Lunaz team is very discreet about the specific figures and intricate details of their powertrains.

Amidst the technical prowess and innovative processes, what stands out most at Lunaz is the human element. Each team member, from engineers to designers, clearly shares a deep passion for their work. This collective drive is palpable in every corner of the facility and in each vehicle they produce.

Lunaz’s expertise isn’t confined to their $500-850.000 luxury classics. The company’s mission extends to commercial vehicles, especially refuse trucks. In this arena, they demonstrates its commitment to environmental sustainability and practical innovation. The transformation of garbage collection vehicles from diesel to electric is a significant stride towards cleaner, more efficient urban environments. By upcycling existing trucks, Lunaz is making a tangible impact on reducing waste and carbon emissions. “It’s about rethinking how we approach the lifecycle of vehicles,” Lorenz asserts. “We’re not just converting them; we’re giving them a new lease of life.”

Lunaz are poised to become a global leader in commercial vehicle electrification.

These vehicles, equipped with a staggering 5000Lb-ft of torque and capable of accelerating from 0-50mph in just six seconds, represent a leap in efficiency and performance in the world of commercial vehicles. Lunaz’s upcycled electric garbage truck, soon to be delivered to Buckinghamshire Council, is a testament to the company’s ability to transform what was once a diesel-powered necessity into a cutting-edge, environmentally friendly powerhouse. The truck, based on the proven Mercedes Econic platform, retains 80% of the donor vehicle in a refurbished state, showcasing Lunaz’s commitment to sustainability by saving a significant amount of embedded carbon compared to manufacturing a new EV from scratch.

The implications of such innovation extend beyond environmental benefits. Lunaz’s approach to refurbishing these heavy-duty vehicles offers a financially viable alternative to local authorities, saving costs without compromising on functionality or performance. With each refuse truck preserving much of its original structure while receiving Lunaz’s bespoke electric powertrain, the company demonstrates how upcycling can be a pragmatic and effective solution in the transition to cleaner energy. This pioneering work not only positions Lunaz as a leader in sustainable automotive practices but also serves as a blueprint for the future of commercial vehicle electrification. They plan to deliver 57 electric ‘bin lorries’ by the time you read this.

Lunaz’s ambitions stretch far beyond the UK. With their recent expansion of the Silverstone facility and discussions with various governments, they are poised to become a global leader in vehicle electrification. This expansion reflects not only their growth but also the UK’s prominence in the field of electric vehicle technology. Jon Hilton’s contribution to Lunaz is a crucial element of their success. His extensive experience in Formula One and hybrid powertrains brings a level of technical excellence and innovation that sets Lunaz apart. “The expertise we’ve cultivated here is unique, blending high-performance engineering with sustainable practices,” Hilton shares. At its core, Lunaz is driven by a philosophy that challenges the conventional automotive lifecycle. By upcycling existing vehicles, they offer a solution to the emissions crisis that doesn’t simply shift the problem elsewhere. “Each vehicle we convert is a step towards a cleaner future,” Lorenz concludes. “We’re dedicated to reducing global emissions, one vehicle at a time.”

As we complete our tour of Lunaz, it’s evident that this isn’t just a car company, it blends heritage with forward-thinking technology. The story of Lunaz is about more than electrifying classic cars; it’s about inspiring change in an industry often criticized for its environmental impact. With each vehicle they restore and electrify, Lunaz is steering us towards a more sustainable, more conscientious automotive future.

Photos by Jerome Andre

Imagine a world where a classic Ferrari purrs absolutely silently. Sounds like heresy, right? Well, hold onto your gated gear knob because Gas Monkey Garage, in cahoots with Legacy EV, decided to turn this wild thought into reality. Meet the “Testa,” a car that looks like it came straight out of a retro-futuristic comic book. It’s what happens when old-school cool crashes headfirst into the electric revolution.

Gas Monkey Garage, the wizards of car transformations, joined forces with Legacy EV, the conversion vehicle gurus. Their mission? To electrify a Ferrari Testarossa in just 40 days with a budget of $350,000. You read that right—turning a roaring beast into a purring cat without losing its claws.

The story of the Testa begins with Richard Rawlings, the maverick behind Gas Monkey Garage. Known for its hit TV show “Fast N’ Loud,” the garage had always pushed the boundaries of car restoration and customization. However, the Testa project was different. It was a foray into the world of electric vehicles, a territory Gas Monkey had never ventured into before. The idea sparked when Rawlings acquired not one but five Ferrari Testarossas used as screen props in the 2021 film “Infinite,” starring Mark Wahlberg. These vehicles, each with its own story, were about to embark on a transformation journey like no other.

