Motortopia Staff

.

February 20, 2026

.

Press Release

Motortopia Staff

.

February 20, 2026

.

Press Release

It’s one of the most common questions we hear — from DIY enthusiasts, fleet operators, classic car owners, and even investors watching the electrification space. The honest answer is nuanced. EV conversion is unlikely to experience a sudden price drop. But something more meaningful is happening: the industry is evolving toward higher quality and greater accessibility simultaneously.

The Question Everyone Asks — And How the Market Is Really Evolving

In the early days, EV conversions were largely experimental and DIY. Builders were adapting salvaged motors, repackaging used battery modules, and engineering solutions on the fly. Creativity was high, documentation was scarce, and every project felt like a prototype. Costs varied wildly because every build was essentially custom R&D.

Today, expectations are very different. Customers want reliability. They want predictable range. They want proper thermal management, safe high-voltage architecture, well-integrated regenerative braking, clean packaging, and robust battery management systems.

They want their converted vehicle to feel engineered — not improvised.

That shift in expectations has raised the quality bar across the industry. Professional shops now design repeatable systems rather than one-off experiments. Modular battery boxes are replacing improvised enclosures. Advanced BMS solutions protect battery longevity. Integration between motor, inverter, and battery is more deliberate. Safety practices, from proper fusing to HV disconnects, are becoming standard.

This maturation naturally increases professionalism. And professional labor has a cost. Engineering time, testing, validation, and support do not disappear simply because component prices fluctuate. That is one reason why dramatic price drops in battery cells have not materialized across the board.

However, accessibility is improving in parallel. Battery technology continues to evolve. Energy density is increasing. Manufacturing scale is expanding globally. Repurposed battery packs and motors are being professionally tested and sold as kits with warranties. Motors from mainstream EVs are more widely available. Knowledge sharing across the industry is accelerating.

There are also powerful counterarguments that suggest the economics could shift more rapidly in the future.

Battery innovation is the most obvious catalyst. If next-generation chemistries significantly reduce cost per kilowatt-hour while simplifying cooling and packaging requirements, conversion builds could become materially cheaper and easier. Improvements in modular pack formats, or breakthroughs could reduce integration complexity and lower barriers to entry. If battery costs drop sharply at scale, the ripple effect would be felt throughout the conversion market.

Policy could be another game-changer. In many states, incentives primarily support the purchase of new electric vehicles. But what if tax credits or grants were extended to vehicle conversions? Converting an existing vehicle prevents manufacturing emissions associated with producing a new car and extends the lifecycle of durable assets. If policymakers recognize that environmental benefit and design targeted incentives for conversions, affordability could improve immediately.

Regulation also plays a crucial role. Today, regulatory frameworks for converted vehicles vary widely by countries and states. This lack of standardized regulations can create hesitation among consumers, insurers, and fleet operators. Without clear safety standards and homologation processes, buyers may worry about long-term compliance, resale value, or insurance coverage.

Standardized regulations would not necessarily make conversions cheaper overnight. But they would reduce uncertainty — and uncertainty carries a cost.

Clear rules encourage manufacturers to design compliant kits. They reassure insurers. They give consumers confidence. Most importantly, they enable scale. And scale is where meaningful cost reductions happen.

From our perspective at Fuel2Electric, we experience this evolution every day.

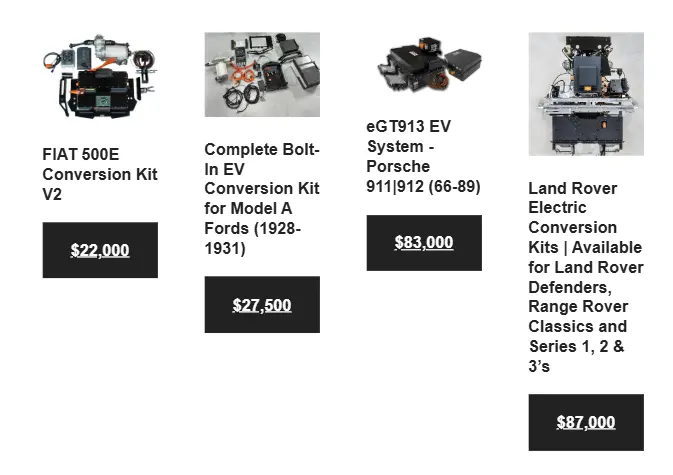

Some days, we feel extremely optimistic. We see custom builds reaching levels of refinement that rival OEM vehicles. We see professional shops developing scalable drop-in kits: Fiat 500, Ford Model A, Defender and Porsche 911… We see fleet operators seriously evaluating electrification strategies. We see better engineering discipline, stronger supplier networks, and increasing demand for high-quality systems. On those days, we are convinced we are moving in the right direction — building vehicles that are safer, smarter, and more durable.

Other days — especially the rainy ones — we wish progress moved faster. We wish there were more drop-in kits available for more vehicle platforms, and less expensive. We know that for EV conversion to reach broader adoption, integration must become simpler. Packaging must become more standardized.

EV conversion may not become “cheap” in the way consumer electronics do. Vehicles are complex mechanical systems. Safety standards matter. Reliability matters. Professional labor matters. But while dramatic price collapses may be unlikely in the short term, steady progress is undeniable.

The industry is becoming more engineered. More structured. More reliable. More trusted.

And that is why we continue building — even on the rainy days.

Share Link