The vision for the Testa was clear: to create a one-of-a-kind EV, preserving the Testarossa’s iconic design. To achieve this, Gas Monkey Garage partnered with Legacy EV. The Phoenix-based team brought their expertise in propulsion systems, battery management, and overall electric vehicle dynamics to the table. Their role was to ensure that the Testa was not just an electric vehicle in appearance but a fully functional, high-performance EV.

The team at Gas Monkey Garage had to meticulously deconstruct the Testarossa, evaluating each component’s condition and potential for reuse. The goal was to retain as much of the original Ferrari essence as possible while making room for modern EV components. One of the most significant challenges was integrating the electric motor and battery pack without compromising the car’s iconic design and balance. The teams opted for a single electric motor setup, strategically placed to maintain the original 40:60 front-to-rear weight distribution of the 1989 Testarossa. This was crucial to preserve the car’s handling characteristics.

The Testa traded its gas-guzzling 180-degree V-12 heart with an IDM 190 Cascadia Motion setup composed of a BorgWarner Electric Drive Module (motor/transmission) and CM200 inverter. This configuration produces a jaw-dropping 4140 Nm of axle torque, a figure that would make the original Ferrari blush—well, any Ferrari or supercar, too! With 225 kW or 300 hp, the powerplant is not aimed at sheer top speed but is probably the world’s best tire-slaying Ferrari ever. The motor and transmission mounts, crucial to this transformation, were skillfully crafted in-house at Gas Monkey Garage by Josh Paris, while the control software was sourced from AEM Electronics. Powering this beast are 36 Kore Power battery modules, topping at 84.6kWh, ensuring a blend of efficiency and endurance.

This blurs the lines between automotive tradition and innovation. It’s a love letter to what cars were and a bold statement about what they could be.

The Testa retains its original chassis, but don’t be fooled—it’s been beefed up by Gas Monkey to handle its new electric soul. The suspension system got a high-tech hug with the Bilstein Motorsport AS2R setup, ensuring the car sticks on the road in all conditions. The factory Ferrari control arms and spindles stayed, because why mess with perfection?

Let’s talk shoes and stoppers. The Testa rolls on 19-inch Vossen LC301 custom rims, powdercoated white and wrapped in Continental Extreme Contact Sport tires. The rear follows suit, but they’re sized up to 20 inches. The braking system was significantly upgraded with Brembo components, providing the necessary stopping power for the vehicle’s increased performance. The gear ratio was meticulously set at 8.28:1, with axles and driveshaft being built in-house by Josh Paris.

The Testa looks like it drove out of a sci-fi movie set in Miami. Painted in Axalta Spies Heckler “Super White” by the artiste Mike Coy, it’s like a ghostly apparition of its former self. Check out the custom badging by Brandon DePrato that adds a dash of exclusivity and fun, while the grille, equipped with an XK Glow sequential LED light bar, winks at the future.

Perhaps the most visually striking modification was the absence of a roof and a full-sized windscreen. Instead, the Testa featured a small wind deflector and a roll hoop, giving it a bold, roadster-like appearance. This design choice was not just aesthetic but also a nod to weight reduction and performance enhancement. The windshield, now custom cut, gives the nod to the 1960s racing Ferraris’ heritage. And yes, this is a genuine Ferrari windscreen—probably worth $15K, but the “Monkeys” dared to chop it off!

The grille, crafted by Gas Monkey Garage and NTX Audio Innovations, is equipped with an XK Glow sequential LED light bar, enhancing its modern appeal. The wheelwells, kept as factory Ferrari components, were dry-iced and recoated for a fresh look. The bumpers were modified by Gas Monkey Garage, and the body modifications included a custom one-off designed speedster (roof chop), showcasing the team’s exceptional craftsmanship. The headlights, a crucial element in any vehicle, were custom-made housings by Josh Paris, equipped with XK glow 6-inch Razor LED light bars. Similarly, the taillights, created by Gas Monkey Garage and NTX Audio Innovations, featured XK glow Sequential LED light bars.

Step into the Testa, and you’ll find yourself at the heart of a groundbreaking transformation. The interior, masterfully reimagined by Texas Seats, is a harmonious blend of classic Ferrari elegance and avant-garde design. At the core of this revolution is the car’s conversion to a center steer setup—reminiscent of the McLaren F1. The driver’s seat, originally a standard Ferrari seat, has been reskinned with luxurious custom leather, transforming it into a commanding center throne. Flanking this central marvel are two custom-built passenger seats, combining comfort with a touch of exclusivity.

The dashboard, reconfigured for the new setup, now boasts a sleek 13 ½-inch LCD display, serving as a modern nerve center for the driver. The classic Ferrari Momo steering wheel, elegantly reskinned by Texas Seats, complements this unique layout, marrying tradition with innovation. Completing this interior symphony are the state-of-the-art Hertz subwoofers and Audison amplifiers, creating an auditory experience as refined as the ride itself. Thanks to Soundskins’ expert sound deadening, the interior becomes a serene sanctuary, insulated from the chaos of the outside world.

Gas Monkey and Legacy EV turned a roaring beast into a purring cat—without losing its claws.

As the Testa rolls out onto the streets, it carries with it the legacy of two pioneering companies, a legacy of innovation, craftsmanship, and a bold vision for the future of automotive design. In every aspect, from its striking appearance to its impressive performance, the Testa stands as a beacon of what is possible when passion meets technology, tradition meets innovation, and the past meets the future.

Richard Rawlings and his team’s creation is a pure manifesto: “We love the past, but we’re not stuck in it.”

This blurs the lines between automotive tradition and innovation. It’s a love letter to what cars were and a bold statement about what they could be. No, it is not going to please everyone, but since when did hot rods, customs, and fun cars have to please the world?

Gas Monkey Garage

Motor / Drivetrain

Chassis/Suspension

Wheels/Brakes

Body/Paint

Paint Shop: Gas Monkey Garage, painted by Mike Coy

Interior

Sponsors and Special Thanks:

It takes a lot to set a mini-truck apart from the rest in a sea of show participants—a lot of vision, a lot of time, a lot of money and, unfortunately, a lot of setbacks.

David Pennington, Jr., knows this all too well, but after 16 long years of work, he can also add a lot of something else: pride. His ’93 GMC Sonoma has been a project for a while now, but he’s finally finished it up, and it’s ready for the world to see!

David’s journey with his truck began when he purchased it from a local car lot after seeing his brother’s S-10 taking shape. His first modification was to lower the truck to the ground with air ride, which he accomplished with the help of Phil Fowler of Drop Werks in Newark, Delaware, who used ThorBros parts. That satiated David for a while, but before long he realized that he wouldn’t be happy with the Sonoma until he customized it further—a lot further. A quick call to his buddy Matt for some help yielded shaved handles, a molded roll pan, and even suicide doors!

Again, David was happy with the progress and drove the truck to a few shows, but then Eric Saliba from Little Shop Mfg. (then Little Shop of Horrors) appeared out of nowhere to entice him to cut up his truck even more. That, or David stopped by Eric’s shop to ask about a body drop—we forget which. Anyway, the Sonoma was eventually brought to the shop, where Eric and his talented crew built the 2×3 box-tubing chassis to accomplish a stock-floor body drop, and also added an Accuair E-level to update the air suspension. The next step was yanking the stock 4.3L V-6 and 700R4 to make way for an ’04 Pontiac GTO LS1 engine attached to a 4L60E transmission.

The Little Shop crew also grafted an ’04 Chevy Colorado frontend to the Sonoma’s fenders, as well as fitting Colorado taillights to the rear, to give it an updated new look. For the interior, Eric installed a ’59 Chevy car dashboard to add some retro vibes to the cabin. At some point, the truck received its classy 22-inch Bonspeed Tsunami wheels, adding a whole new dimension to the Sonoma’s evolving look.

As the years went on, David worked on his Sonoma every chance he got, improving it one piece at a time with the help of friends. Custom door panels were made to blend the dash into the doors, and Bobby Moore at EVO Creatives handled the upholstery on the cut-down factory seating and interior panels. Dave at After Hours Fab helped clean up the now-powdercoated chassis by running all of the wiring through the framerails, and he even built a custom firewall and wheel tubs for the truck before Rusty Townsend at Igloo Customs doused it with PPG Mineral Metallic paint, after which Darren Ives followed up with green and butterscotch-colored pinstriping.

David’s truck has come a long way since he first purchased it. The truck has been transformed from a stock ’93 GMC Sonoma to a custom truck that is sure to turn heads. David’s truck is a testament to the fact that with a lot of vision, a lot of time, and a lot of money, anything is possible. David’s truck is a reflection of his passion for custom trucks and his dedication to his craft. David’s truck is a work of art that he can be proud of for years to come.

Owner

Chassis & Suspension

Wheels & Tires

Engine & Drivetrain

Body & Paint

Interior & Stereo